Goods advancing device

A propulsion device and cargo technology, applied in the direction of shelves, household appliances, applications, etc., can solve the problems of high push plate, unusable, easy to lose parts, etc., and achieve the effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

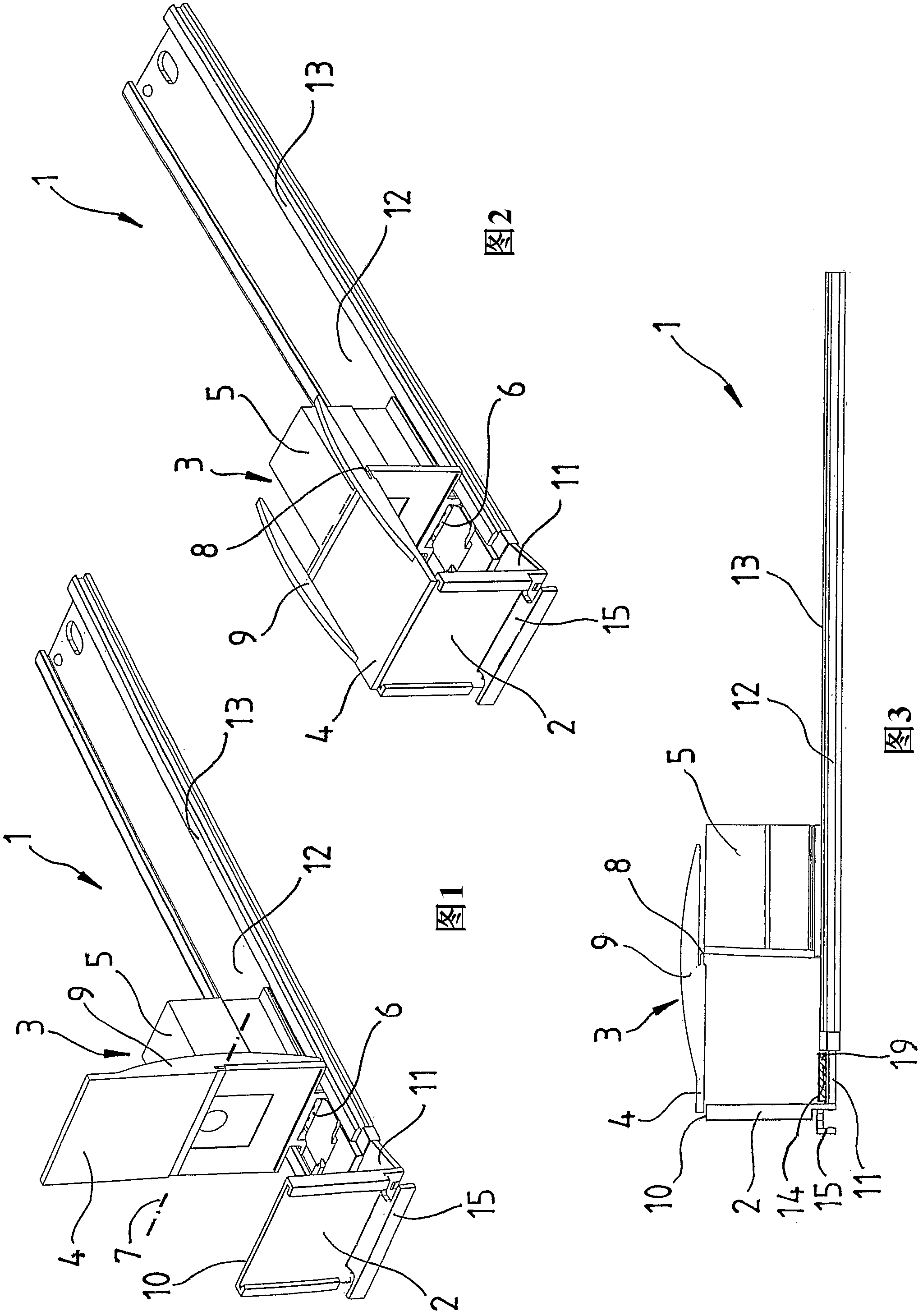

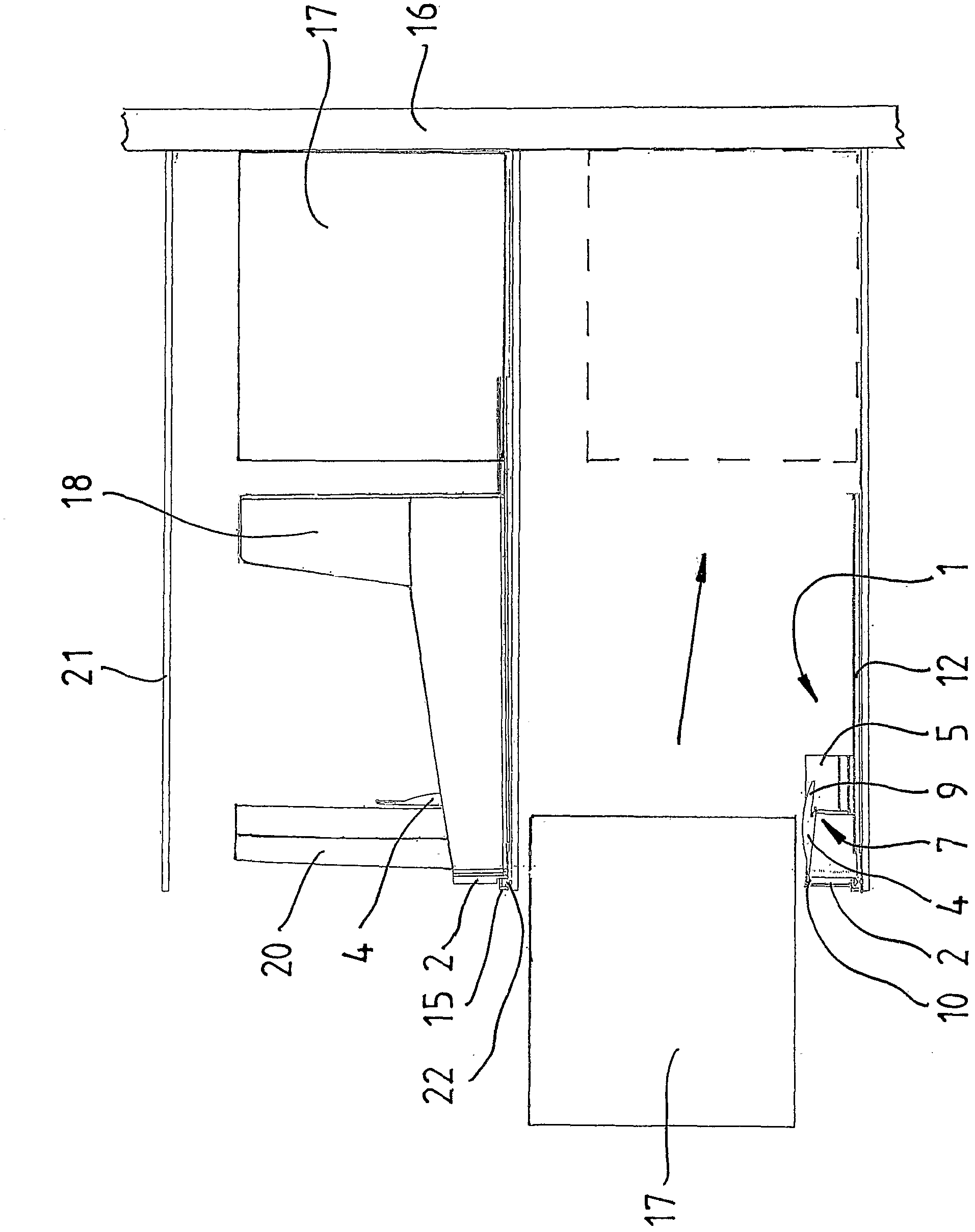

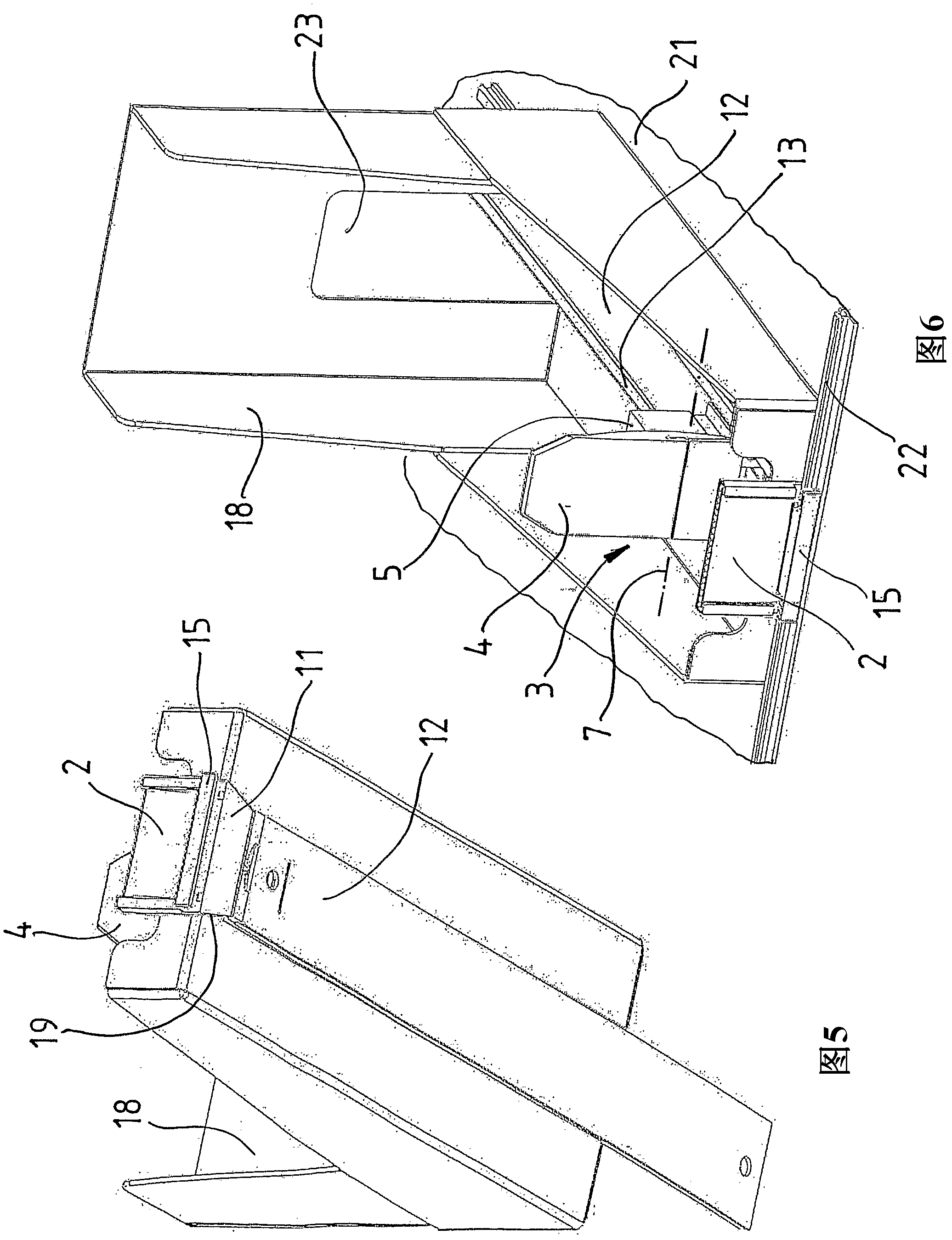

[0023] The cargo propulsion device 1 consists of a cargo pusher 3 which in turn consists of a horizontally divided pusher plate 4 whose upper part is pivotably hinged around an axis 7 on the pusher housing 5 , wherein the shaft 7 is configured as a membrane hinge 8 . Embodiments with conventional hinge structures are also possible, but not shown. In addition, the cargo propulsion device 1 is provided with a front anchor 2 , which is connected at the end side via a connecting piece 11 to a guide profile 12 in which the pusher housing 5 is guided. A coil spring is mounted rolled up in the pusher housing 5 , the ends of which are fastened to the front anchor 2 . The front anchor 2 has a clip-on fastening 15 for an adaptation system, for example for a clamping rail 22 .

[0024] The connecting element 11 has a lower height than the guide profile 12, so that in the bottom area 14 of the carton / goods pallet 18 placed in the goods pusher 1 of the rack-ready packaging system, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com