Patents

Literature

44results about How to "Small headroom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

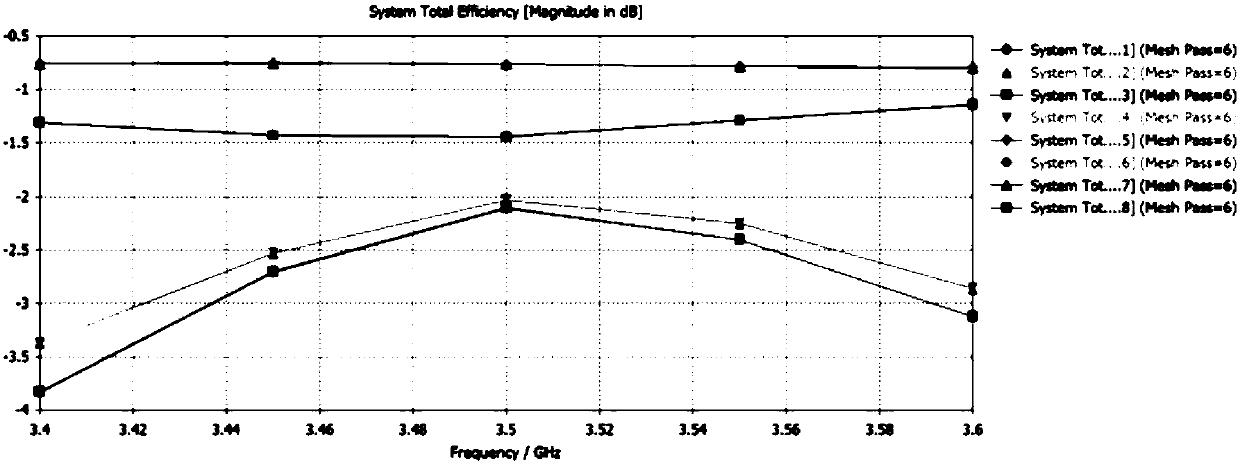

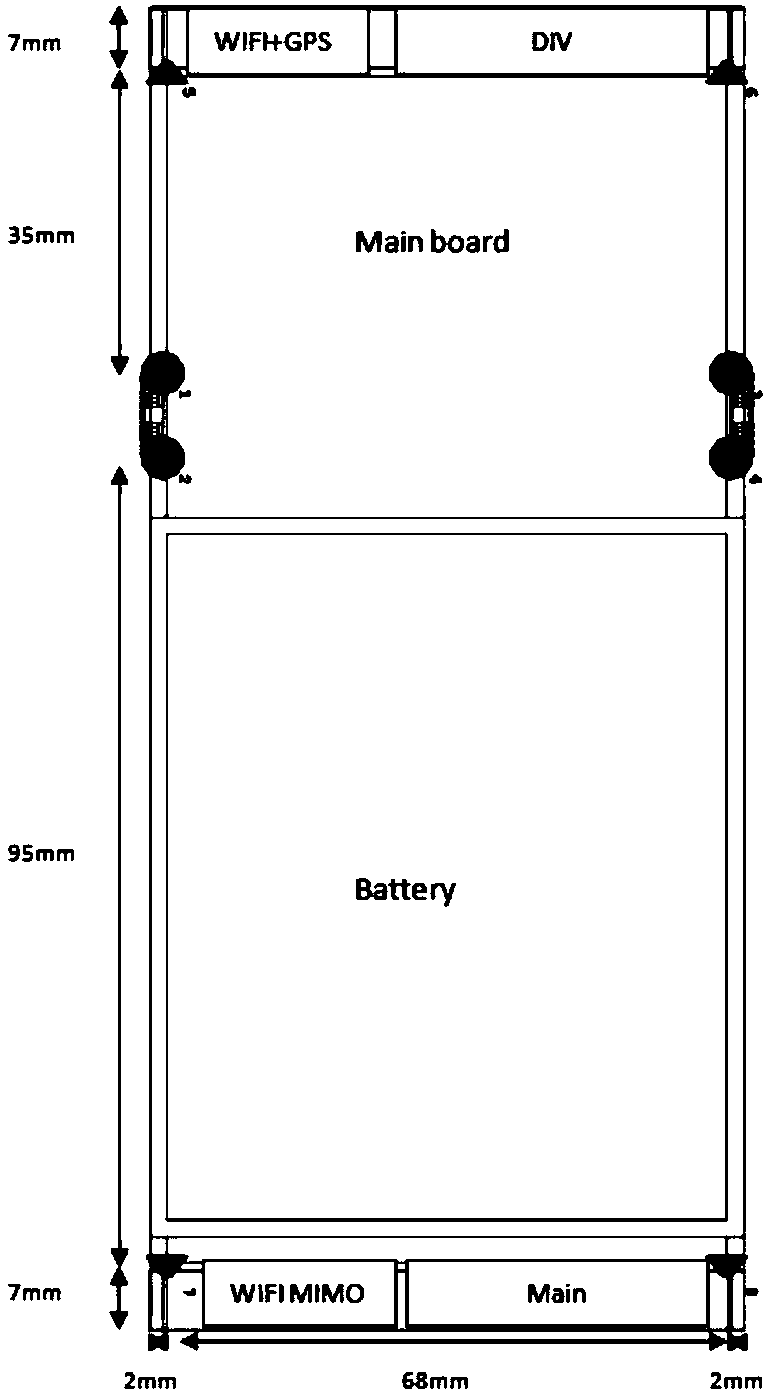

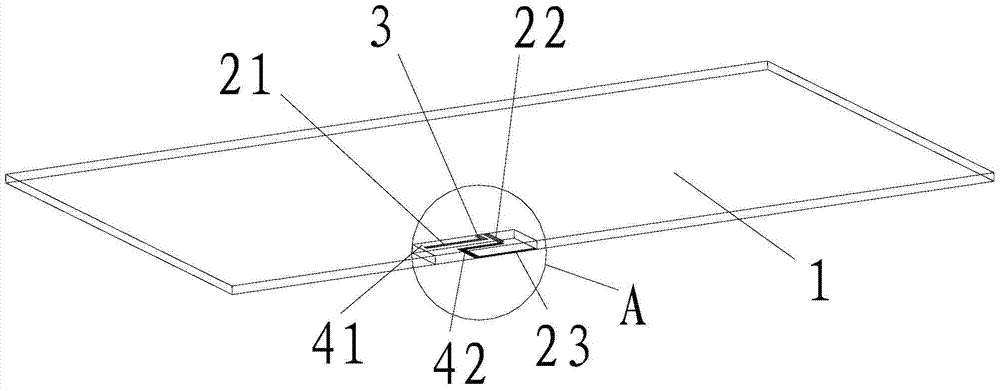

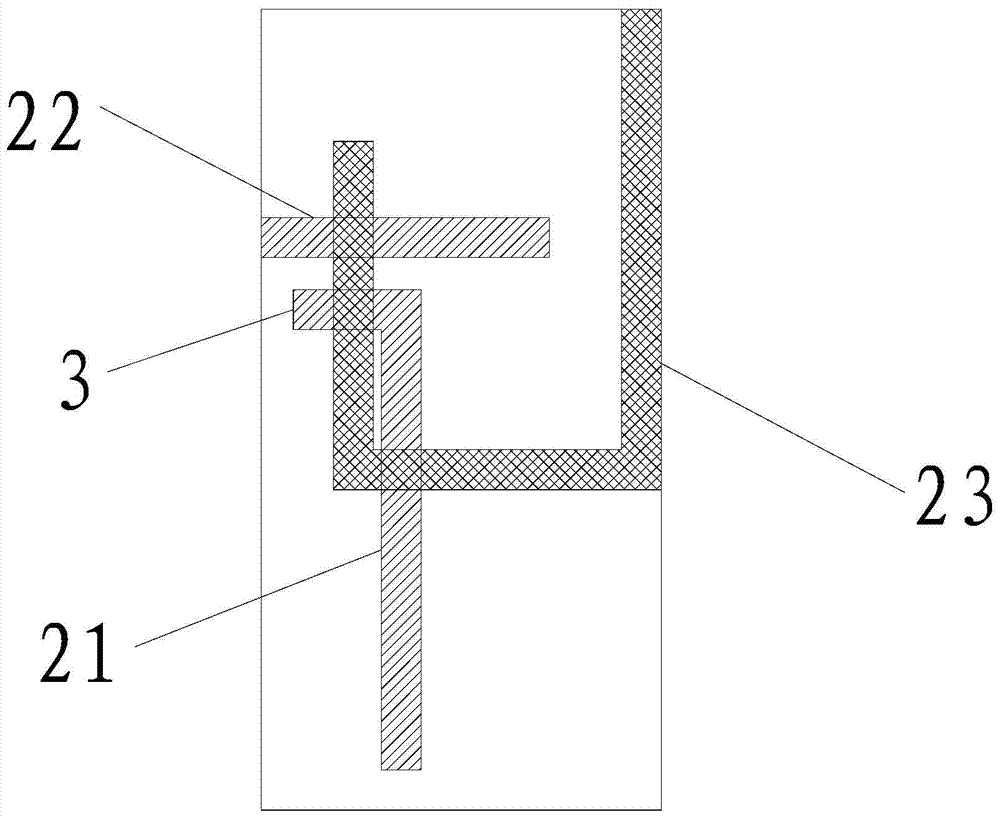

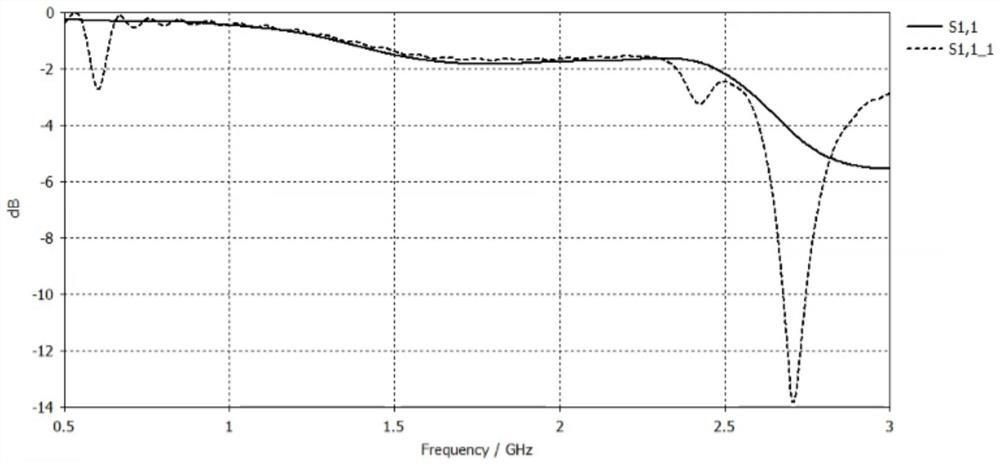

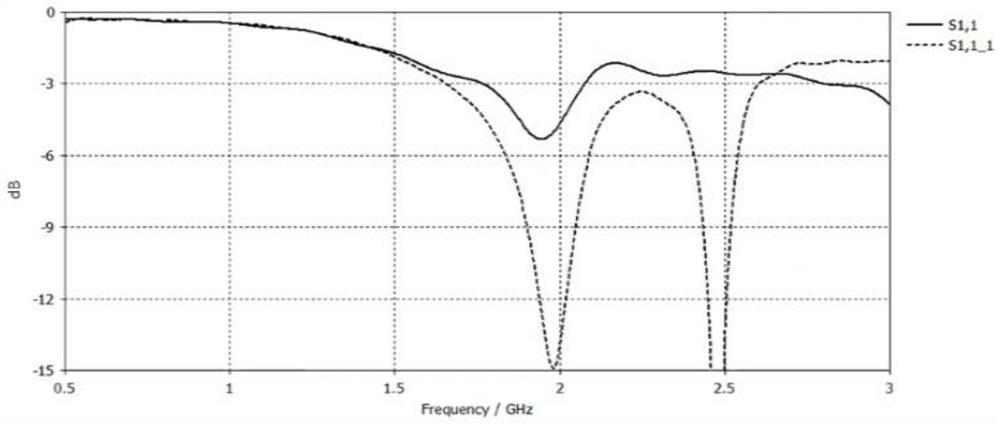

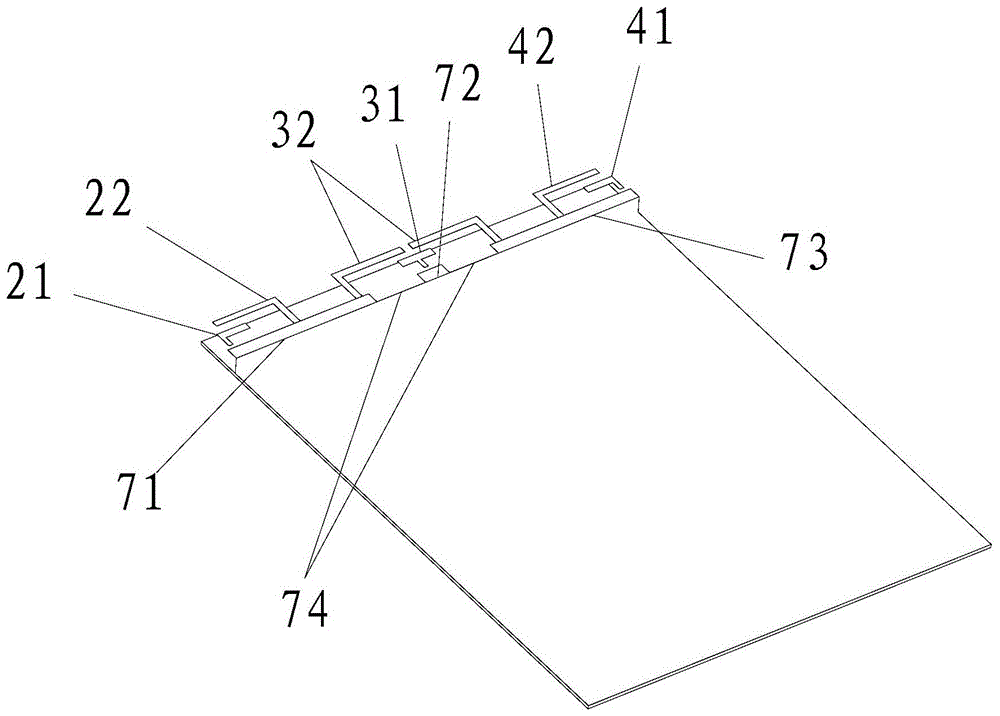

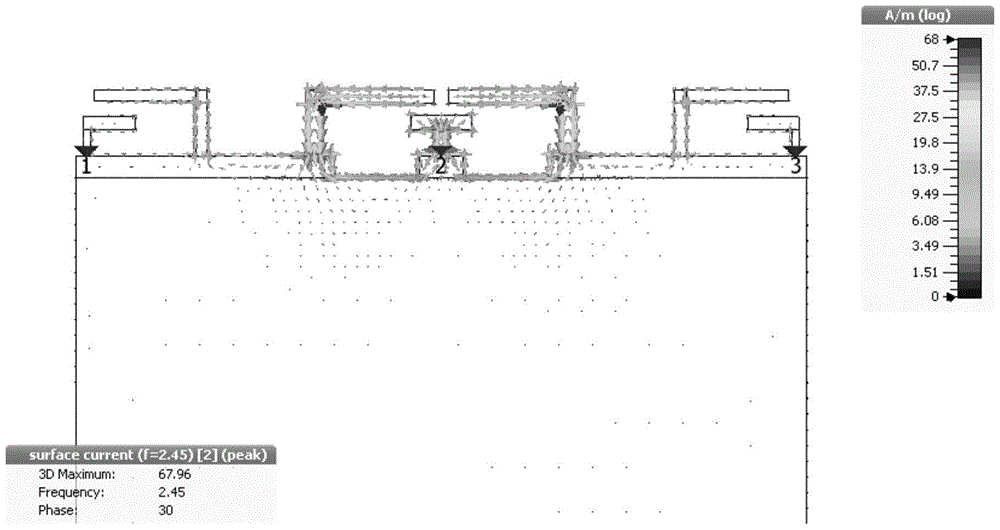

Broadband 5G MIMO mobile phone antenna based on orthogonal mode pair

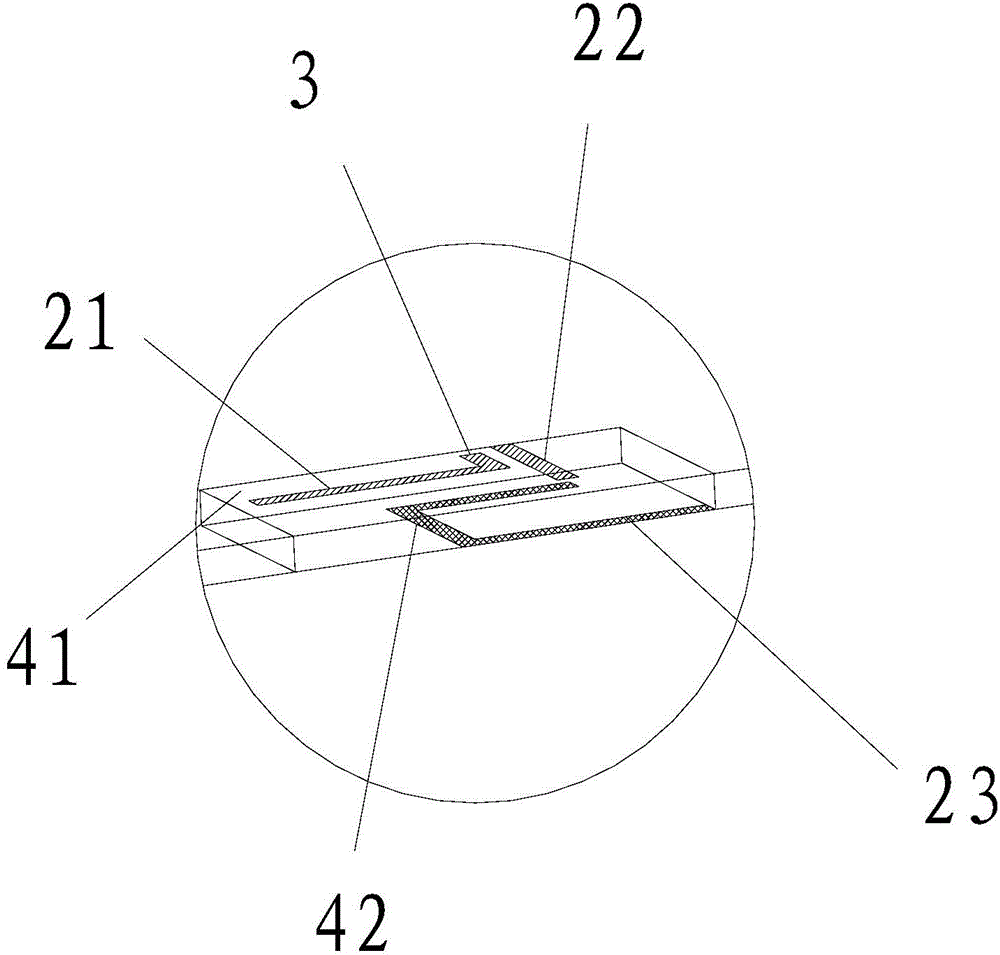

ActiveCN110061349AImprove isolationSmall headroomSimultaneous aerial operationsAntenna supports/mountingsCouplingMimo antenna

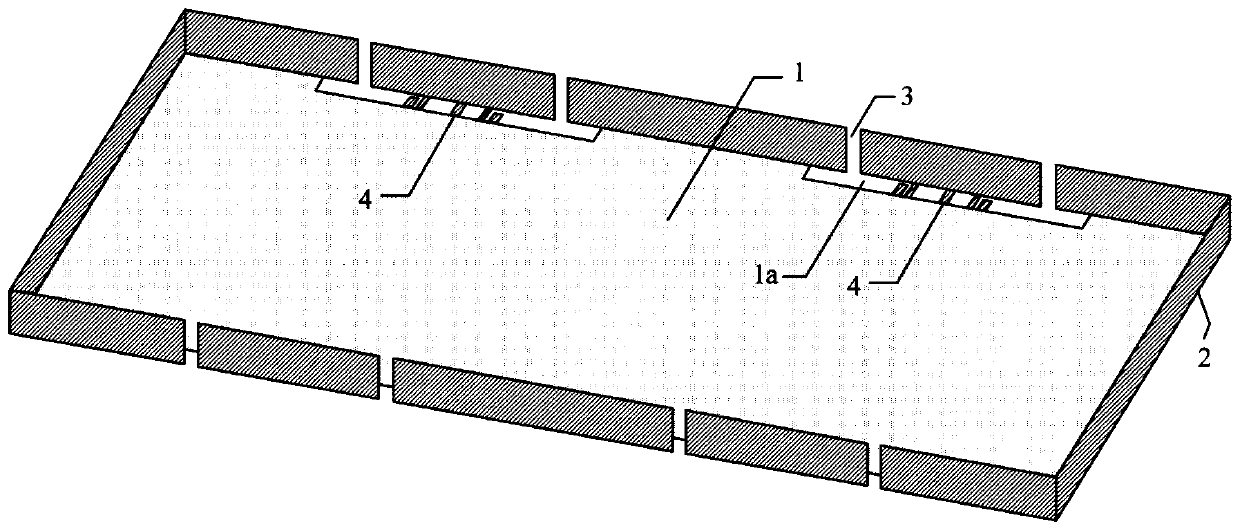

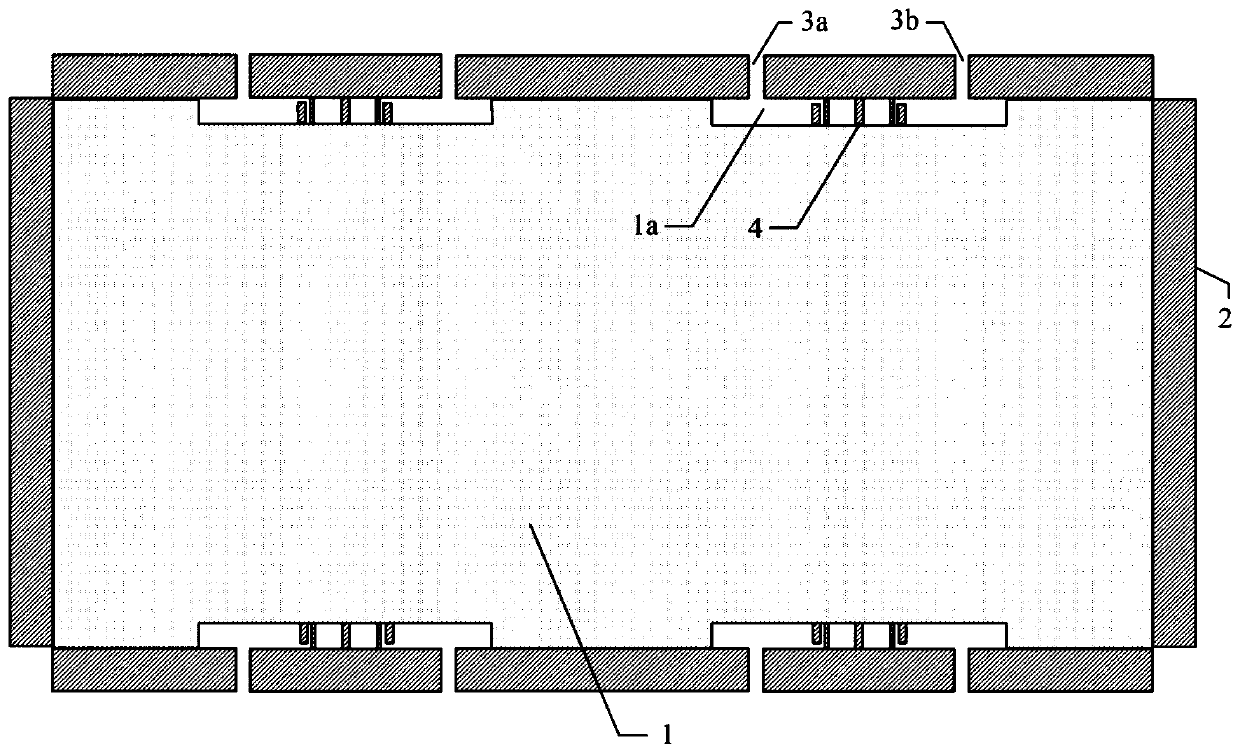

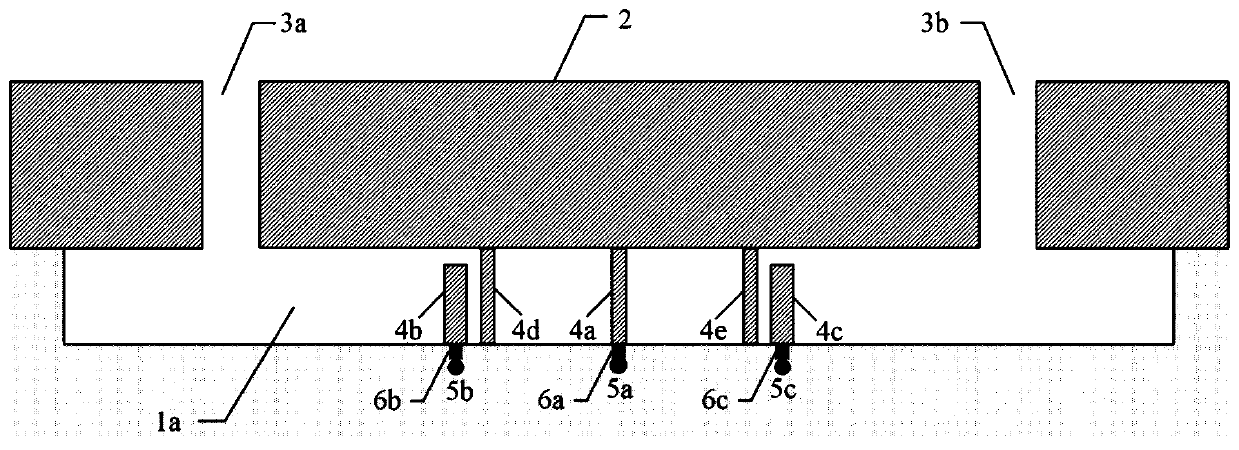

Disclosed is a broadband 5G MIMO mobile phone antenna based on an orthogonal mode pair. The antenna comprises a metal floor, a metal frame, and one or more orthogonal antenna pairs, wherein one or more floor gaps are formed in the long edge of the metal floor; the four sides of the metal frame are closed, and an even number of frame gaps are formed in the metal frame; and each group of orthogonalantenna pairs comprises two antenna units, wherein the antenna unit comprises a central feeding branch, a first side feeding branch, a second side feeding branch, a first coupling branch and a secondcoupling branch. The two antenna units in the orthogonal antenna pair are in an orthogonal mode, so that high isolation characteristics can be realized under the integration of double antennas. In addition, the metal frame and the multi-mode cooperative work and the like are adopted for further broadening the bandwidth of the antenna units. The antenna has the advantages of being wide in broadband, compatible with the metal frame, high in isolation degree, small in clearance, integrated in a double-antenna mode and the like, and is suitable for the 5G MIMO antenna of various small mobile terminals with mobile phones as representatives.

