Patents

Literature

30results about How to "Prevent roof fall accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surrounding rock plastic zone size-based quantitative roadway support design method

ActiveCN108062439APrevent roof fall accidentsSupport parameters are scientific and reasonableMining devicesDesign optimisation/simulationSite monitoringGeomorphology

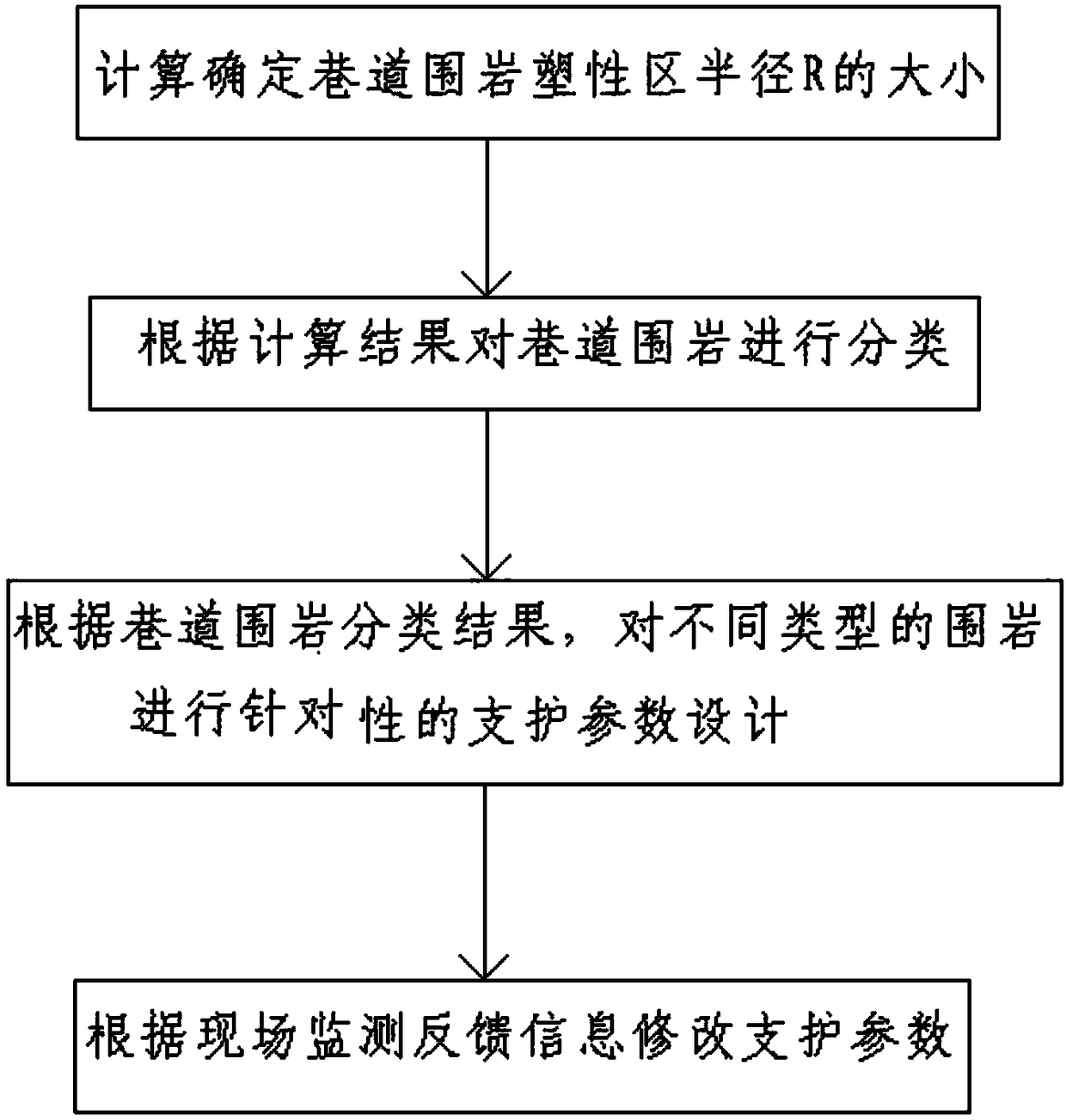

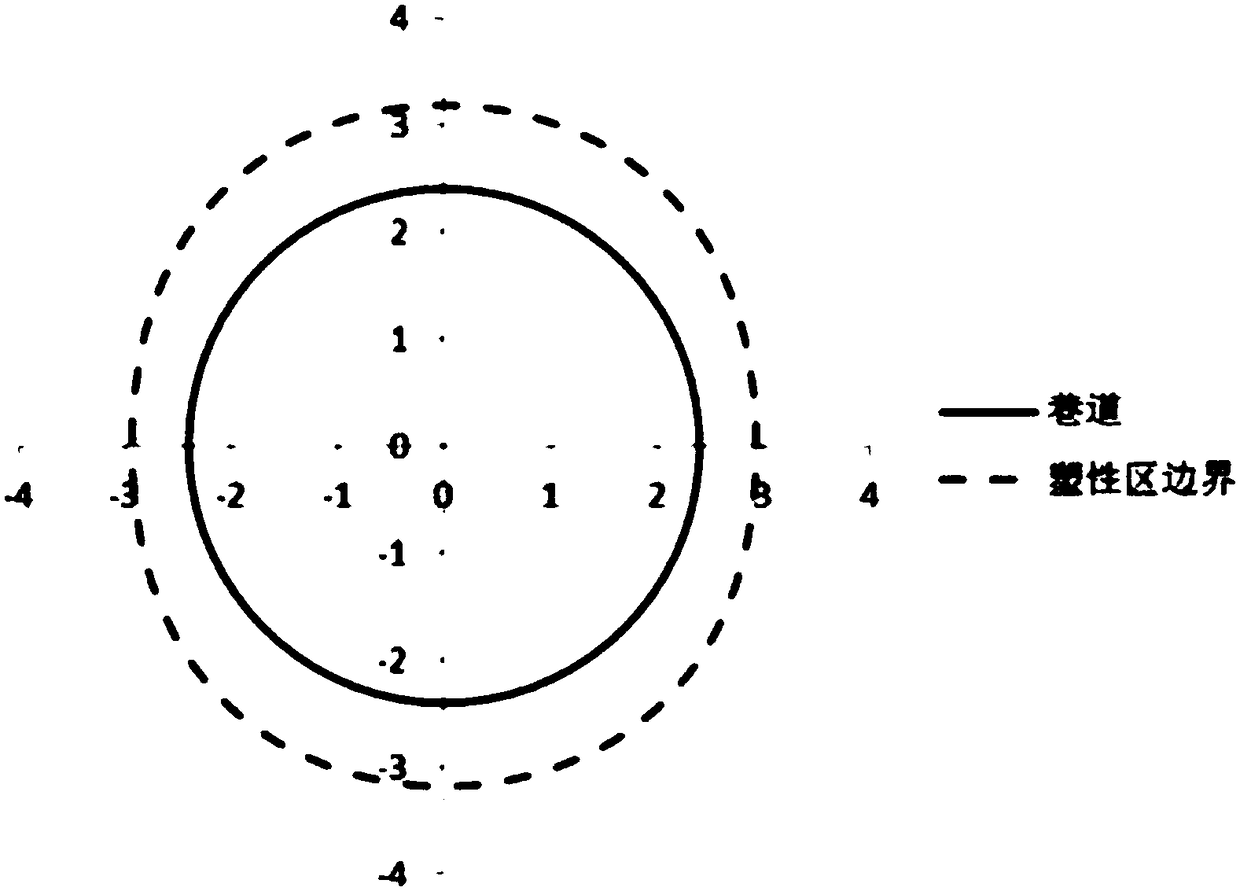

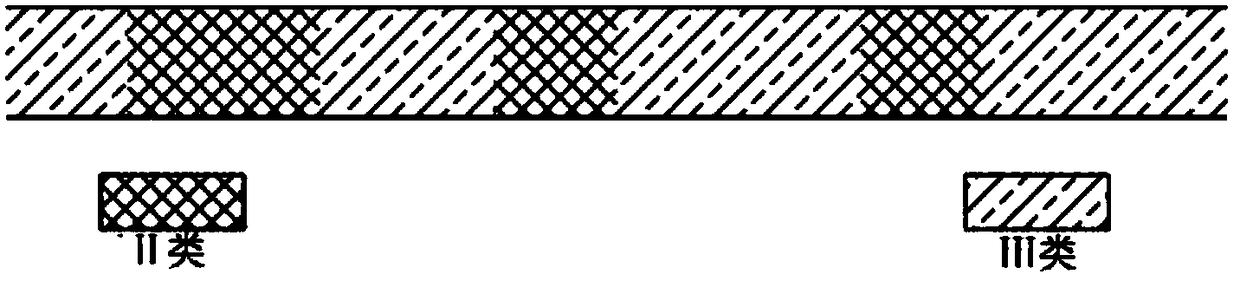

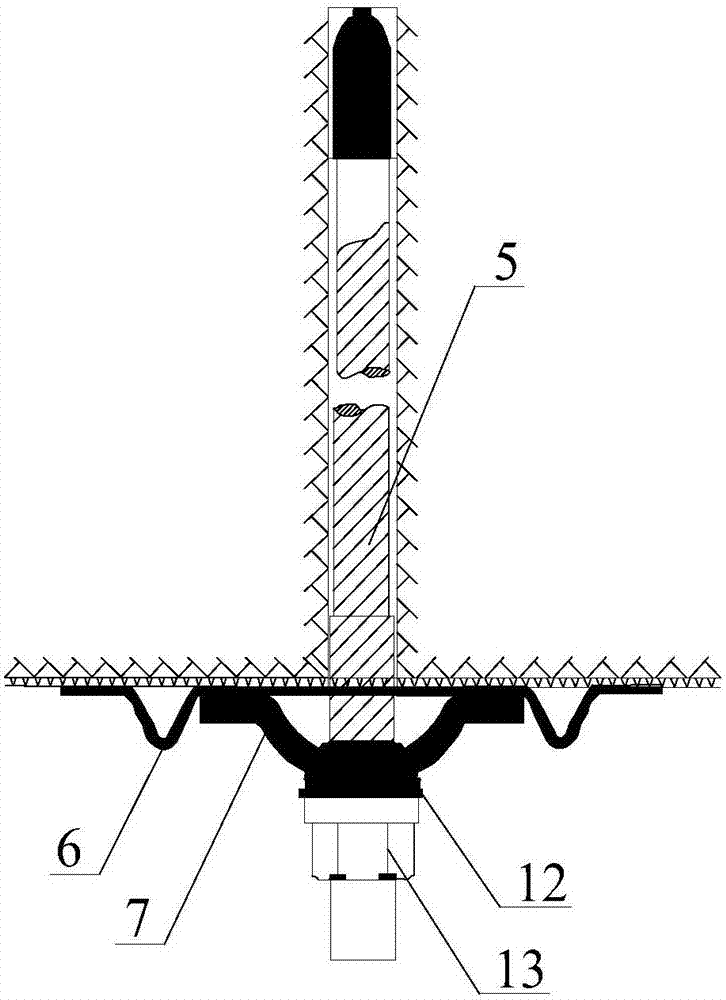

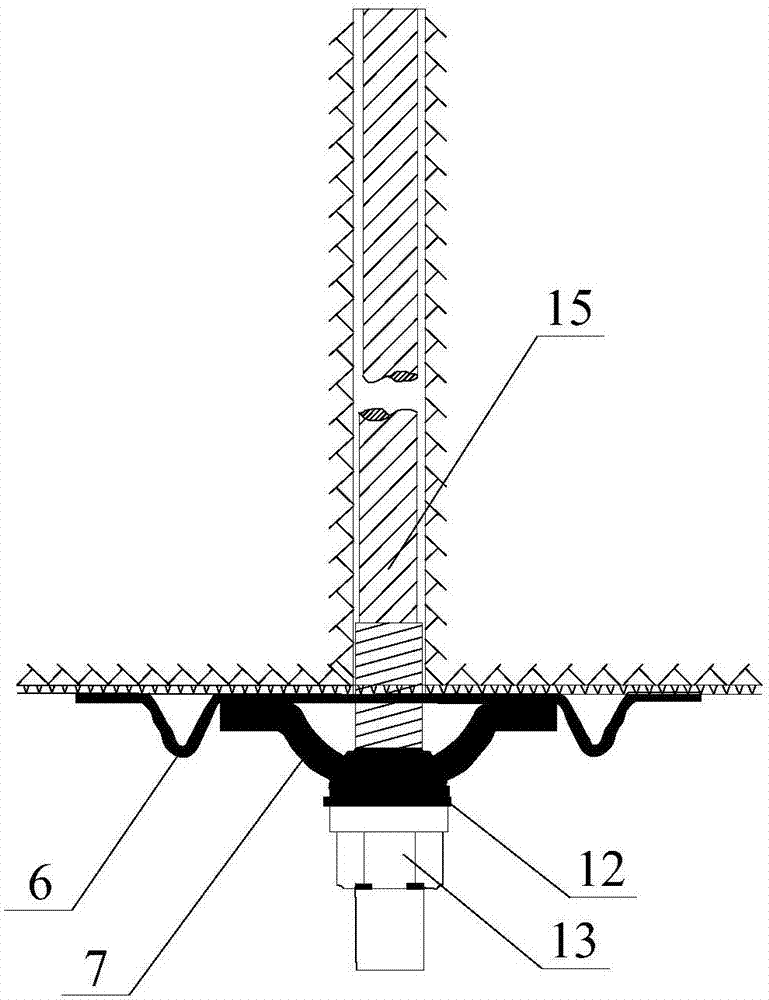

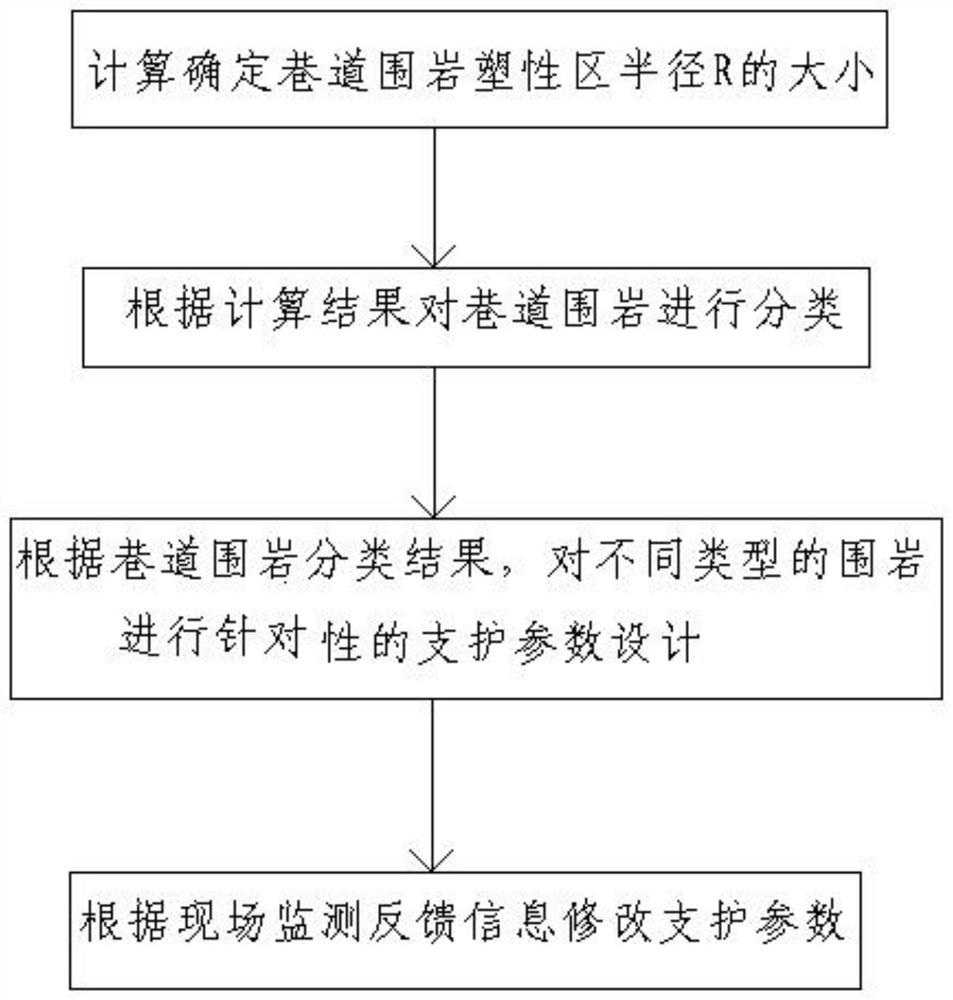

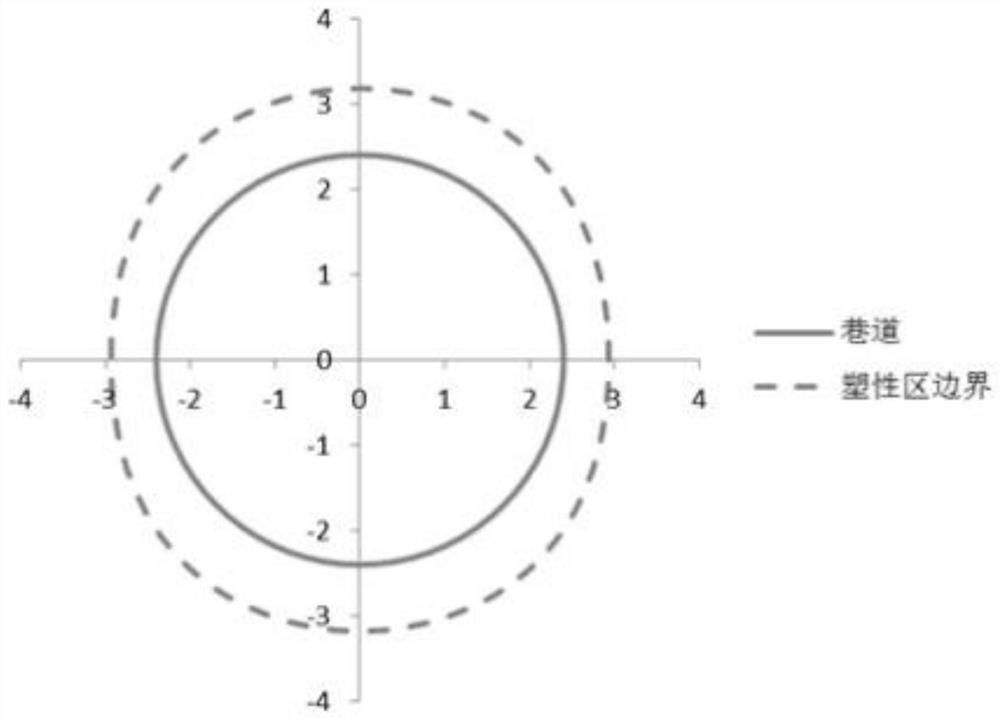

The invention discloses a surrounding rock plastic zone size-based quantitative roadway support design method. The method comprises the following steps of: 1, carrying out calculation to determine a size of a radius R of a roadway surrounding rock plastic zone; 2, classifying roadway surrounding rocks according to the calculation result; 3, carrying out targeted support parameter design on different types of surrounding rocks according to the roadway surrounding rock classification result; and 4, modifying and adjusting support parameters according to on-site monitoring feedback information. According to the method, support parameters designed on the basis of plastic zone sizes are scientific and reasonable, and roadway surrounding rock classification is carried out by taking plastic zoneradius sizes as main indexes, so that targeted support parameter design is carried out on different types of surrounding rocks so as to ensure the scientificity and economy of roadway support design.For roadway support, the method is capable of playing a part of preventing roadways from roof fall accidents.

