Fully mechanized mining recovery technology with large mining height and large mining height in complex thick coal seam with large dip angle structure

A technology with complex structure and thick coal seam, which is used in surface mining, mining equipment, earth-moving drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

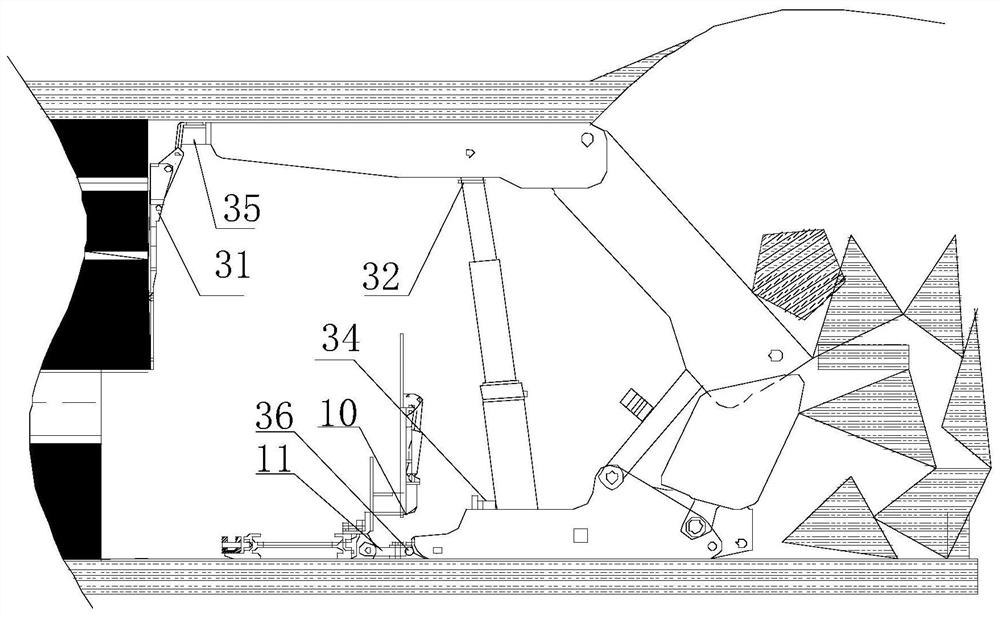

Embodiment Construction

[0033] The present invention is further described below.

[0034] The fully mechanized mining recovery technology disclosed by the present invention has a complex thick coal seam with a large dip angle structure and a large mining height, comprising the following steps:

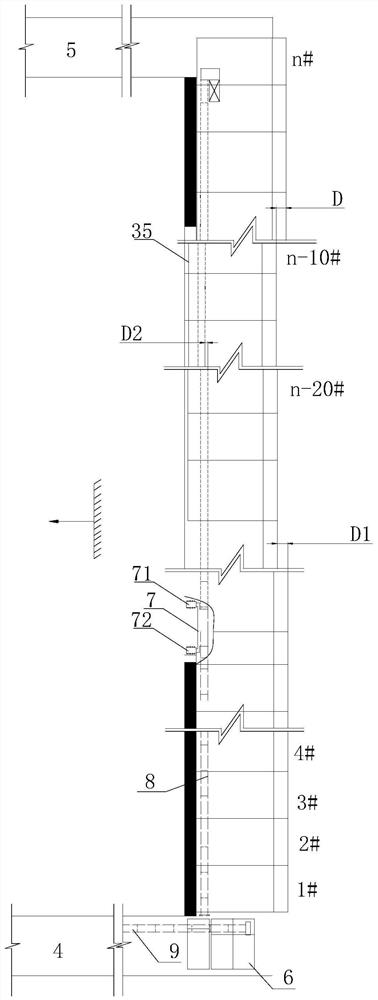

[0035] The coal shearer enters the knife from the end of the working face without cutting, such as figure 2 As shown, a section of uncut coal is reserved near the upper end of the air return lane 5, and the shearer 7 starts cutting coal directly from below, and the shearer 7 cuts coal downwards, that is, from the upper return air lane 55 downward toward the bottom The transport lane 4 of the transport lane cuts coal in sequence, and the upward direction refers to the movement from the transport lane 4 below to the return air lane 55 above;

[0036] Follow the shearer 7 to move the hydraulic support 3 for the first time, and the moving distance is less than the depth of the shearer 7;

[0037] Move the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com