A fully loaded self-moving anti-fall and anti-skid hydraulic support

A hydraulic support, full load-bearing technology, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., can solve the problem of difficult deflection and other problems, and achieve the effects of difficult deflection, reasonable space and good overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

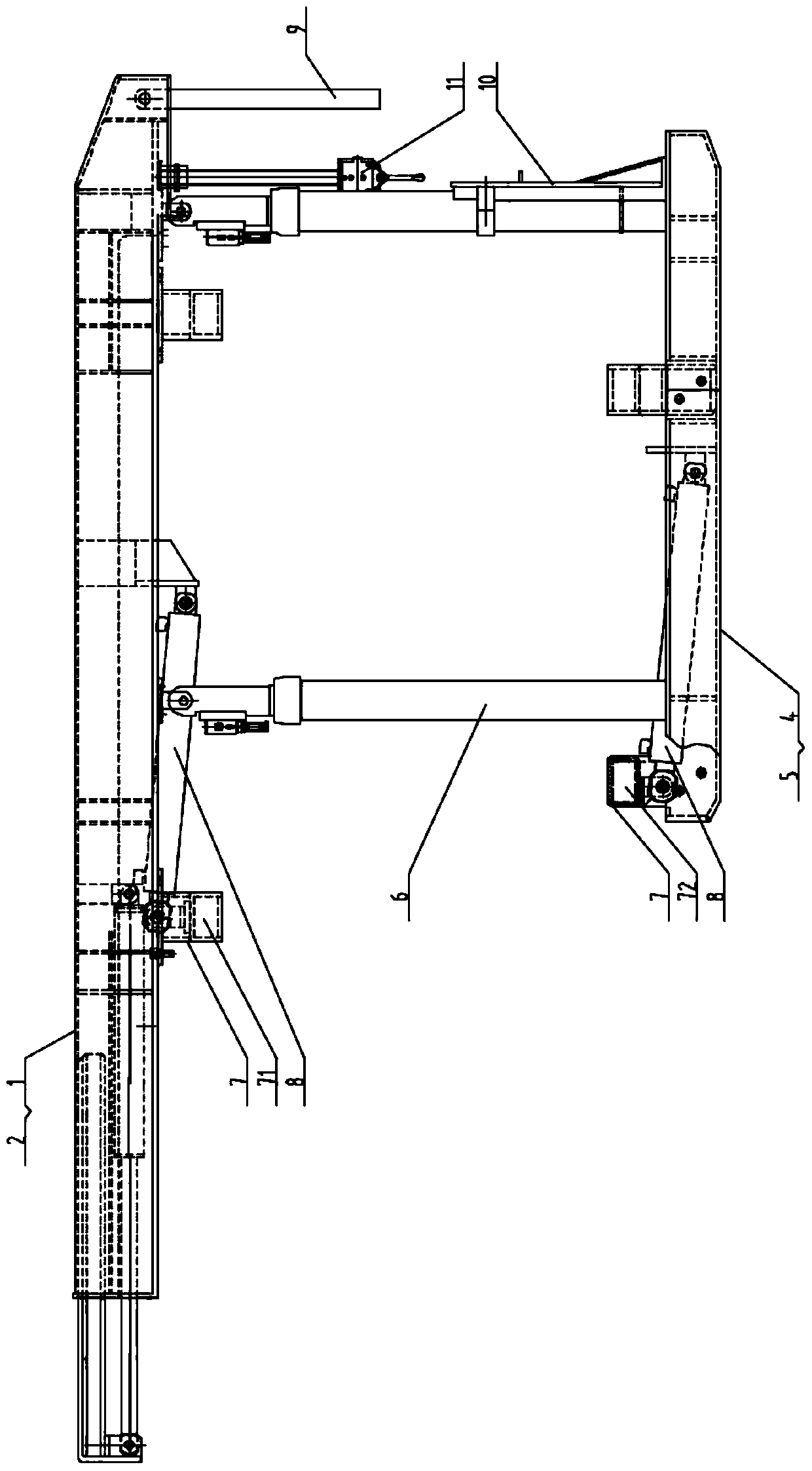

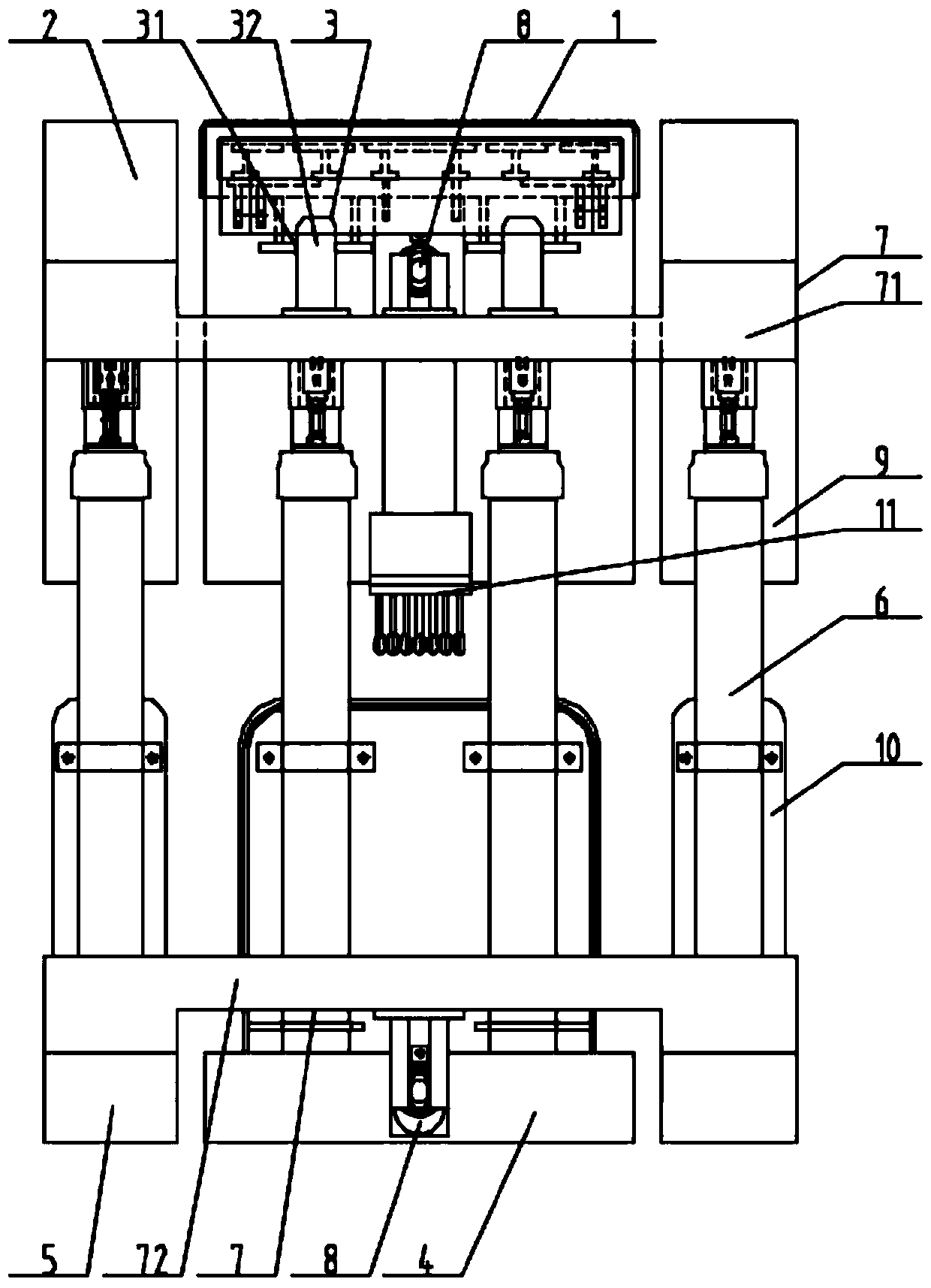