Owner:XIAN UNIV OF SCI & TECH

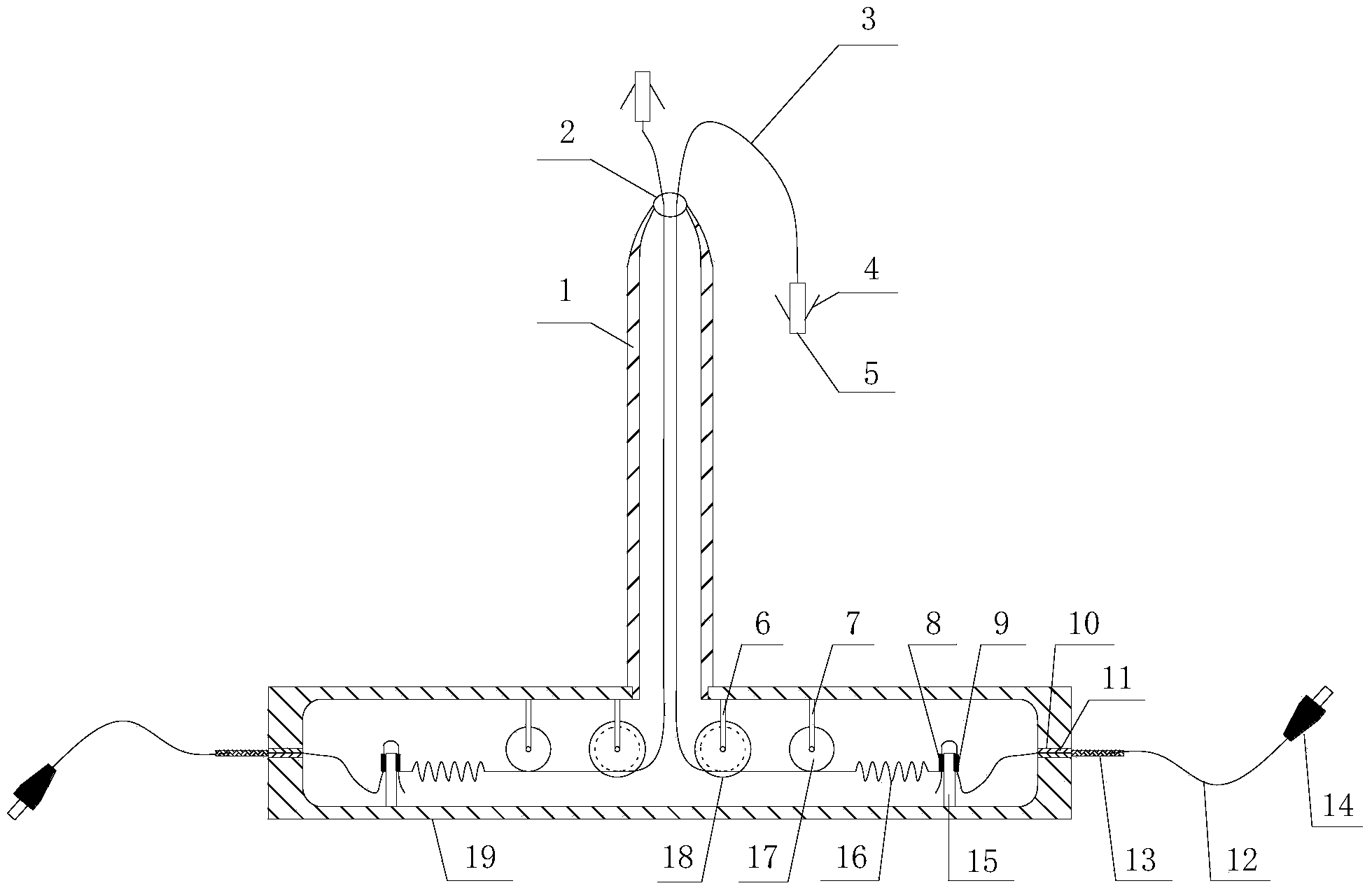

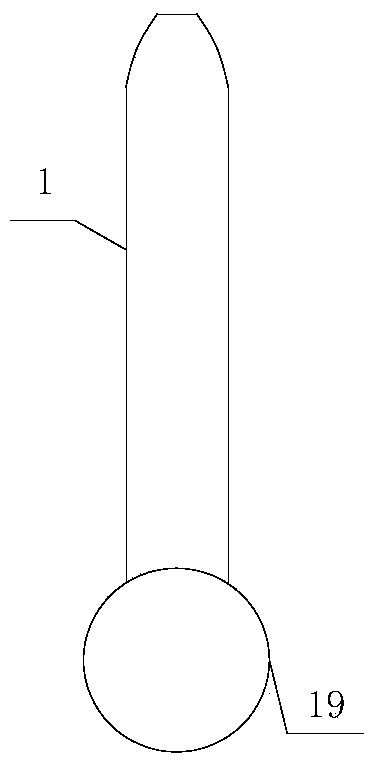

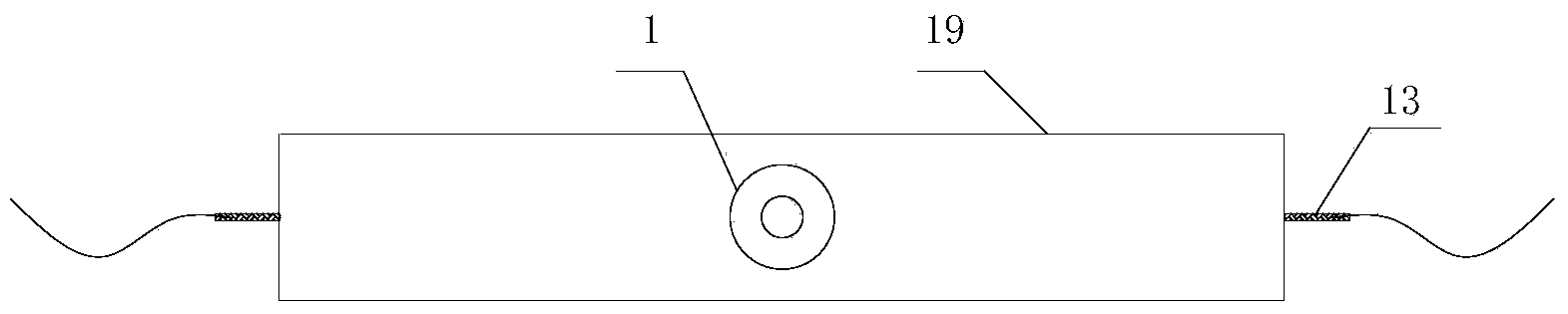

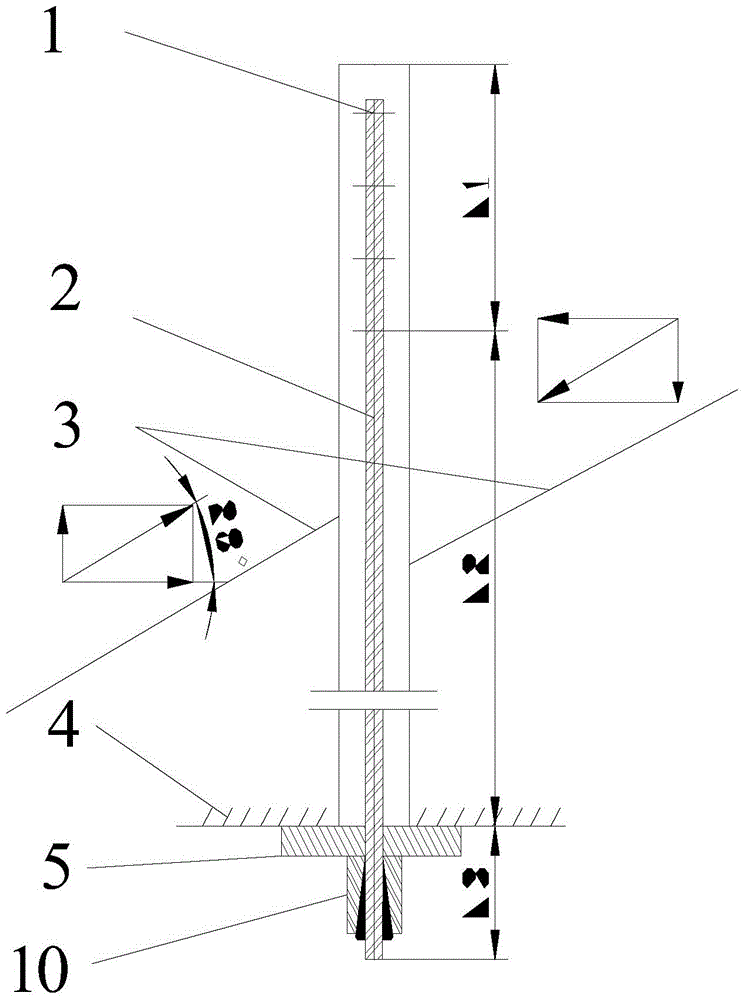

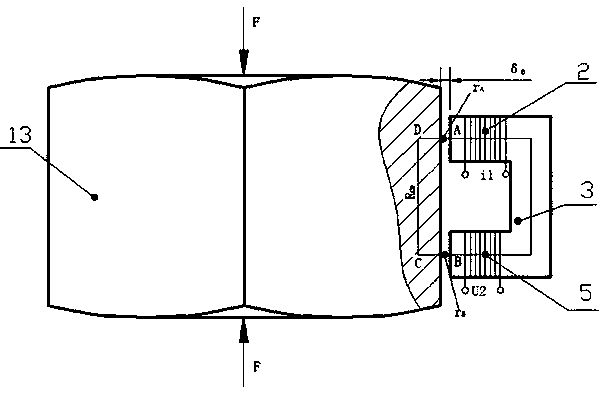