Owner:TSINGHUA UNIV

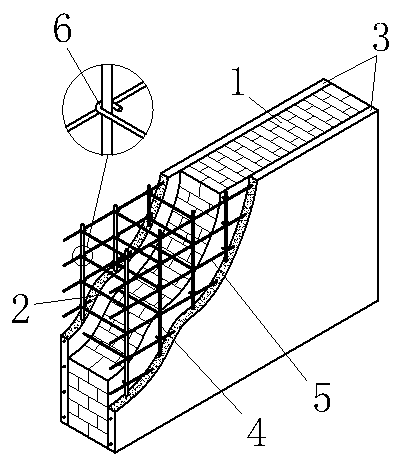

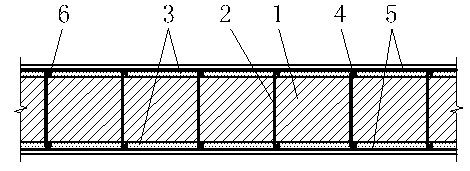

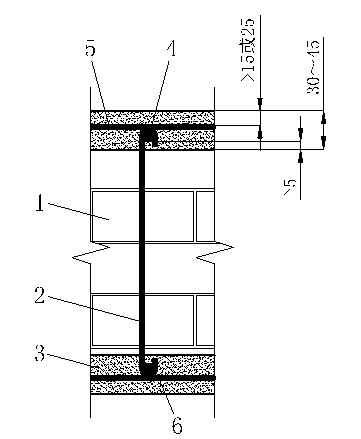

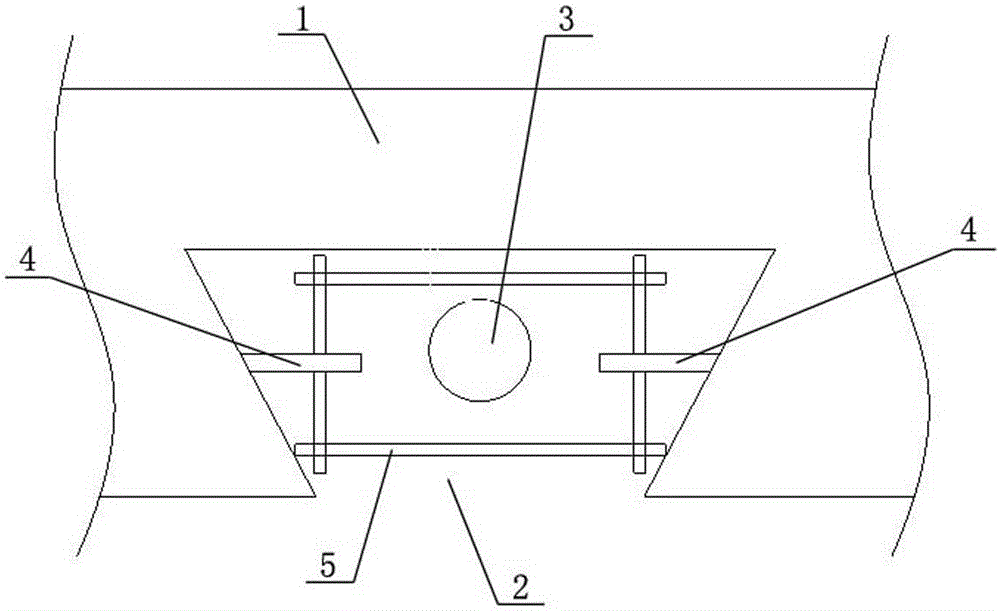

Brick wall reinforcing method and structure

The invention discloses a brick wall reinforcing method and structure. The method includes the steps of enabling reinforcing mesh pieces to be attached to the two faces of a brick wall after a paint layer is removed from the surface of the brick wall to be reinforced, fixing the reinforcing mesh pieces on the two sides of the wall body through steel ties, enabling the wall body to be clamped between the reinforcing mesh pieces, and then spraying cement mortar. The wall body and a reinforcing body are connected into a whole, and therefore bearing capacity, lateral stiffness and wall body ductility of the brick wall can be greatly improved. According to the brick wall reinforcing method and structure, a traditional brick wall cross section expanding method is changed for reinforcement, and influences on clearance and attractiveness of a building are small. The method is safe and reliable in technology, easy and convenient to implement and high in operability, and practice shows that the reinforcing effect is good as well.

Owner:GUIYANG AL-MG DESIGN & RES INST

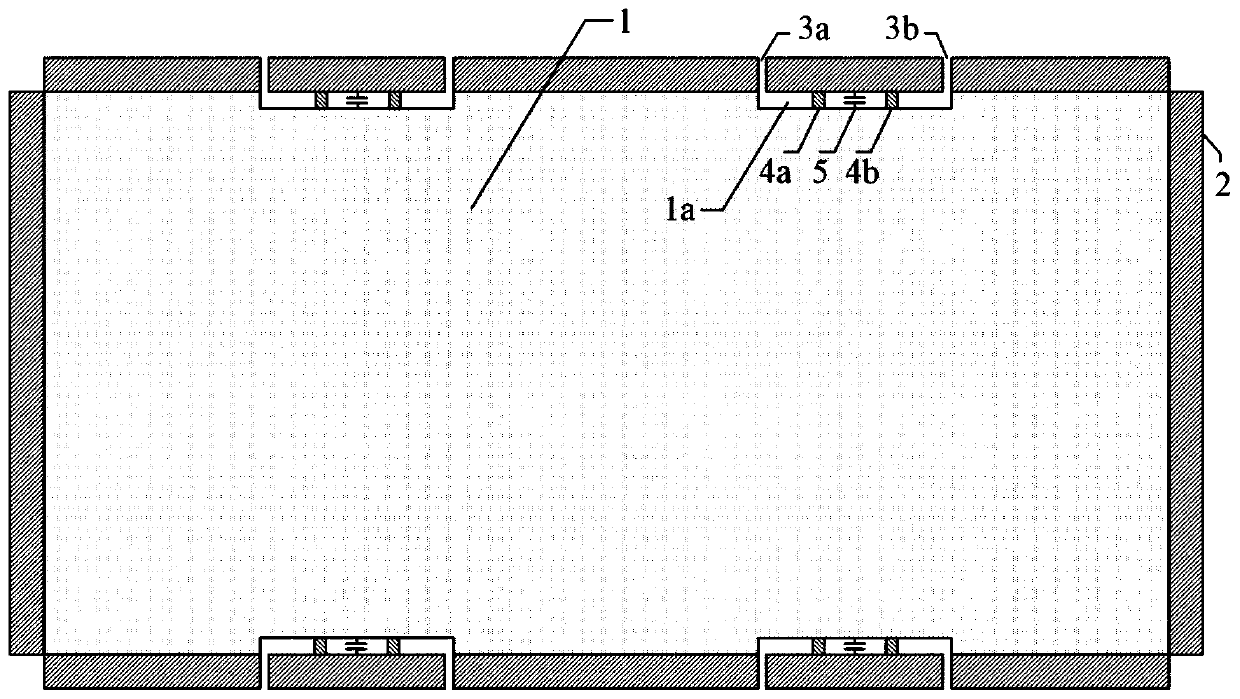

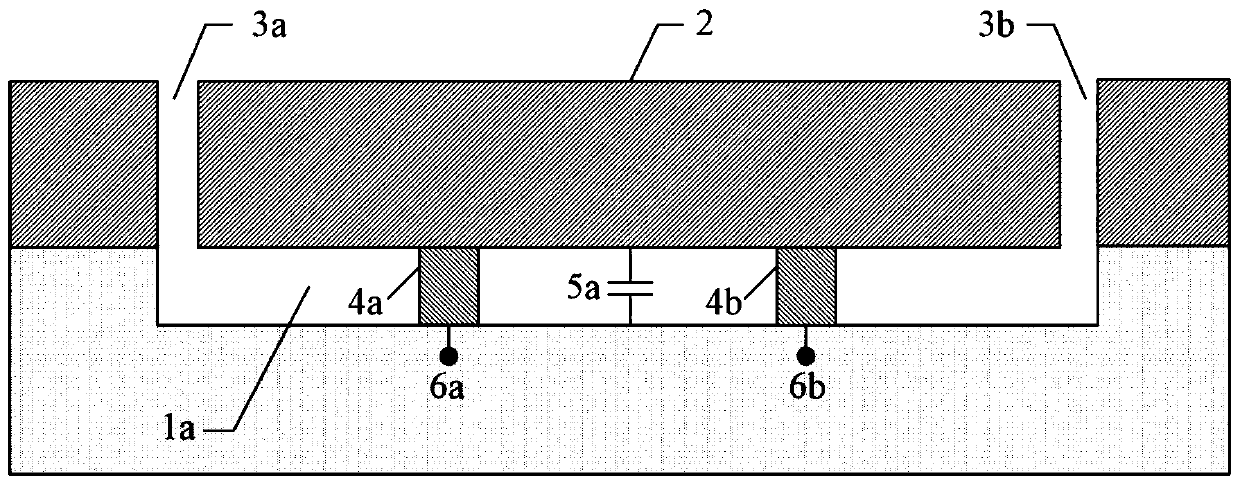

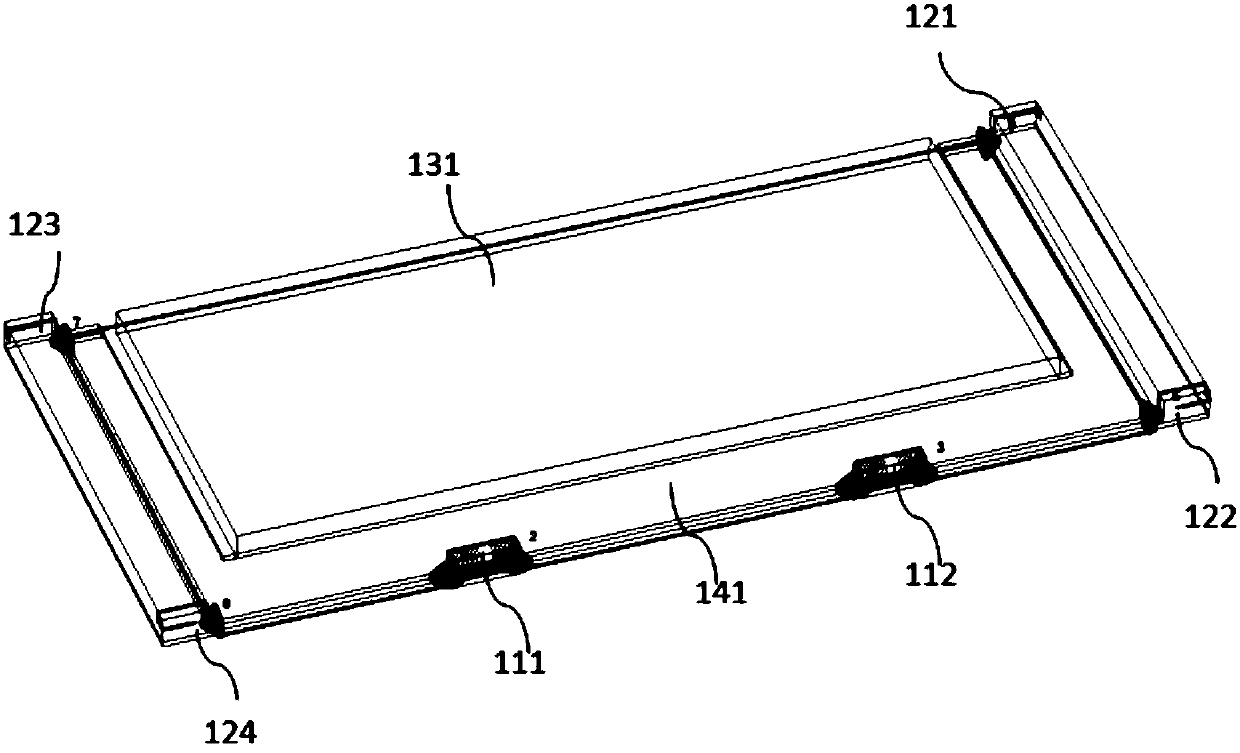

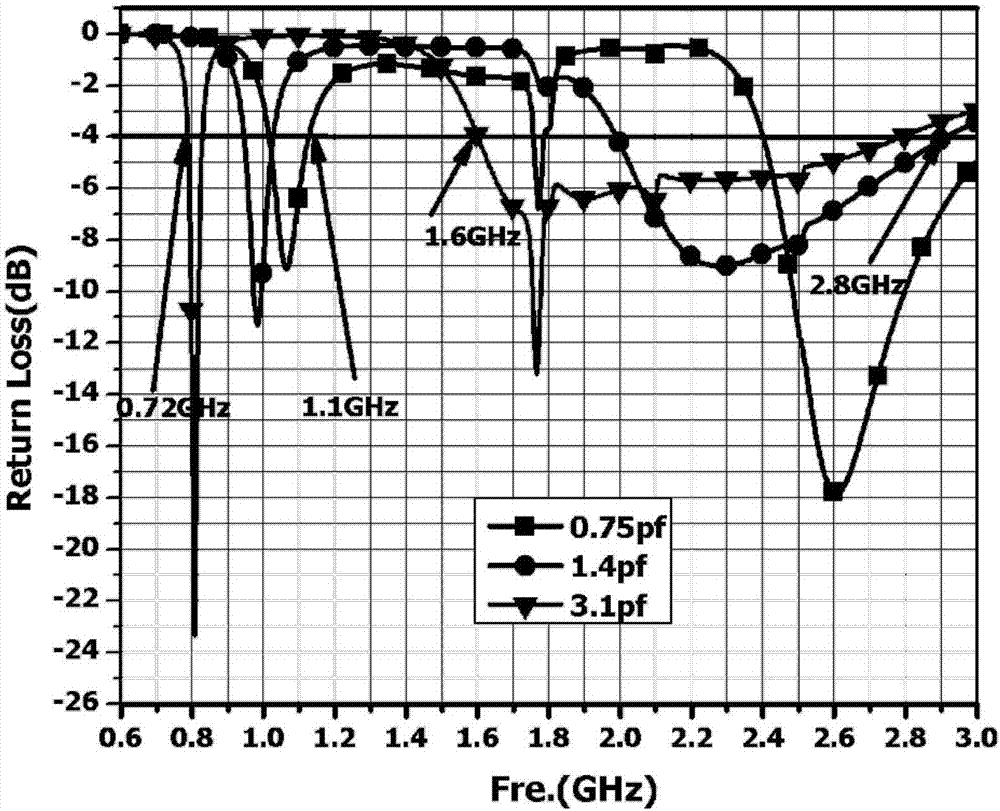

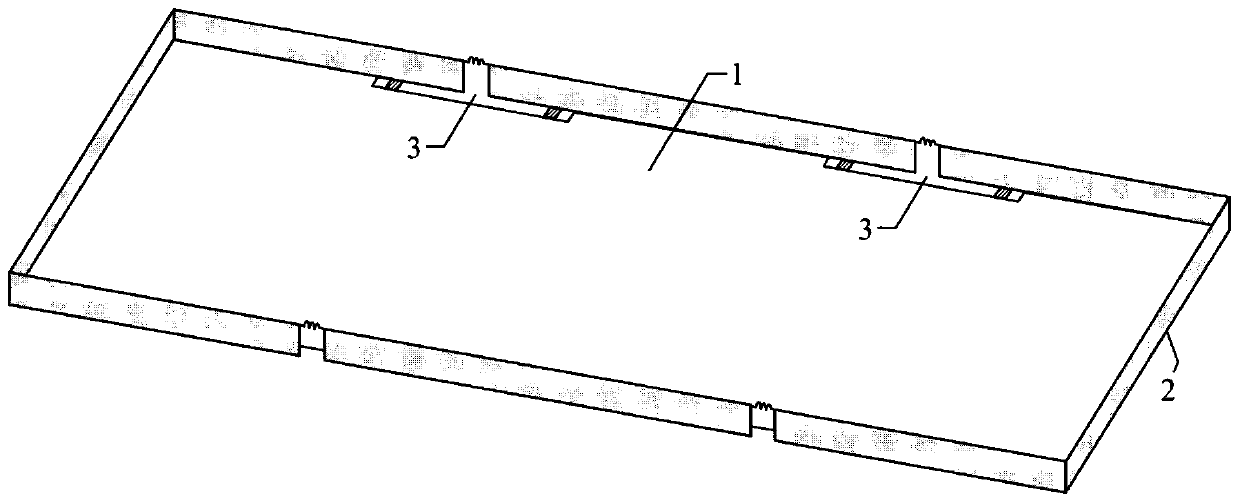

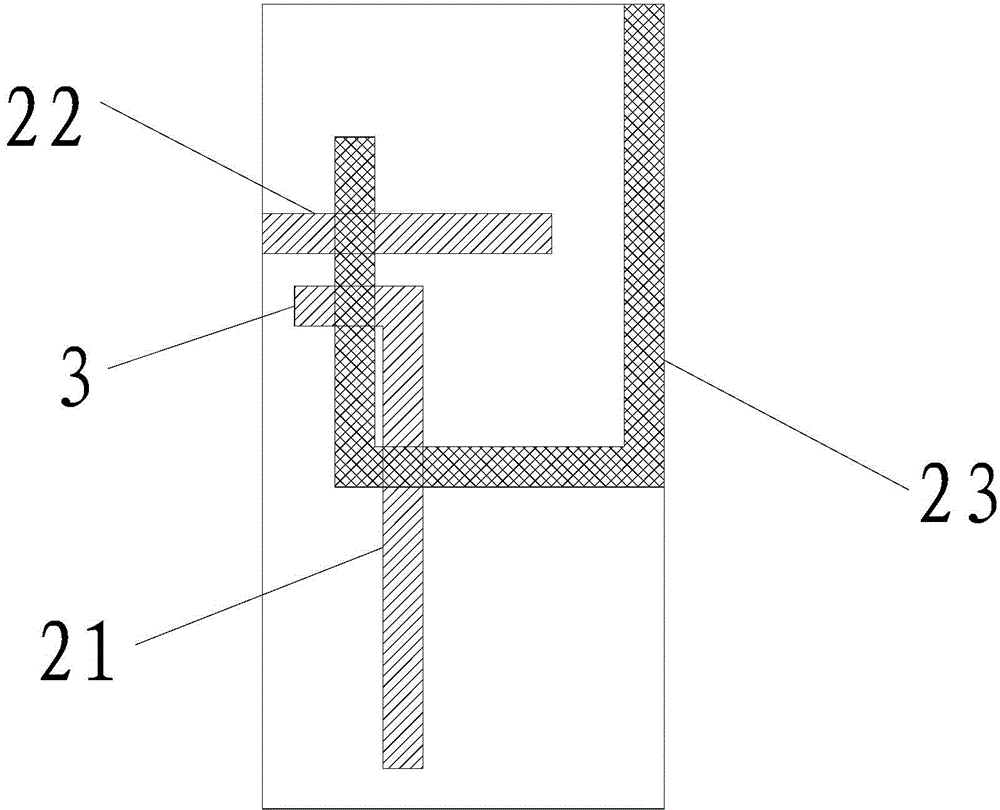

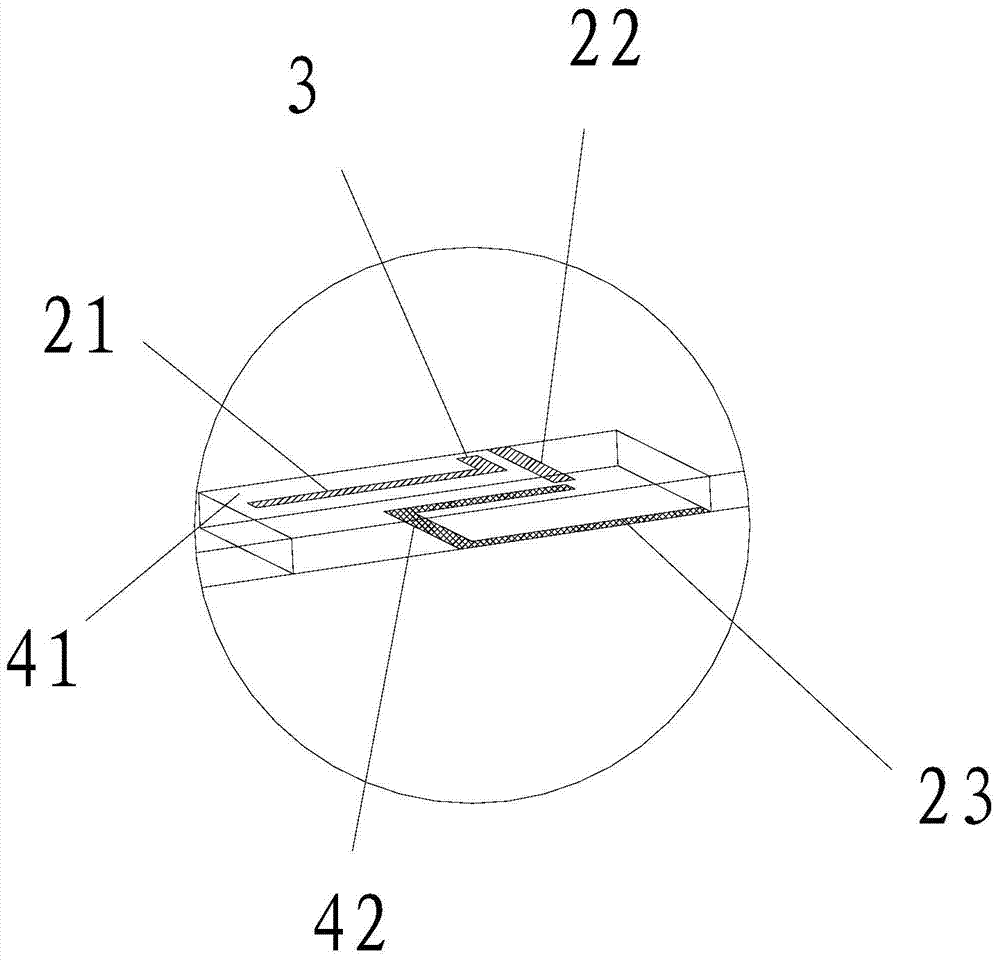

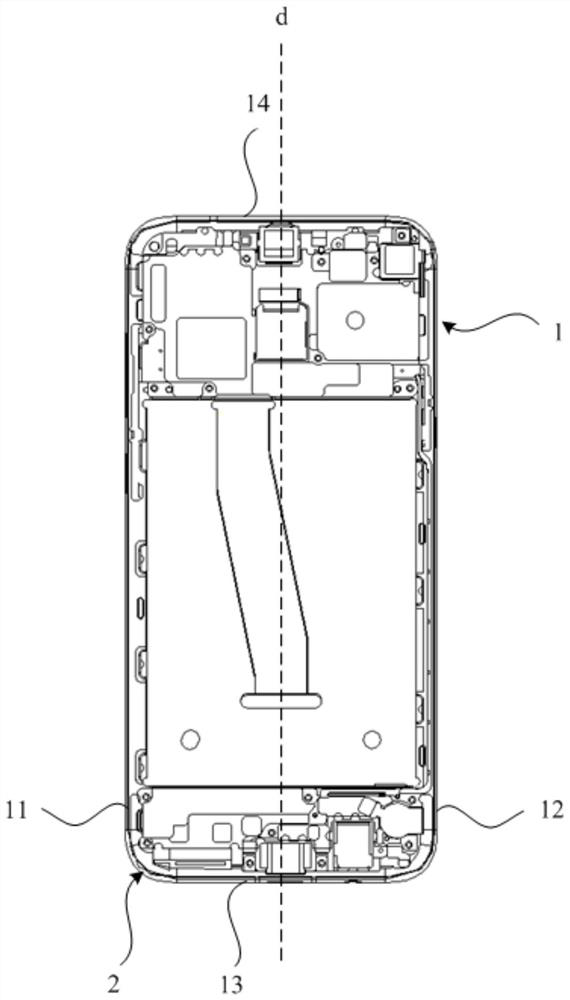

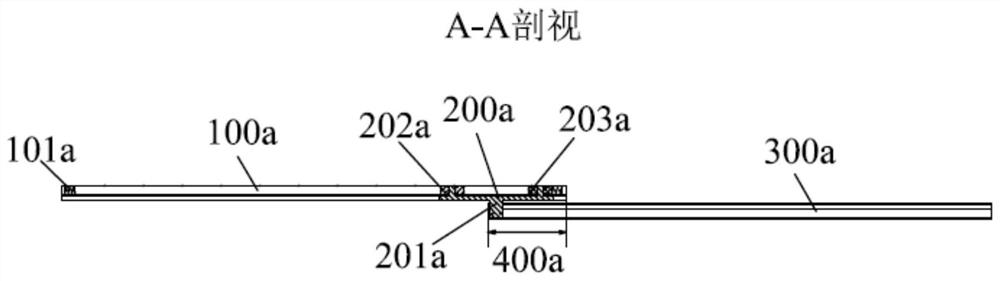

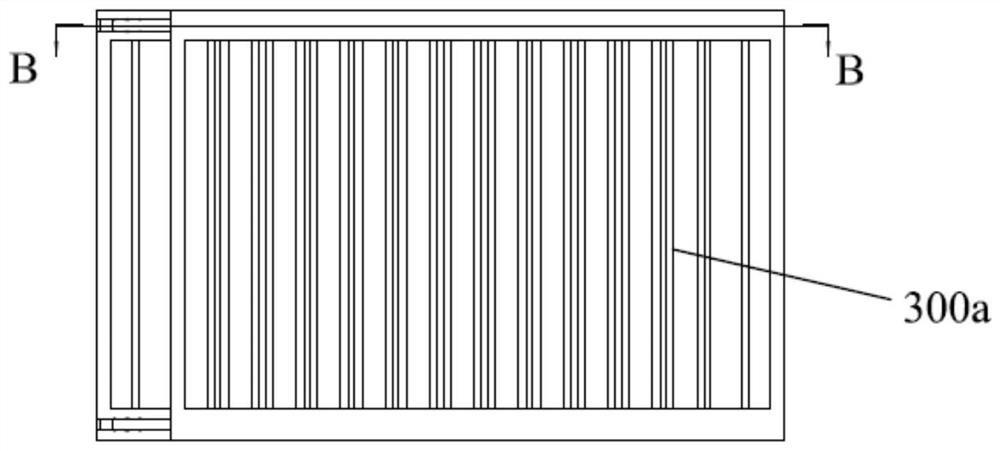

Capacitively-decoupled broadband 5G MIMO mobile phone antenna

InactiveCN110137681AImprove efficiencySmall sizeParticular array feeding systemsAntenna supports/mountingsBroadbandCapacitance

A capacitively-decoupled broadband 5G MIMO mobile phone antenna comprises a metal floor, a metal frame and one or more sets of integrated dual-antenna assemblies. The metal floor is provided with oneor more floor slots at the edge, and the integrated dual-antenna assemblies are installed in the floor slots in a one-to-one correspondence manner. The metal frame is a closed connection structure with an even number of frame slots, and each set of integrated dual-antenna assembly corresponds to two frame slots. Each integrated dual-antenna assembly contains a first feeding branch, a second feeding branch and a decoupling assembly, and the decoupling assembly can be a lumped capacitor or a distributed capacitor. The 5G MIMO antenna designed by the capacitive decoupling technology has the advantages of broad band, high efficiency, small size, low headspace, compatibility with a metal frame and dual-antenna integration, and is suitable for various small mobile terminals represented by mobilephones.

Owner:TSINGHUA UNIV

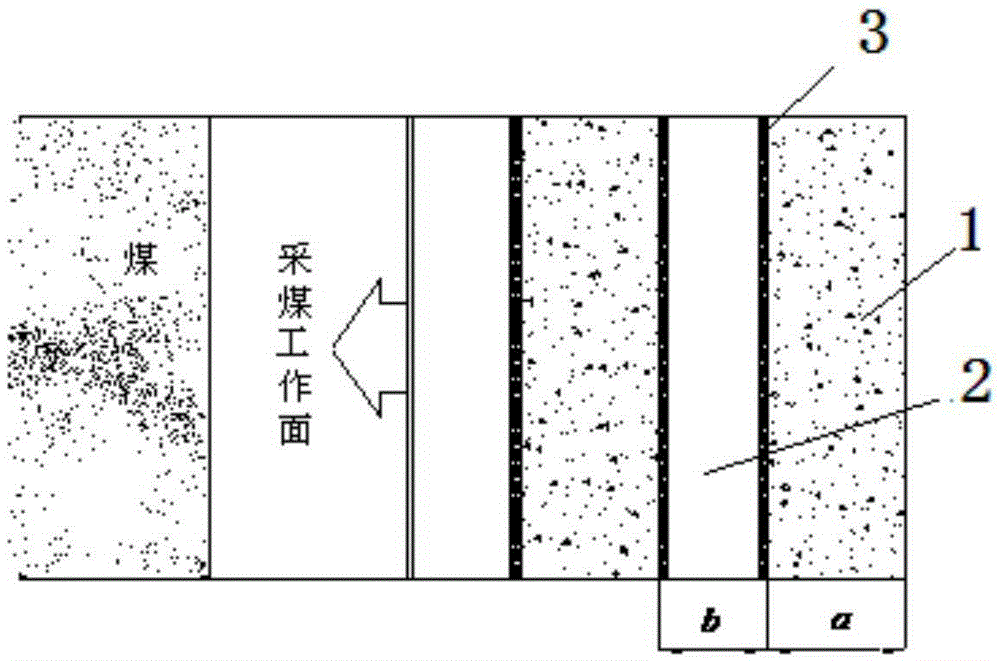

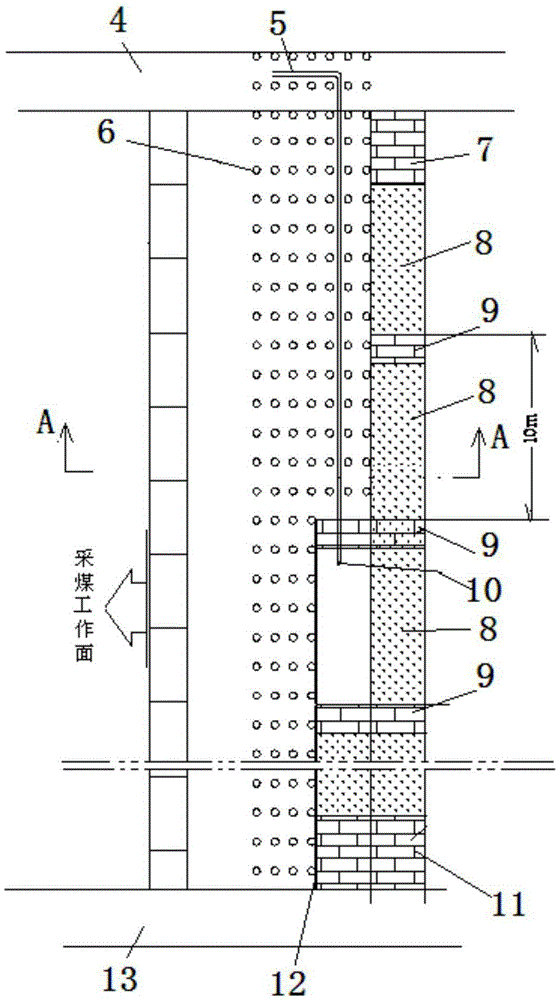

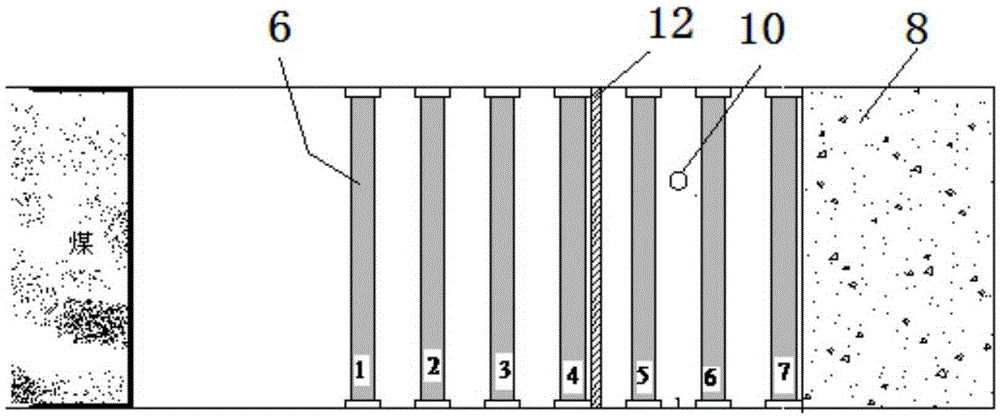

Strip filling method of conventional mining face goaf pumping cementing materials

InactiveCN105332733AThere will be no collapse accidentsSinking is stable and controllableMaterial fill-upBody positionsSlurry

The invention discloses a strip filling method of conventional mining face goaf pumping cementing materials. The method includes: designing strip filling bodies in a goaf along an advancing direction, constructing a first small filling strip at determined strip filling body positions according to a principle that the intervals among rear four rows of support columns are filled when a conventional mining face advances to the seventh row of support columns, sequentially completing small filling sections from bottom to top along the inclination direction of the mining face in the same manner, and building an upper-end gangue wall on the lying side of an upper roadway so as to prevent gangue slurry from overflowing and form the first small filling strip; constructing a second small filling strip and the like according to the construction step of the first small filling strip until the design width of the strip filling bodies is reached. The method has the advantages that during the filling process and after the strip filling is completed, the method is good in roadway safety, good in strip forming quality, high in construction efficiency, low in filling cost, and the like.

