Large-range goaf group filling method

A processing method and technology for goafs, which are applied in filling materials, mining equipment, earthwork drilling, etc., can solve the problems of complex filling process, high filling cost, low filling efficiency, etc., so as to simplify the filling process, ensure normal production, The effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

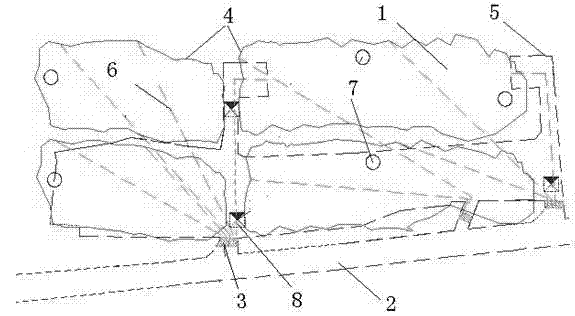

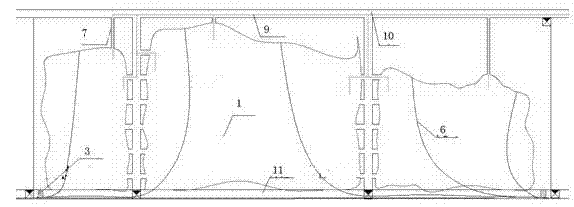

[0026] In the example, a large-scale open-pit mining of an iron mine began in 1975. In 2001 and 2003, the mineral resources in the middle section of -60 meters were developed and constructed twice, and mine rooms and roadways were formed during underground mining. , the vein-piercing roadway runs through the ore body. There is illegal mining near the veins, which destroys the mining plan of the mine and forms some goafs 1 and roadways 2 . Due to the adoption of open-field mining and management, 147 goafs have been formed at the -60m level, and most of the goafs have been penetrated, criss-crossing, and many places have appeared penetration points with the upper horizontal roadway, and the stability is extremely poor , Seriously affecting the normal production of mines, it is a typical large-scale goaf group.

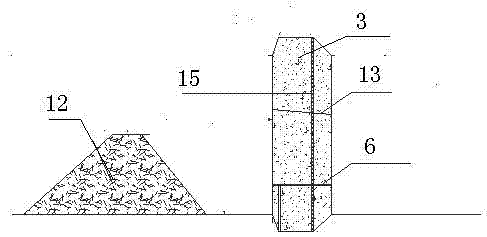

[0027] The method of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com