Strip filling method of conventional mining face goaf pumping cementing materials

A technology for strip filling and cementing materials, which is used in filling materials, mining equipment, earth-moving drilling, etc., can solve the problems of increased filling cost, poor control effect of overlying rock, and low filling body strength, and achieves safe and reliable construction process. The effect of good strip forming quality and good roadway safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

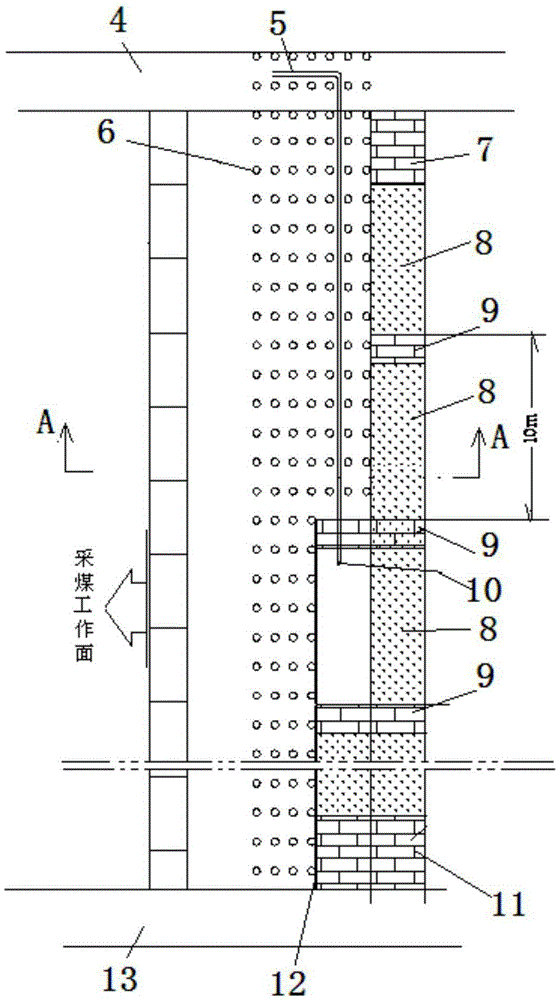

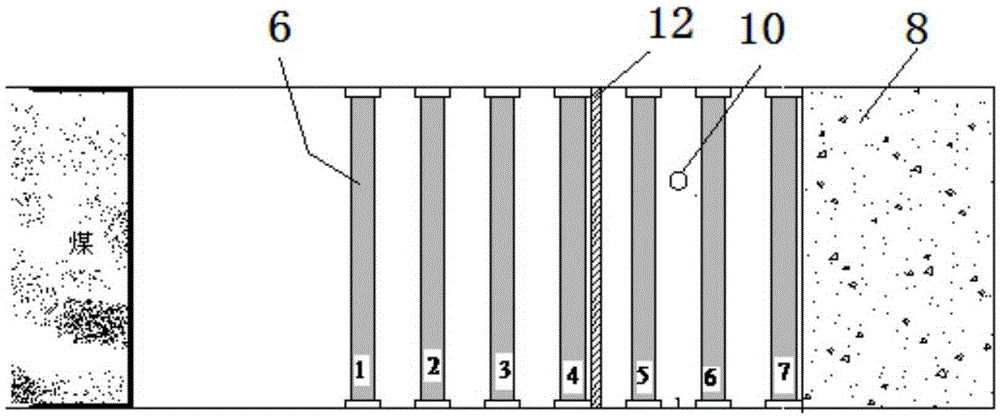

[0037] The specific embodiments of the present invention will be further described in detail below in conjunction with examples and accompanying drawings.

[0038] Example of embodiment: The general mining working face of a certain coal mine is 180m long, and the working face adopts a single hydraulic prop to support the roof, the prop row distance c=1.0m, and the maximum control top distance is the width of seven rows of props, which is 7m.

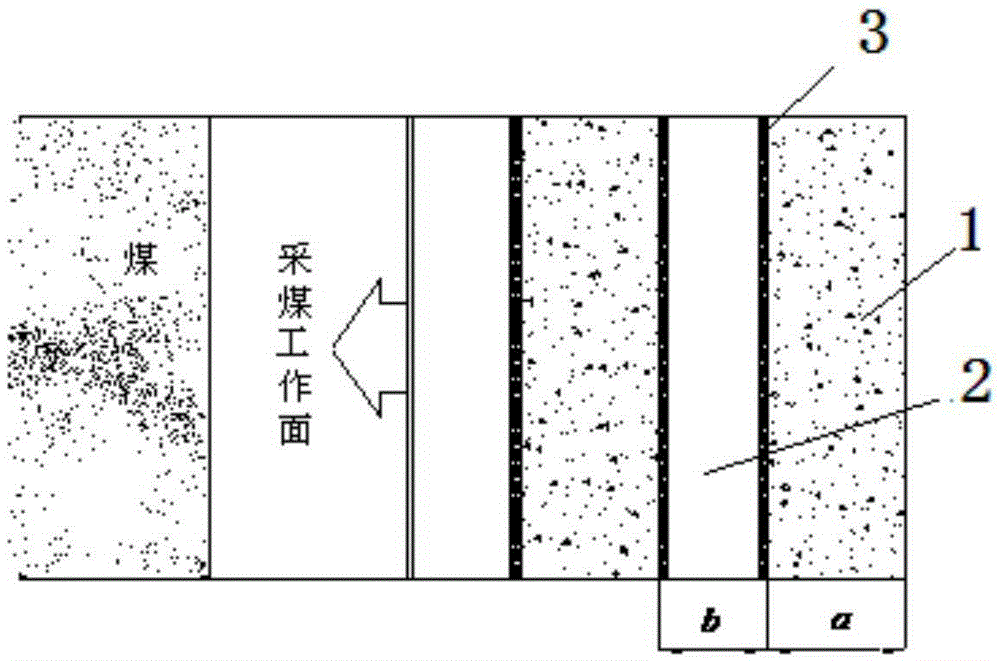

[0039] Such as figure 1 , figure 2 , image 3 As shown, a strip filling method for pumping cementing material in the goaf of a general mining face includes the following steps:

[0040] In the first step, before filling the goaf, the strip filling body 1 is designed along the advancing direction in the goaf. According to the condition of the overlying rock roof, the strip filling body 1 is determined through the theoretical calculation of mine pressure and the mechanical performance experiment of the filling body. Width a and non-filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com