Quaternary-system transparent-substrate-included light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and transparent substrates, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to achieve high light extraction rates, and achieve improved bonding yields, improved light extraction rates, and firm bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

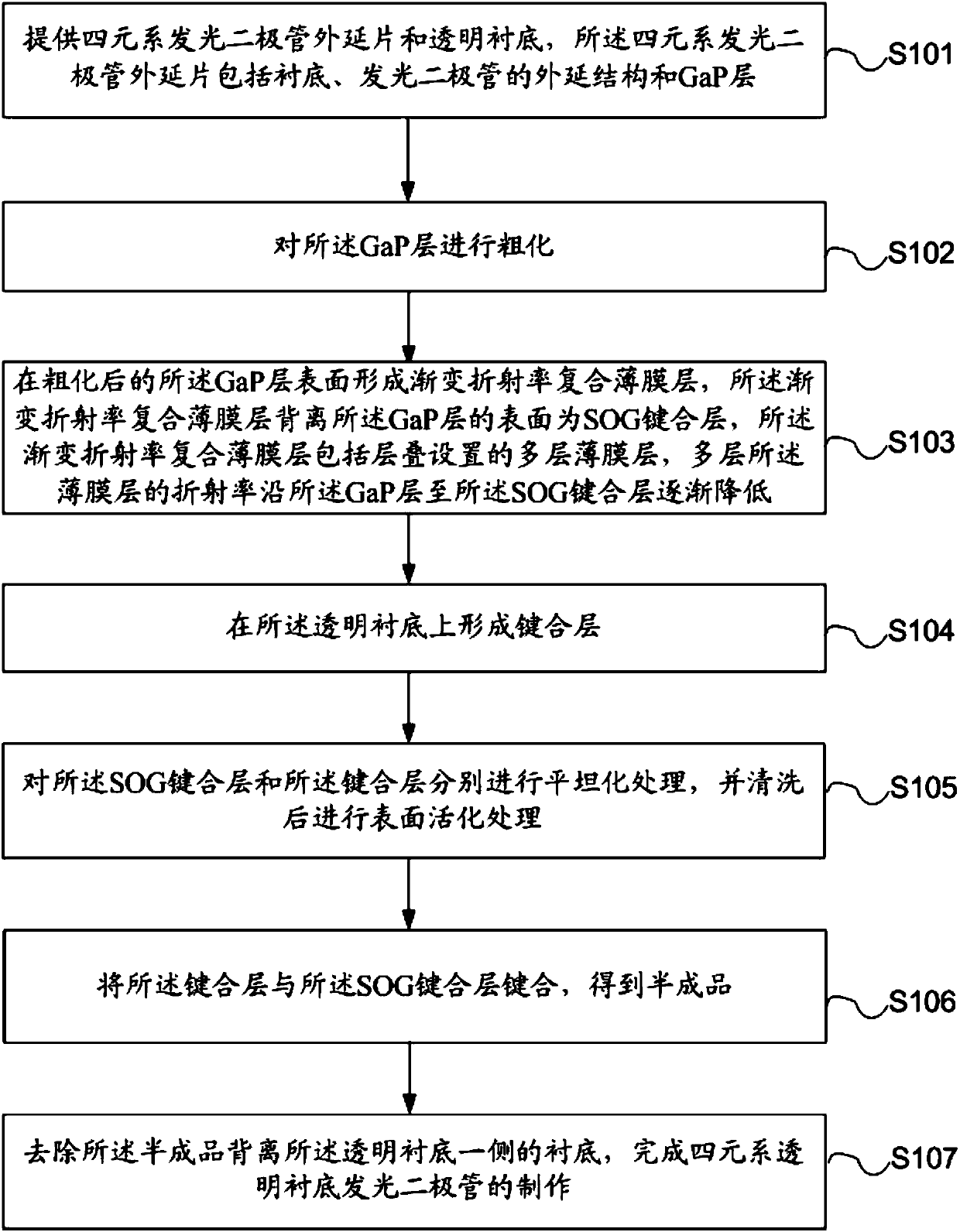

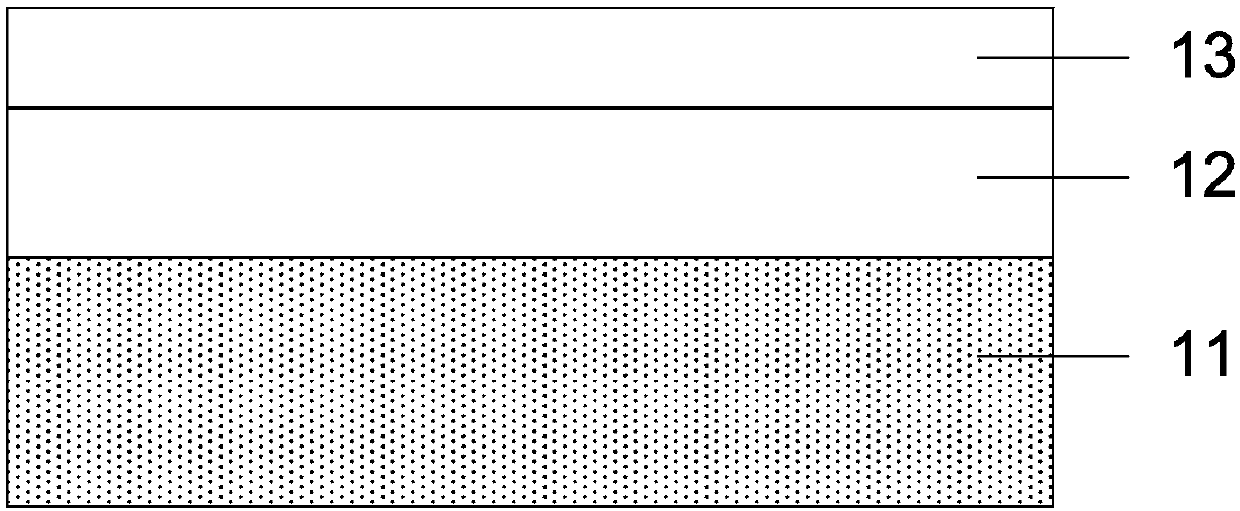

[0084] A method for preparing a quaternary light-emitting diode with a transparent substrate as described above, comprising the steps of:

