Parallel balanced filling method for high-capacity semi-management surface tension storage tank

A Surface Tension Tank, Large Capacity Technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

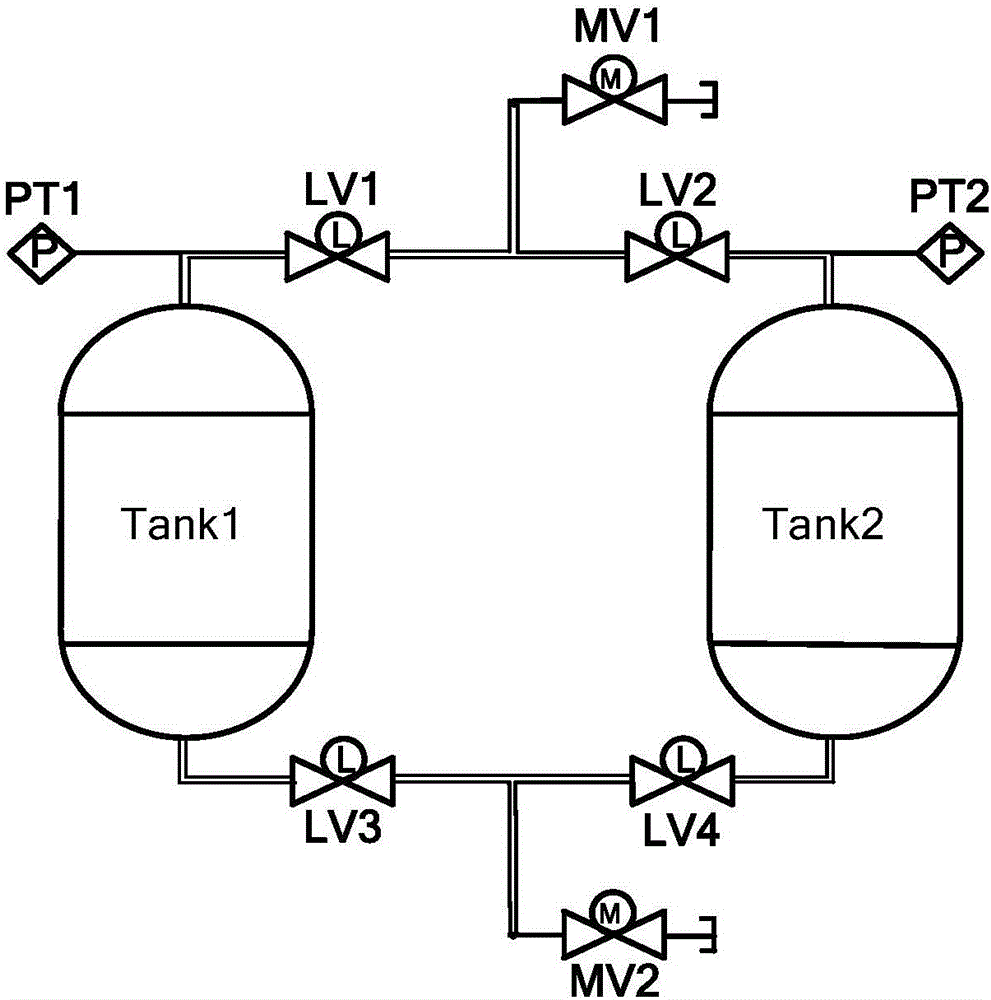

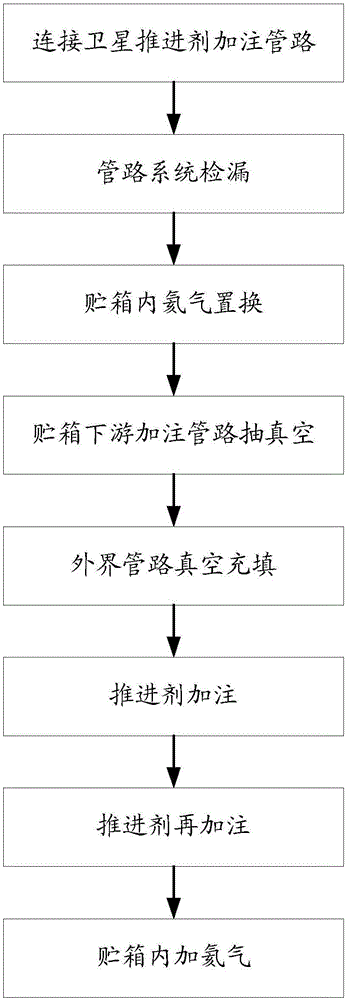

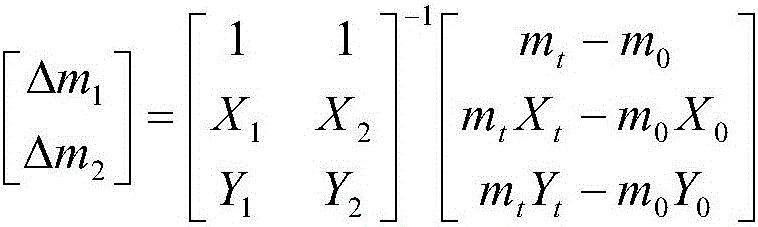

[0030]The basic thinking of the present invention is: propose a kind of large-capacity semi-management type surface tension storage tank parallel connection balanced filling method: (1) connect the satellite propellant filling pipeline, confirm that the leakage rate of the filling pipeline system meets the requirements; ( 2) Replace the two parallel storage tanks with helium at the same time until the sampled gas passes the test; (3) Vacuum the propellant filling pipeline and the pipeline downstream of the parallel storage tank; (4) Fill the propellant to the valve port of the filling and discharging valve of the parallel storage tank; (5) fill the parallel storage tank smoothly at the same time until 90% or more of the rated filling volume is completed; (6) refill the parallel storage tank until The amount of filling in a single storage tank meets the task requirements; (7) Add an air cushion to the required air cushion pressure in the storage tank. The method can realize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com