Owner:SHANDONG UNIV OF SCI & TECH

MIMO antenna system of terminal

InactiveCN107623176AReduce complexitySimple designSimultaneous aerial operationsRadiating elements structural formsMultiplexingMimo antenna

The invention provides a MIMO antenna system of a terminal. The system is composed of eight antennas that are divided into two groups, three groups or four groups of compact high-isolation antenna units; each compact high-isolation antenna unit group includes two antennas. When two groups of compact high-isolation antenna units are arranged, the two groups of compact high-isolation antenna units are arranged at the edge of a main board of the terminal at an interval; and the rest of four independent antennas are arranged at intervals by being far away from the main board in the terminal or inan antenna synchronization multiplexing manner based on the fixedly setting function inside the terminal. According to the MIMO antenna system, the space is saved.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

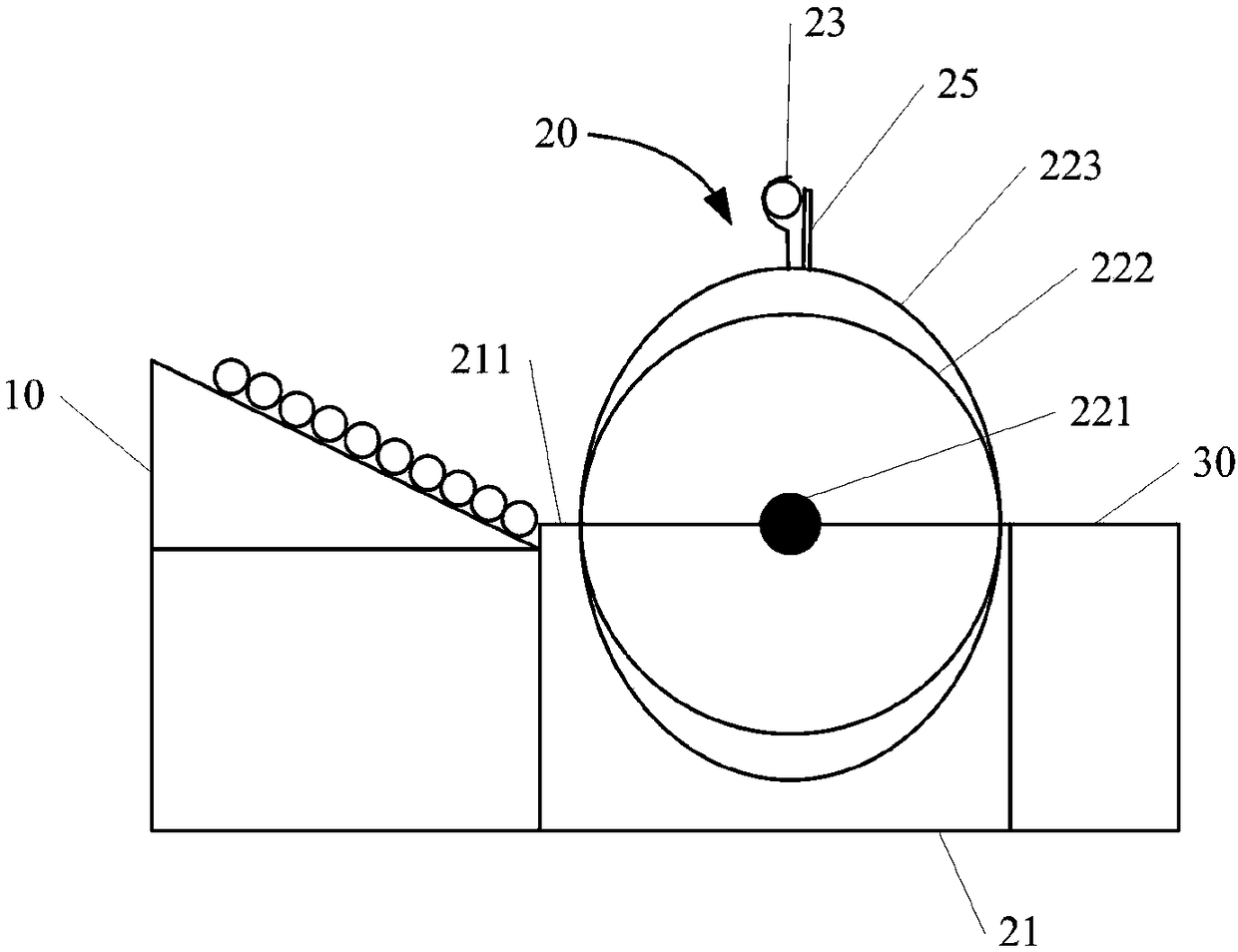

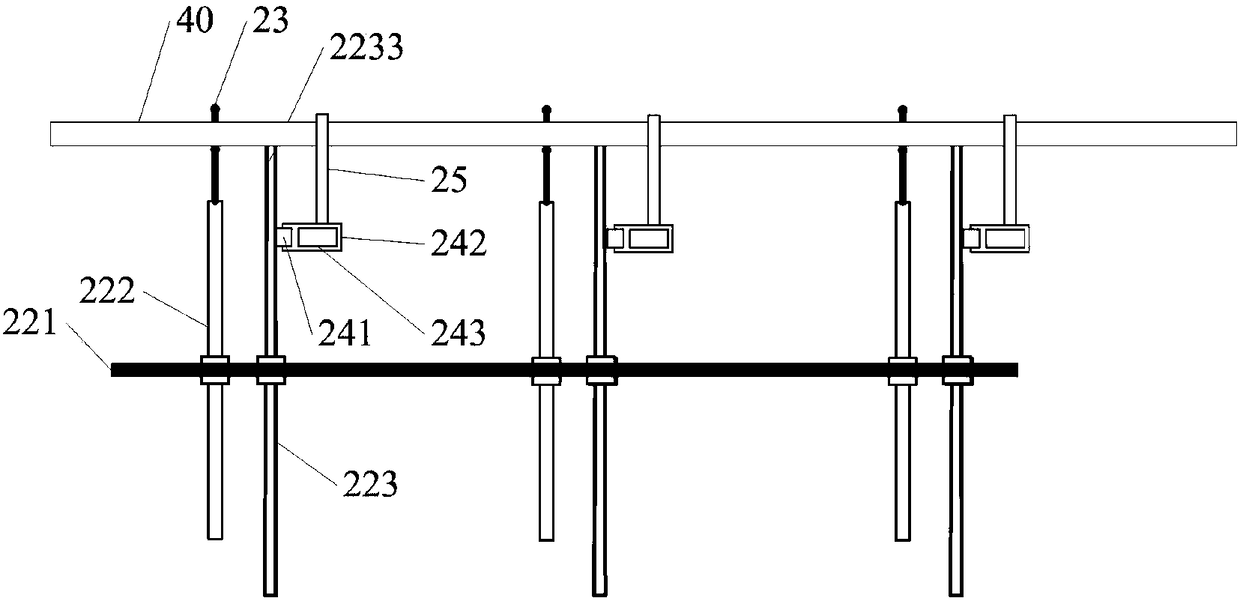

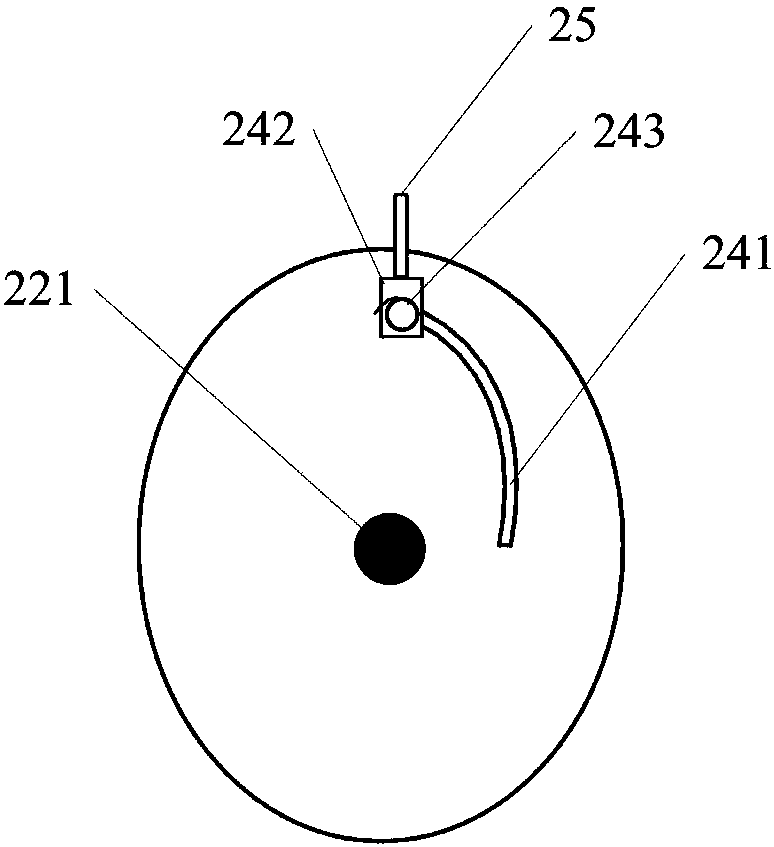

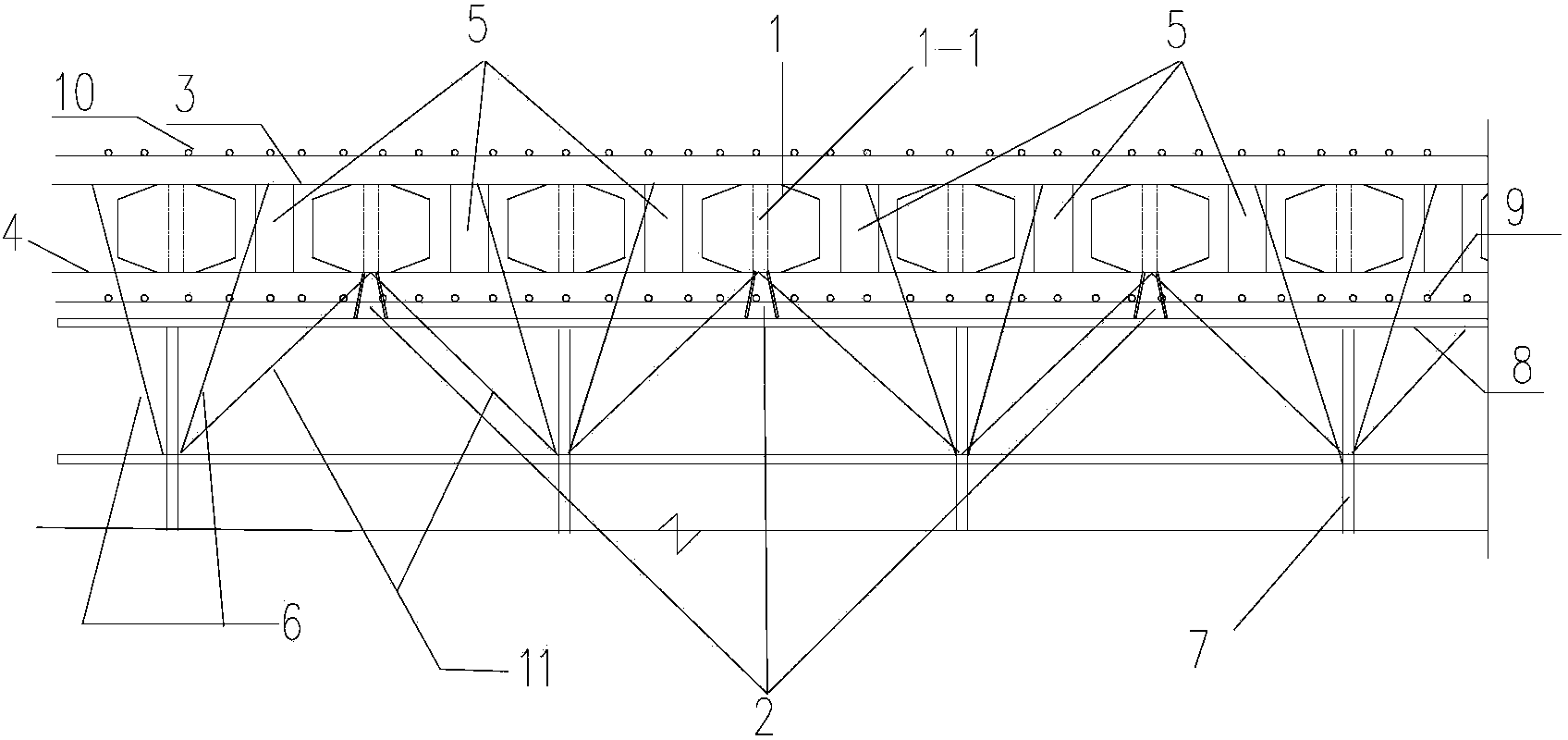

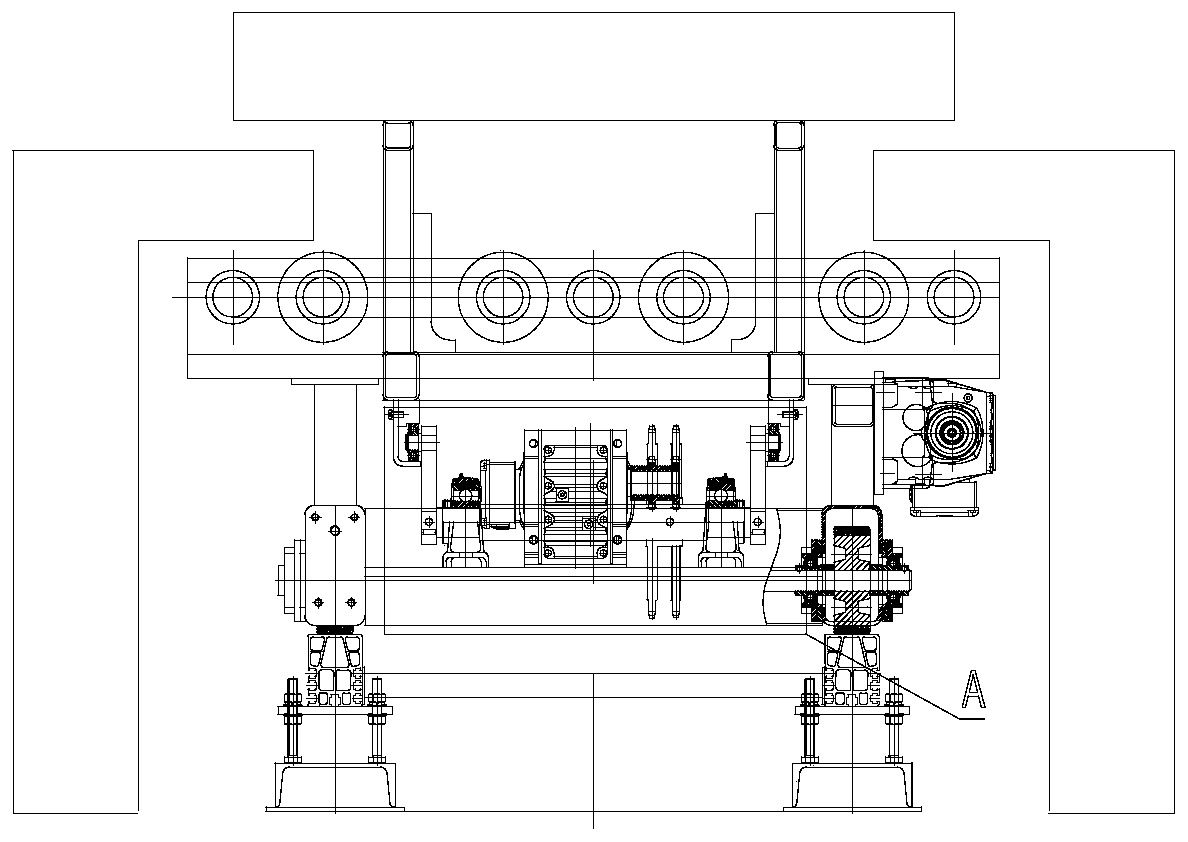

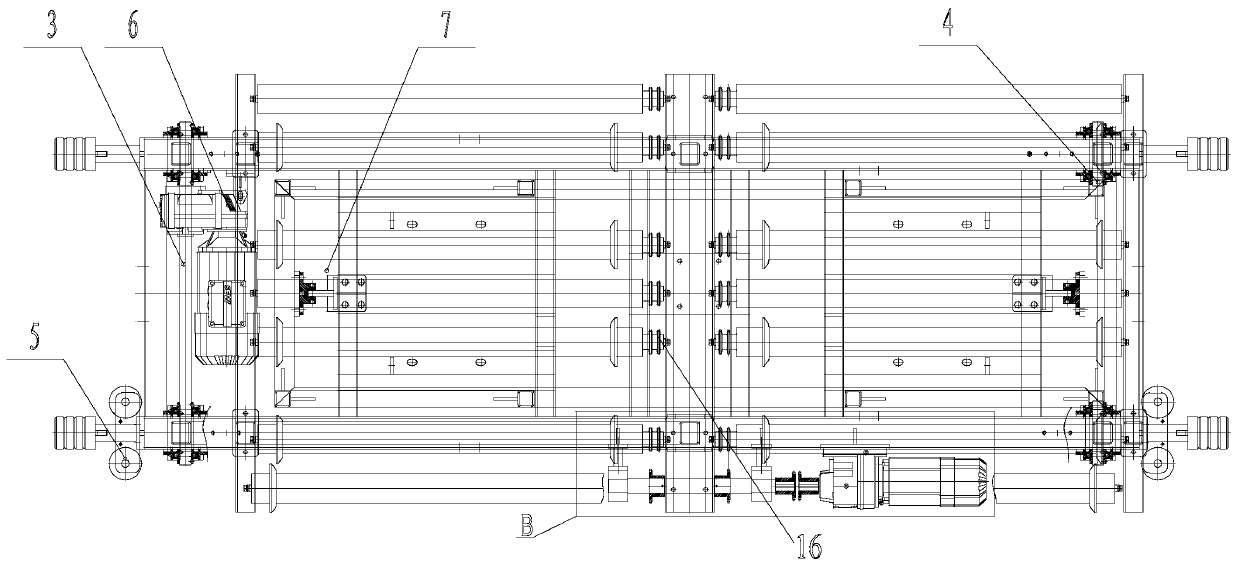

Loading system for full-automatic numerical control laser pipe cutting machine

The invention discloses a loading system for a full-automatic numerical control laser pipe cutting machine. The loading system comprises a pipe frame, a pipe fitting carrying module and a pipe cuttingconveying table arranged in sequence; multiple metal pipes to be cut are arranged on the pipe frame in sequence; and the pipe fitting carrying module is operated to transfer the metal pipes to be cutfrom the pipe frame to arrange on the pipe cutting conveying table end to end in sequence. The loading system for the full-automatic numerical control laser pipe cutting machine can orderly load themetal pipes, arranged in sequence, on the cutting conveying table in sequence by the pipe fitting carrying module for cutting, realizes synchronous implementation of loading and cutting of the metal pipes, improves the cutting efficiency, and saves both time and power.