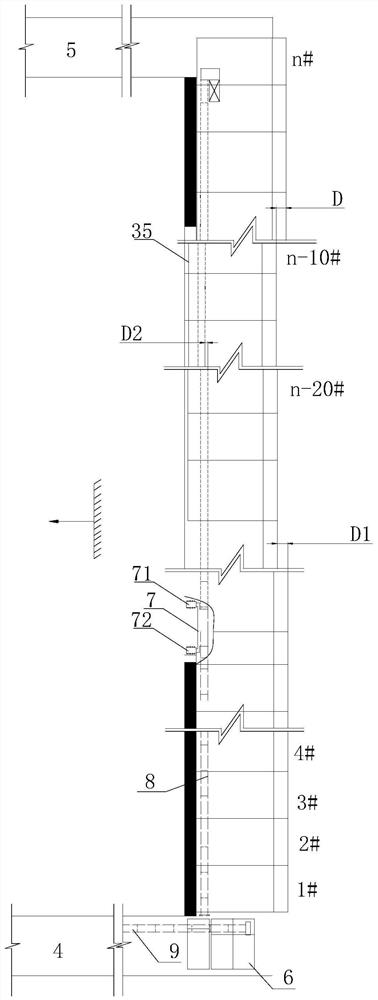

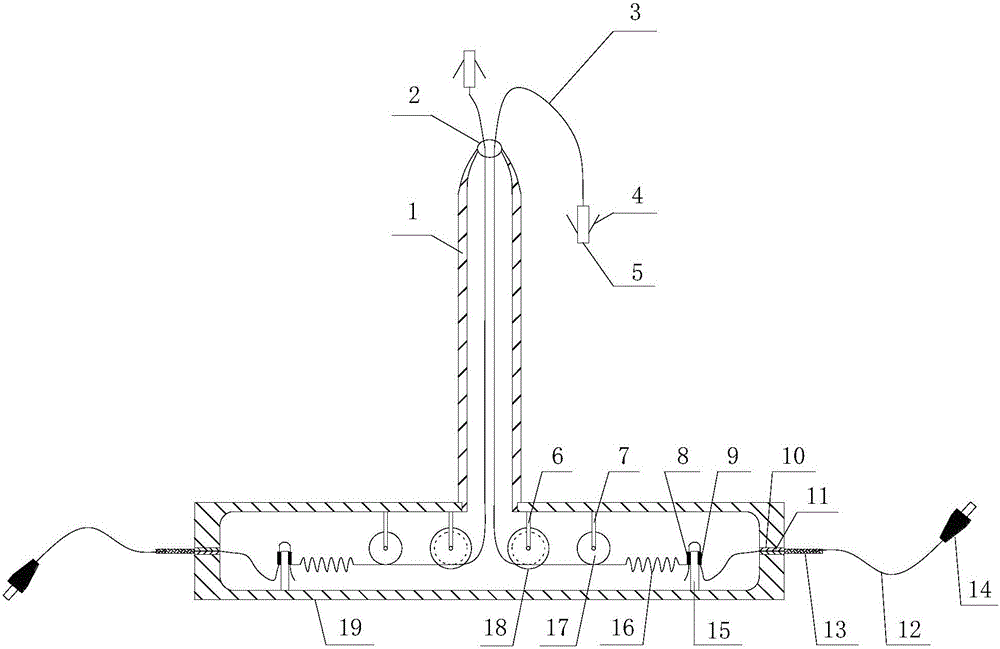

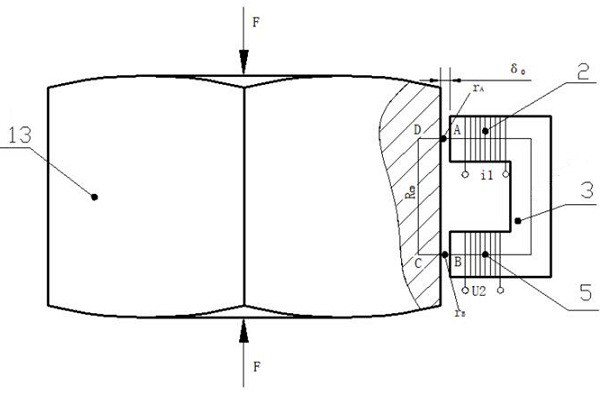

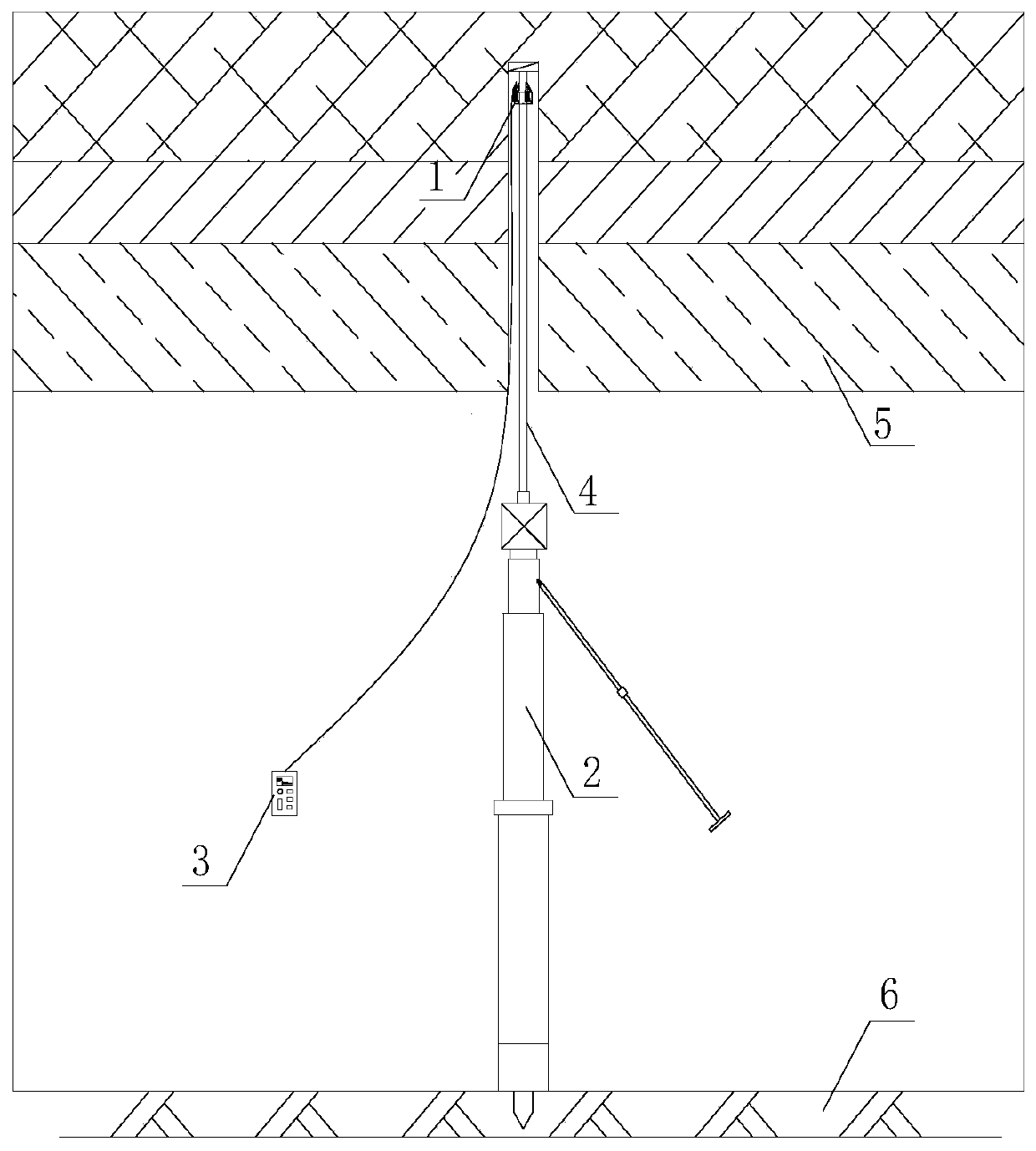

Monitoring device and monitoring method for mining FBG (fiber bragg grating) roof separation layer