[0085] 1) The surface of the GaP layer of the AlGalnP-LED epitaxial wafer is mechanically ground to obtain a rough surface, which is used as the bonding surface, and then thin films of titanium oxide, zinc oxide, and oxide are deposited on the bonding surface in sequence by electron beams. Aluminum, and then use the method of spin coating, spin coating SOG, wherein, the thickness of SOG is 3um, mainly because the thickness of the polishing layer needs to be thick enough to have a chance to polish flatness; the composite film layer mainly uses the method of gradient refractive index, It is more conducive to the output of light.

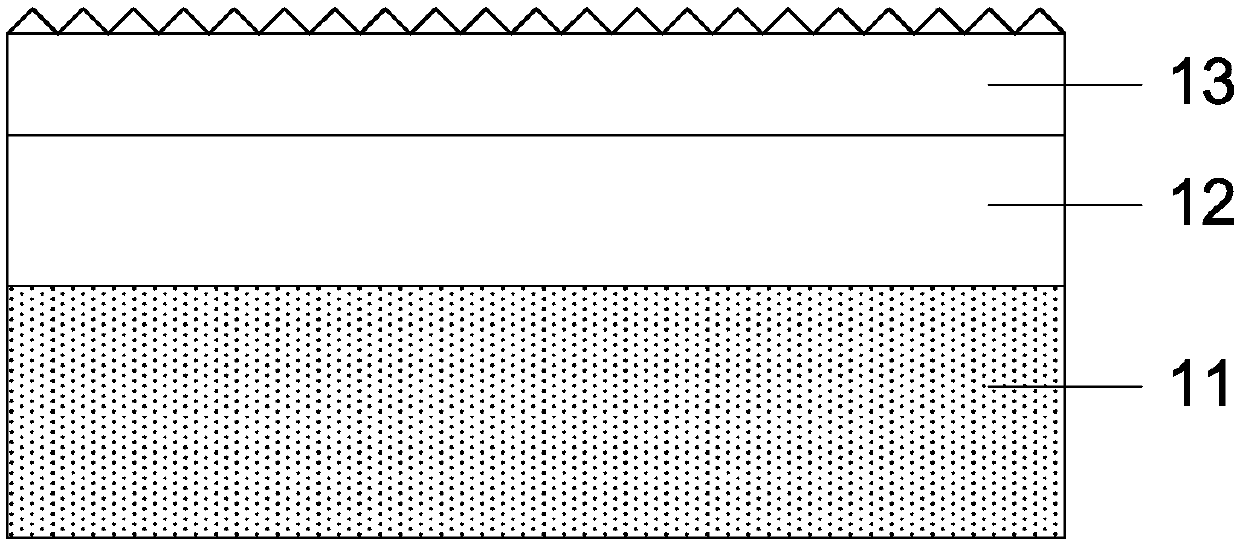

[0086] 2) Among them, the surface of the GaP layer is roughened by mechanical grinding;

[0087] 3) Among them, after SOG spin coating, the curing process is carried out according to a certain process. The curing ...

example 2

[0095] A method for preparing a quaternary light-emitting diode with a transparent substrate as described above, comprising the steps of:

[0096] 1) The surface of the GaP layer of the AlGalnP-LED epitaxial wafer is mechanically ground to obtain a roughened surface, which is used as the bonding surface, and then the thin films of titanium oxide and zinc oxide are sequentially deposited on the bonding surface by electron beams, and then Spin-coating is used to spin-coat SOG, and the thickness of SOG is 3um, mainly because the thickness of the polishing layer needs to be thick enough to have a chance to polish flatness; the composite film layer mainly uses the method of refractive index gradient, which is more conducive light output.

[0097] 2) Among them, the surface of the GaP layer is roughened by mechanical grinding;

[0098] 3) Among them, after SOG spin coating, the curing process is carried out according to a certain process. The curing process includes performing on a...

example 3

[0106] A method for preparing a quaternary light-emitting diode with a transparent substrate as described above, comprising the steps of:

[0107] 1) The surface of the GaP layer of the AlGalnP-LED epitaxial wafer is mechanically ground to obtain a roughened surface, which is used as the bonding surface, and then the ITO thin film layer is sequentially deposited on the bonding surface by sputtering, and then spin-coated The method, the spin coating thickness is 3um SOG, mainly because the thickness of the polishing layer needs to be thick enough to have a chance to polish the flatness; the composite thin film layer mainly uses the refractive index gradient method, which is more conducive to the output of light.

[0108] 2) Among them, the surface of the GaP layer is roughened by mechanical grinding;

[0109] 3) Among them, after SOG spin coating, the curing process is carried out according to a certain process. The curing process includes performing on a hot plate. Bake at ℃ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com