Brick wall reinforcing method and structure

A brick wall and wall technology, applied in the field of masonry structure reinforcement, can solve problems such as the inability to produce occlusal action, easy cracks in brick walls, and unsatisfactory reinforcement effects, and achieve good reinforcement effects, simple construction, and improved bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, but not as any limitation to the present invention.

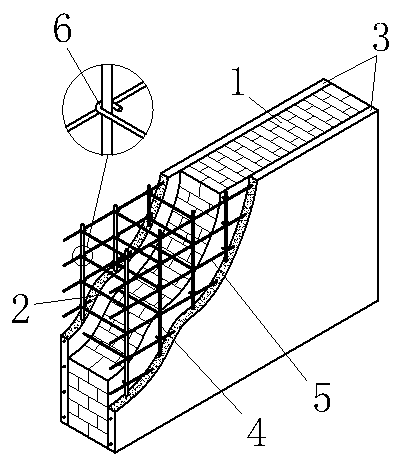

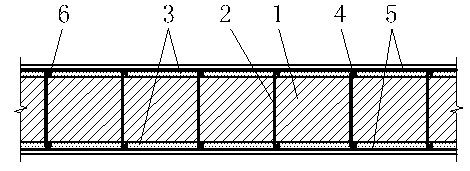

[0028] A method of strengthening a brick wall such as figure 1 with figure 2 shown. The method is constructed according to the following procedures:

[0029] ①. Remove the mortar layer on both sides of the brick wall to be reinforced;

[0030] ②. Remove the loose bricks on the surface of the brick wall, clean them with water, and then repair the removed part with cement;

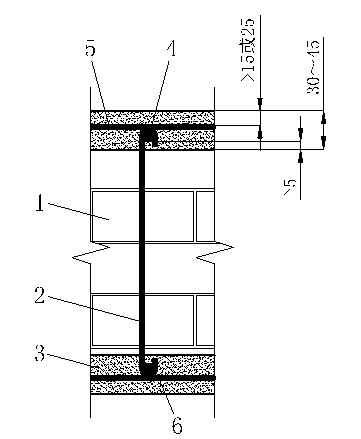

[0031] ③. Bind or weld steel mesh sheets with steel bars and attach them to both sides of the brick wall; the steel mesh sheets are bound or welded with criss-cross steel bars; the longitudinal steel bars are compression steel bars, and HPB300 steel bars with a diameter of not less than 8mm are used. The net distance of longitudinal reinforcement is not less than 30mm; the diameter of transverse reinforcement is 4-6mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com