Automatic Dust Reduction Method of Flour Dust Overrun in Fully Mechanized Mining

A technology for fully mechanized mining face and dust reduction, which is applied in the fields of dust prevention, mining equipment, earthwork drilling, etc. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

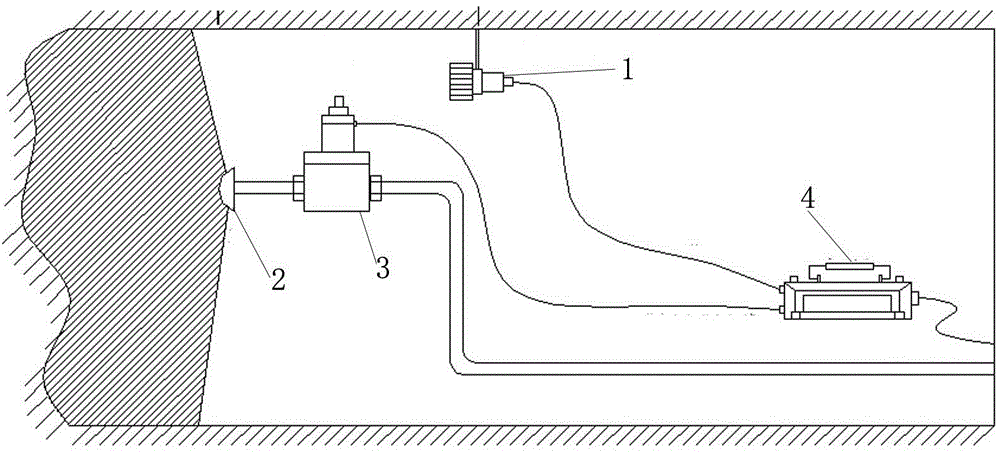

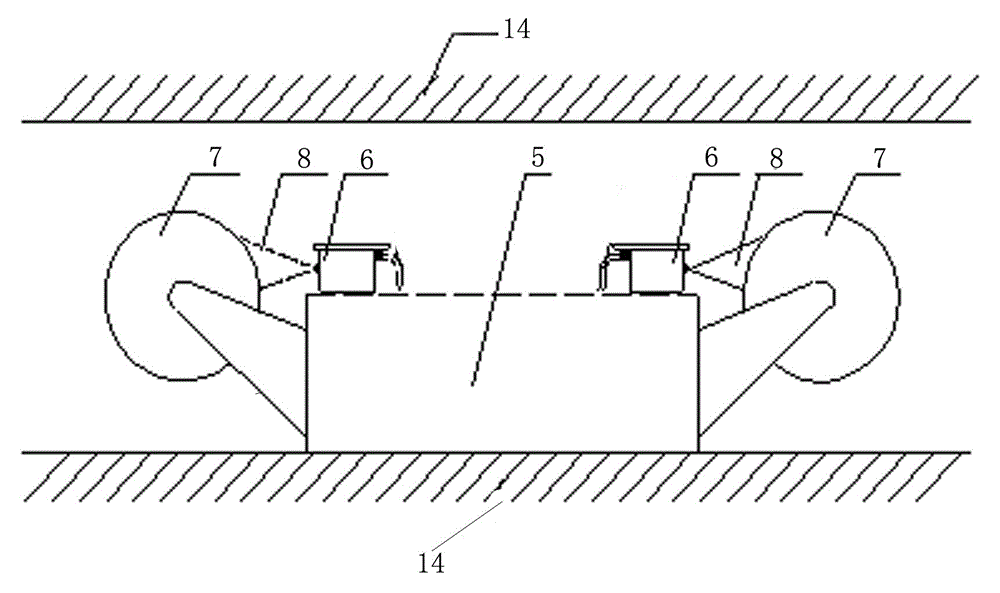

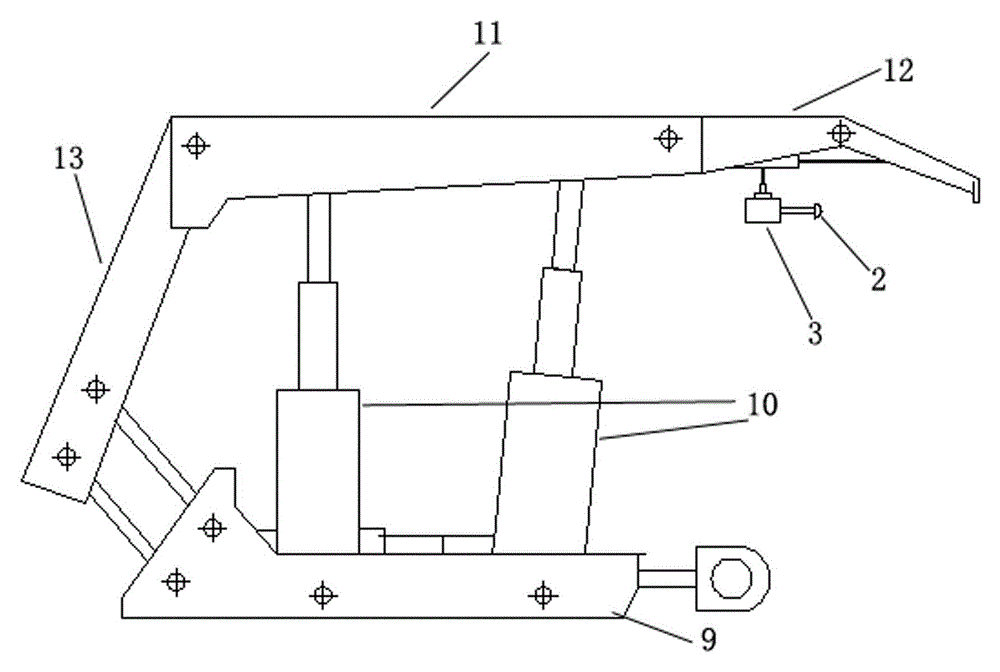

[0016] An automatic dust reduction method for flour dust exceeding the limit in fully mechanized mining work, including dust suppression by using a fully mechanized mining face dust suppression system and a shearer dust suppression system, and the fully mechanized mining face dust suppression system includes a distance of 20 + 1m along the arrangement direction of the hydraulic supports, several dust concentration sensors 1 arranged on the hydraulic supports and several first atomizing nozzles 2 arranged on the front beam 12 of each hydraulic support; the first atomizing nozzles 2 are all connected by pipelines There is an electric valve 3; the signal output end of the dust concentration sensor 1 is connected with a central processing unit 4, and the signal output end of the central processing unit 4 is connected with the signal input end of the electric valve 3; the electric valve 3 is connected with the electric valve through a pipeline. The air source and the water source ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com