Method for enhancing luminous efficiency of nitride-based LED by using metal nanoparticles

A technology based on metal nanoparticles and nitrides, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of limiting external quantum luminous efficiency and the reduction of c-plane light extraction rate, so as to improve luminous efficiency, high repeatability, The effect of simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

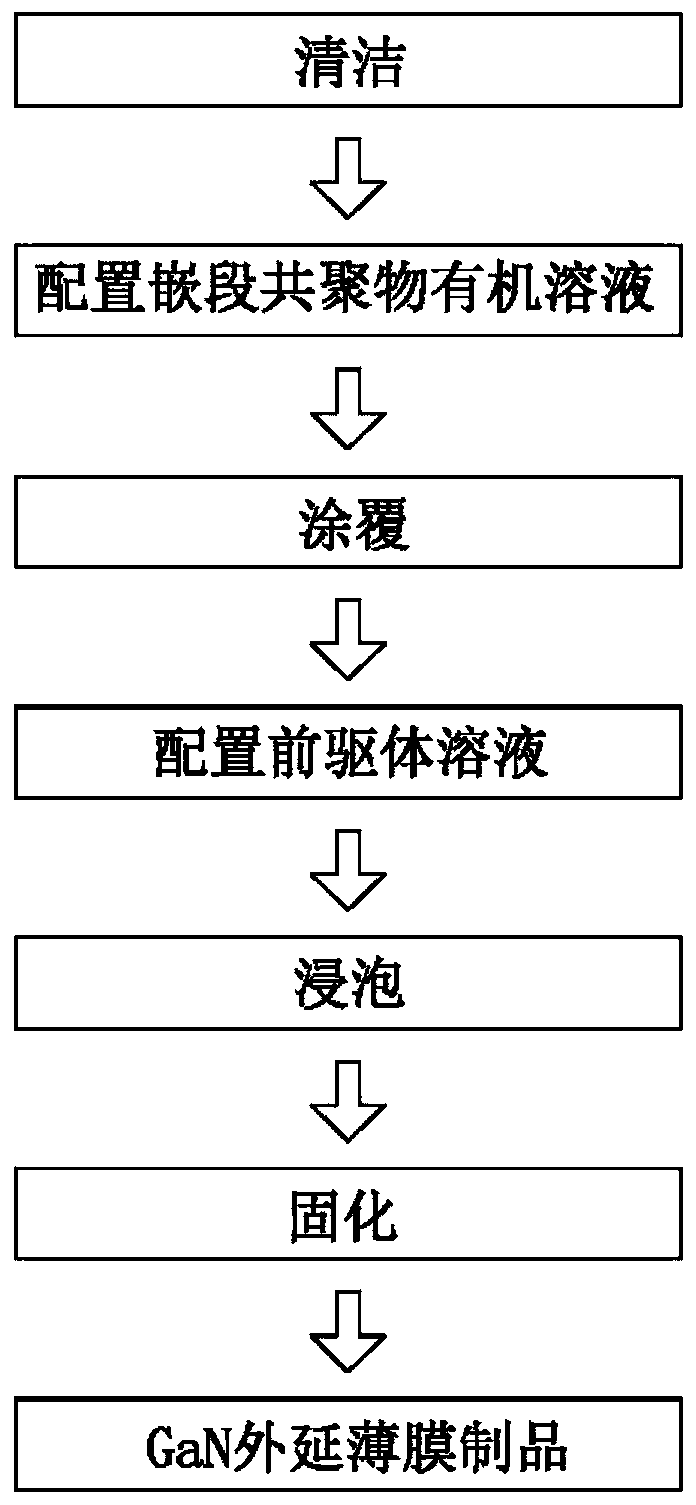

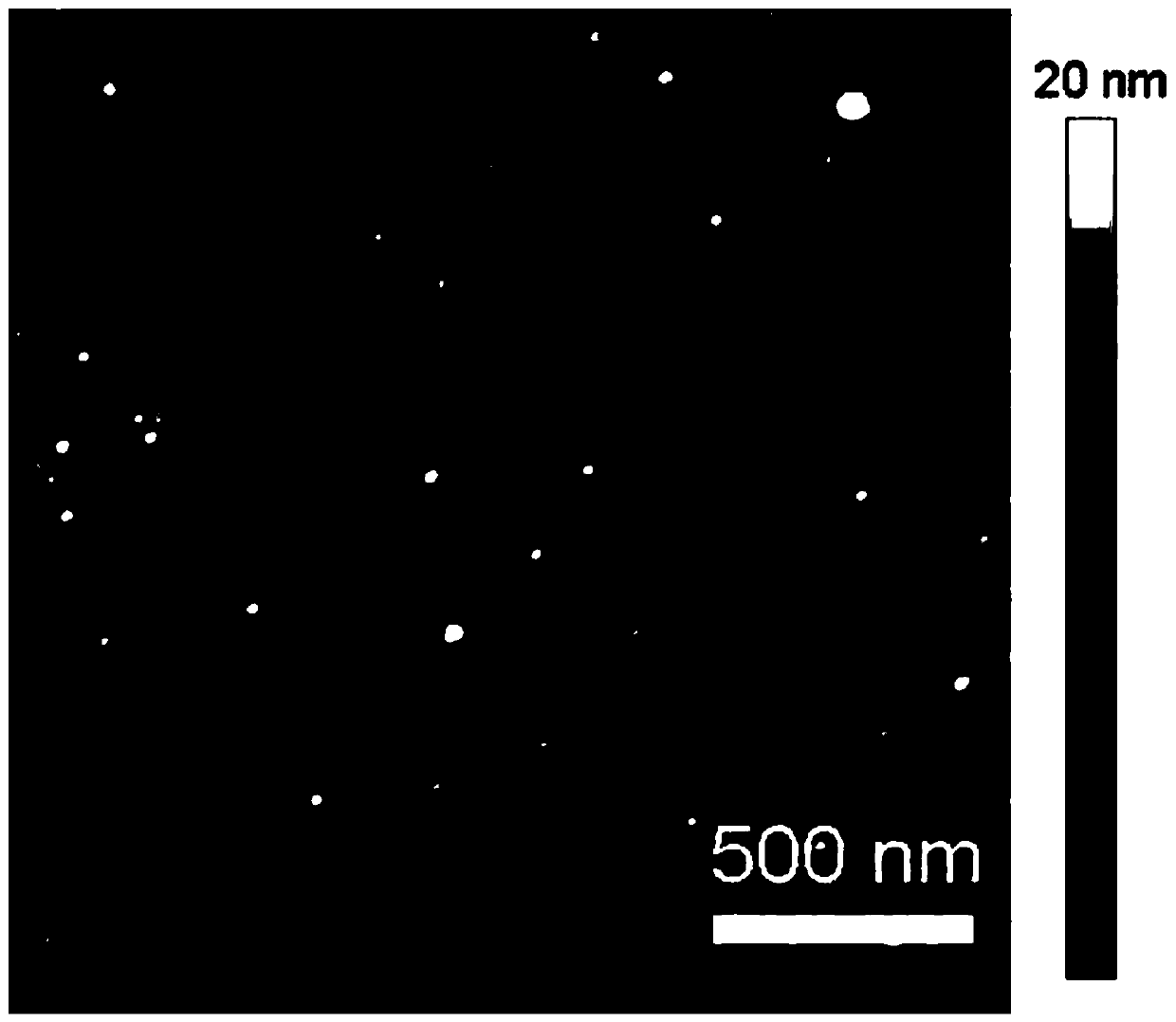

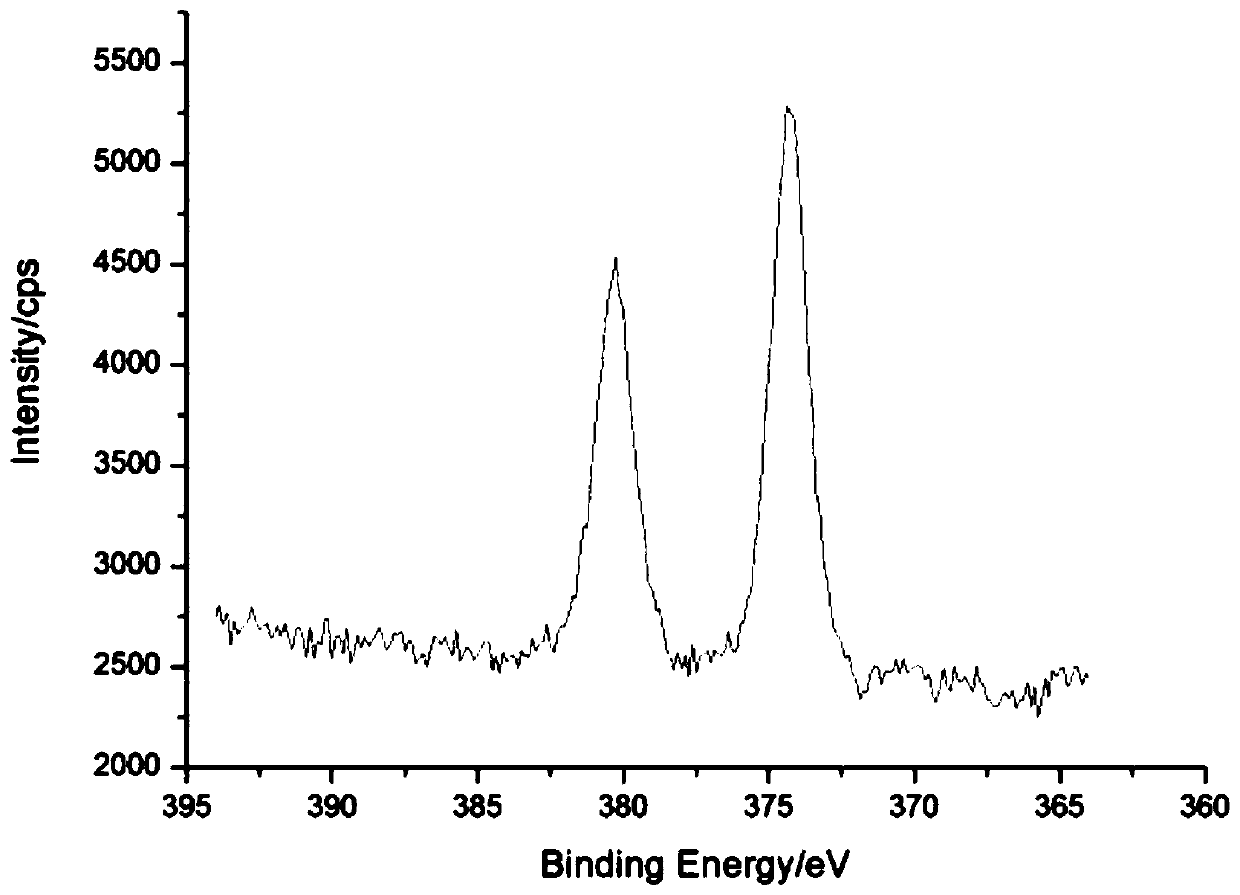

[0027] This example provides a method of using metal nanoparticles to enhance the luminous efficiency of nitride-based LEDs. The block copolymer PS-b-P4VP used has a block ratio of 25000:7000, and the assembled Ag has a high degree of order , and the size of the nanoparticles is uniform, specifically, the following steps are included:

[0028] (1) Place the GaN-based LED epitaxial wafer in an acetone solution for ultrasonic cleaning to remove surface organic dirt, take it out and place it in nitrogen to air dry;

[0029] (2) dissolving the PS-b-P4VP block copolymer with a block ratio of 25000:7000 in toluene, an organic solvent, to configure a block copolymer organic solution with a mass fraction of the block copolymer of 0.6%;