Owner:JINAN BODOR LASER CO LTD

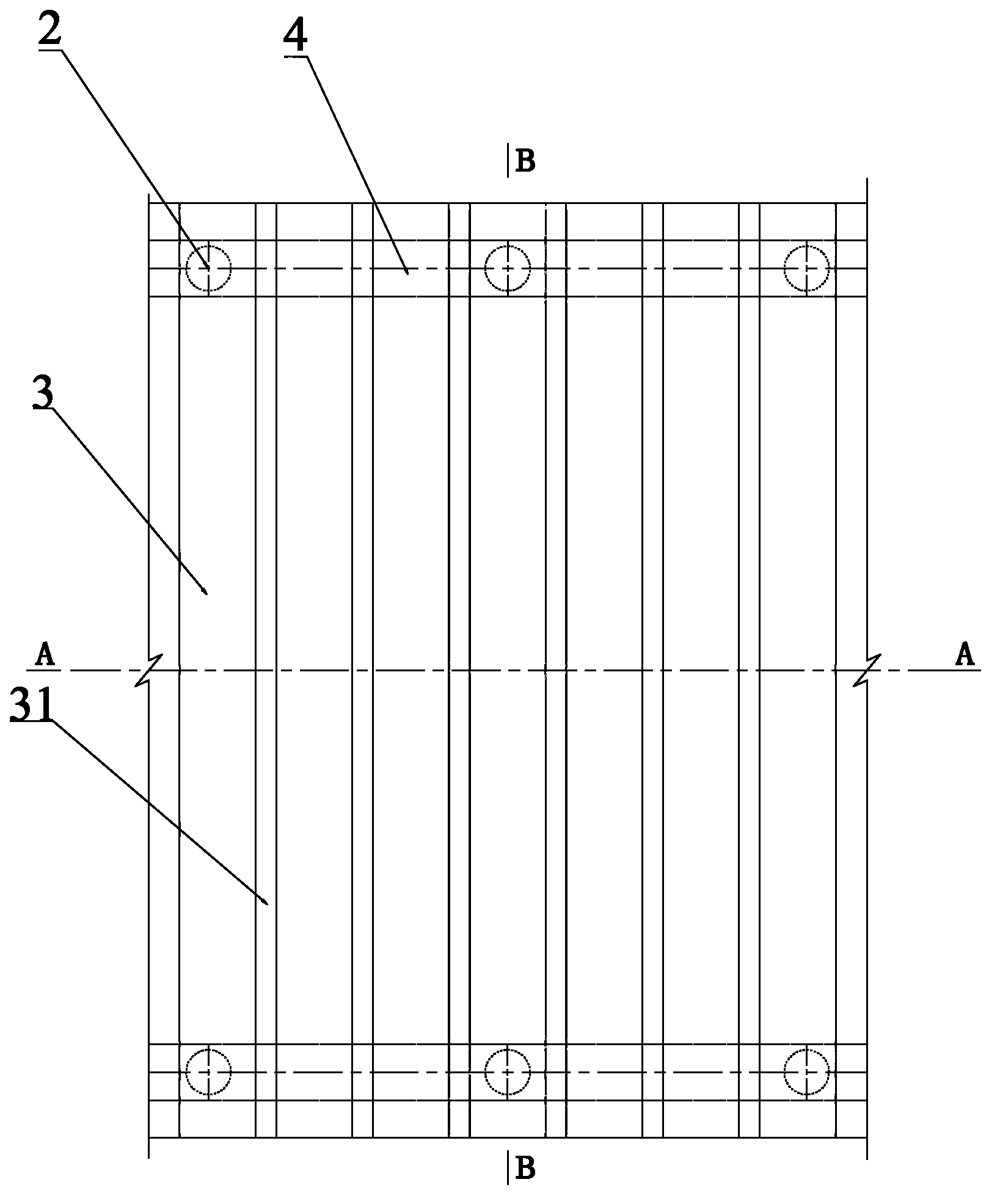

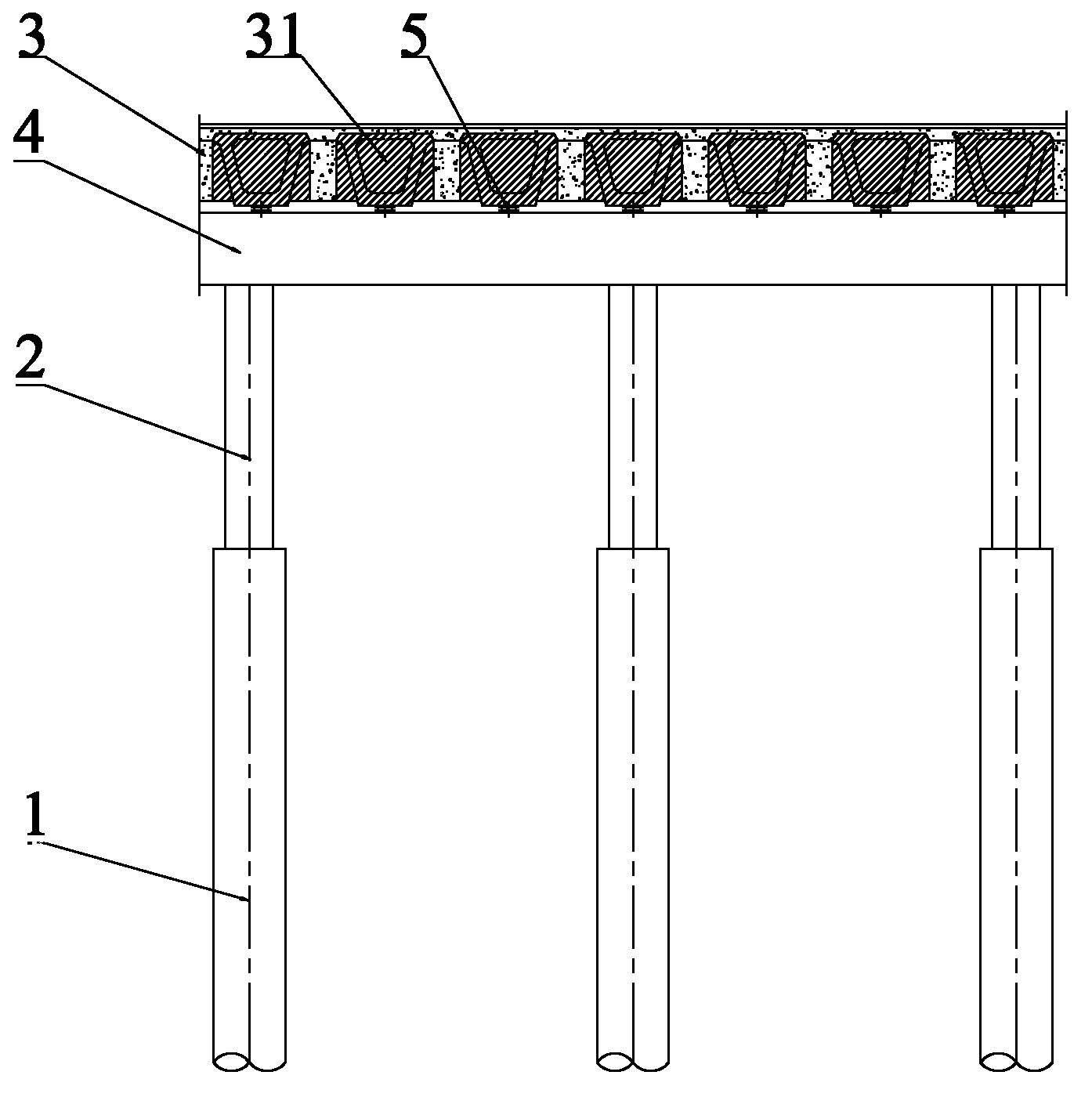

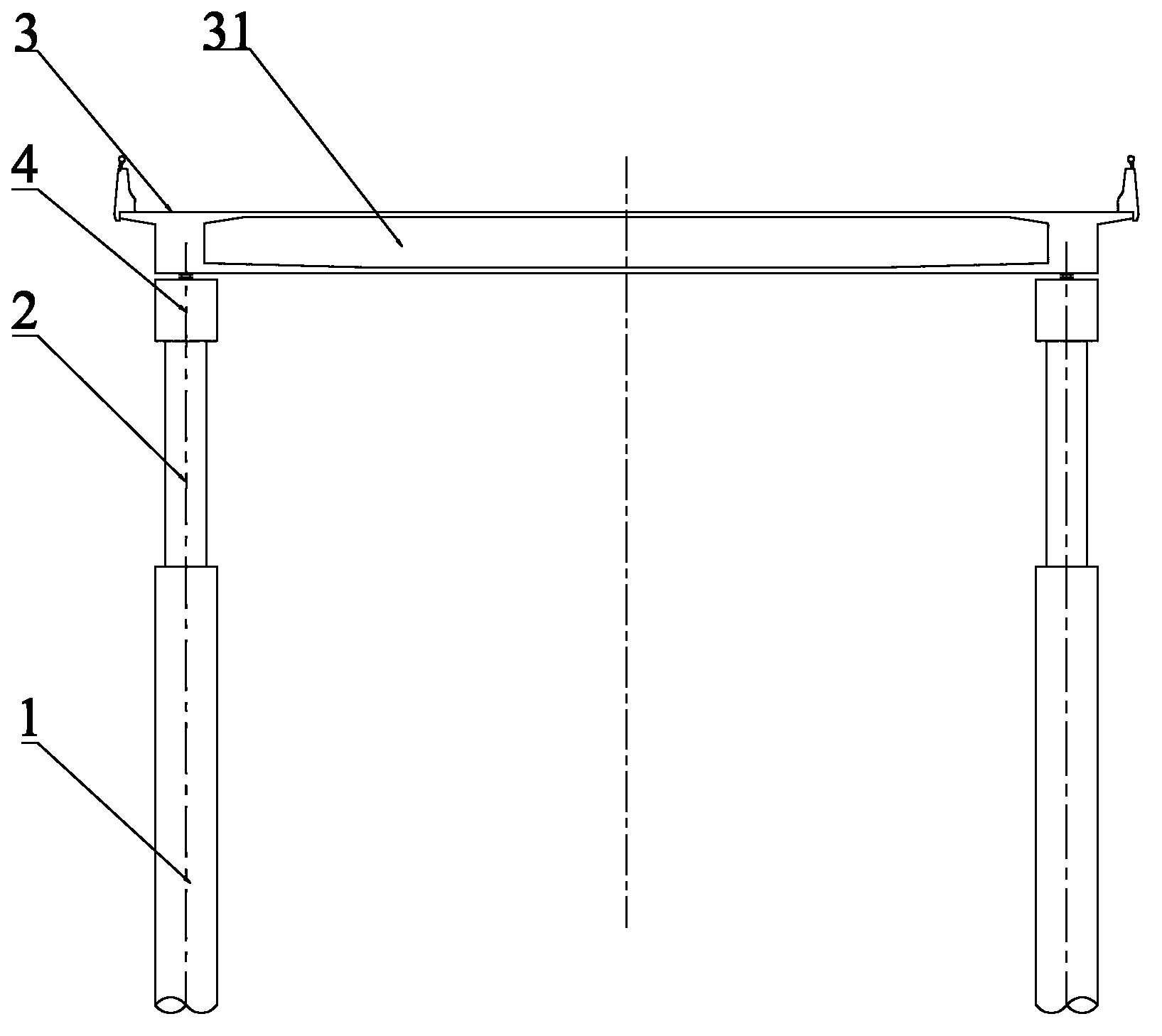

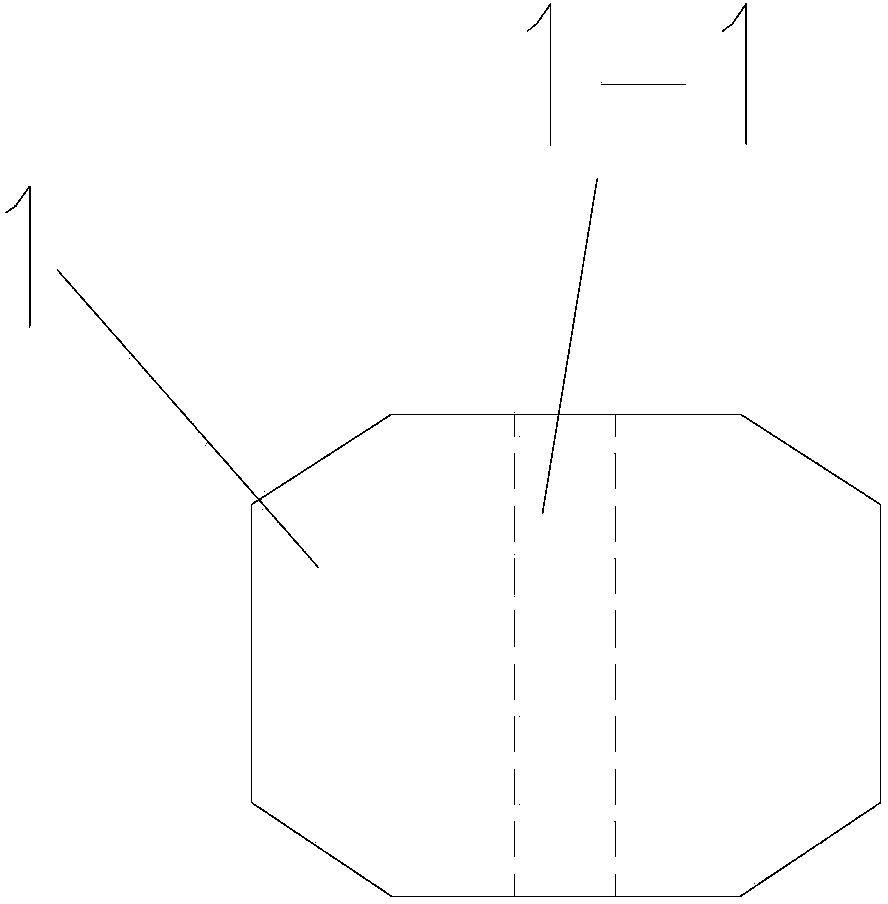

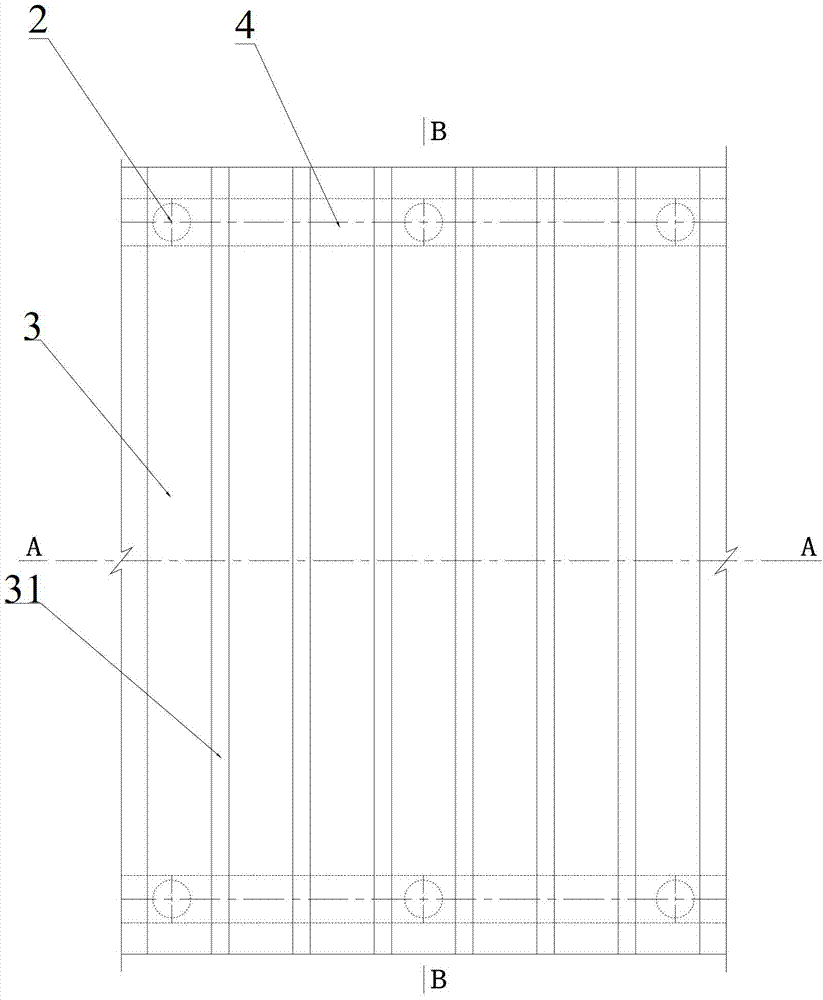

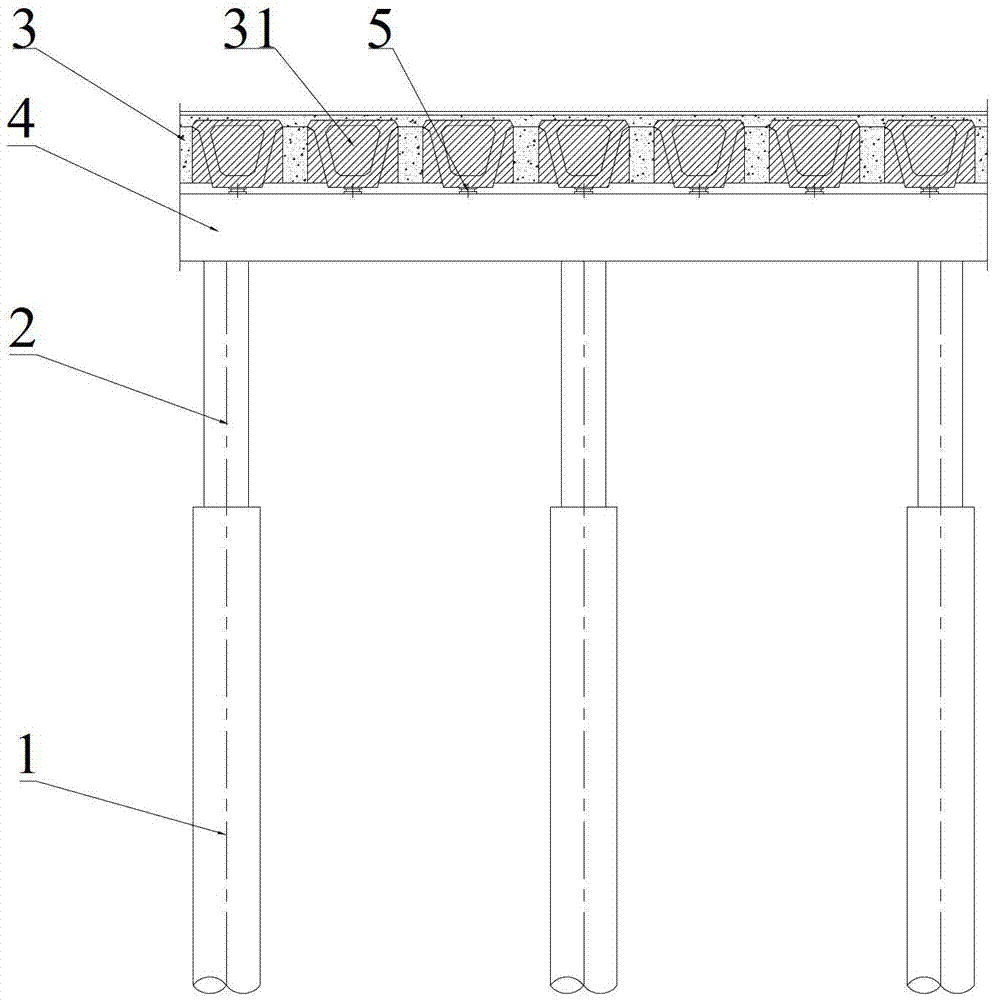

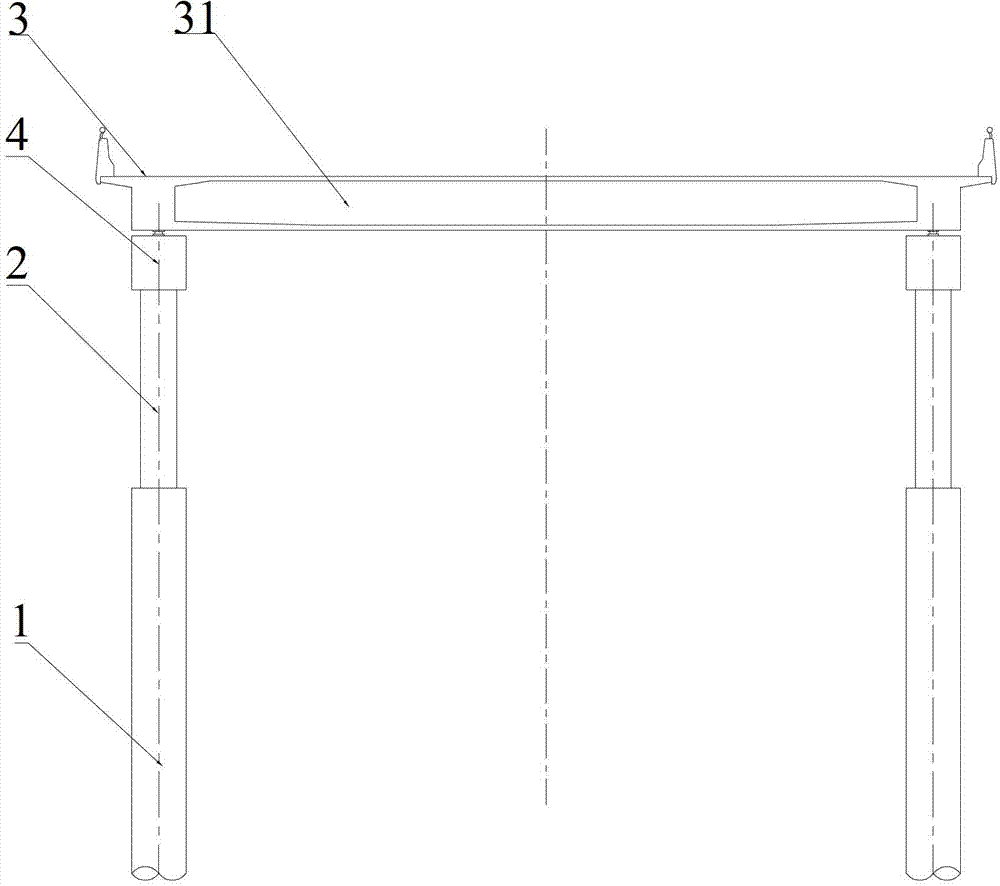

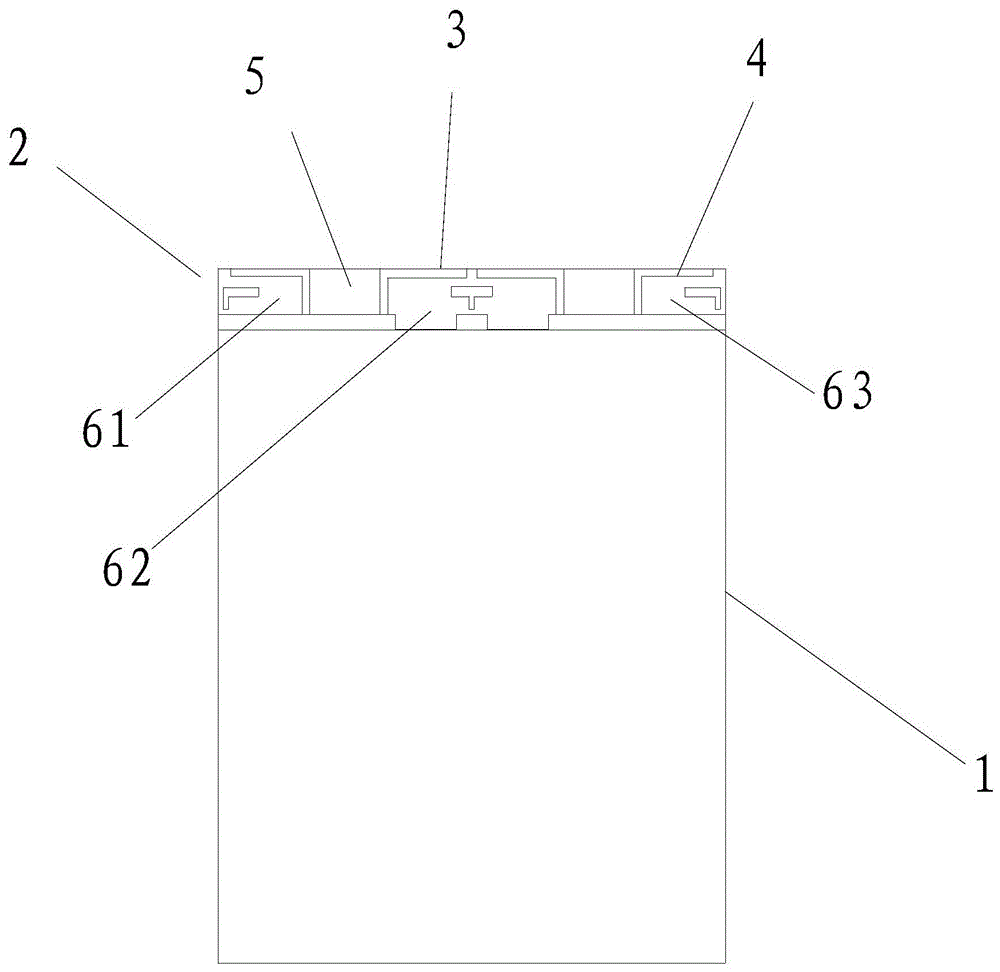

Bridge with transverse bearing system

The invention discloses a bridge with a transverse bearing system. The bridge comprises a plurality of foundation piles, pier columns and a bridge deck, wherein the pier columns are arranged on the foundation piles, the bridge deck is arranged on upper sides of the pier columns, a bent cap body is arranged between the pier columns and the bridge deck in the longitudinal direction of the bridge deck, the bridge deck comprises a plurality of transverse element girders, and the transverse element girders are arranged on the bent cap body in the transverse direction of the bridge deck. The bridge with the transverse bearing system has the advantages that the bent cap body is arranged between the pier columns and the bridge deck in the longitudinal direction of the bridge deck, and is positioned at both sides of the existing obstacle, and the number of pier columns and the span diameter of the bent cap body can be freely adjusted according to the obstacle under the bridge and the weight on the bridge deck, so the clearance under the bridge or the ground is effectively saved; and meanwhile, the transverse element girders are arranged on the bent cap body in the transverse direction of the bridge deck, and the moving loads and the dead weight of the bridge decks can be directly borne by the transverse element girders, so the capability of crossing over the obstacle under the bridge or the ground is higher in comparison with the traditional transverse bent cap which firstly bears the longitudinal load of the bridge deck. The bridge with the transverse bearing system is used for the field of bridges.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Antenna system based on smart phone with all metal back cover

ActiveCN107230823AImprove integrityImprove Radiation PerformanceSimultaneous aerial operationsAntenna supports/mountingsEngineeringMetal backed

The invention discloses an antenna system based on a smart phone with an all metal back cover. The antenna system comprises a metal back cover and an integrated PCB, wherein the upper edge and the lower edge of the metal back cover are each provided with a C-shaped clearance, the upper end of the metal back cover form a C-shaped radiation main body due to a part separated by the clearance, the integrated PCB is provided with a plurality of coupling units coupled with the C-shaped radiation main body, and the clearance is provided with a connecting piece communicating the C-shaped radiation main body with the integrated PCB. Due to the all metal back cover structure, the antenna system has an excellent radiation performance, and the radiation performance of each frequency of the antenna is improved while the metal back cover is more integral.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

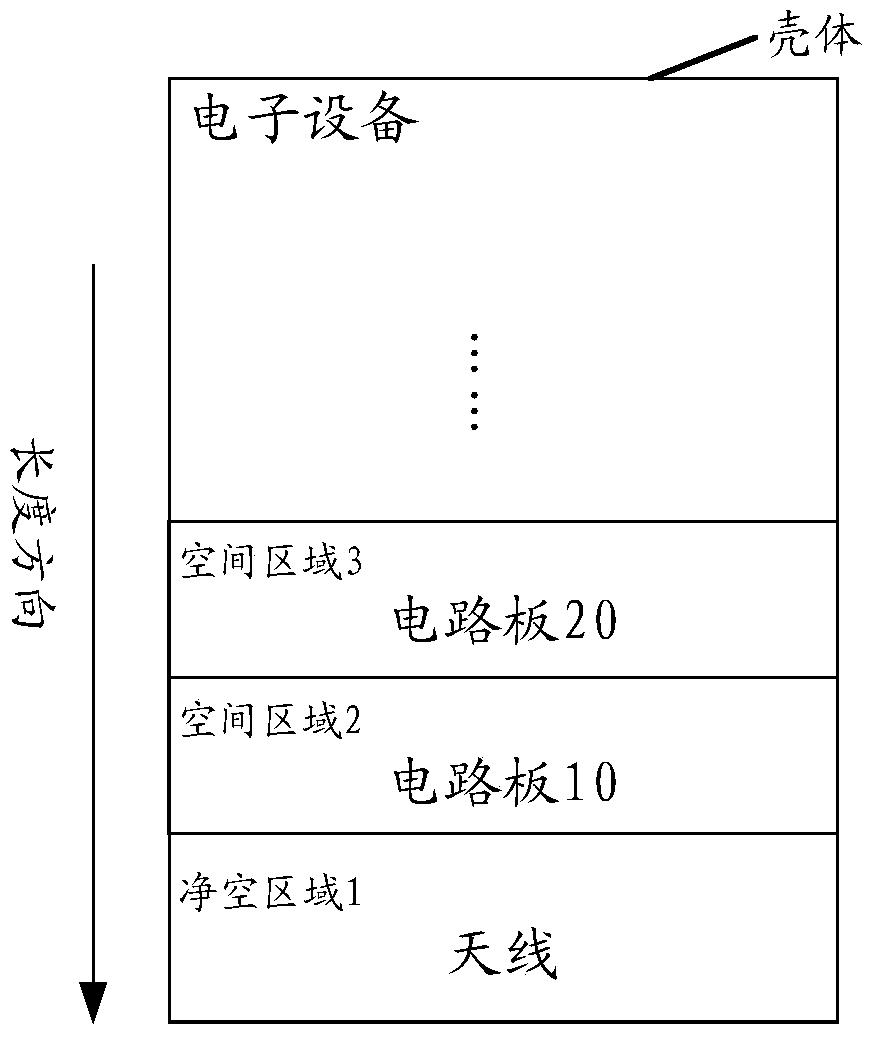

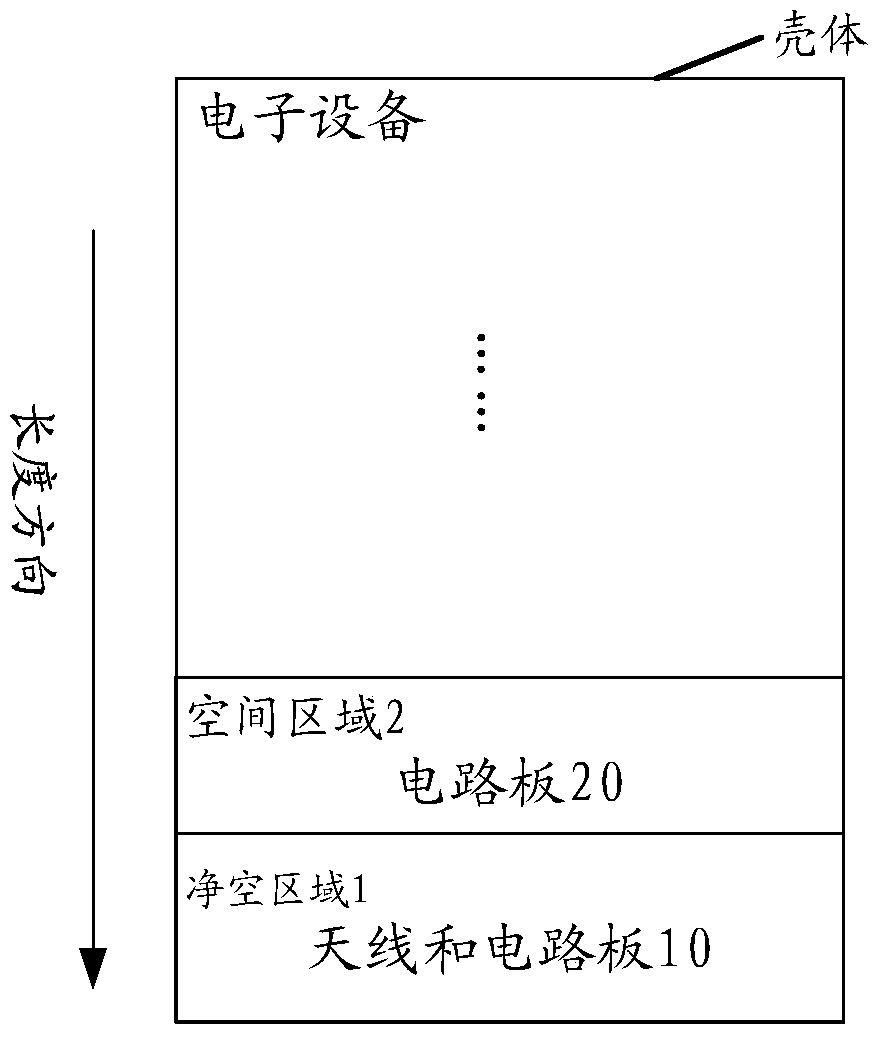

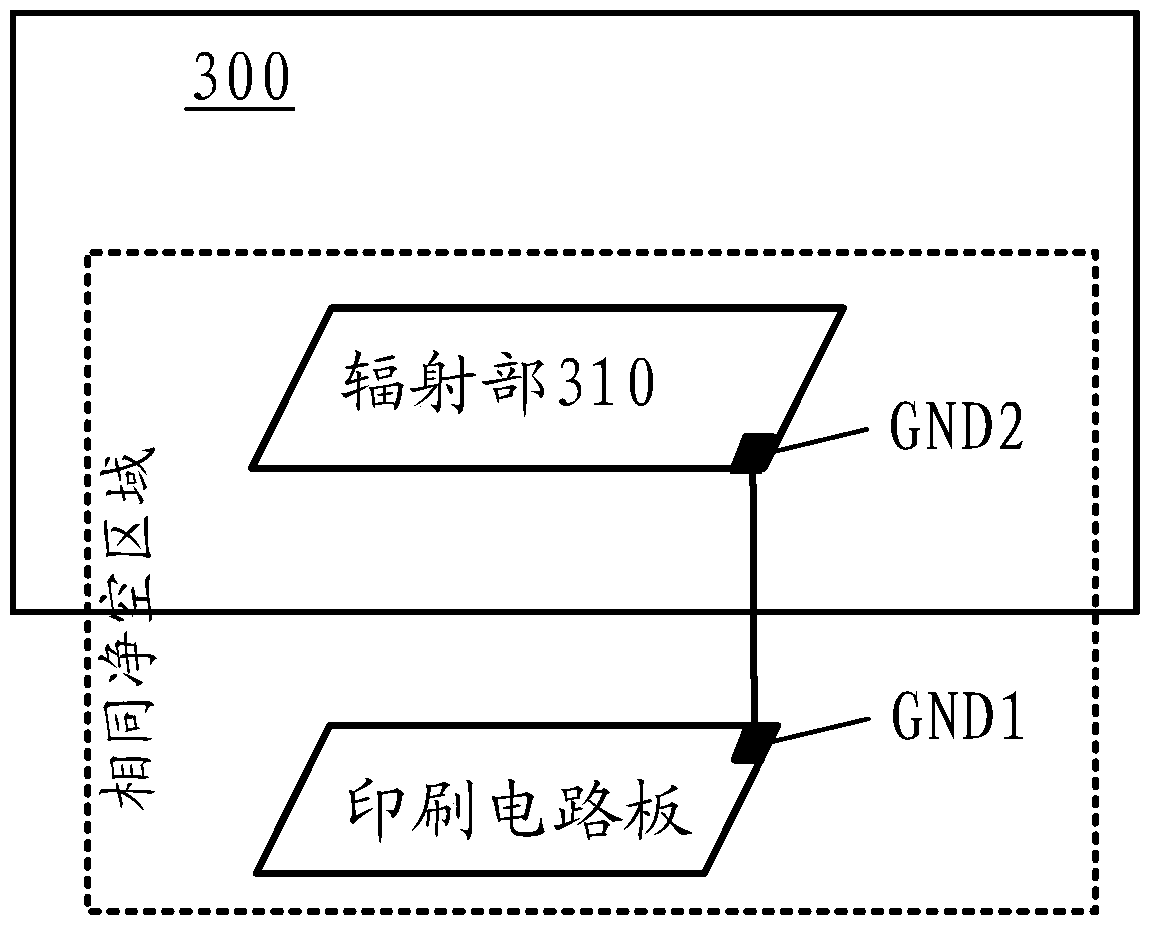

Antenna device and electronic device

The invention provides an antenna device and an electronic device comprising the antenna device. The electronic device comprises a housing; a printed circuit board, which is disposed in the housing, and is used to realize the predetermined function, and is provided with a first grounding end; the antenna device, which comprises a radiation part and a second grounding end. The radiation part is used for the radiation and the receiving of antenna signals, and the radiation part and the printed circuit board are disposed on the same clearance area. The second grounding end is disposed on the radiation part, and is connected with the first grounding end. According to the invention, the ground-sharing of the antenna device and the printed circuit board can be realized, and the antenna device and the printed circuit board are disposed on the same clearance area, and then the clearance occupied by the component parts of the electronic device can be saved, and therefore both of the communication performance of the electronic device and the appearance design requirement can be considered.