ActiveCN103528530ARealize online measurementTimely warningMining devicesTesting machinesGratingBoundary values

The invention provides a monitoring device and a monitoring method for a mining FBG roof separation layer. The device comprises a vertical measurement barrel and a packaging casing, wherein fixed pulleys, tape pulleys and constant-strength cantilever beams are symmetrically arranged in the packaging casing; a steel wire rope penetrates through the tape pulleys and the fixed pulleys and penetrates out from a steel wire rope guide hole in the top part of the vertical measurement barrel; one end of the steel wire rope is connected with an anchor head; a shallow part measurement point and a deep part measurement point are distributed inside a drill hole; the anchor head is pushed to the measurement points in the drill hole; when the stress of the steel wire rope changes, the stress change is displayed through wavelength values of an FBG A and an FBG B; a wavelength demodulation device is used for demodulating the wavelength values into digital signals, the digital signals are sent to a computer for real-time processing, and a separation layer numerical value is combined for drawing a separation layer quantity changing curve and a set separation layer boundary value; whether the separation layer exists is judged; and the data change of the roof separation layer is monitored in real time. Temperature compensation is performed with a differential form, on-line measurement of the roof separation layer is realized, the reliability and the accuracy are high, an early warning signal can be issued, and roof fall accidents can be avoided.

Owner:CHINA UNIV OF MINING & TECH

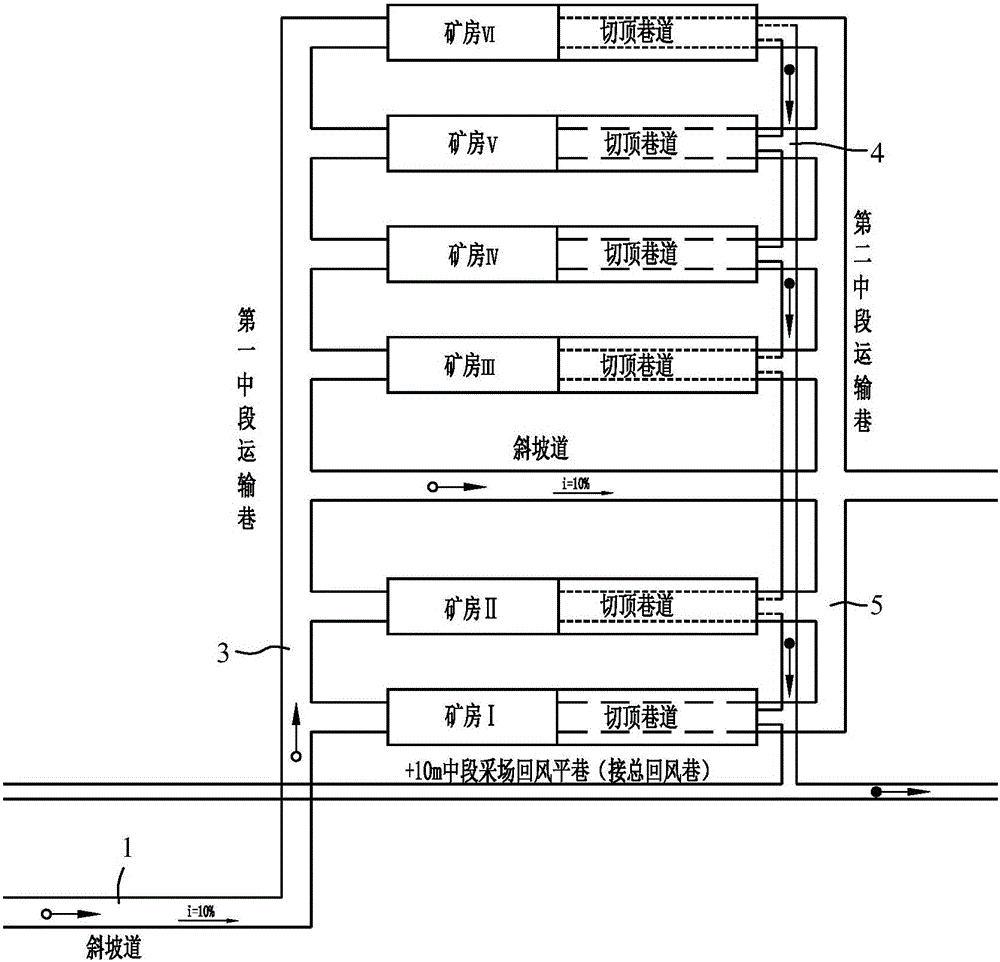

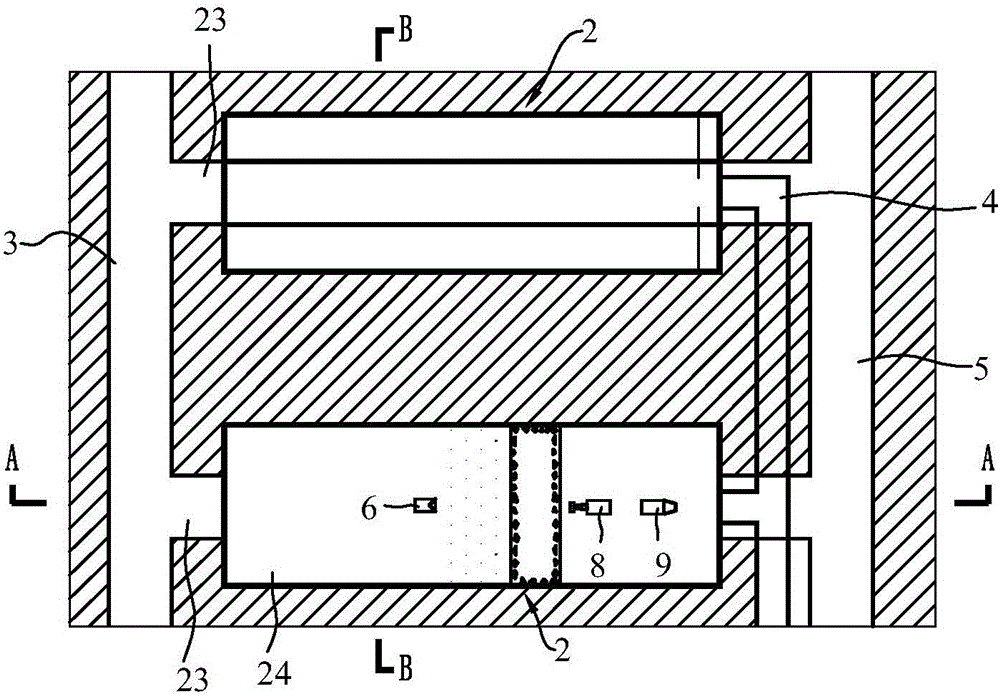

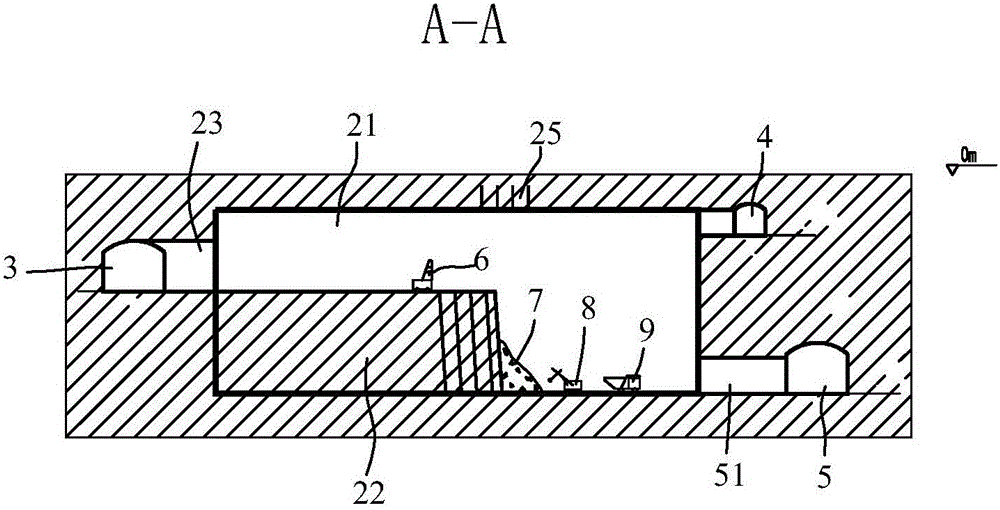

Medium-deep hole room pillar mining method for limestone underground mine mining

InactiveCN104989402AHigh degree of mining mechanizationImprove labor productivityUnderground miningSurface miningRoom and pillar miningStop time