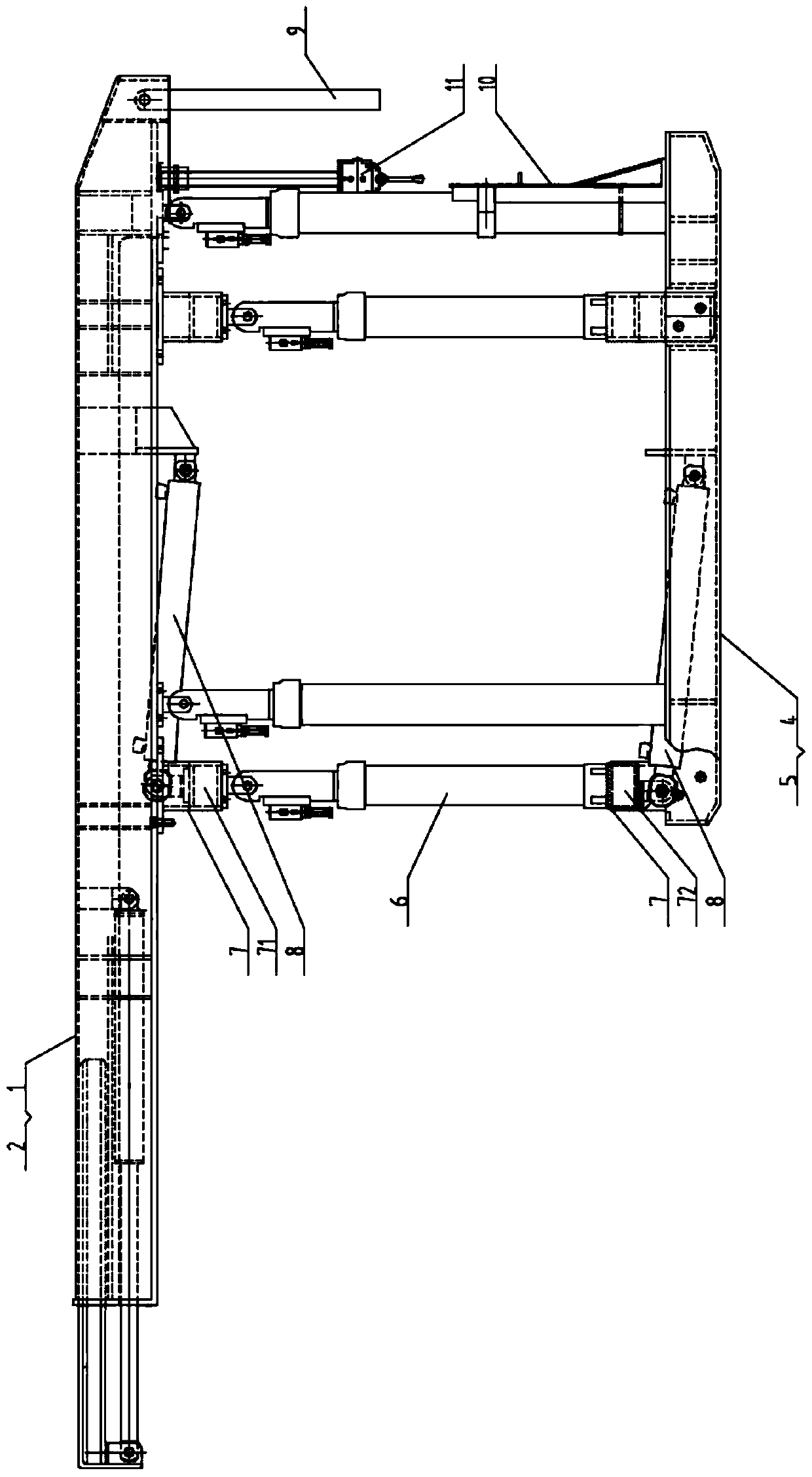

[0037] like Figure 1 to Figure 4As shown, the fully loaded self-moving anti-falling anti-skid hydraulic support includes a main top beam 1, an auxiliary top beam 2, a top beam connecting device 3, a main base 4, an auxiliary base 5, a column 6, a horizontal connecting device 7 and a moving jack 8 .

[0038] The main top beam 1 is arranged at the middle position of the whole full load self-moving anti-fall anti-skid hydraulic support, and its front end is provided with a front telescopic beam.

[0039] Described sub-top beam 2 is arranged as two pieces, symmetrically arranged on the left and right sides of main top beam 1, and the length dimension of sub-top beam 2 top plate is the same as the length dimension of main top beam 1, and the width dimension is smaller than that of main top beam 1 Width dimension.

[0040] The roof beam connecting device 3 is arranged be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com