Owner:LENOVO (BEIJING) LTD

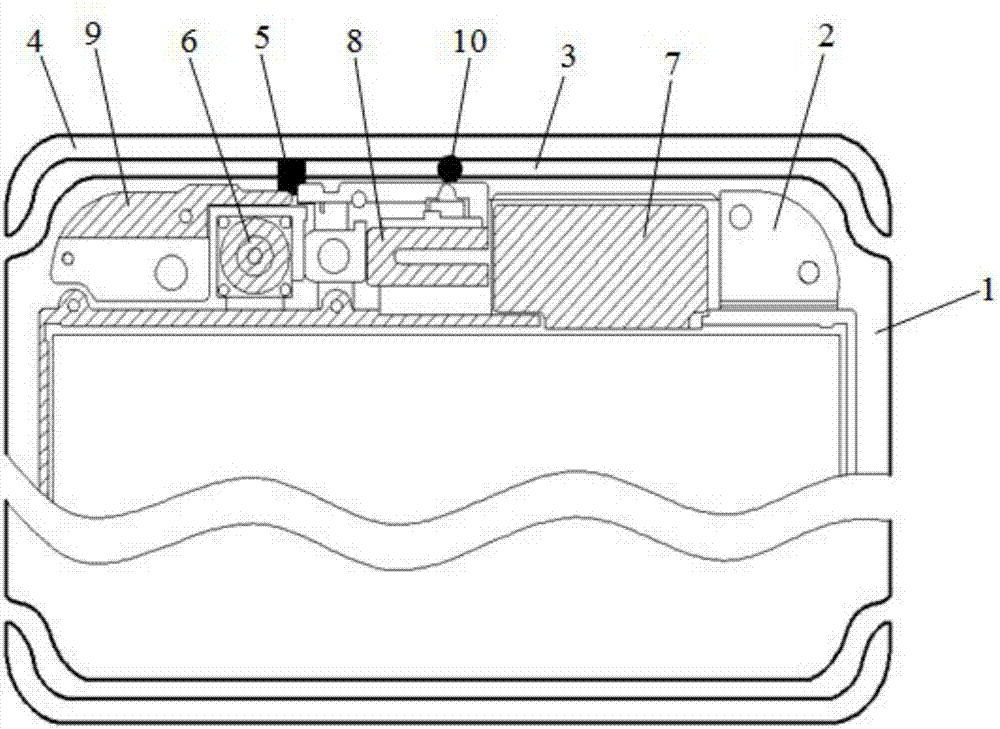

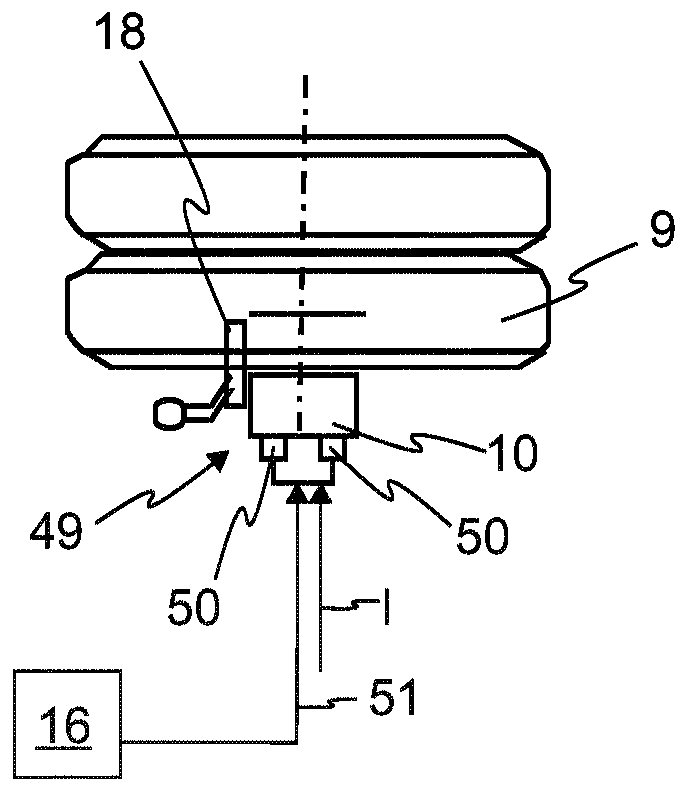

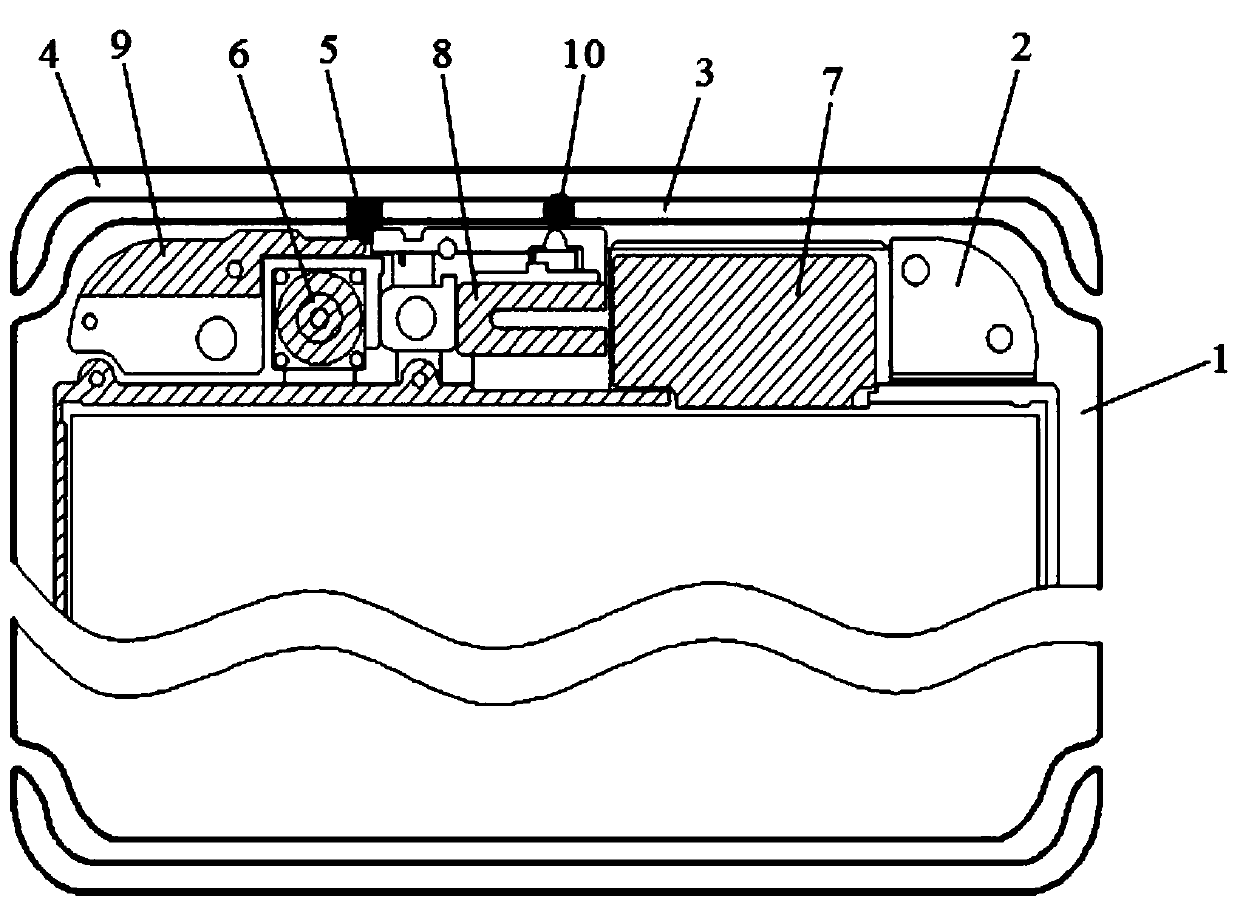

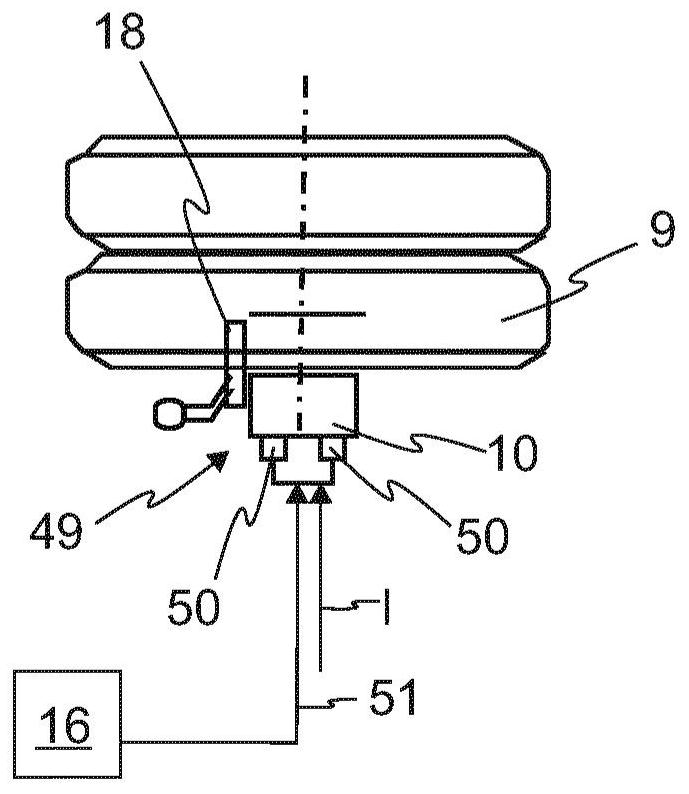

Liquid antenna assembly and electronic equipment thereof

InactiveCN110165371AImprove performanceChange lengthSimultaneous aerial operationsAntenna supports/mountingsLiquid storage tankComputer terminal

The invention relates to the technical field of terminals, and particularly relates to a liquid antenna assembly and electronic equipment thereof. Conductive liquid is used as an antenna radiator so as to reduce clearance required for a mobile phone antenna. A power output source drives a piston to move in a liquid storage tank and the conductive liquid in the liquid storage tank flows into or outof the cavity so as to change the length of the conductive liquid as the antenna radiator in the cavity, adjust the frequency band of the liquid antenna, reduce the extra insertion loss caused by adjusting the frequency band of the antenna by the antenna switch or the tuner and improve the performance of the antenna.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

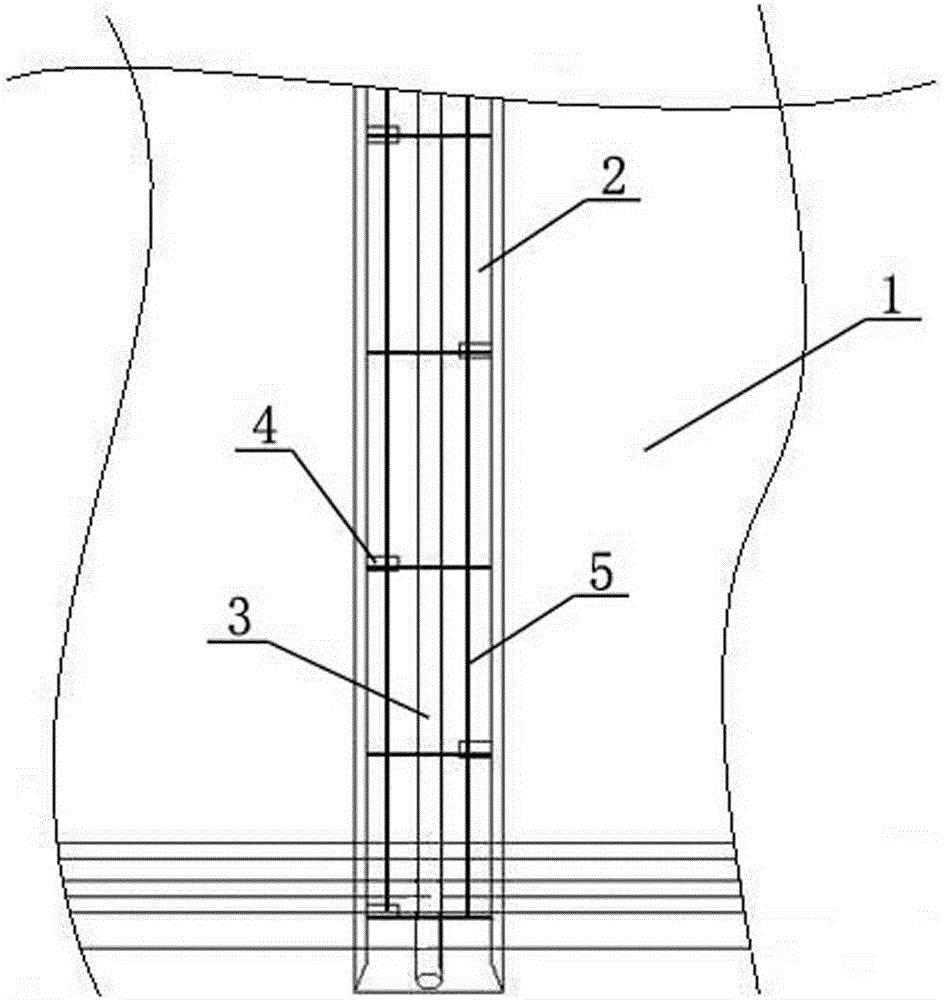

Construction method for repairing water seepage disease of tunnel lining

ActiveCN103437779BSolve the problem that the lining trolley cannot be used for constructionGuaranteed cohesion fixation effectUnderground chambersDrainageFilling materialsEngineering

The invention discloses a construction method for renovating tunnel lining water seeping damage. The method solves the problem of sealing and blocking quality control of a groove passage and the connection with the lining at two sides in the traditional tunnel lining water seeping damage control process. According to the method, firstly, a trapezoidal groove passage in the annular direction of the tunnel is formed in a water seeping position on the tunnel lining, a guide and discharge pipeline and a reinforcing mesh are arranged in the trapezoidal groove passage, expansion screw bolts used for fixing the reinforcing mesh are arranged on the two side walls of the trapezoidal groove passage, a plurality of lining plates are arranged, sealed and covered on the groove passage, in addition, the concrete is respectively filled into the groove passage in a sequence of the side wall, the arch waist and the arch top, and is compactly vibrated and beaten, and the lining template is removed after the concrete intensity meets the requirements. The method adopting the reinforcing mesh and the lining template for cooperated fixation is adopted, the connection between the filling materials in the groove passage and the lining at the two sides is optimized, the firmness of the filling materials is enhanced, and the falling of the filling materials is effectively prevented. The construction method has the advantage that under the condition of meeting the construction safety, the operation safety of the existing railway is also ensured.

