Slow-release corrosion and scale inhibitor capsule for oil wells and preparation method thereof

A corrosion and scale inhibitor, corrosion and scale inhibition technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of oilfield production impact, complex process, and inconvenient continuous addition, etc. Achieve the effects of long corrosion and scale prevention period, simple filling process, and improved effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of slow-release corrosion and scale inhibitor capsules for oil wells, comprising the following steps:

[0047](1) Mix the prepared integrated corrosion and scale inhibitor, carrier and density weighting agent at 40°C and a stirring speed of 250r / min according to the above ratio of parts by weight, and knead in a kneader for 40 minutes to further mix, Dry in a vacuum drying oven at 60°C for 24 hours. After the surface is basically dry, a loading integrated agent is obtained and set aside.

[0048] (2) In a 2L ceramic reactor, disperse coating agent A in warm water at 30°C at a mass concentration of 5%-10%, turn on the stirrer for 30 minutes, slowly raise the temperature to 90-95°C, and keep warm for more than 4 hours , cooled to obtain the coating agent A solution, and set aside.

[0049] (3) Prepare the encapsulating agent B solution with a mass concentration of 5%-10%, and the glutaraldehyde solution with a mass...

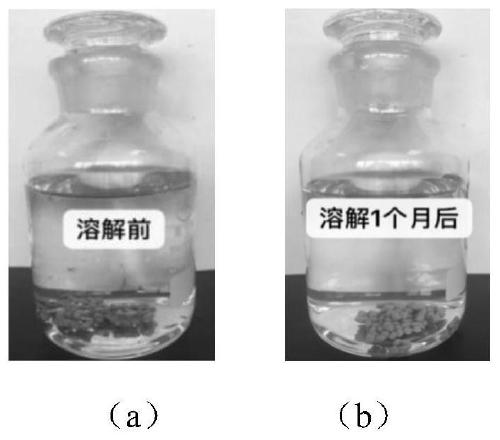

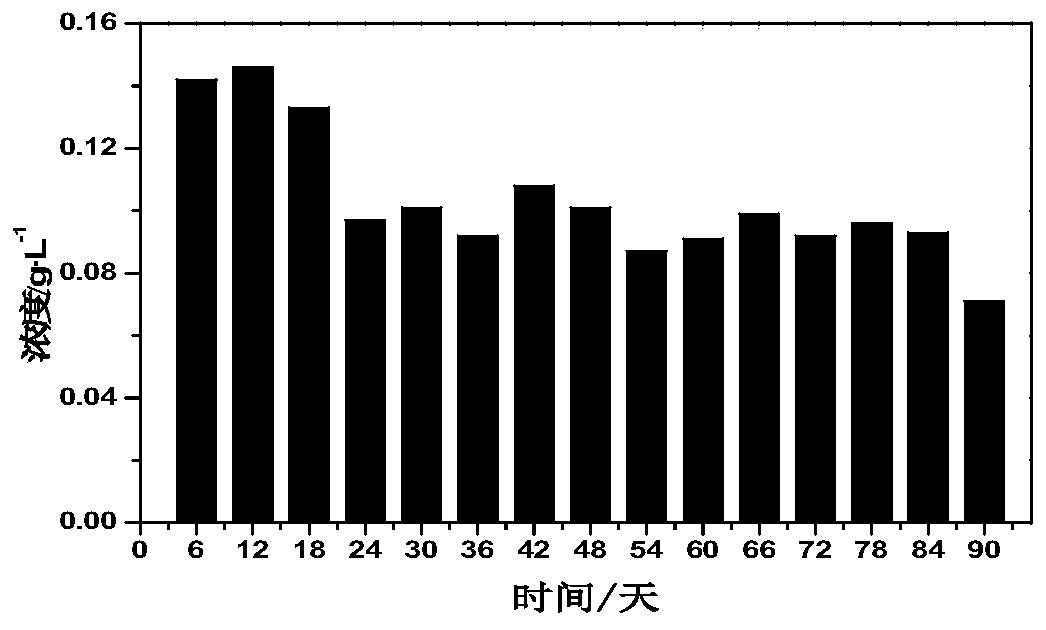

Embodiment 1

[0054] This embodiment provides a double-membrane controlled-release corrosion and scale inhibition capsule, which consists of 20 parts by weight of an integrated corrosion and scale inhibitor, 20 parts of attapulgite, 5 parts of potassium formate, 10 parts of polyvinyl alcohol, polyethylene Composed of 5 parts of pyrrolidone and 10 parts of glutaraldehyde.

[0055] The preparation method of the corrosion and scale inhibition integrated agent: ammonium persulfate is used as the initiator, isopropanol is used as the chain transfer agent, and it is prepared by solution polymerization. The details are as follows:

[0056] (1) In parts by weight, dissolve 1 part of ammonium persulfate in 100 parts of water, add 4 parts of acrylic acid, 0.5 parts of acrylic urea and 8 parts of isopropanol while stirring, adjust the temperature to 65-70 °C, and continue stirring 10min, make the system mix evenly, carry out prepolymerization 1h, obtain the mixture;

[0057] (2) 20 parts of acrylic a...

Embodiment 2

[0069] This embodiment provides a sustained-release corrosion and scale inhibitor capsule for oil wells, which consists of 40 parts of corrosion and scale inhibitor integrated agent, 40 parts of attapulgite, 8 parts of potassium bromate, 20 parts of polyethylene glycol, 10 parts of polyvinylpyrrolidone and 20 parts of glutaraldehyde

[0070] composition.

[0071] The preparation method of the integrated corrosion and scale inhibitor is the same as that in Example 1.

[0072] A preparation method of a dual-membrane controlled-release corrosion and scale inhibition capsule:

[0073] (1) Mix well weighed 40 parts of corrosion and scale inhibition integrated agent, 40 parts of attapulgite and 8 parts of potassium bromate, and then knead in a kneader for 20-40 minutes to further mix, and put them in a vacuum oven for 60 Dry at ℃ for 24 hours, and use it after the surface is basically dry.

[0074] (2) In a 2L ceramic reaction kettle, disperse polyethylene glycol in warm water at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com