A transverse bearing system girder bridge

A horizontal and systematic technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as occupation, weak spanning ability, and unsightly appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

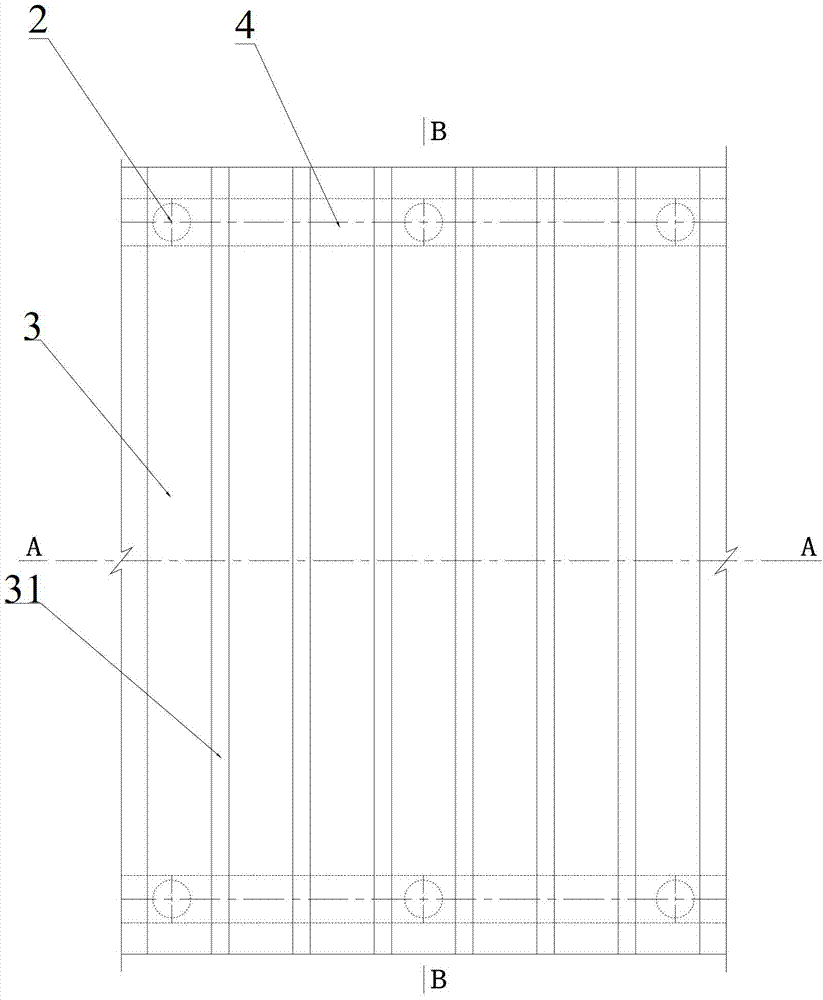

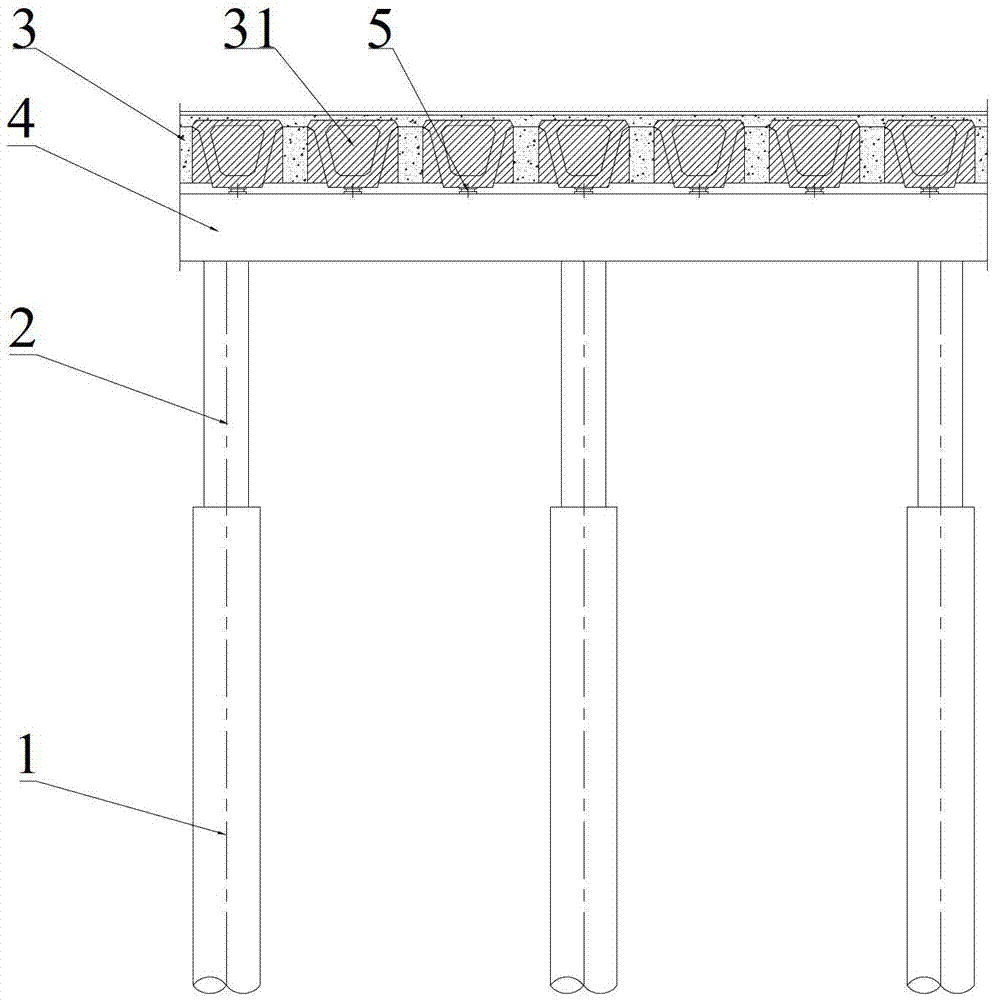

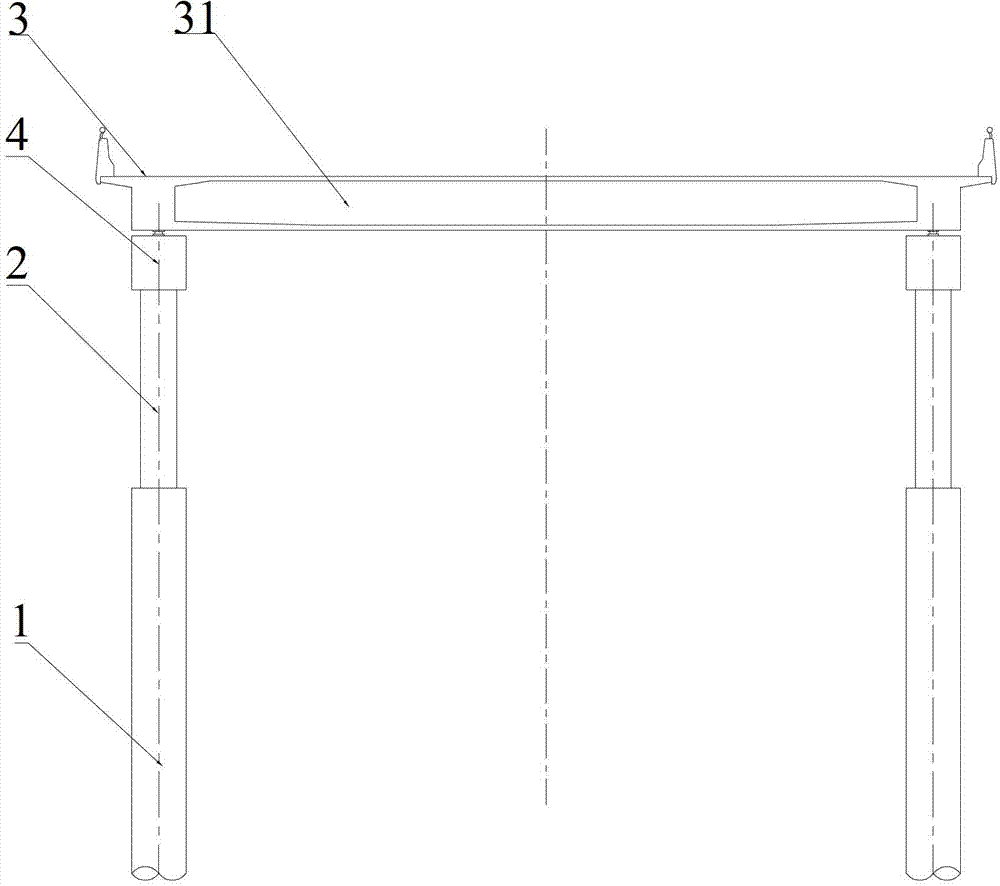

[0020] refer to Figure 1 to Figure 7 , the present invention provides a beam bridge with a transverse bearing system, comprising several foundation piles 1, pier columns 2 arranged on the upper side of the foundation piles 1, and a bridge deck 3 arranged on the upper side of the pier columns 2, and the gap between the pier columns 2 and the bridge deck 3 A cover beam body 4 is arranged longitudinally along the bridge deck 3 , and the bridge deck 3 includes a plurality of transverse unit beams 31 arranged on the upper side of the cover beam body 4 along the bridge deck 3 transversely.

[0021] In the girder bridge of this transverse load-bearing system, the cover beam body 4 is arranged longitudinally between the pier column 2 and the bridge deck 3 along the bridge deck 3, and is located on both sides of existing obstacles. The number of pier columns 2 and the span of the cover beam body 4 can vary Freely adjust according to the weight of the obstacles under the bridge and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com