[0030] (3) Spin-coat the configured PS-b-P4VP block copolymer solution on the surface of the GaN-based epitaxial wafer with a homogenizer;

[0031] (4) Configure Ag precursor solution AgNO 3 , the solvent is a 1:1 mixed solvent of water and ethanol,...

Embodiment 2

[0035] This example provides a method for using metal nanoparticles to enhance the luminous efficiency of nitride-based LEDs. The block copolymer PS-b-P4VP used has a block ratio of 22000:22000, and the assembled Ag has a high degree of order , and the size of the nanoparticles is uniform, specifically, the following steps are included:

[0036] (1) Place the GaN-based LED epitaxial wafer in an acetone solution for ultrasonic cleaning to remove surface organic dirt, take it out and place it in nitrogen to air dry;

[0037] (2) dissolving the PS-b-P4VP block copolymer with a block ratio of 22000:22000 in toluene, an organic solvent, to configure a block copolymer organic solution with a mass fraction of the block copolymer of 0.5%;

[0038] (3) Spin-coat the configured PS-b-P4VP block copolymer solution on the surface of the GaN-based epitaxial wafer with a homogenizer;

[0039] (4) Configure Ag precursor solution AgNO 3 , the solvent is a mixed solvent of water and ethanol 1...

Embodiment 3

[0043] This example provides a method for using metal nanoparticles to enhance the luminous efficiency of nitride-based LEDs. The block copolymer PS-b-P4VP used has a block ratio of 17000:49000, and the assembled Ag has a high degree of order , and the size of the nanoparticles is uniform, specifically, the following steps are included:

[0044] (1) Place the GaN-based LED epitaxial wafer in an acetone solution for ultrasonic cleaning to remove surface organic dirt, take it out and place it in nitrogen to air dry;

[0045] (2) dissolving the PS-b-P4VP block copolymer with a block ratio of 17000:49000 in toluene, an organic solvent, to configure a block copolymer organic solution with a mass fraction of the block copolymer of 5%;

[0046] (3) Spin-coat the configured PS-b-P4VP block copolymer solution on the surface of the GaN-based epitaxial wafer with a homogenizer;

[0047] (4) Configure Ag precursor solution AgNO3 , the solvent is a 1:1 mixed solvent of water and ethanol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com