sliding door

A technology of sliding doors and door rows, which is applied in the field of sliding doors, can solve problems such as wasting door opening clearance, and achieve the effects of reducing floor space, saving door opening clearance, and eliminating stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

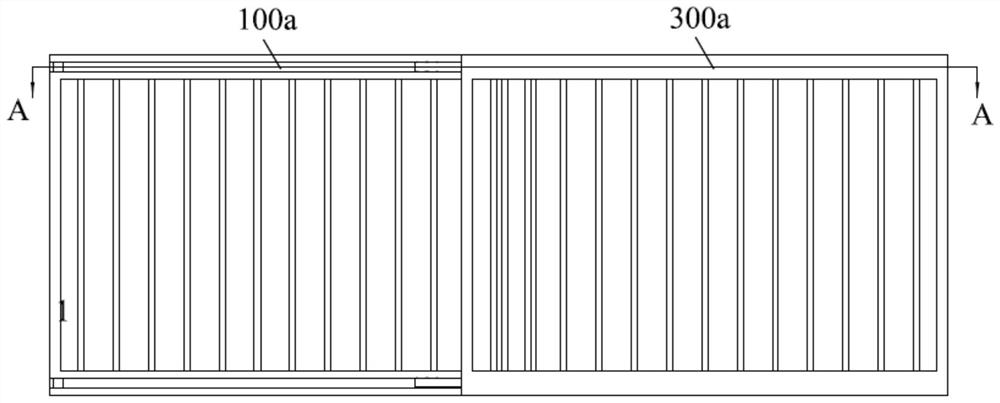

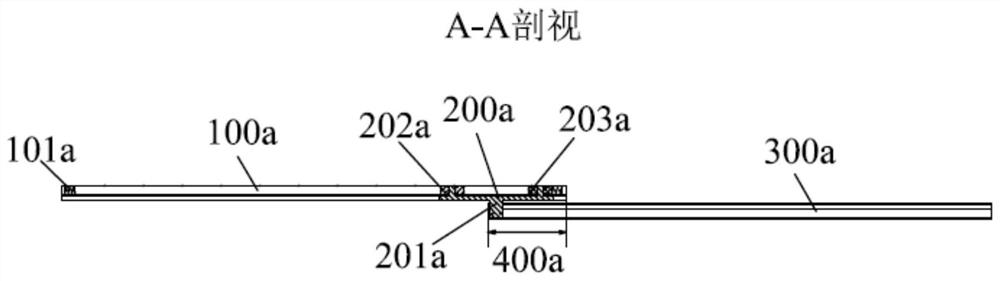

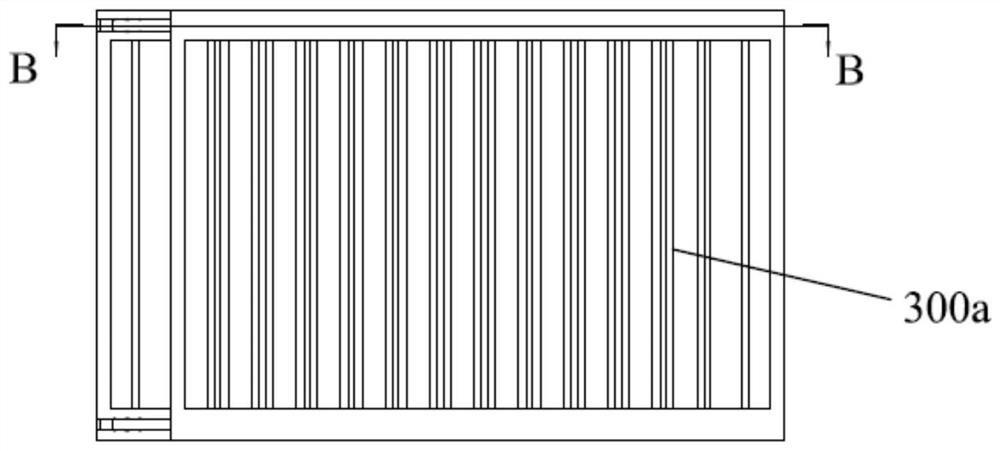

[0067] see Figure 5 to Figure 9 , the translational door of the first embodiment of the present invention includes a guide assembly 200, a door row assembly 100 and a door row assembly 300, and the door row assembly 100 includes a door row main body 105, a face beam 103, a face beam 104, and a door row top opening Limit 101, door closing limit 102 at the top of the door row, door opening limit 106 at the bottom of the door row, and door closing limit 107 at the bottom of the door row. The surface beam 103 is fixed on the top of the door row main body 105, and the surface beam 104 is fixed at the bottom of the main body 105 of the door row. The door row assembly 300 includes a door row main body 305, a face beam 303, a face beam 304, a door row top door opening limiter 301, a door row top door closing limiter 302, a door row bottom door opening limiter 306 and a door row bottom door closing limiter 307 , the face beam 303 is fixed on the top of the door row main body 305 , an...

no. 2 example

[0095] see Figure 10 , the translation door provided by the second embodiment of the present invention, the guide bracket 205 includes a first frame body 2051 and a second frame body 2052 arranged in parallel, and the first frame body 2051 and the second frame body 2052 are connected The middle frame body 2053.

[0096] The difference between this embodiment and the first embodiment is that the first guide includes a first guide wheel 201b rotatably connected to the first frame body 2051, and the second guide includes a first guide wheel 201b rotatably connected to A second guide wheel 202b on the second frame body 2052 . The guide bracket 205 is provided with a guide wheel shaft 2054 , and the first guide wheel 201b and the second guide wheel 202b are both rotatably connected to the corresponding guide wheel shafts 2054 . The outer end of the guide wheel shaft 2054 is provided with a hoop 206 to prevent the first guide wheel 201b and the second guide wheel 202b from fallin...

no. 3 example

[0099] see Figure 11 In the translation door provided by the third embodiment of the present invention, the guide bracket 501 includes a first frame body 5011 and a second frame body 5012 arranged in parallel, and the first frame body 5011 and the second frame body 5012 are connected The intermediate frame body 5013.

[0100] The difference between this embodiment and the second embodiment is that the first guide includes a first slider 502 fixedly connected to the first frame body 5011, and the second guide includes a first slider 502 fixedly connected to the first frame 5011. Describe the second slider 503 on the second frame body 5012. The guide bracket 501 is provided with an installation shaft 5014 , and the first slider 502 and the second slider 503 are installed on the respective corresponding installation shafts 5014 . The outer end of the installation shaft 5014 is provided with a hoop 504 to prevent the first sliding block 502 and the second sliding block 503 from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com