The invention discloses a medium-deep hole room pillar mining method for limestone underground mine mining. The method comprises the steps of: S10. exploiting a ramp, tunneling a first intermediate section haulage roadway along the front end of a to-be-mined stope room from the ramp, and tunneling an air return roadway along the rear end of the to-be-mined stope room from the ramp; S20. dividing an upper sub-layer and a lower sub-layer; S30. stoping the upper sub-layer, tunneling a roof cutting roadway, conducting slope expansion on the roof cutting roadway to form a roof cutting space in the stope room, transporting the ores generated by slope expansion out of the ground surface by the ramp; and S40. stoping the lower sub-layer, tunneling a second intermediate section haulage roadway from the ramp, blasting the lower sub-layer, and transporting the generated ores out of the ground surface by the ramp. The method provided by the invention has the advantages of small mining preparation workload, simple process and good ventilation conditions, etc. The labor production efficiency is high, the mining cost is low, and the ore block production capacity is large. The method can reduce the number of underground workers, shorten ore block stoping time, reduce the exposure time of workers in an open stope, and prevent roof fall accidents, and is a safe and efficient mining method.

Owner:GUANGDONG METALLURGICAL & ARCHITECTURAL DESIGN INST

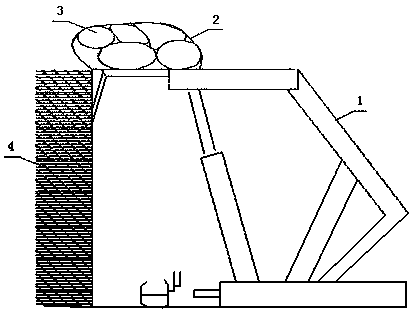

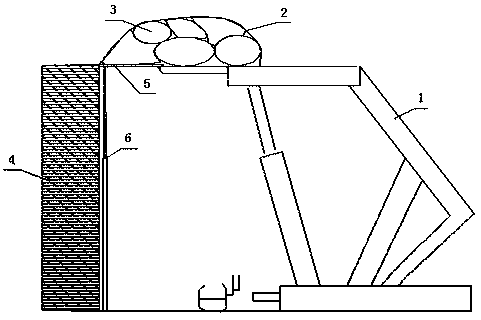

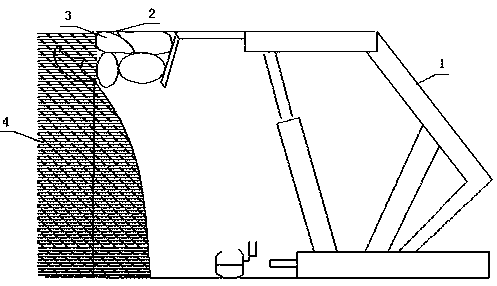

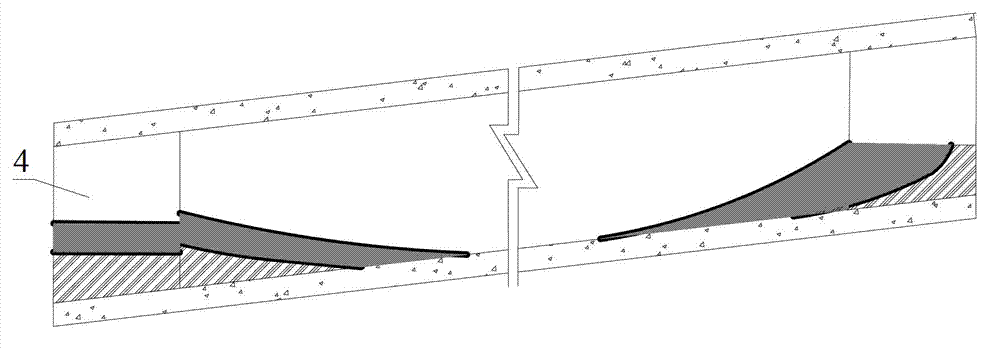

Methods for treating fully mechanized coal mining face roof accidents through flexible air bags

InactiveCN107687348AEffective controlPrevent roof fall from exacerbatingMining devicesEngineeringCantilever

The invention relates to methods for treating fully mechanized coal mining face roof accidents through flexible air bags. The methods comprise the treatment method for fully mechanized coal mining face roof caving, the treatment method for fully mechanized coal mining face roof caving and wall caving, the treatment method for fully mechanized coal mining face coal wall cheek corner non-supporting,and the treatment method for fully mechanized coal mining face roadway wall non-supporting. According to the methods, the flexible air bags are adopted and are pressurized through air inflation to replace to cantilever slabs, driven nogs, backboards and driven columns to provide temporary support, and quick roof connection and wall sealing are ensured; and finally through timely pulling and moving of a support and control over a caved roof, a caved wall area, the coal wall cheek corners, the roadway walls and nearby surrounding rocks, the problems of fully mechanized coal mining face roof caving, the wall caving area, coal wall cheek corner non-supporting, roadway wall non-supporting and the like can be solved quickly, safely and reliably. The methods are simple, operation is easy, the effect is good, and the reliable guarantee is provided for construction safety; and the problems that as for existing methods, in the treating process, roof caving work and aloft work are needed, the construction technology is complex, the construction time is long, and the construction safety is difficult to guarantee are solved.

