Diamond collator and grinding machine table with same

An organizer and diamond technology, applied in the direction of manufacturing tools, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of affecting the cleaning effect of the grinding pad, reducing the grinding efficiency, etc., to achieve convenient movement, prolong service life, Guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

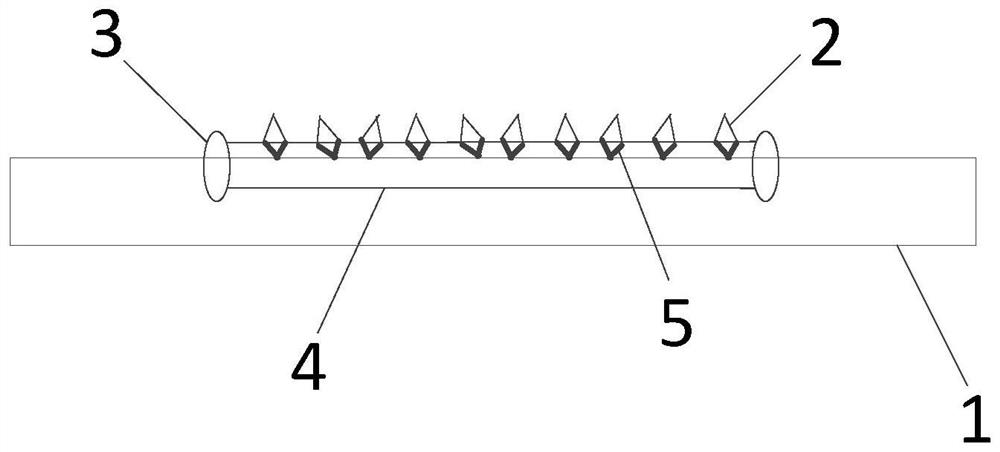

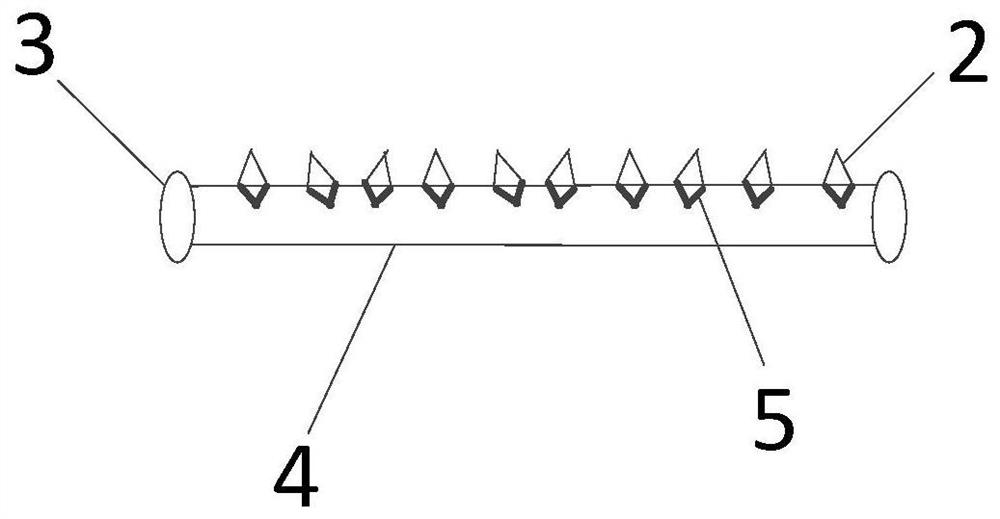

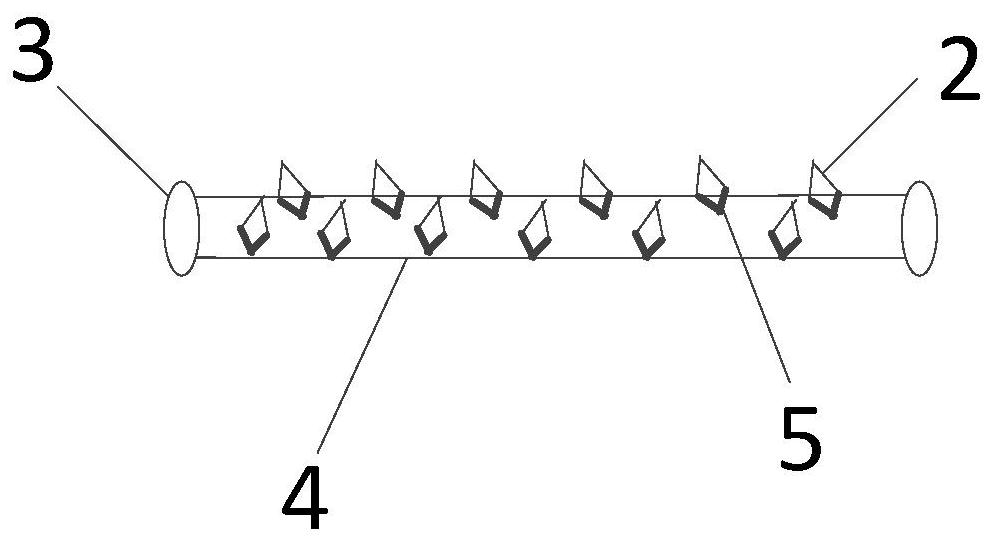

[0031] To this end, this application proposes as figure 1 and 2 A specific implementation of the diamond organizer shown includes a body 1, a support structure provided on the body 1, and a plurality of diamonds 2 fixed on the support structure.

[0032] The support structure is rollingly connected with the body 1 , and when the body moves, the support structure rolls back and forth relative to the body 1 . The support structure has an arc-shaped bearing surface, and the arc-shaped bearing surface is provided with a plurality of accommodation cavities 5. The accommodation chambers 5 are formed by inward depressions on the arc-shaped bearing surface, and the shape is consistent with that of the diamond 2, and its size is slightly smaller than that of the diamond 2. size. Specifically, the support structure is a cylinder, including a bearing 3 and a roller 4 disposed in the bearing 3, the bearing 3 is fixed on the body 1, and the two ends of the roller 4 are respectively insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com