Owner:山西天昇测绘检测工程有限公司

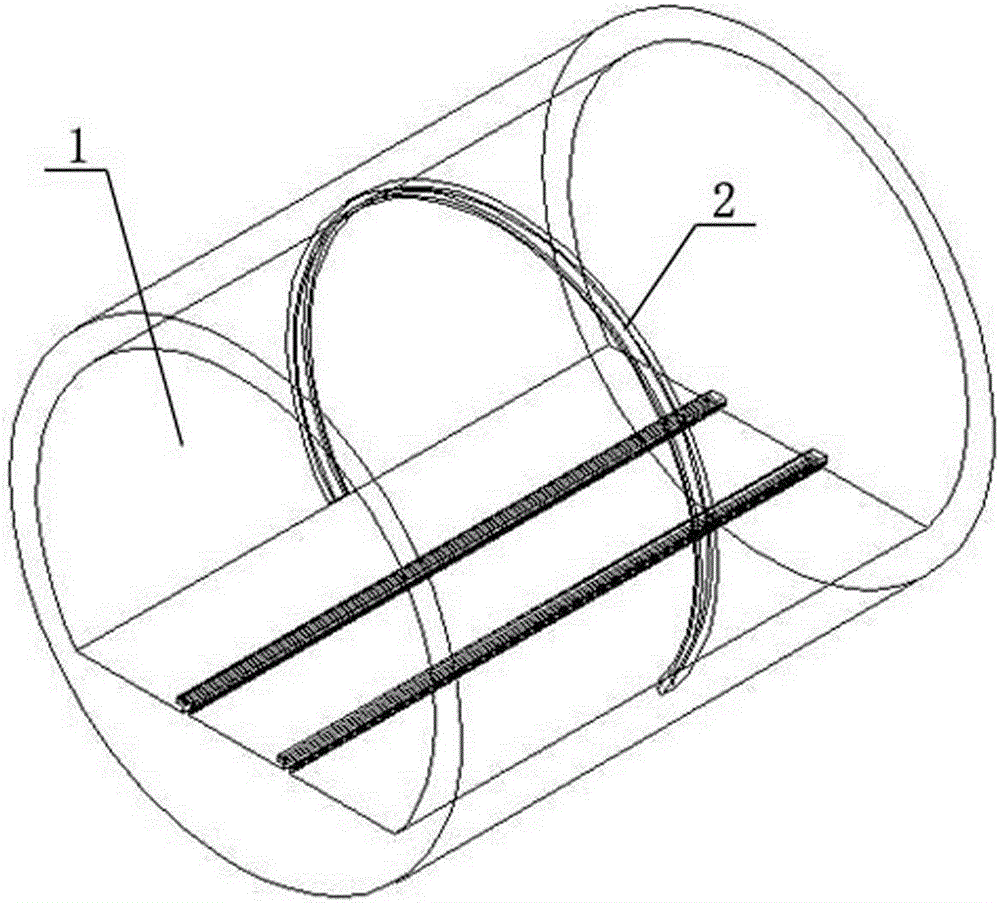

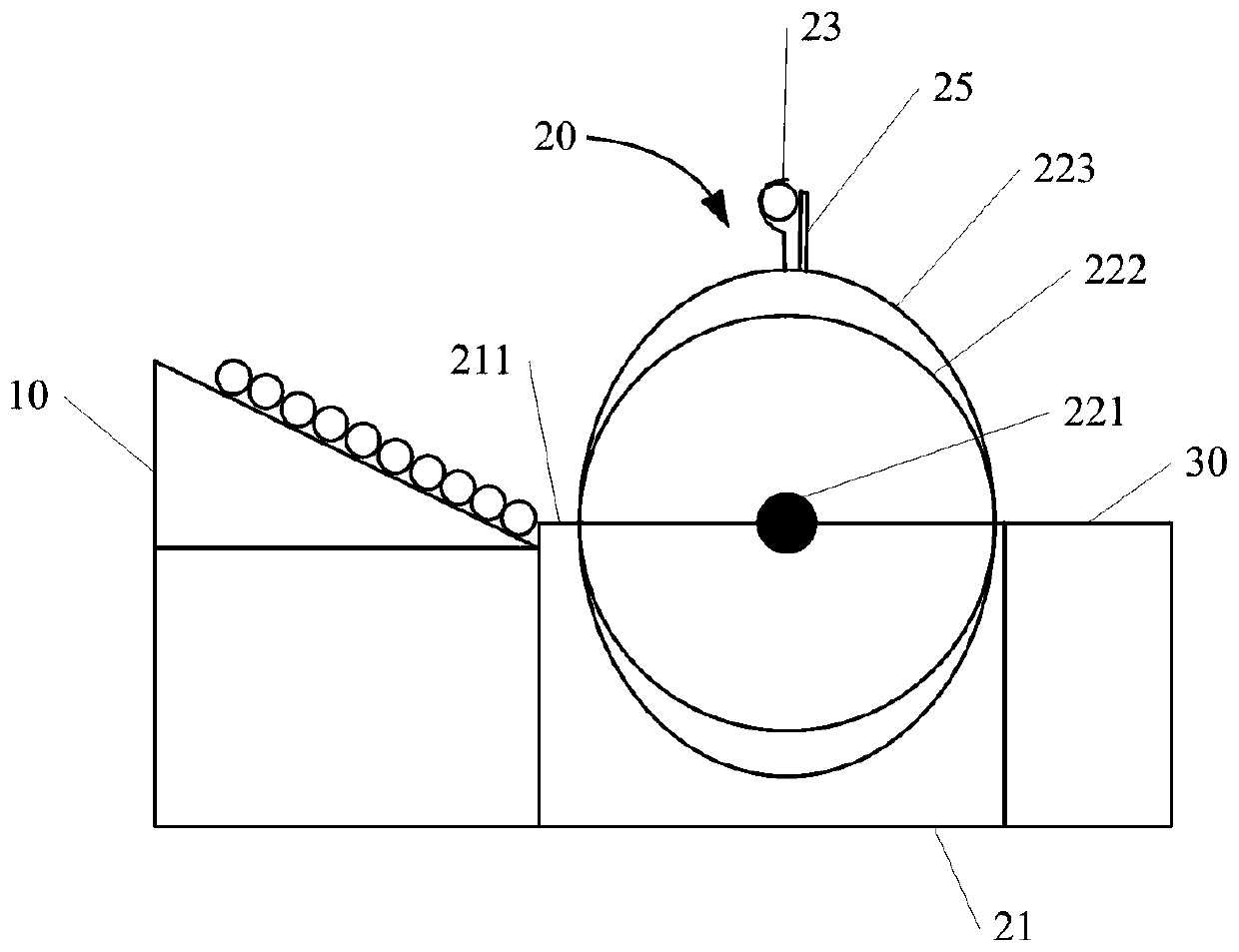

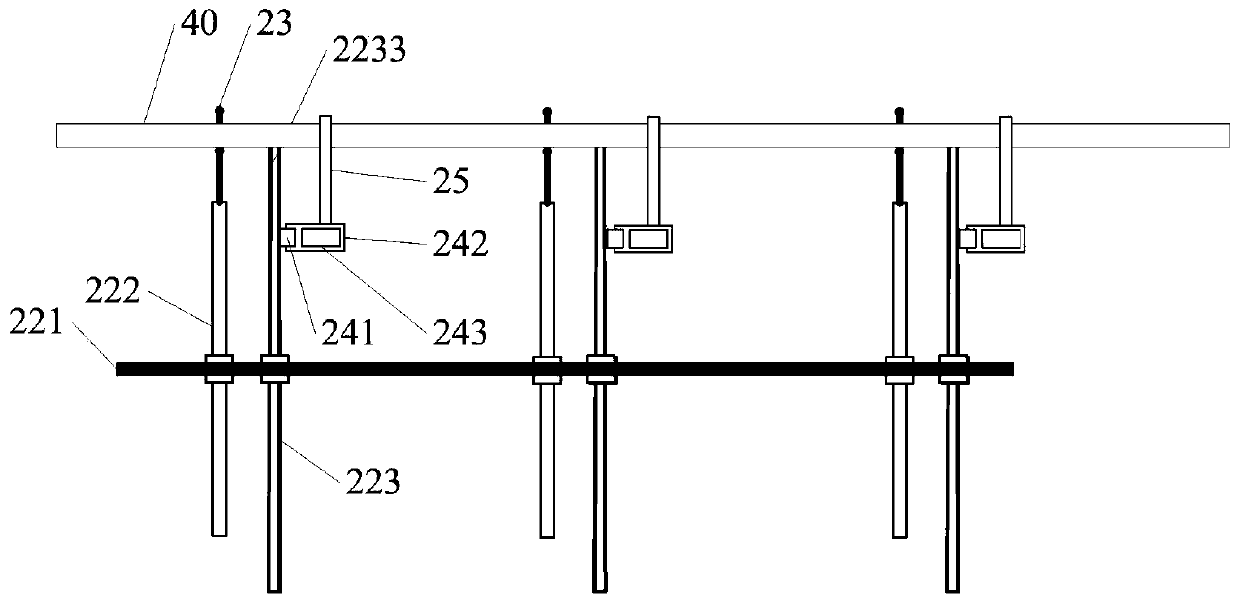

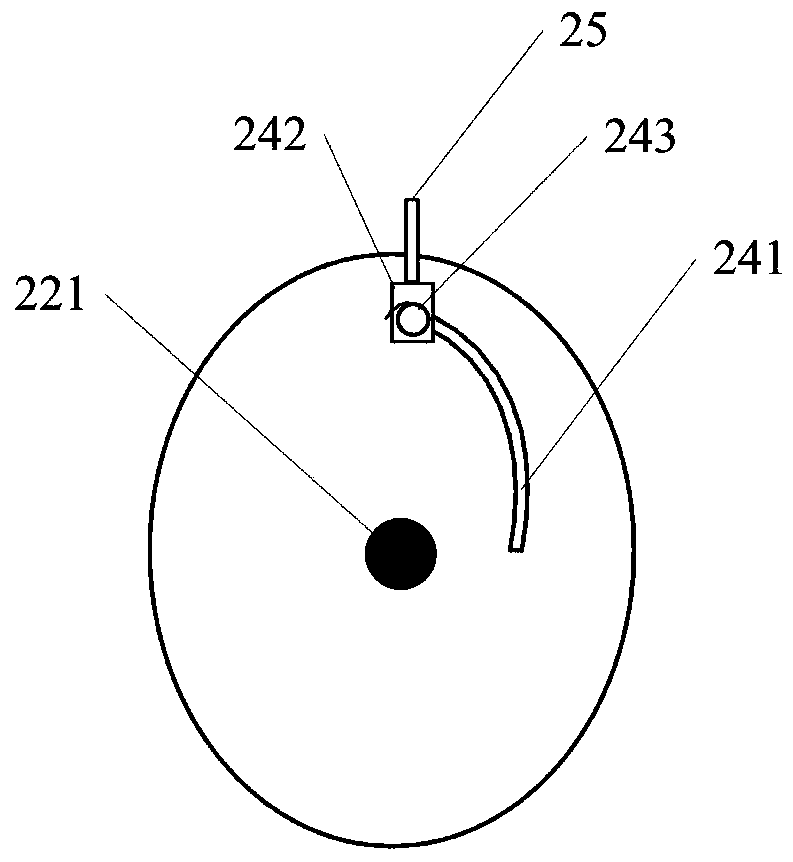

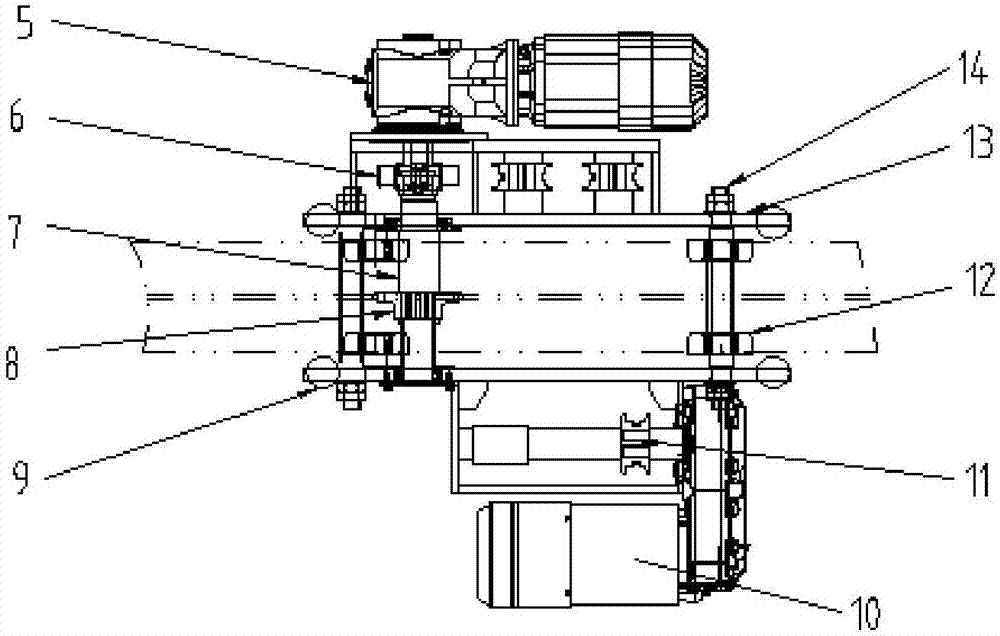

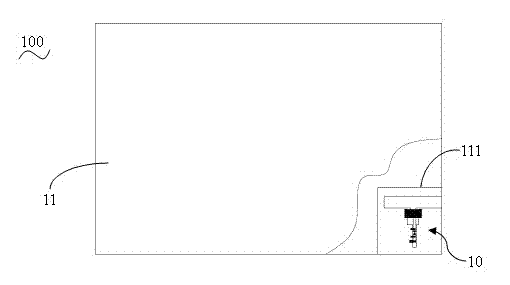

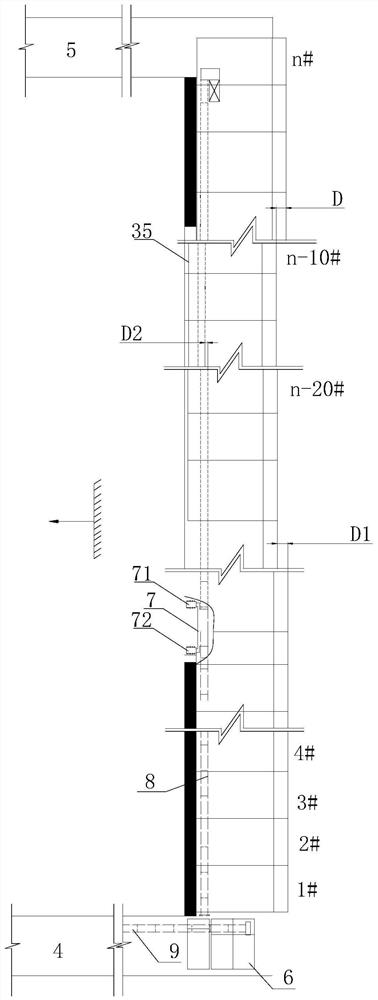

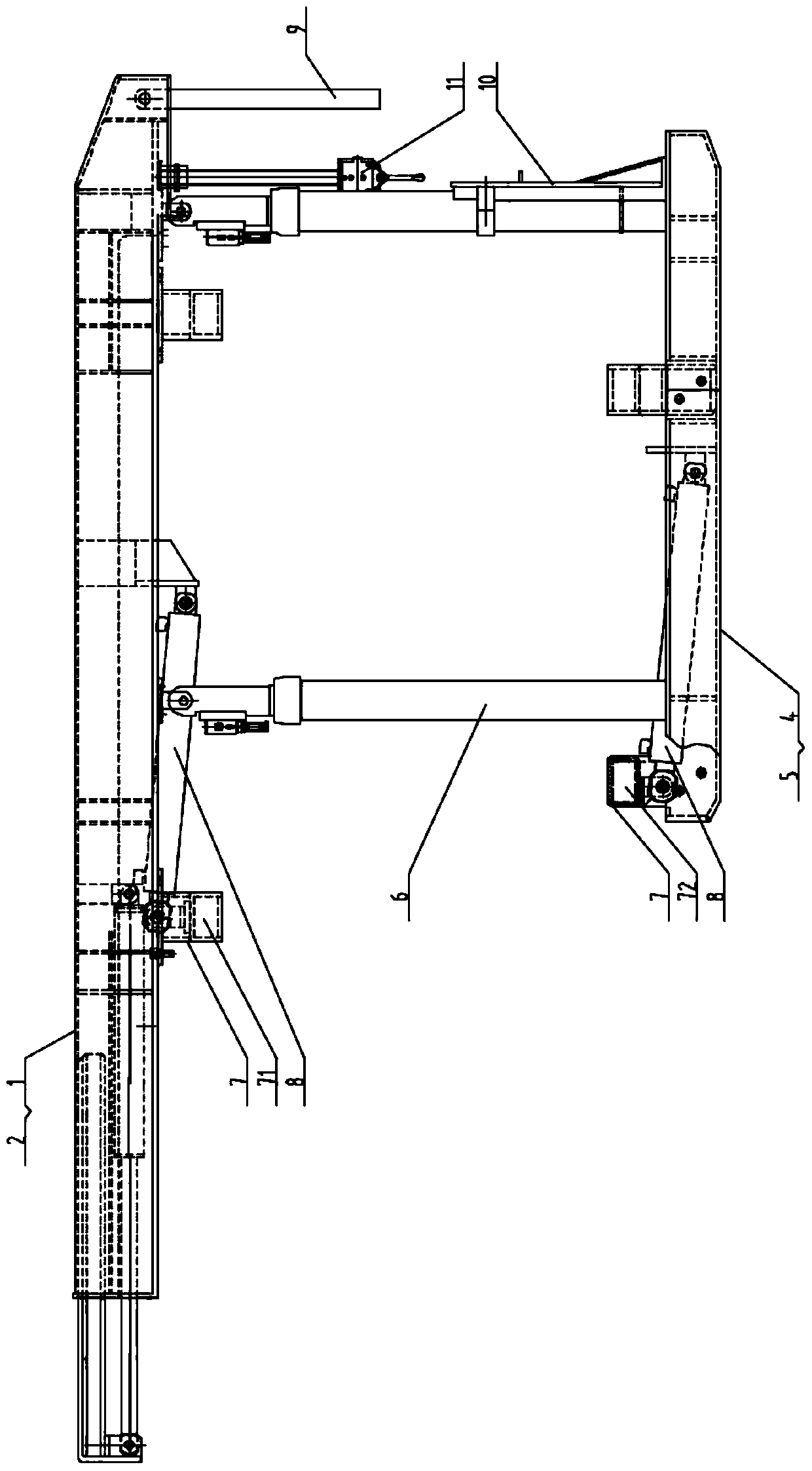

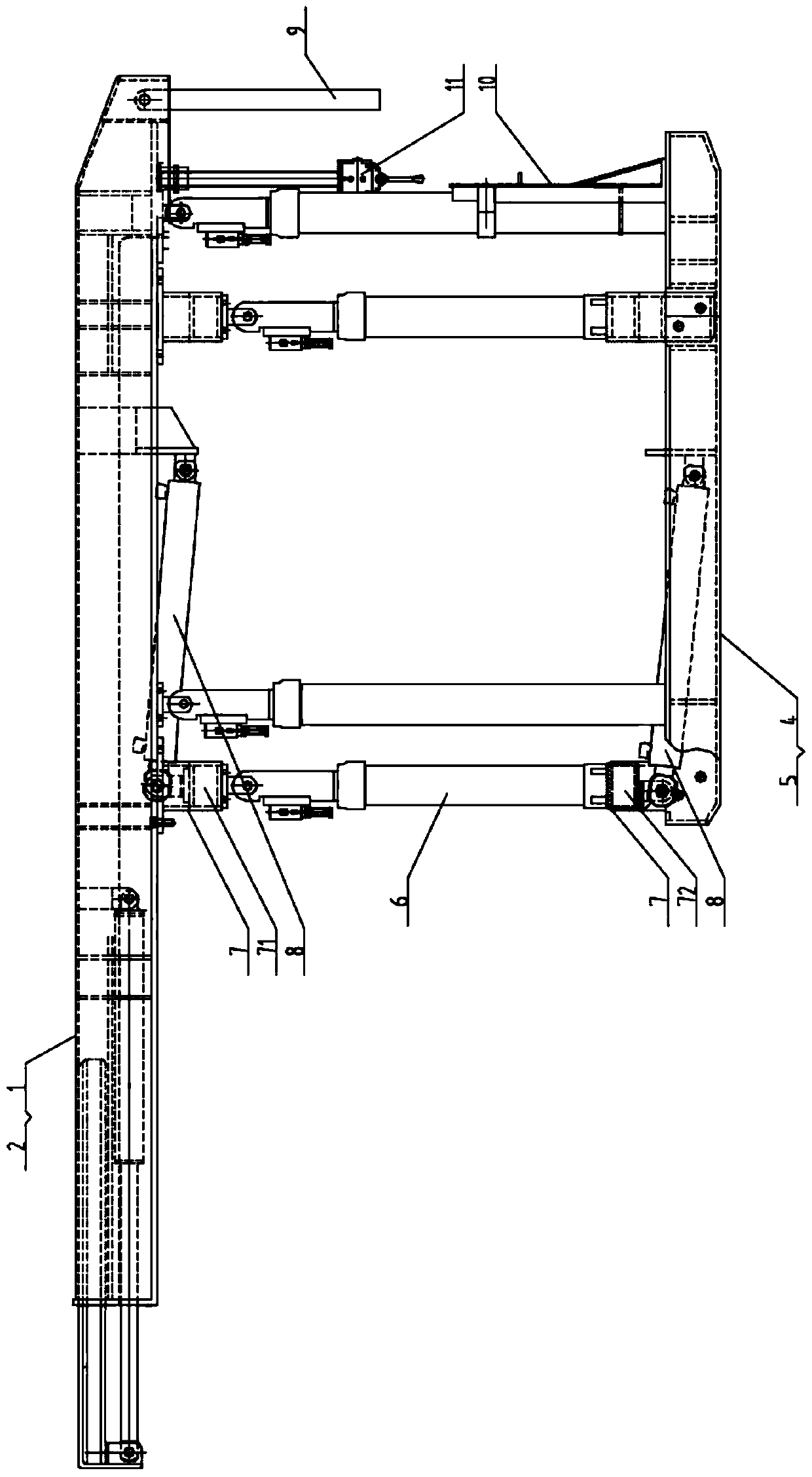

Feeding system for automatic CNC laser pipe cutting machine

ActiveCN108526686BSmooth transferSmall headroomLaser beam welding apparatusTubular articlesNumerical controlPipe fitting

The invention discloses a loading system for a full-automatic numerical control laser pipe cutting machine. The loading system comprises a pipe frame, a pipe fitting carrying module and a pipe cuttingconveying table arranged in sequence; multiple metal pipes to be cut are arranged on the pipe frame in sequence; and the pipe fitting carrying module is operated to transfer the metal pipes to be cutfrom the pipe frame to arrange on the pipe cutting conveying table end to end in sequence. The loading system for the full-automatic numerical control laser pipe cutting machine can orderly load themetal pipes, arranged in sequence, on the cutting conveying table in sequence by the pipe fitting carrying module for cutting, realizes synchronous implementation of loading and cutting of the metal pipes, improves the cutting efficiency, and saves both time and power.

Owner:JINAN BODOR LASER CO LTD

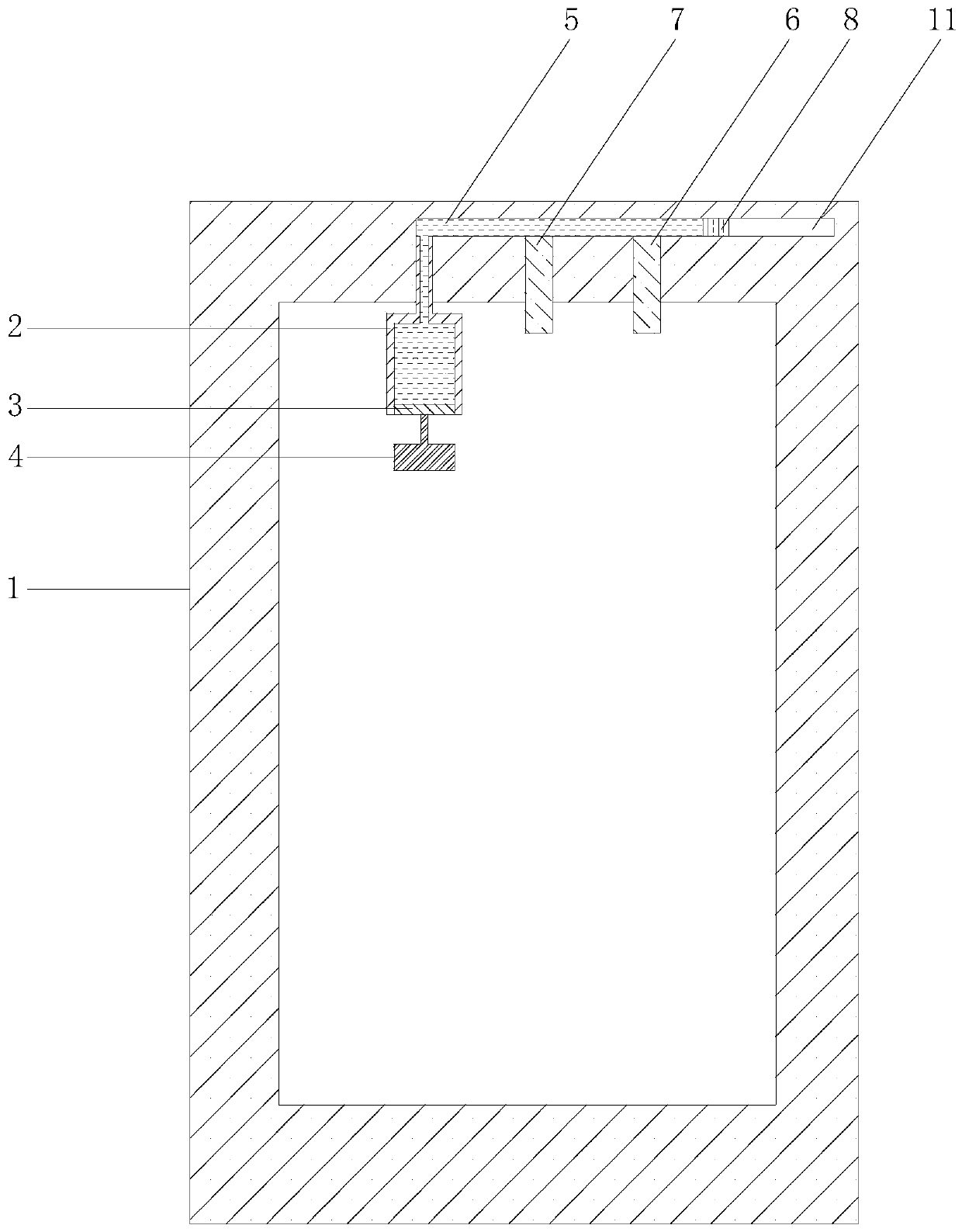

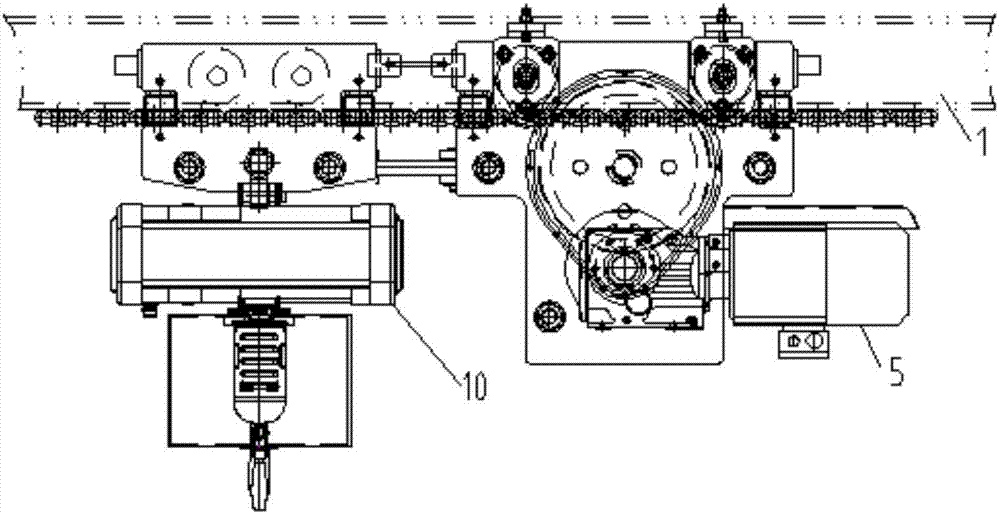

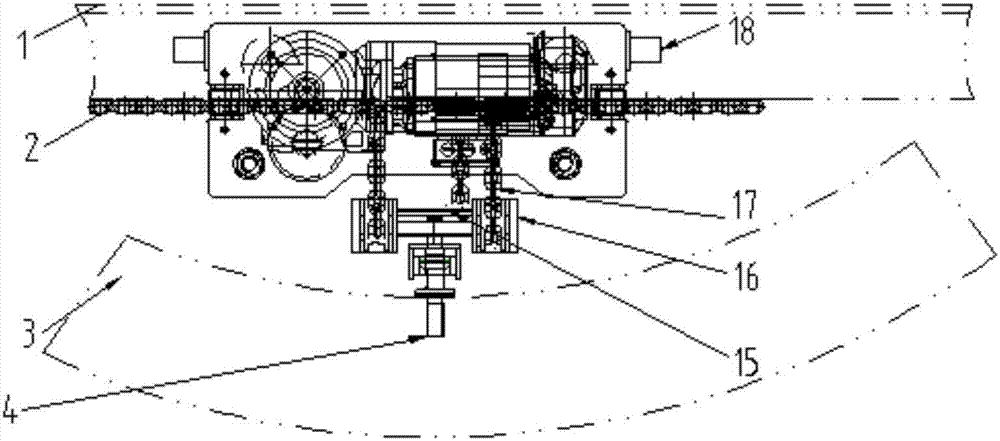

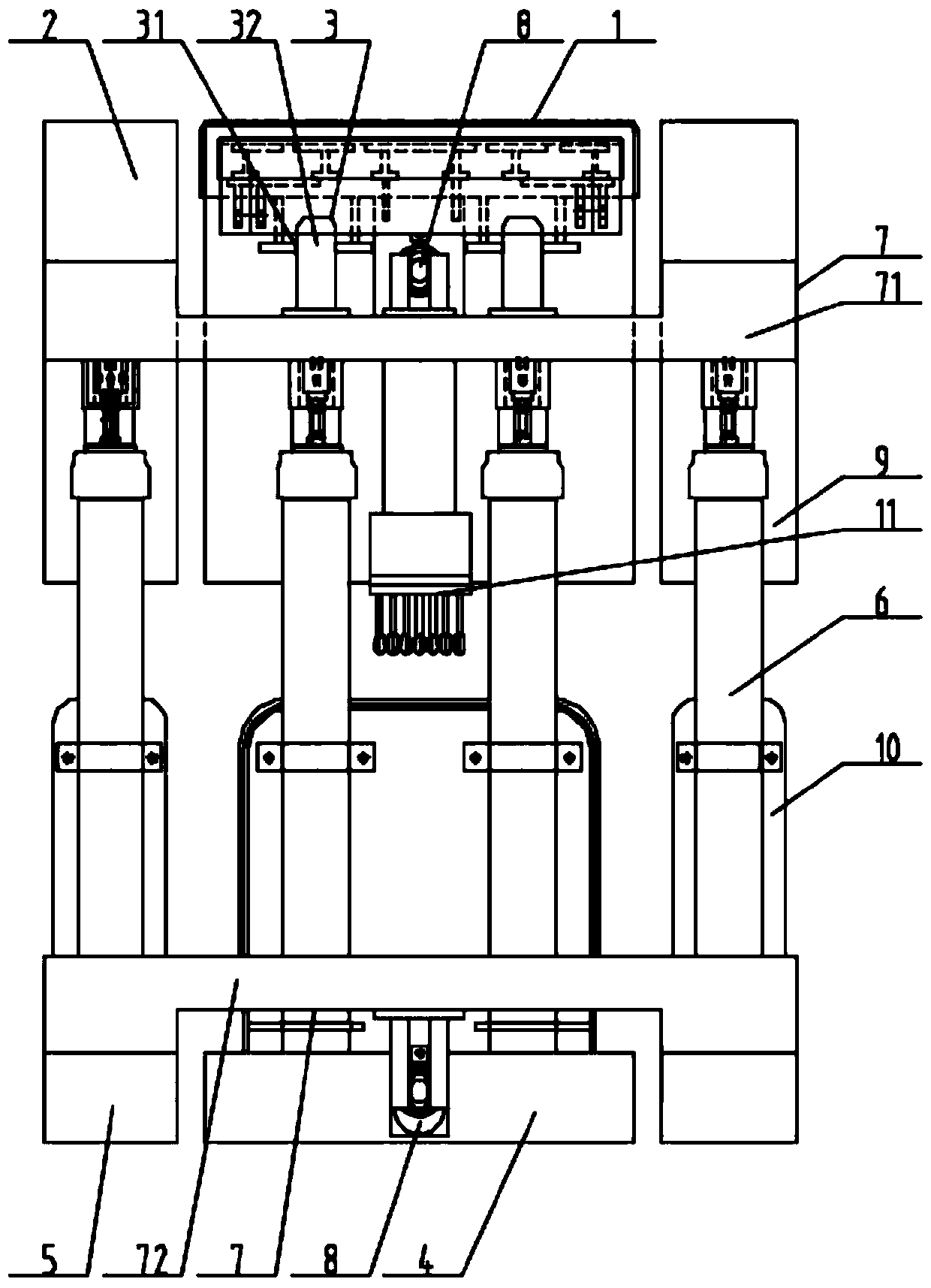

Low-clearance lifting device and lifting system

InactiveCN107324210ACrawl quicklySmall headroomTravelling gearTrolleysWeight distributionHigh weight

The low-headroom hoisting device and the hoisting system provided by the present invention relate to the technical field of engineering and construction. The low-headroom hoisting device includes: a casing, a spreader, a traveling unit and a hoisting unit; the traveling unit includes driving the casing The hoisting unit includes a hoisting motor that drives the spreader to lift and lower, and the hoisting motor and the traveling motor are respectively arranged on both sides of the running track. In the low-headroom hoisting device provided by the present invention, the hoisting motor and the traveling motor are respectively arranged on both sides of the running track, which can not only greatly reduce the clearance of the whole device, but also can grab heavy objects higher. At the same time, it can also make the weight distribution of the whole device reasonable, and the center of gravity is on the center line of the running track, which has the advantages of low headroom and structural size.

Owner:EUROCRANE

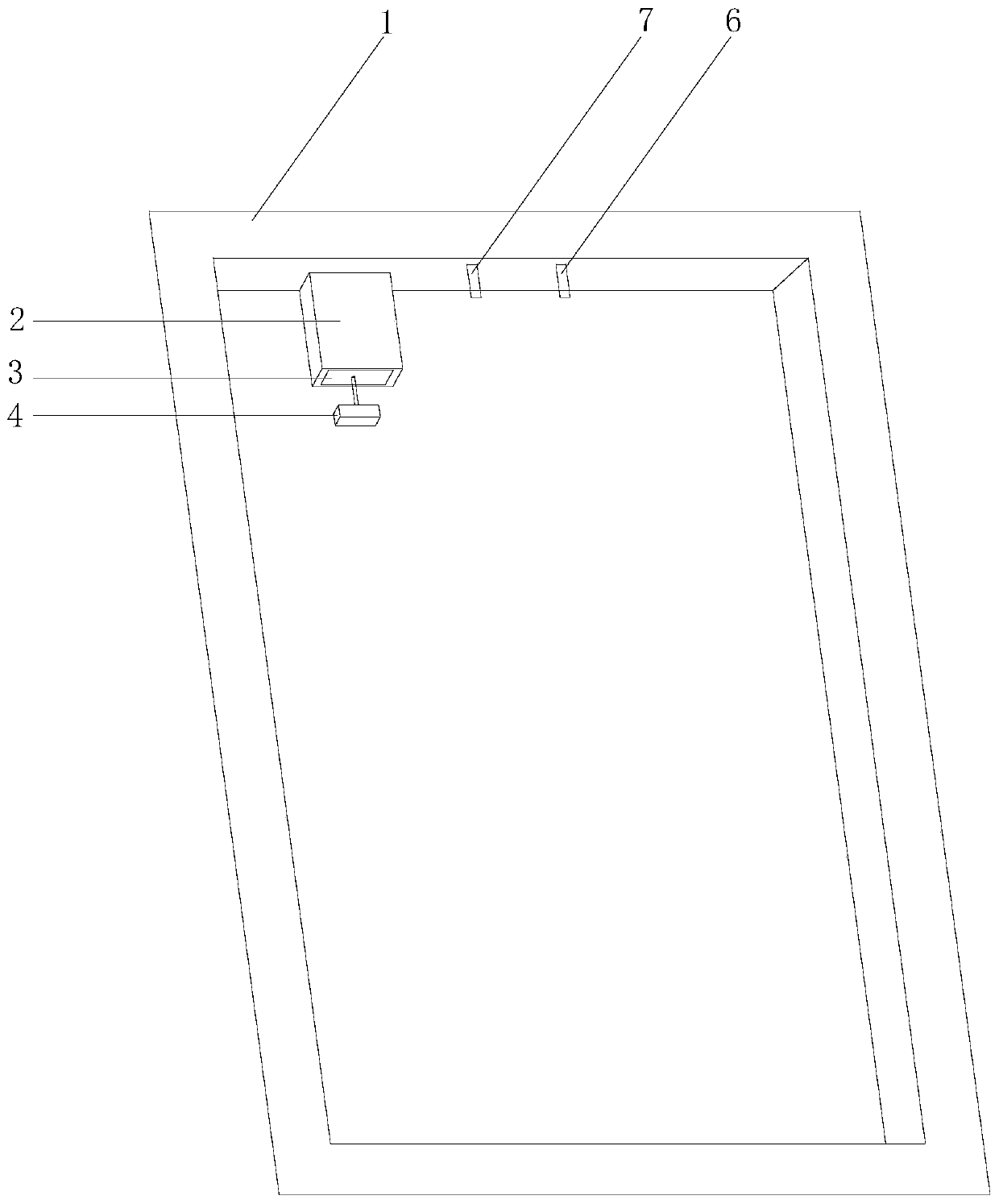

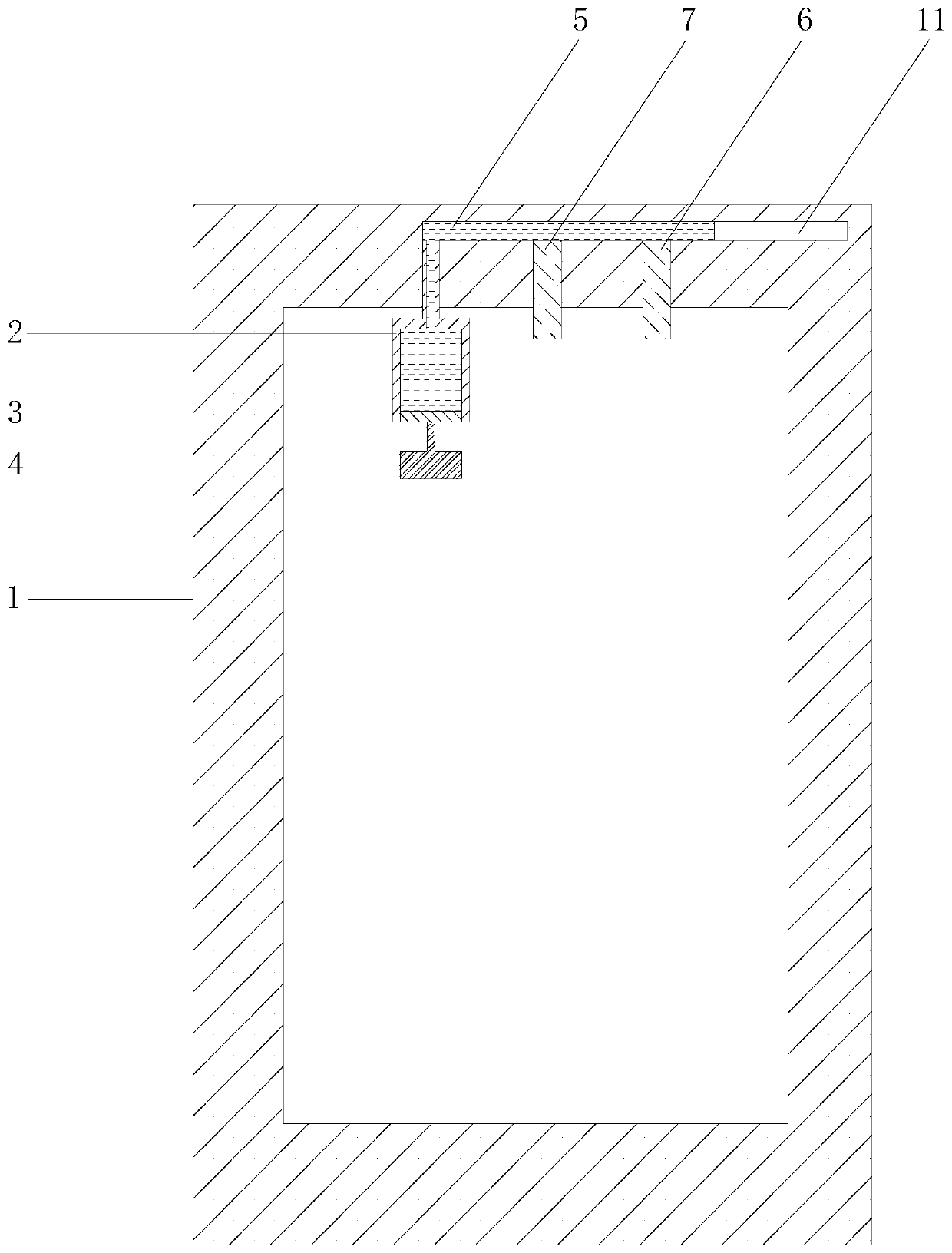

Chip antenna device and purpose thereof, and electronic product provided with the chip antenna device

InactiveCN103928746AReduce volumeSmall headroomMagnetic/electric field screeningAntenna supports/mountingsEngineeringRadiation

The invention provides a chip antenna device and purposes thereof, and an electronic product provided with the chip antenna device. The chip antenna device comprises a chip antenna, a transmission line, and a shielding case arranged outside the chip antenna. The chip antenna comprises a substrate and a radiation part which is arranged on the substrate and is connected with the transmission line. The shielding case is provided with an opening. The radiation part is disposed in the shielding case. The chip antenna device has the following advantages: the size is small, the net clearance is small, the effects are comprehensive, and good antenna performance can be maintained under a shielding condition.

