Annular heat pipe array heat exchanger and heat exchange system comprising annular heat pipe array heat exchanger

An annular heat pipe and heat exchange system technology, applied in the field of heat exchange, can solve the problems such as the inability to exert the heat exchange capacity of the condensing side, the uneven temperature distribution of the condensing side, and the increase of the temperature difference between the evaporation end and the condensing end. The ability of uneven distribution of cold and heat sources is strong, the energy consumption of air conditioners is saved, and the flow resistance is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

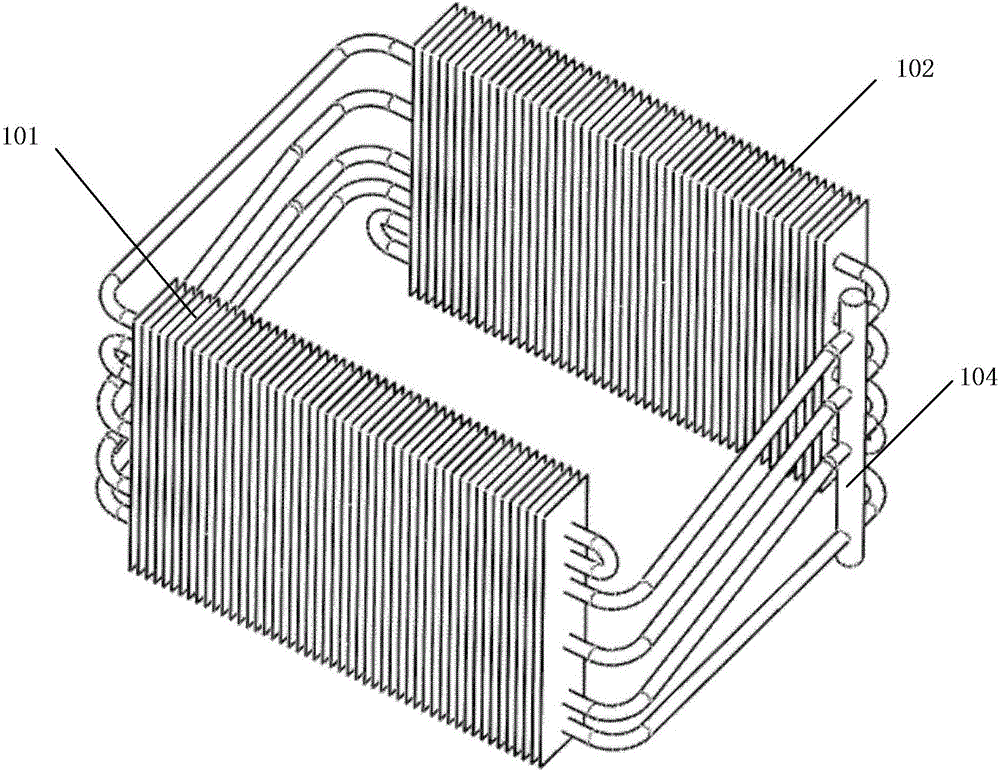

[0045]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

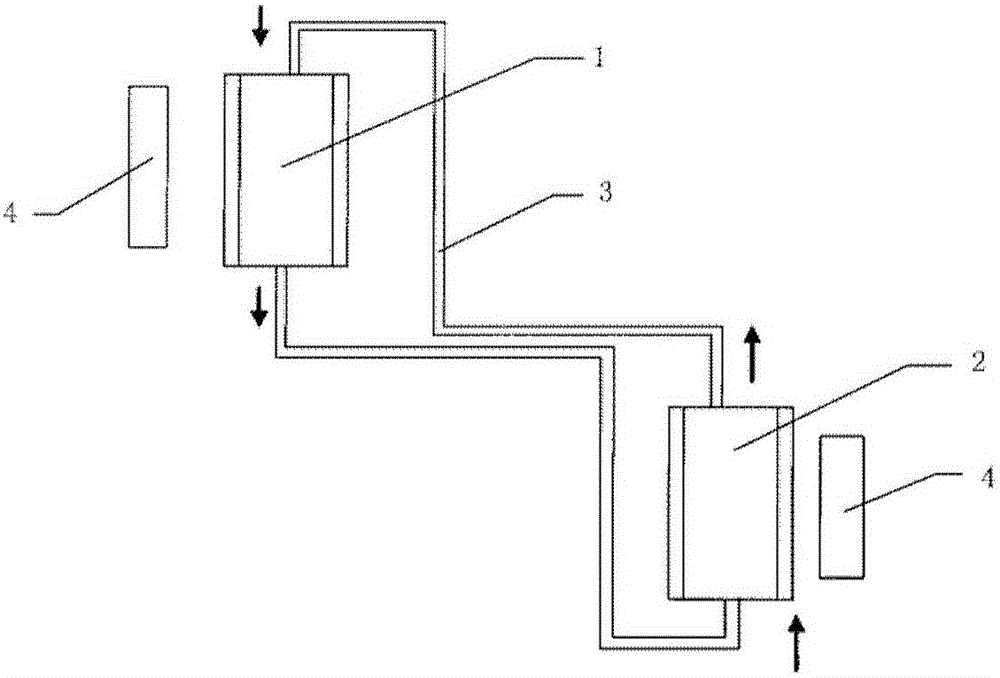

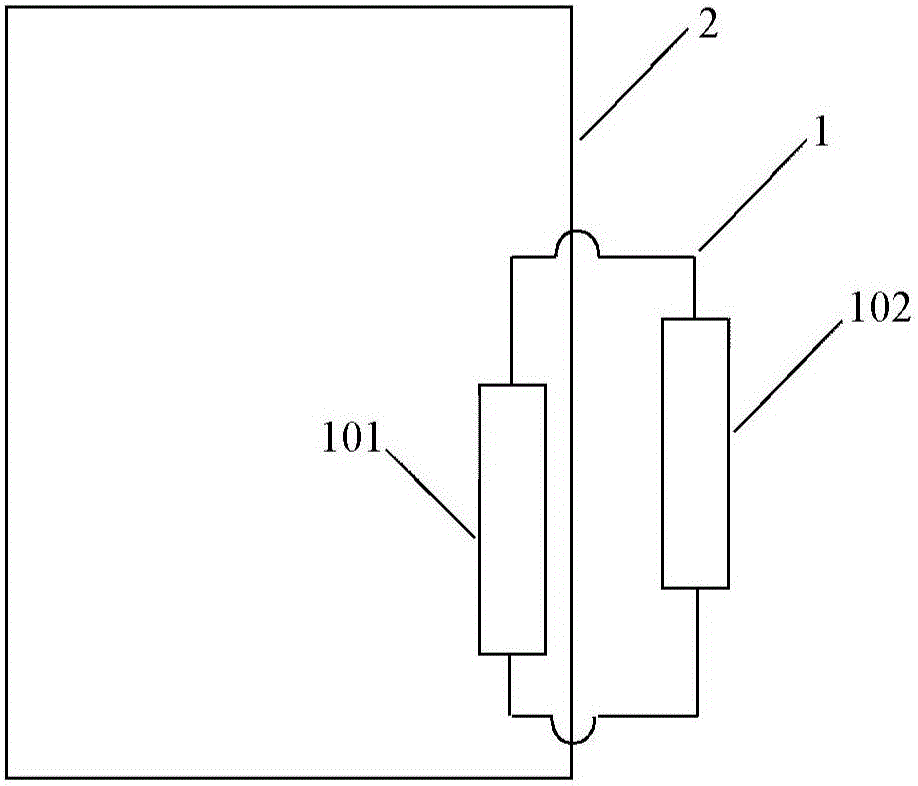

[0046] According to the general inventive concept of the present invention, an annular heat pipe array heat exchanger is provided, which includes a condensation end and an evaporation end, and realizes multi-loop heat exchange through two multi-pass pipelines arranged oppositely. The arrangement of each component will be described in detail below in conjunction wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com