Method for improving wire bonding performance

A technology of wire bonding and performance, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of residual pollutants and unsatisfactory bonding performance, and achieve improved bonding performance, Effect of Improving Wire Bonding Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

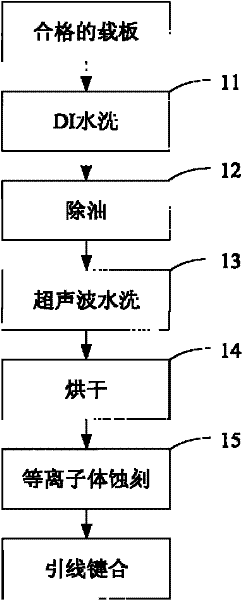

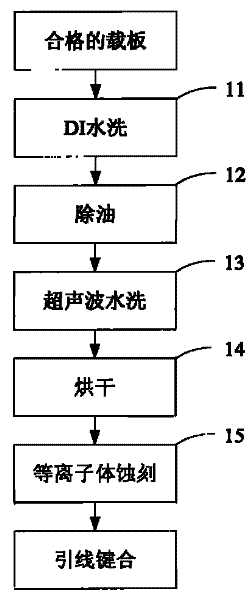

Embodiment 1

[0042] (11) Washing

[0043] Rinse the surface of the carrier board with water to remove the dust and some granular substances such as scum on the surface of the carrier board. In this embodiment, it is preferable to use deionized water (DI water) to rinse the surface of the carrier plate. The rinse time is 1.0-5.0 min, preferably 1.5-3.5 min, and most preferably 2.0-3.0 min. The moving speed of the plate in the water tank (or called the speed of water flow) is 0.5-1.5 m / min, preferably 0.8-1.2 m / min.

[0044] (12) Degreasing

[0045] Clean the carrier with an alkaline degreaser (eg MS100 cleaner ALK) to remove most of the organic contaminants such as fingerprints on the surface of the carrier. During degreasing and cleaning, the temperature of the degreasing agent is 25 to 35°C, preferably 20 to 32°C; and / or, the linear velocity of the carrier (ie the flow rate of the alkaline degreasing agent) is 0.5 to 1.5m / min, Preferably 0.8-1.2 m / min; and / or, the oil removal time is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com