Owner:KAILUAN ENERGY CHEM

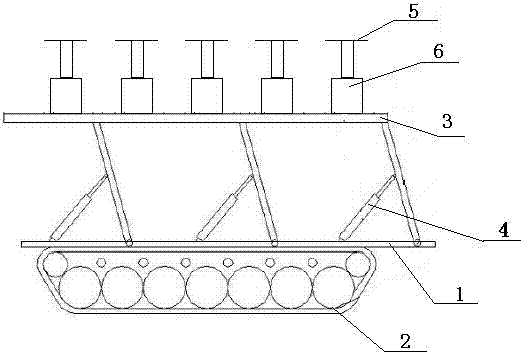

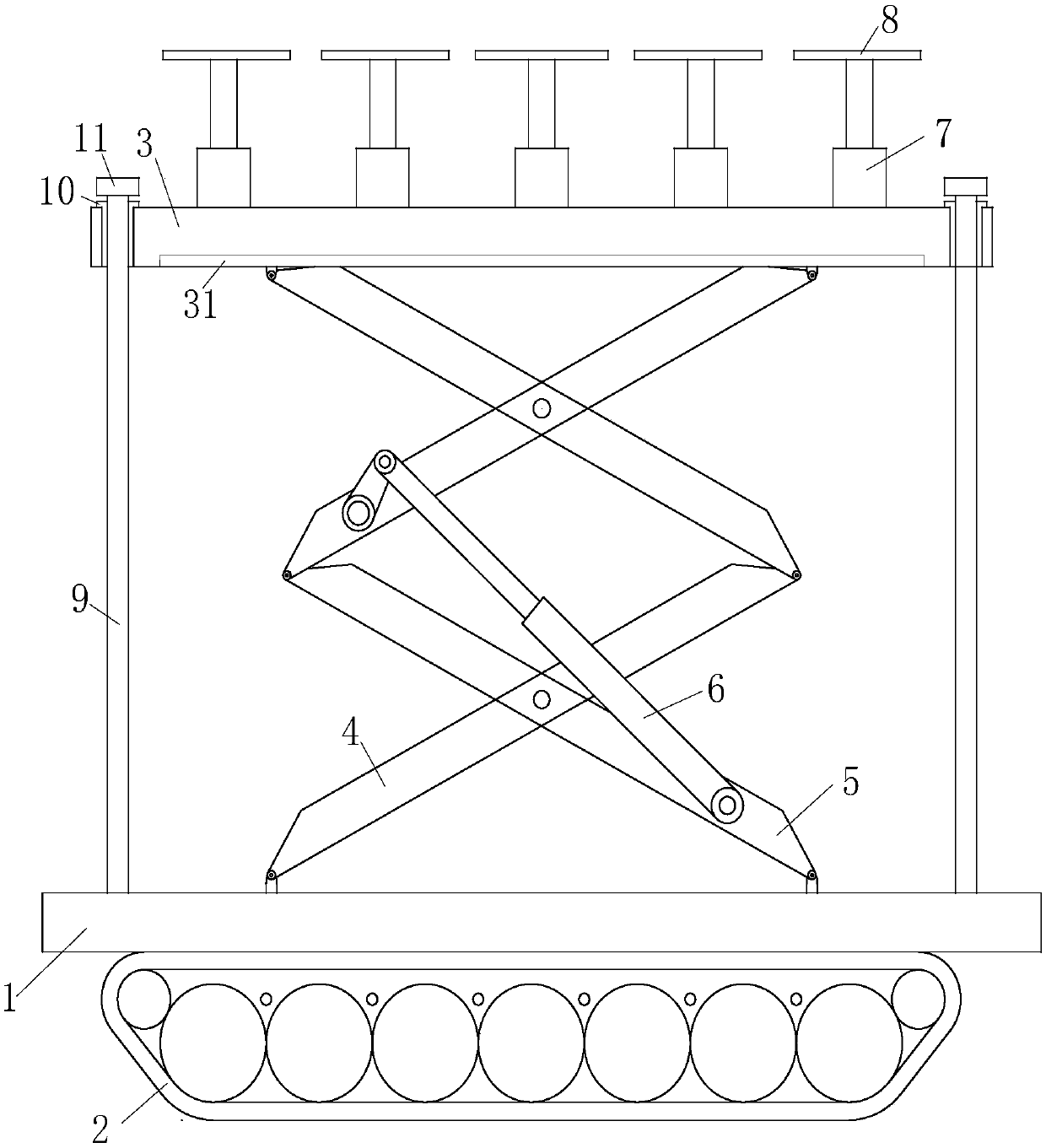

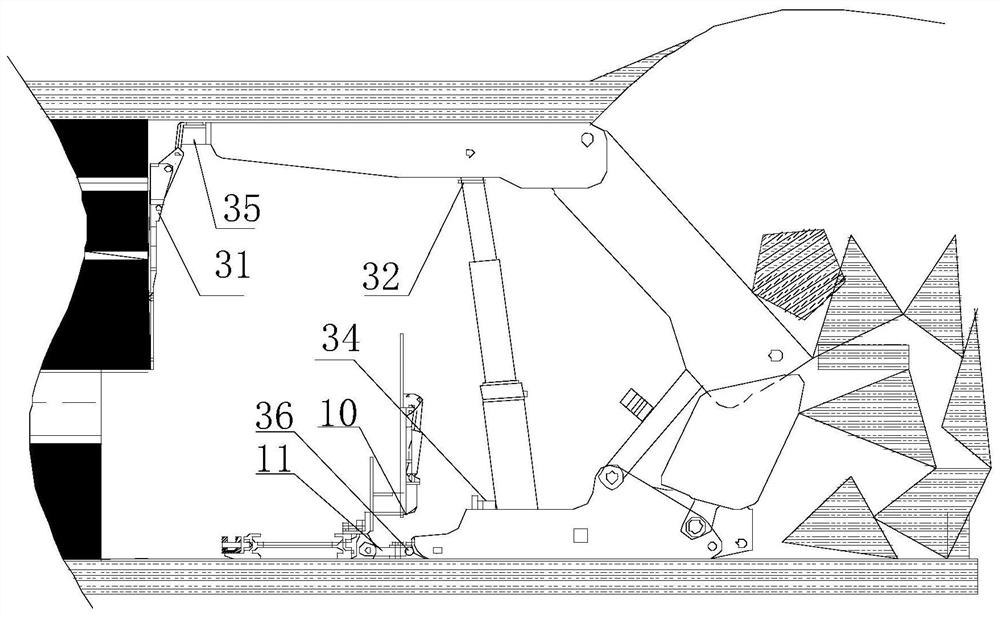

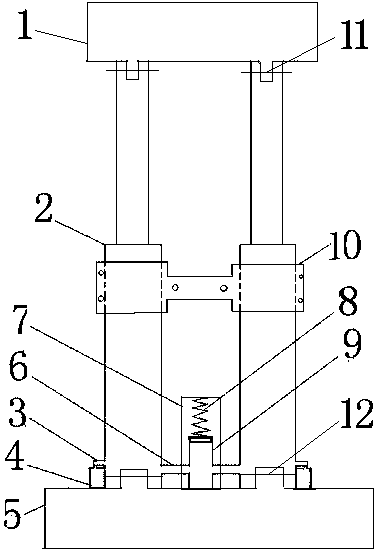

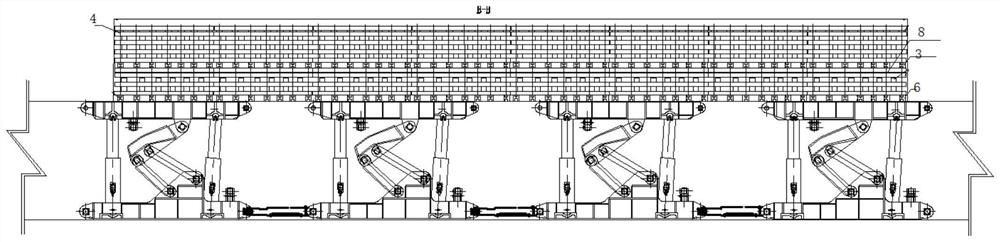

Exploitation tunneling shield support for mine

InactiveCN104712357AEnsure safetySimple structureMine roof supportsHydraulic cylinderMining engineering

The invention relates to an exploitation tunneling shield support for a mine. In the coal exploitation process, in order to prevent roof falling accidents, a hydraulic support needs to be used for timbering a top plate. As a top beam of the hydraulic support is rigid, and uneven loads between the top beam and the top plate will be caused by unevenness generated by directly supporting the plate, the local roof falling accidents will be easily caused, and even the safety hidden dangers of causing large mine roof falling accidents exist. The exploitation tunneling shield support for the mine comprises a base, the top beam, a crawler device and a first hydraulic cylinder, a plurality of second hydraulic cylinders are arranged on the top beam, and the top plate is connected to the top ends of the second hydraulic cylinders. The exploitation tunneling shield support has the advantages of being simple in structure, safe and convenient to operate, good in timbering performance, easy to apply and popularize and the like; the roof falling accidents can be effectively prevented, and the coal exploitation operation safety is guaranteed.

Owner:WESTERASOFT

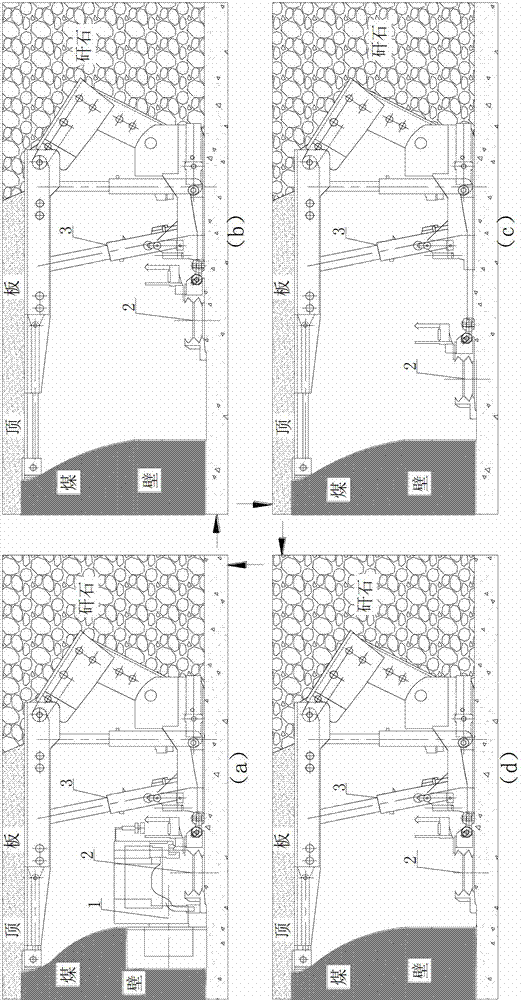

Top-shoveling and bottom-cutting type full-seam mining fully-mechanized coal mining method for extrasoft thick coal seam

InactiveCN103195427APrevent roof fall accidentsProtect in timeUnderground miningSurface miningMineralogyCost savings

The invention provides a top-shoveling and bottom-cutting type full-seam mining fully-mechanized coal mining method for an extrasoft thick coal seam. The method comprises the following steps of: tunneling along the top of a coal seam in a mining roadway, wherein a lapping mode with a working face is a slantwise lapping mode, namely according to the propelling degree in every, manually bottoming bottom coal along the propelling direction of the work surface in a fully mechanized coal mining work surface mining roadway, and recovering the bottom coal in the roadway by using the lapping method. In the recovery process, the girder end distance of a top girder of a support is approximate to zero or a negative value, the front end of a shovel type telescopic girder is provided with a coal shoveling board, and after the bottom coal is cut by a front expansion cylinder of a coal mining machine, the coal shoveling board can timely extend out, so that top coal can be shoveled under the condition that the top coal can not be sufficiently dribbled, an exposed roof can be timely protected, and the roof caving accident can be avoided. The stroke of the telescopic coal shoveling board is greater than a web of the coal mining machine, and fallen coal is filled by a back expansion cylinder. For the coal seam condition of the extrasoft (f is less than 0.5) thick coal seam (3.5-6m), the method has the advantages of being cost-saving, simple in technology, safe, high-efficiency and the like.

