Mine working face dust hazard online monitoring system and method

A working surface and dust technology, which is applied in measuring devices, suspension and porous material analysis, particle size analysis, etc., can solve the problems of inability to measure the dust exposure of respiratory dust in real time, and the online monitoring system and method of harm, so as to ensure the health health status effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described in detail below in conjunction with examples and specific implementation methods. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

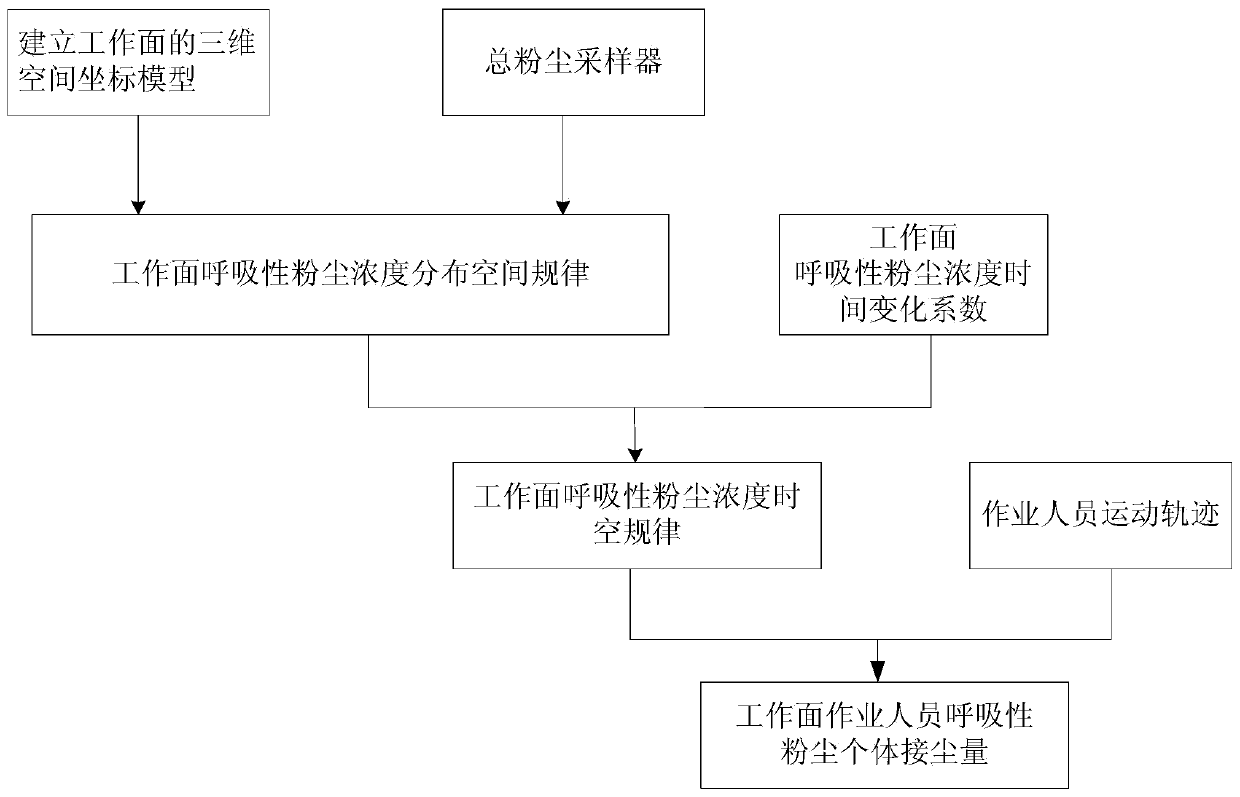

[0047] refer to figure 1 , the present invention provides a method for calculating the individual exposure to respirable dust of working face workers, which specifically includes the following steps:

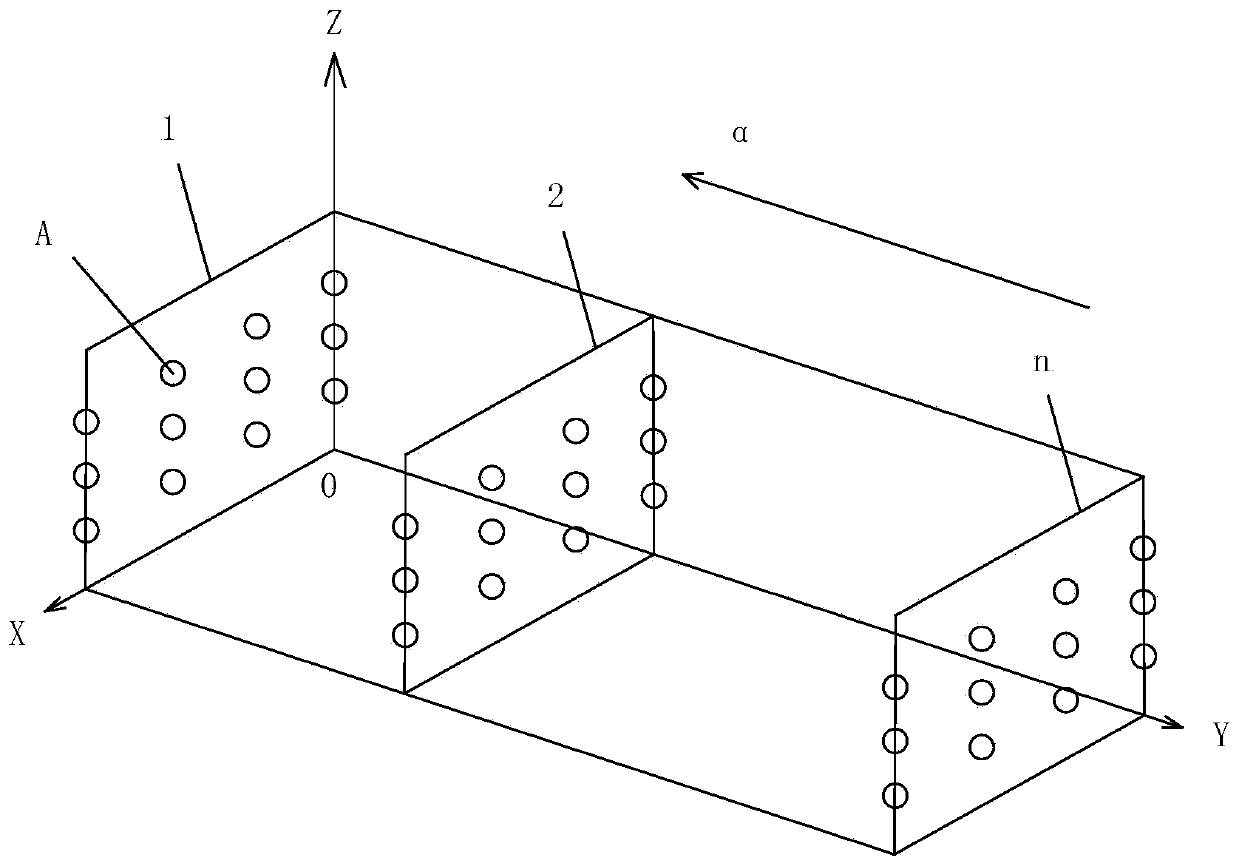

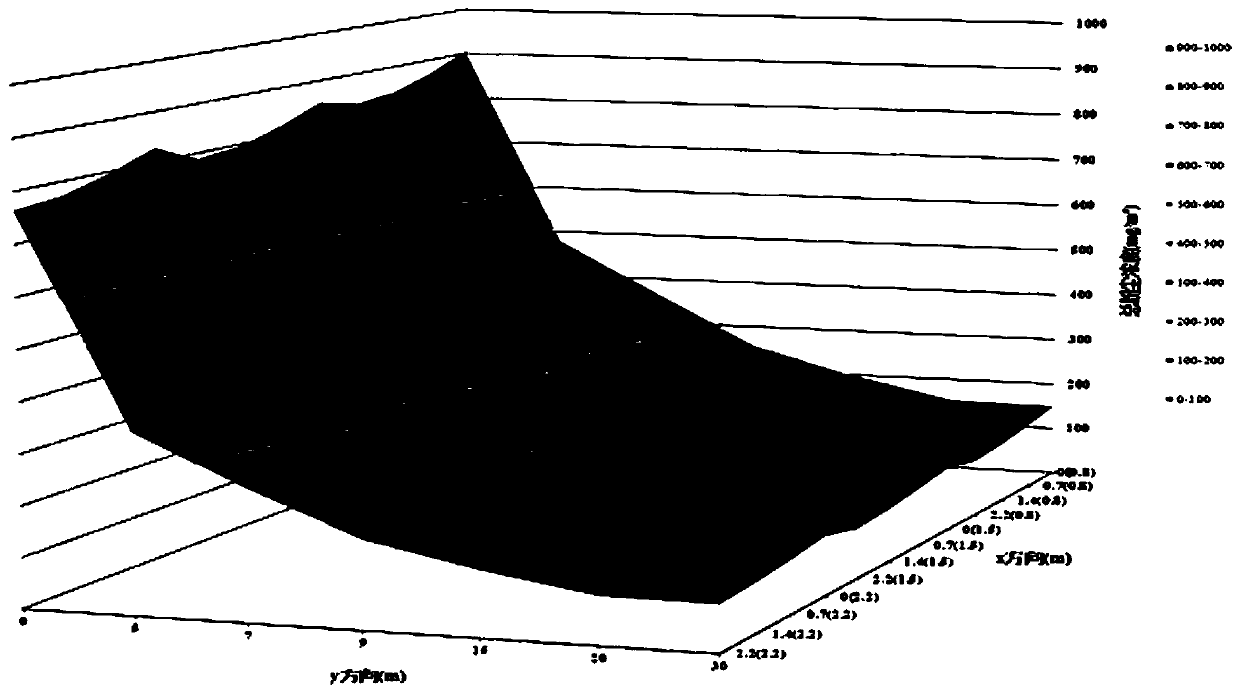

[0048] Establish the (x, y, z) three-dimensional space coordinate model of the working face, and arrange the total dust sampler at each measurement point in the three-dimensional model of the working face for dust sampling, and obtain the total dust concentration value and the proportion value of respirable dust at each measurement point , the spatial law of the distribution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com