Filling and mining method of coal gases

A mining method and gas technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of restricting the promotion of filling mining technology, high cost of filling material transportation, and difficult sources of filling materials, so as to simplify the filling process and improve coal mining efficiency. The recovery rate and the effect of slowing down the subsidence of the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

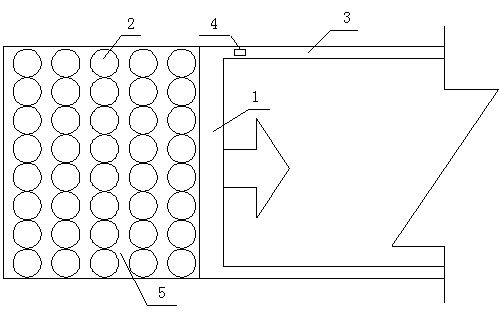

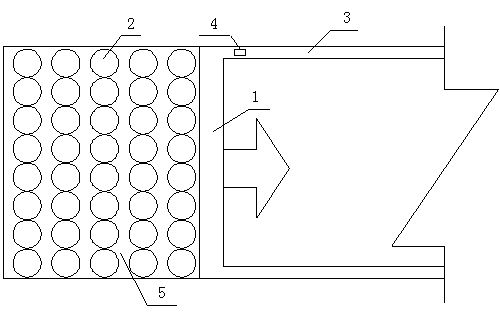

[0020] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0021] In the coal mine gas filling and mining method of the present invention, a gas booster room is firstly installed near the surface auxiliary shaft, and a ground gas booster pump and a high-pressure gas storage tank equipped with 0.8-1Mpa high-pressure gas are installed in the gas booster room; The underground gas booster pump 4 connected to the pipeline of the ground high-pressure gas storage tank is arranged in the transportation level roadway 3 of the mining area 5-20m in front of the coal working face 1; In the goaf 5 behind the coal mining face 1, a row of cylindrical rubber airbags 2 with the same height as the coal mining is arranged. The ratio of the diameter of the cylindrical rubber airbags 2 to its height is 0.4 to 0.6; 4 Inflate the cylindrical rubber airbag 2 arranged in the goaf 5 through the pipeline until it is connected to the top, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com