Owner:HOLYPAO

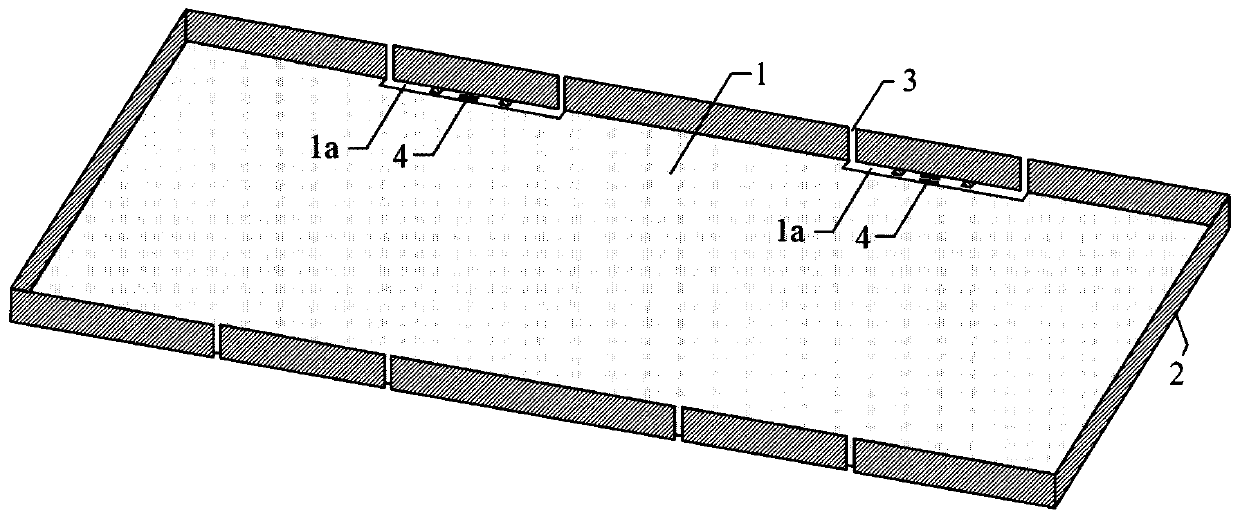

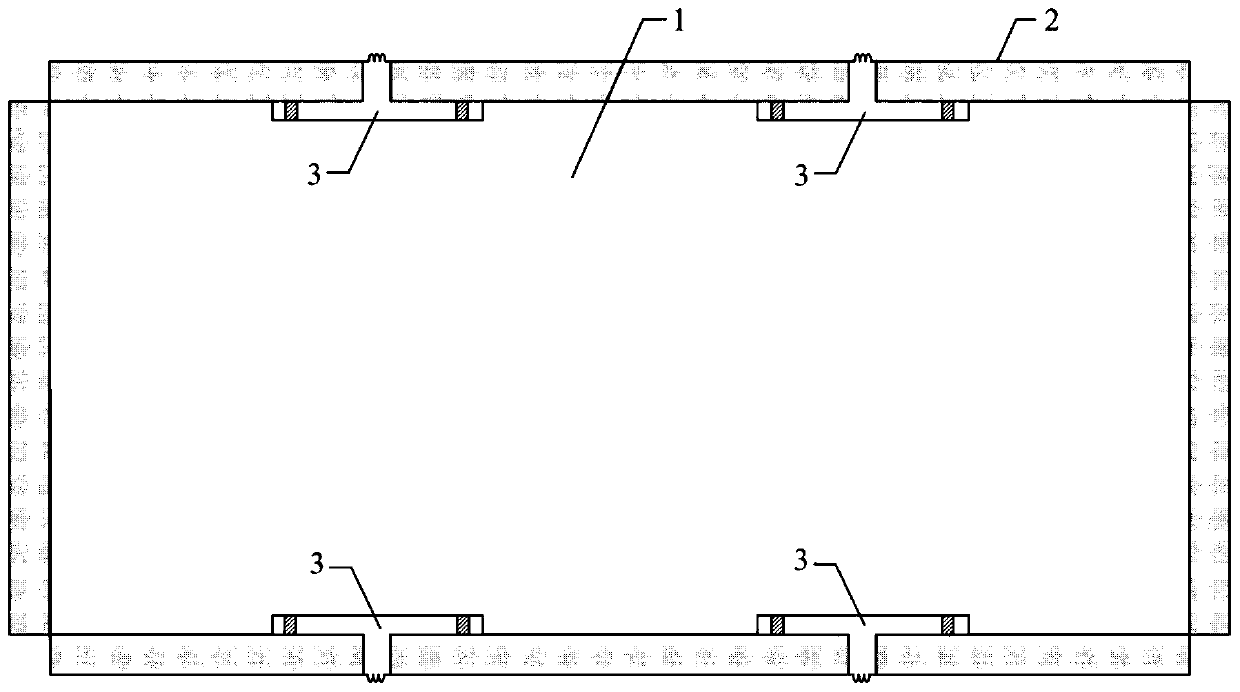

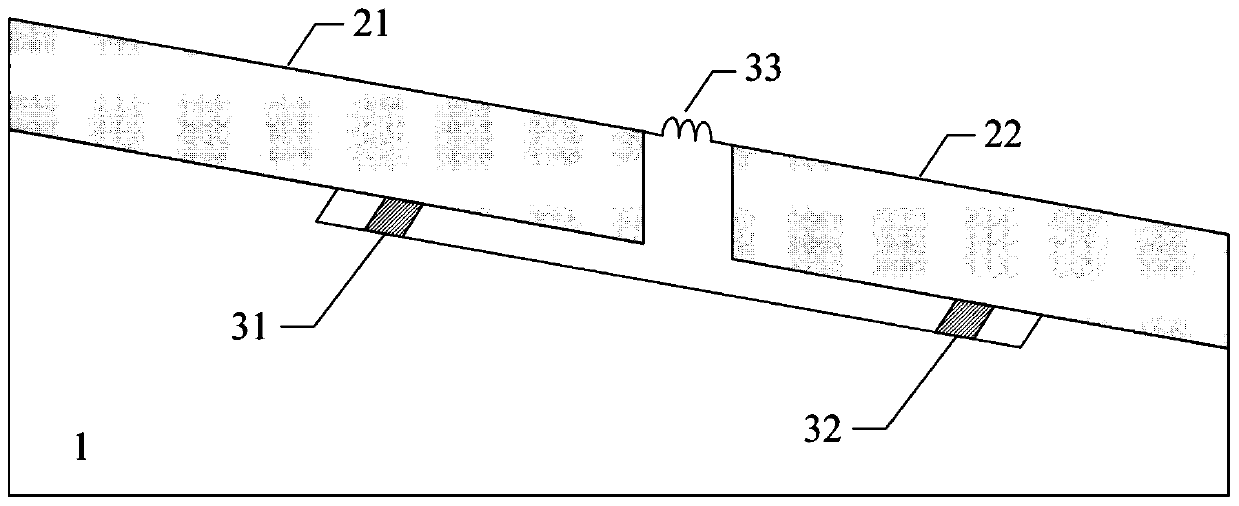

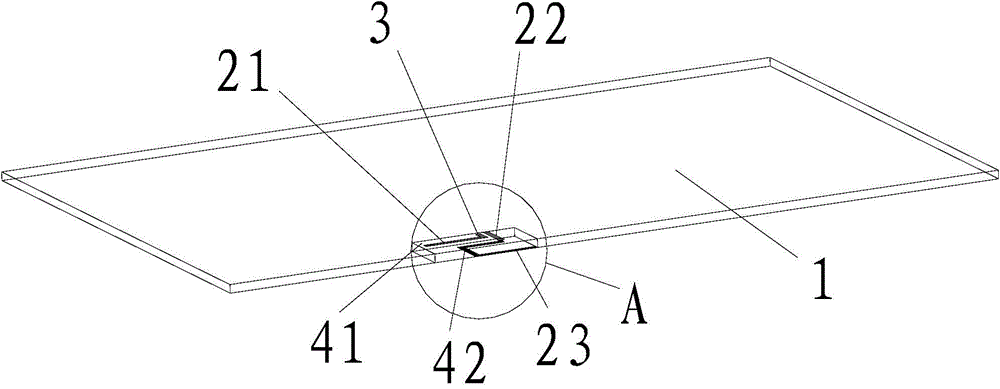

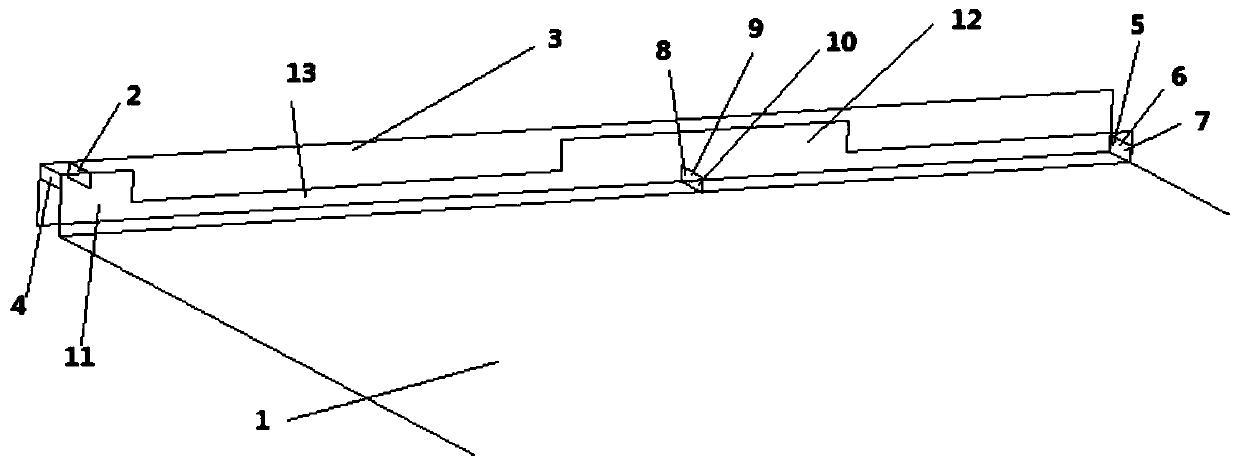

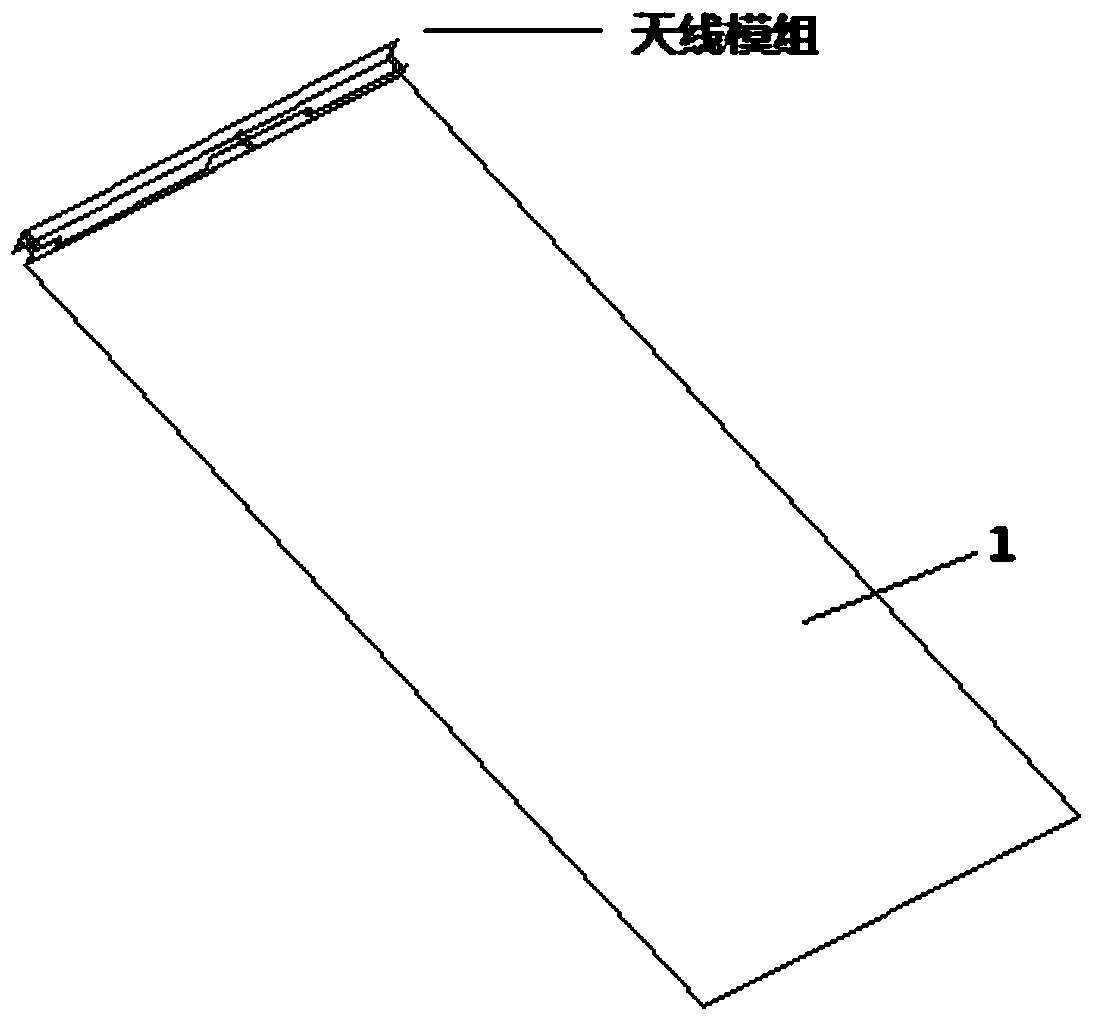

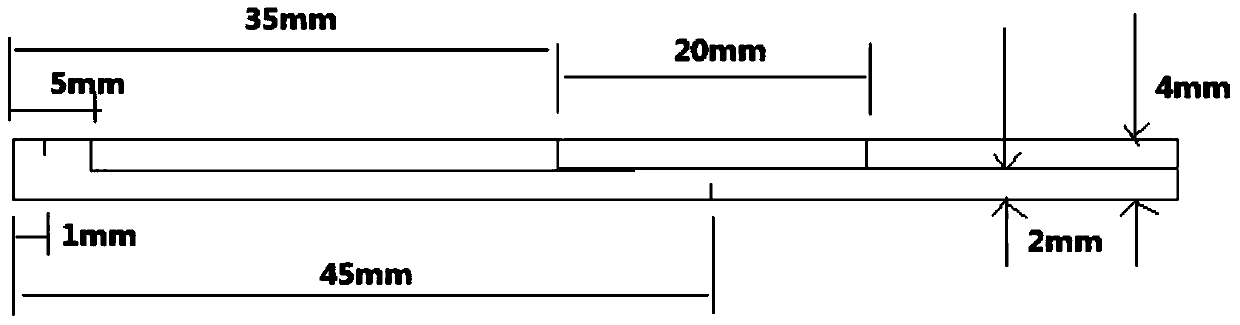

A broadband 5g MIMO terminal antenna integrated with dual antennas

ActiveCN110137664BSmall sizeSmall headroomParticular array feeding systemsAntenna supports/mountingsBroadbandingInductor

A dual-antenna integrated broadband 5G MIMO terminal antenna includes a metal floor, a metal frame, and N integrated dual-antenna assemblies. N floor slots are symmetrically arranged in the edge of the metal floor, and N is an integer from 1 to 4. The four sides of the metal frame are closed and connected, the bottom of the metal frame is connected with the edge of the metal floor, and the metal frame is provided with N frame slots having a one-to-one correspondence with the floor slots. The N integrated dual-antenna assemblies are distributed in the N floor slots respectively, and the centerof each integrated dual-antenna assembly corresponds to one frame slot. Each integrated dual-antenna assembly includes first and second feeding branches and an inductive decoupling assembly, and the inductive decoupling assembly is a lumped inductor or a bent metal branch connected across the two ends of the corresponding frame slot. The dual-antenna integrated broadband 5G MIMO terminal antenna has the advantages of small size, low headspace, broad band, high efficiency, compatibility with a metal frame, fewer frame slots and dual-antenna integration, and is suitable for various small mobileterminals represented by mobile phones.

Owner:TSINGHUA UNIV

Novel Bluetooth/WLAN antenna and intelligent equipment

ActiveCN104409834ASmall headroomImprove radiation resistanceAntenna supports/mountingsRadiating elements structural formsResonanceEngineering

The invention discloses a novel Bluetooth / WLAN antenna and intelligent equipment. The novel Bluetooth / WLAN antenna comprises a PCB and an antenna component, wherein an antenna clearance area is arranged on the PCB; the antenna clearance area comprises a first clearance area arranged on the upper surface of the PCB and a second clearance area arranged on the lower surface of the PCB; the antenna component comprises a first radiator, a second radiator and a third radiator; the first radiator and the second radiator are arranged inside the first clearance area; a feed part is arranged on the first radiator; the third radiator is arranged inside the second clearance area; the second radiator and the first radiator are coupled to form a first resonance branch; the second radiator and the third radiator are coupled to form a second resonance branch. The antenna disclosed by the invention is small in occupied area, high in design flexibility, high in radiation impedance and good in omni-directivity.

Owner:SUNWAY COMM JIANGSU CO LTD

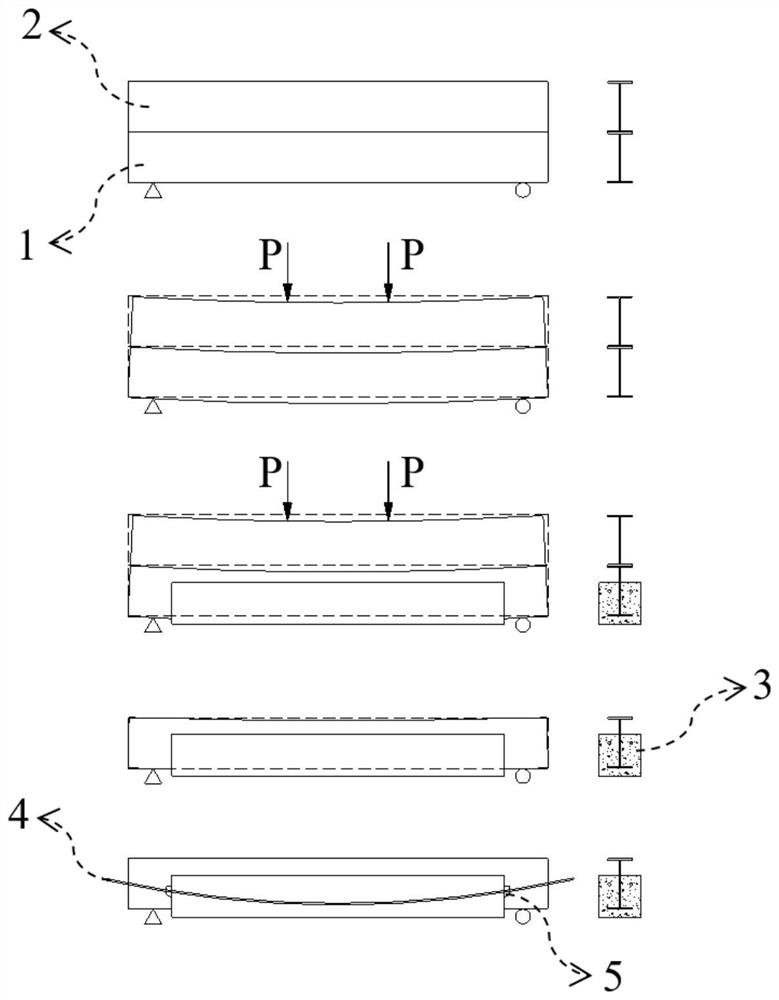

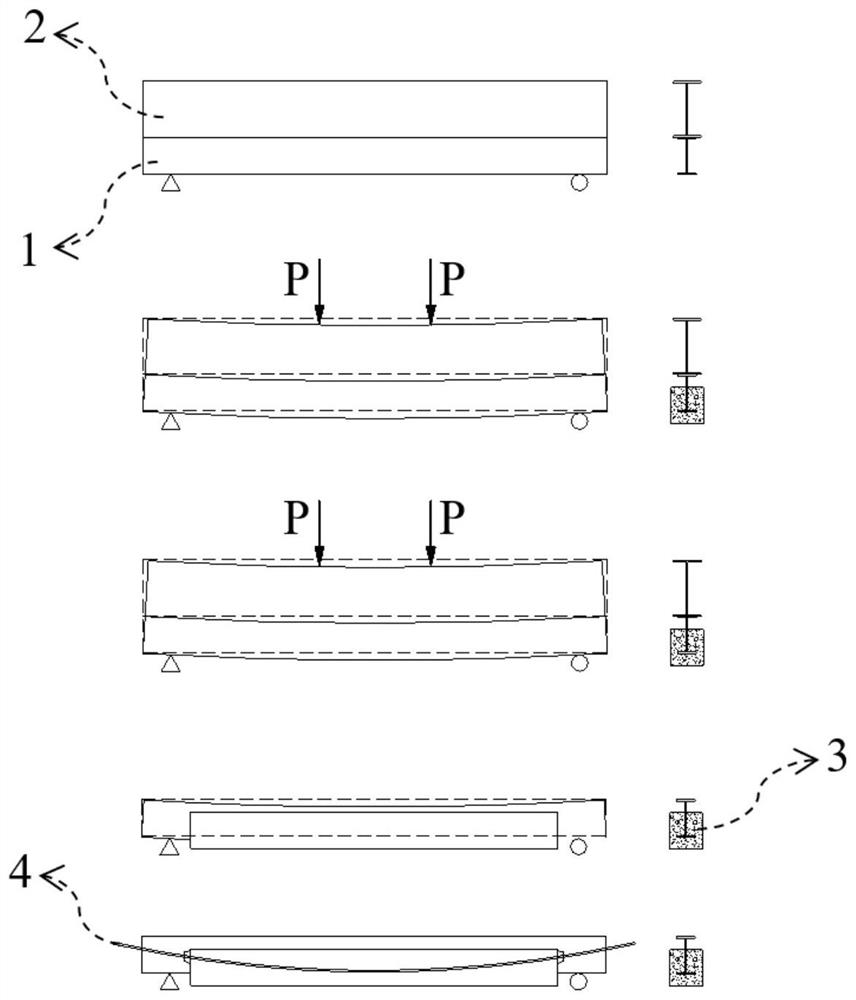

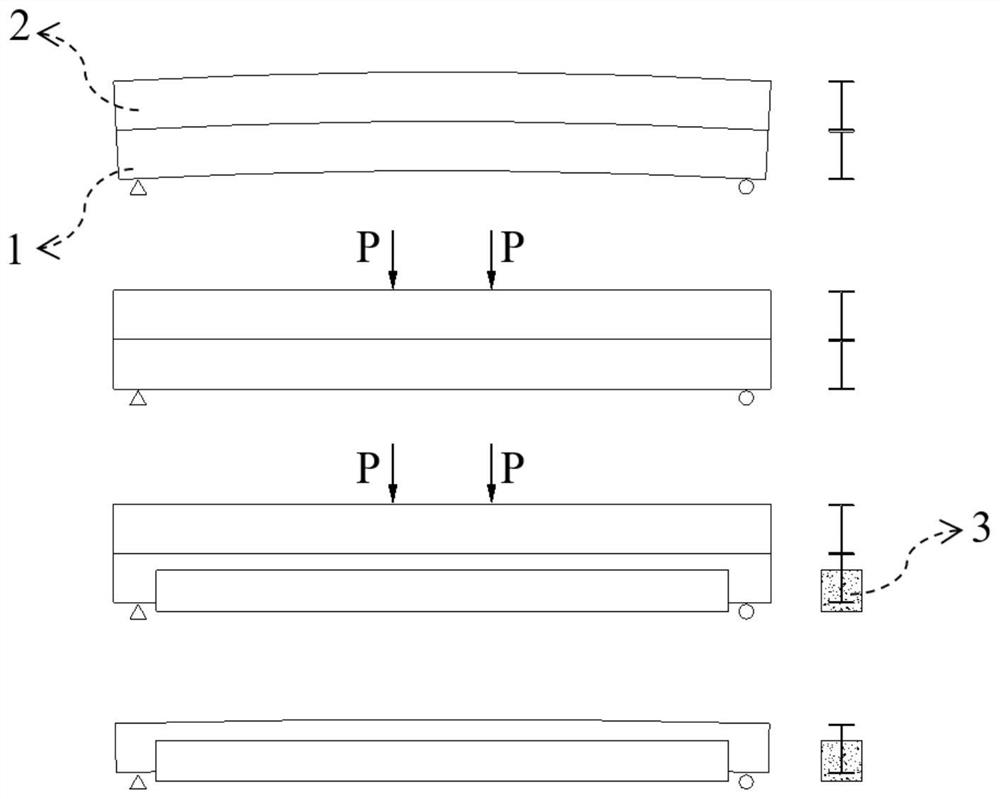

Prestress construction method for combined steel beam

PendingCN114412189ASignificant comprehensive benefitsReduce in quantityLoad-supporting elementsBuilding material handlingPre stressLong span

The main process of the combined steel beam prestress construction method comprises the steps of pre-bending of a combined steel beam, pouring of prefabricated concrete and tensioning of prestressed tendons. Wherein the combined steel beam is composed of the lower section steel and the auxiliary section steel which are fixed through bolts, and in the pre-bending process, due to the fact that the combined steel beam has higher rigidity, the midspan deflection in the pre-bending process can be greatly reduced, and the effects of small deflection and high stress are achieved; after the two are bound, the position of the neutral shaft moves upwards, the area of an effective pre-pressing area is increased, the concrete prefabrication rate is improved, and the site construction amount is reduced. In addition to the most basic double-linear combination mode, the invention also provides a double-arch combination mode and a big-end-up combination mode which are respectively used for solving the problem of overlarge deflection caused by large span and the problem of lower height of a small steel beam prepressing area.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

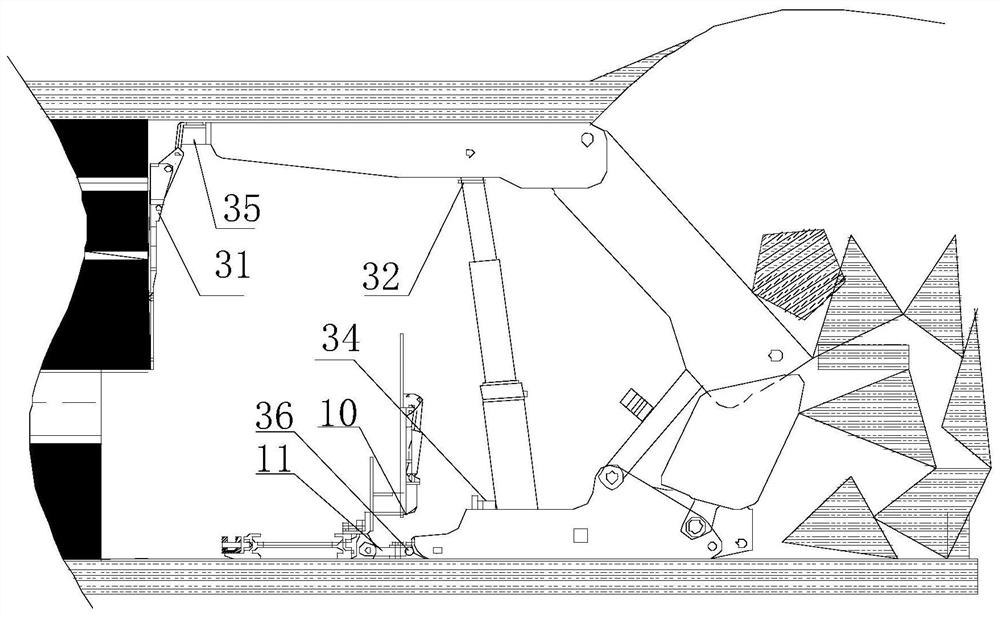

Fully mechanized mining recovery technology with large mining height and large mining height in complex thick coal seam with large dip angle structure

ActiveCN110273686BImprove stabilityGuarantee unimpededUnderground miningSurface miningStructural engineeringMachine

The invention relates to a coal mining technology, and discloses a fully mechanized mining recovery technology with a large mining height and a complex thick coal seam with a large dip angle structure. This process retains the uncut section to feed the knife, and through the supporting effect of the uncut section, the empty roof area is reduced to prevent the occurrence of roof fall accidents. The combination of cutting sections can further improve the stability of the entire working face, and ensure the unimpeded pedestrian passage of the end bracket and tail frame; moving the hydraulic support twice can solve the problem that the hydraulic support cannot be pushed to a cutting depth at one time, and ensure that the scraper conveyor can Push it in place to maintain the safe operation of the equipment.

Owner:SICHUAN CHUANMEI HUARONG ENERGY CO LTD

New bluetooth/wlan antenna and smart device

ActiveCN104409834BSmall headroomImprove radiation resistanceAntenna supports/mountingsRadiating elements structural formsTelecommunicationsBluetooth

The invention discloses a novel bluetooth / WLAN antenna and an intelligent device, wherein, the novel bluetooth / WLAN antenna includes a PCB board and an antenna assembly, the PCB board is provided with an antenna clear area, and the antenna clear area includes a set The first clearance area on the upper surface of the PCB board and the second clearance area arranged on the lower surface of the PCB board; the antenna assembly includes a first radiator, a second radiator and a third radiator, the first radiator and The second radiator is arranged in the first clearance area, and a feeder is arranged on the first radiator; the third radiator is arranged in the second clearance area, and the second radiator and the first radiator The coupling forms a first resonance branch, and the coupling of the second radiator and the third radiator forms a second resonance branch. The antenna of the invention has the advantages of small occupation area, high design flexibility, high radiation impedance and good omnidirectionality of the antenna.

Owner:SUNWAY COMM JIANGSU CO LTD

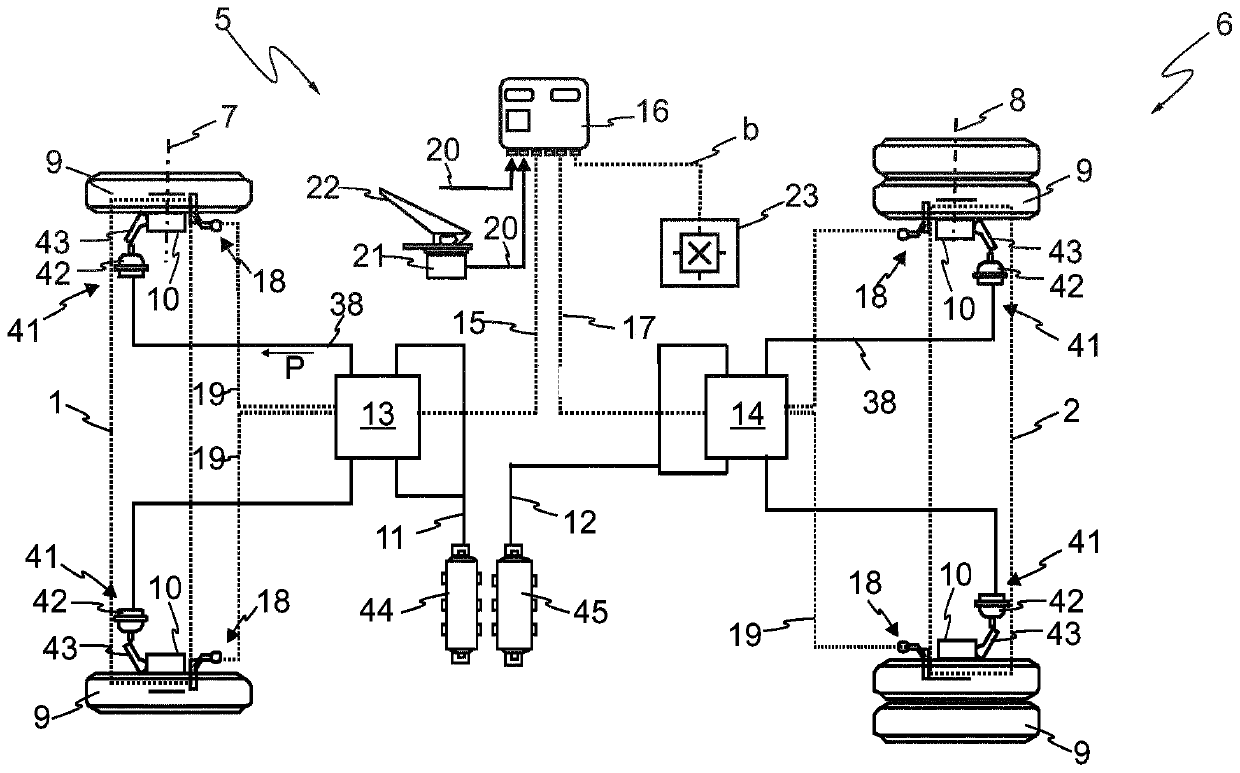

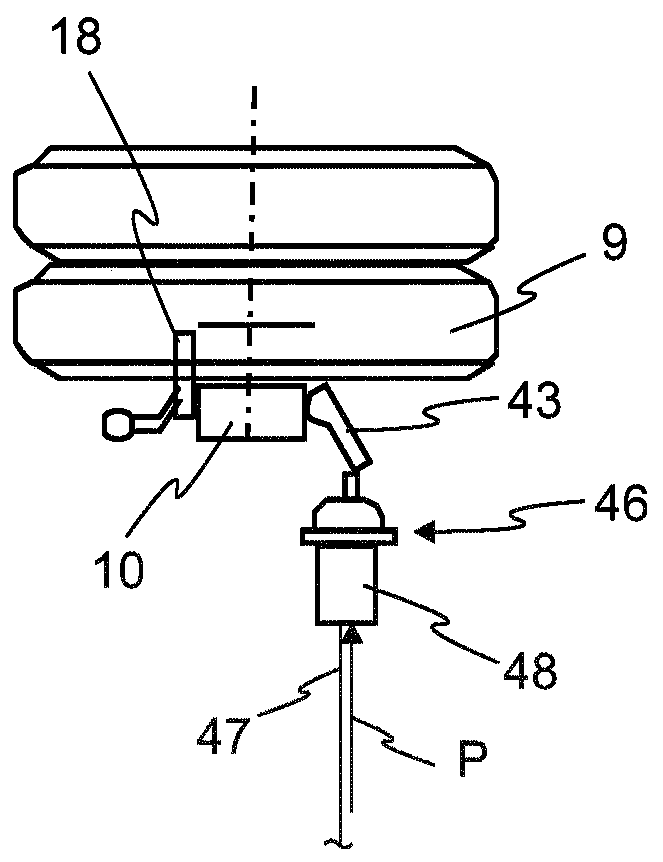

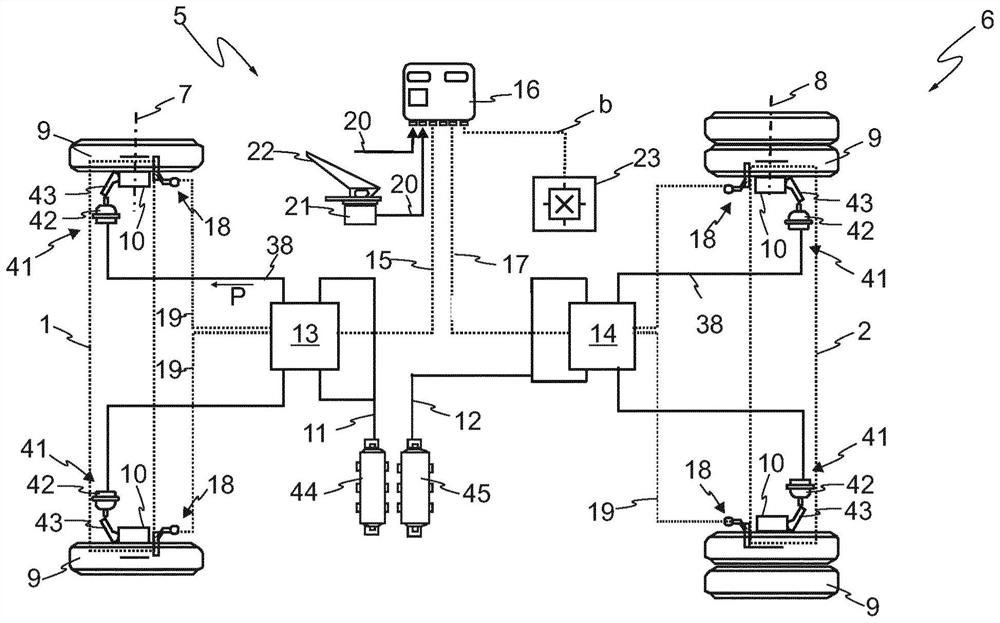

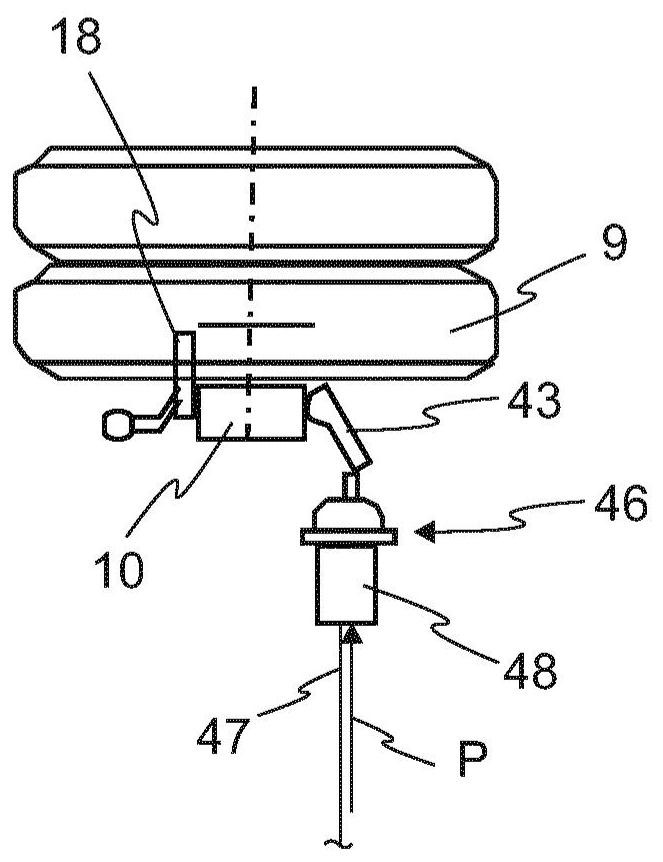

Method for determining the overall utility vehicle deceleration values which can be achieved by actuating wheel brakes, brake system for carrying out the method, and utility vehicle comprising same

ActiveCN110740910AIncrease total braking forceSimple structureAutomatic initiationsABS control systemsControl theoryCommercial vehicle

The invention relates to a method for determining the overall deceleration values (bmax, bmin), which can be achieved by actuating wheel brakes, of a utility vehicle (6) or a vehicle combination (24)comprising multiple axles (7, 8). The invention further relates to a brake system for carrying out the method and to a utility vehicle or a vehicle combination comprising such a brake system for carrying out the method. The aim of the invention is to determine the currently achievable overall deceleration values (bmax, bmin) for decelerating a utility vehicle or a vehicle combination with multipleaxles during travel. According to the invention, this is achieved in that the brake force is distributed (26) such that brake forces (F1, F2, F3, F4) are distributed unequally to brake units (1, 2, 3, 4) comprising the wheel brakes (10) of one or more axles (7, 8) in order to implement a deceleration request (20) during a partial braking process (27). One of the brake units (1, 2, 3, 4) is selected, and a greater brake force (F2) is applied by said selected brake unit (29) than via the other brake units (1, 3, 4), and a current deceleration b of the utility vehicle (6) or the vehicle combination (24) is measured or ascertained and paired with the respective selected brake unit (29) as the corresponding partial deceleration value (b1, b2, b3, b4) and is stored. The achievable overall deceleration values (bmin, bmax) are determined as the sum (31) of the partial deceleration values (b1, b2, b3, b4) of the brake units (1, 2, 3, 4).

Owner:WABCO GMBH

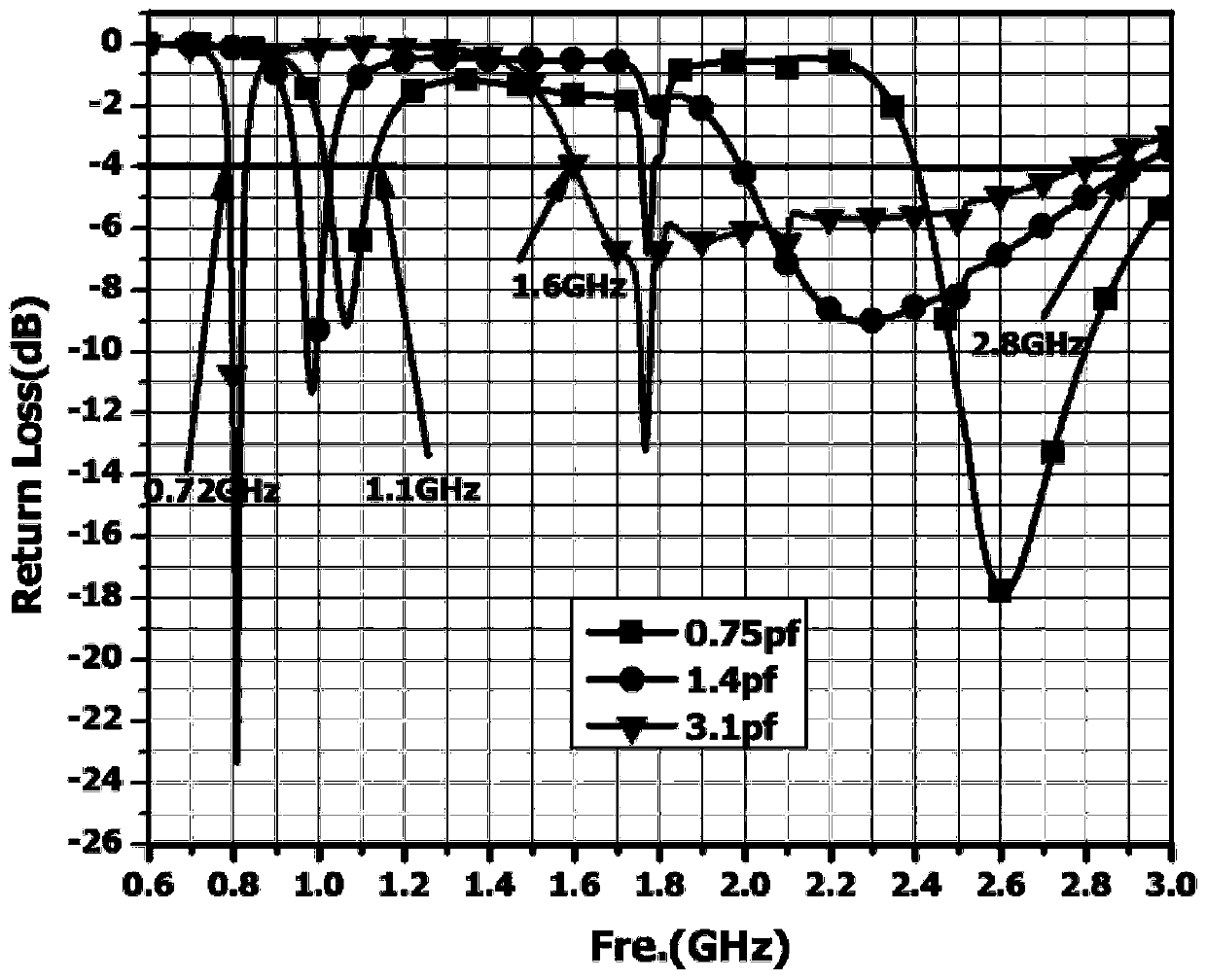

A radio frequency switch type compact multi-band mobile phone antenna

ActiveCN105720368BSmall headroomReduce the overall heightSimultaneous aerial operationsAntenna supports/mountingsMulti bandEngineering

Owner:QINGDAO UNIV

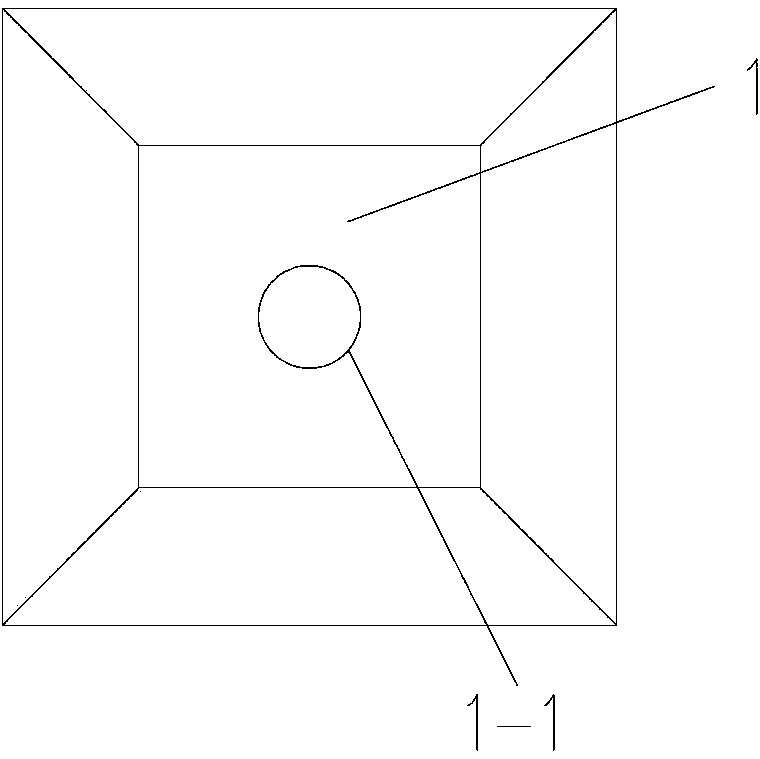

Construction method for prefabricated perforated type filling module of ribbed cast-in-place concrete floor slab

InactiveCN102661051BLose weightImprove insulation performanceBuilding material handlingFloor slabRebar

The invention discloses a construction method for a prefabricated perforated type filling module of a ribbed cast-in-place concrete floor slab. The method comprises the following steps of: constructing a template support frame body; arranging a bottom template of the floor slab; binding two-way bottom-row reinforcements on the bottom template; binding bottom-row transverse ribbed beam reinforcements and bottom-row longitudinal ribbed beam reinforcements of ribbed beams on the two-way bottom-row reinforcements, and binding top-row transverse ribbed beam reinforcements and top-row longitudinal ribbed beam reinforcements on the upper parts of the bottom-row transverse ribbed beam reinforcements and the bottom-row longitudinal ribbed beam reinforcements, thereby forming a plurality of squares; placing two high cushion blocks in the first of every two squares; arranging longitudinal bracket reinforcements in each row of squares; arranging a prefabricated filling module in each square; arranging longitudinal anti-floating reinforcements on each prefabricated filling module; binding two-way top-row reinforcements of the floor slab on the longitudinal anti-floating reinforcements; and pouring floor slab concrete. The method is firm in structure, safe and reliable, anti-floating measures are effective, and the self weight of the floor slab is reduced.

Owner:天津住宅集团建设工程总承包有限公司

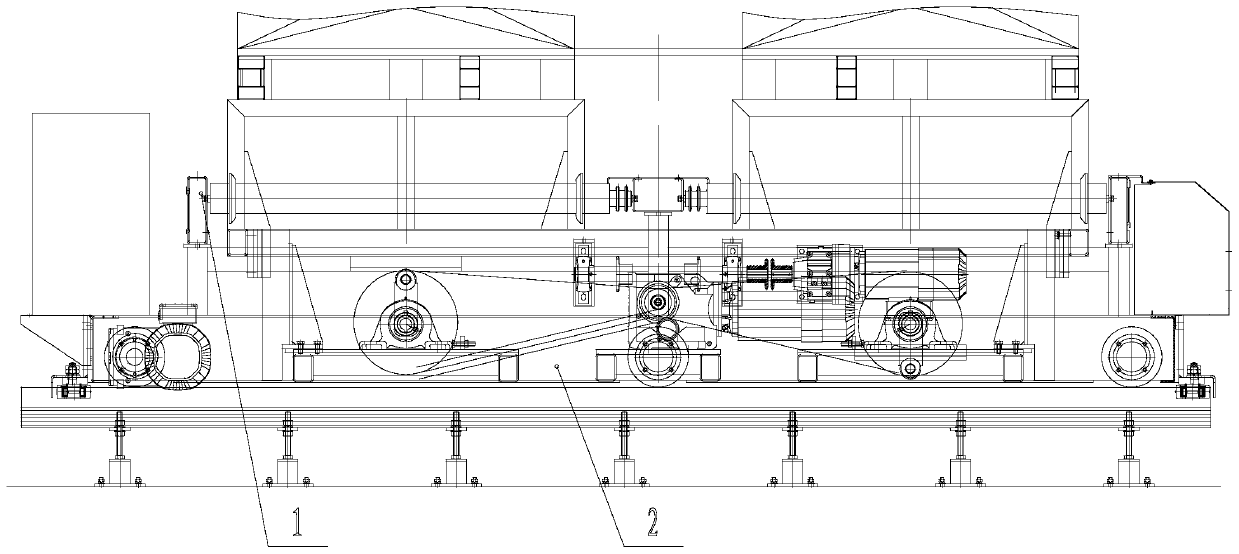

Loading shuttle car for docking with automatic guiding transport vehicle

PendingCN110255105AReduce in quantityHeadroom requirements are smallStorage devicesMechanical conveyorsDrive shaftAutomotive engineering

The invention belongs to the technical field of logistics equipment, and relates to a loading shuttle car for docking with an automatic guiding transport vehicle. The shuttle car comprises a shuttle car bottom frame movably arranged on a rail, wherein one end, along the length direction, of the shuttle car bottom frame is provided with a driving shaft and the other end of the shuttle car bottom frame is provided with a driven shaft; the driving shaft is driven by a horizontal running motor arranged on the shuttle car bottom frame; the driving shaft and the driven shaft are respectively supported on the rail through traveling wheels; a roller conveyor is arranged on the shuttle car bottom frame; the roller conveyor comprises two rows of conveying roller ways arranged in parallel; driven chain wheels are respectively arranged at mutually close ends of two conveying rollers positioned on the same axis in the two rows of conveying roller ways; a roller conveyor driving motor is arranged outside a frame of the roller conveyor; and an output end of the roller conveyor driving motor is connected with the driving shaft. According to the shuttle car, the corresponding number of docking equipment is reduced, and compared with the clearance size of the docking of prior shuttle cars with the roller conveyors, the requirement for plant clearance is small.

Owner:WUXI ZHONGDING INTEGRATION TECH CO LTD

Mobile phone antenna and mobile phone

ActiveCN110544820BSmall headroomReduce the "chin"Antenna supports/mountingsRadiating elements structural formsElectrical and Electronics engineeringHandset antennas

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

An antenna system based on an all-metal back cover smartphone

ActiveCN107230823BImprove integrityImprove Radiation PerformanceSimultaneous aerial operationsAntenna supports/mountingsEngineeringMetal backed

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

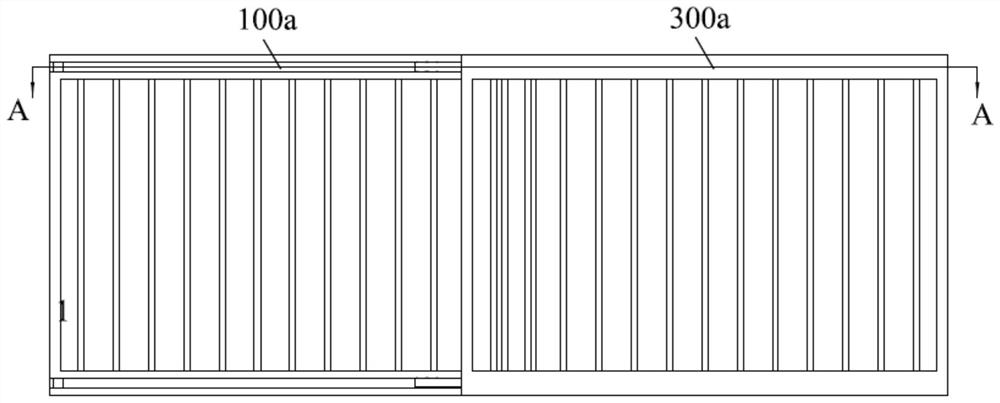

sliding door

ActiveCN112901057BEliminate overlapping bitsEliminate Stretch BitsGates/doorsWing fastenersStructural engineeringMechanical engineering

The invention relates to a translational door, comprising a plurality of door row assemblies, a guide assembly is arranged between two adjacent door row assemblies, and the guide assembly is slidingly connected with the two adjacent door row assemblies, so as to realize the The dislocation sliding of the two door row assemblies, the door row assembly is provided with a door opening limit and a door closing limit for limiting the guide assembly. When all the door row assemblies are fully pulled apart, the guide assembly abuts against the corresponding door closing limits of the two adjacent door row assemblies, and the length of all the door row assemblies when fully pulled is greater than or equal to the length of all the door row assemblies sum; when all the door row assemblies are fully folded, the guide assembly abuts against the corresponding door opening limits of the two adjacent door row assemblies, and the length of all the door row assemblies is equal to the length of the longest door row assembly length. Compared with the prior art, the occupied space of the door row assembly is reduced, and the utilization rate of the door opening is improved.

Owner:HONGMEN ADVANCED TECH CORP

Method for determining the total deceleration value achievable for commercial vehicles by operating the wheel brakes, braking equipment for implementing the method and commercial vehicles having braking equipment

ActiveCN110740910BIncrease total braking forceSimple structureAutomatic initiationsABS control systemsControl theoryCommercial vehicle

The invention relates to a method for determining the total deceleration value (b) which can be achieved by actuating the wheel brakes of a commercial vehicle (6) or a vehicle combination (24) having a plurality of axles (7, 8). max , b min )Methods. The invention also relates to a braking device for carrying out the method and a commercial vehicle or a vehicle combination having such a braking device for carrying out the method. In order to determine the currently achievable total deceleration value (b max , b min ), according to the invention, in order to implement the deceleration request (20) in the partial braking (27), the braking unit (1, 2, 3, 4) unevenly distributed braking force (F 1 , F 2 , F 3 , F 4 ) to distribute the braking force (26), wherein one of the braking units (1, 2, 3, 4) is respectively selected and applied by the selected braking unit (29) and applied by the other braking units (1, 3, 4) Compared with larger braking force (F 2 ), wherein the current deceleration b of the commercial vehicle (6) or vehicle combination (24) is measured or known and used as the partial deceleration value (b 1 , b 2 , b 3 , b 4 ) are each assigned to the selected brake unit (29) and saved. The total deceleration value that will be achieved (b min , b max ) is determined as the partial deceleration value (b) of all braking units (1, 2, 3, 4) 1 , b 2 , b 3 , b 4 ) sum (31).

Owner:WABCO GMBH

A fully loaded self-moving anti-fall and anti-skid hydraulic support

Owner:XUZHOU HUAFENG MEASUREMENT & CONTROL TECH

A transverse bearing system girder bridge

The invention discloses a bridge with a transverse bearing system. The bridge comprises a plurality of foundation piles, pier columns and a bridge deck, wherein the pier columns are arranged on the foundation piles, the bridge deck is arranged on upper sides of the pier columns, a bent cap body is arranged between the pier columns and the bridge deck in the longitudinal direction of the bridge deck, the bridge deck comprises a plurality of transverse element girders, and the transverse element girders are arranged on the bent cap body in the transverse direction of the bridge deck. The bridge with the transverse bearing system has the advantages that the bent cap body is arranged between the pier columns and the bridge deck in the longitudinal direction of the bridge deck, and is positioned at both sides of the existing obstacle, and the number of pier columns and the span diameter of the bent cap body can be freely adjusted according to the obstacle under the bridge and the weight on the bridge deck, so the clearance under the bridge or the ground is effectively saved; and meanwhile, the transverse element girders are arranged on the bent cap body in the transverse direction of the bridge deck, and the moving loads and the dead weight of the bridge decks can be directly borne by the transverse element girders, so the capability of crossing over the obstacle under the bridge or the ground is higher in comparison with the traditional transverse bent cap which firstly bears the longitudinal load of the bridge deck. The bridge with the transverse bearing system is used for the field of bridges.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Dual band wifi antenna system for wireless router

ActiveCN104183903BSmall headroomSuitable for design requirementsAntenna supports/mountingsRadiating elements structural formsWireless routerDual band antenna

The invention discloses a dual-band WiFi antenna system for a wireless router, which includes a router housing, a PCB board is placed inside the wireless router housing, and a first antenna assembly, a second antenna assembly and a second antenna assembly are fixed on the PCB board. Three antenna components, the first antenna component, the second antenna component and the third antenna component are located at the same end of the PCB, and the second antenna component is located between the first antenna component and the third antenna component. The invention has better self-isolation characteristics, meets the requirements of isolation conditions between antennas and gain flatness, and provides bending parts on the long antennas of the antenna assembly, which can reduce the gap between the antennas and is suitable for small-sized routers.

Owner:SUNWAY COMM BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com