Owner:CHINA UNIV OF MINING & TECH

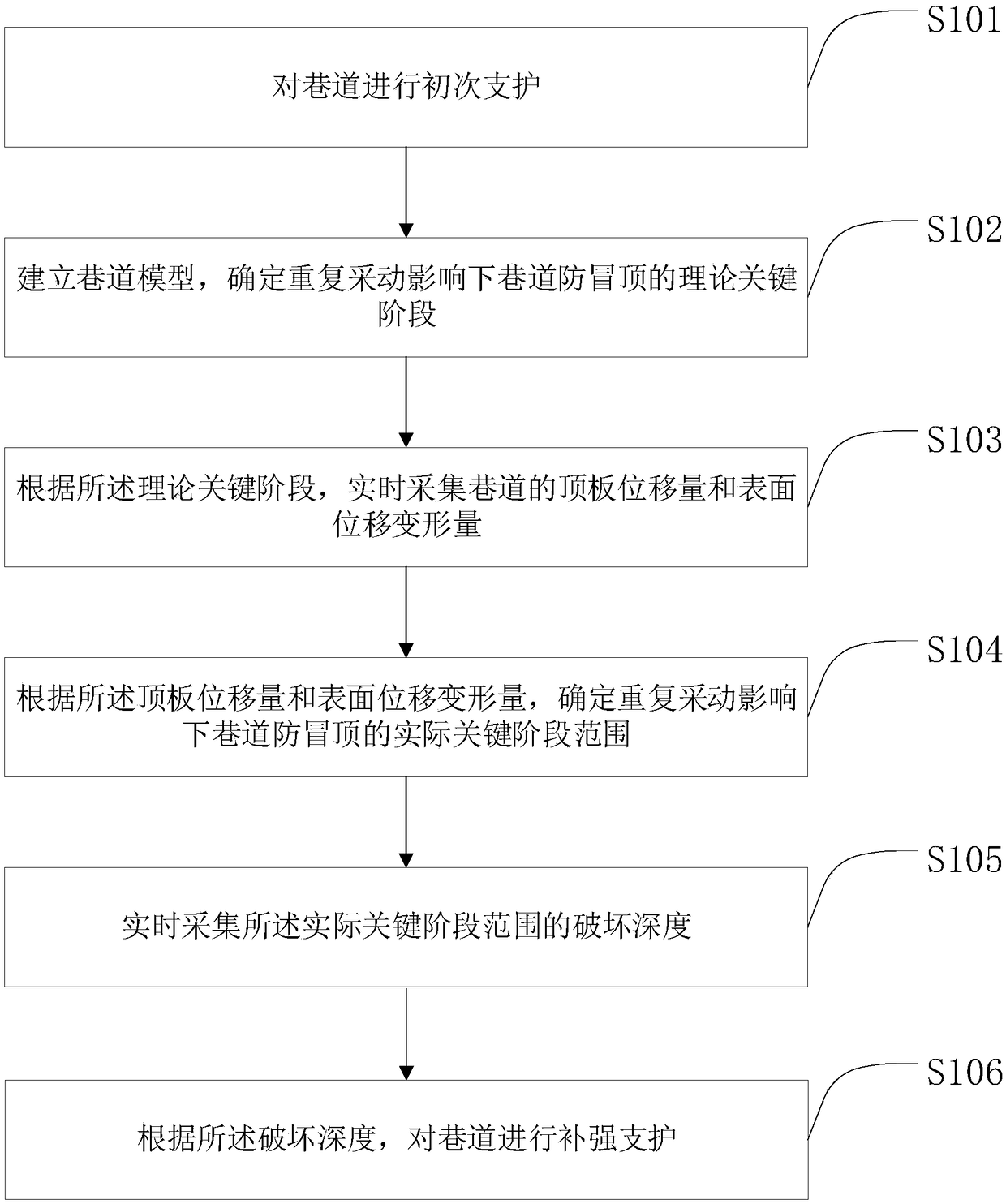

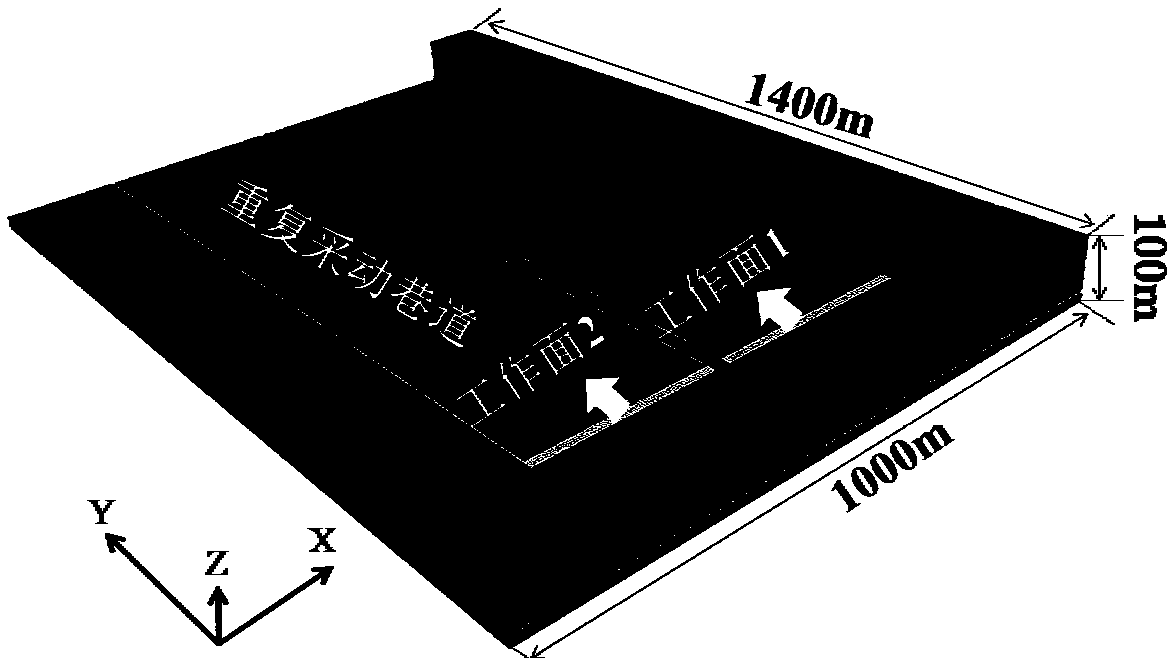

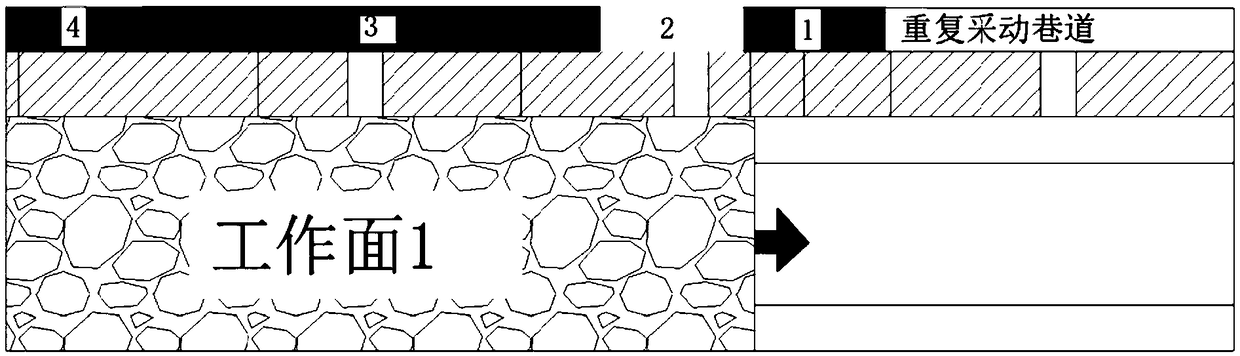

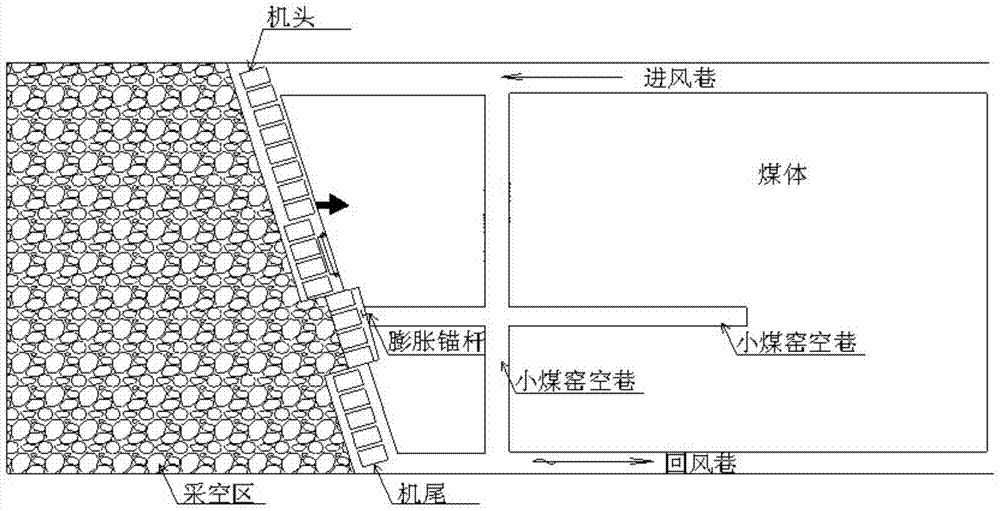

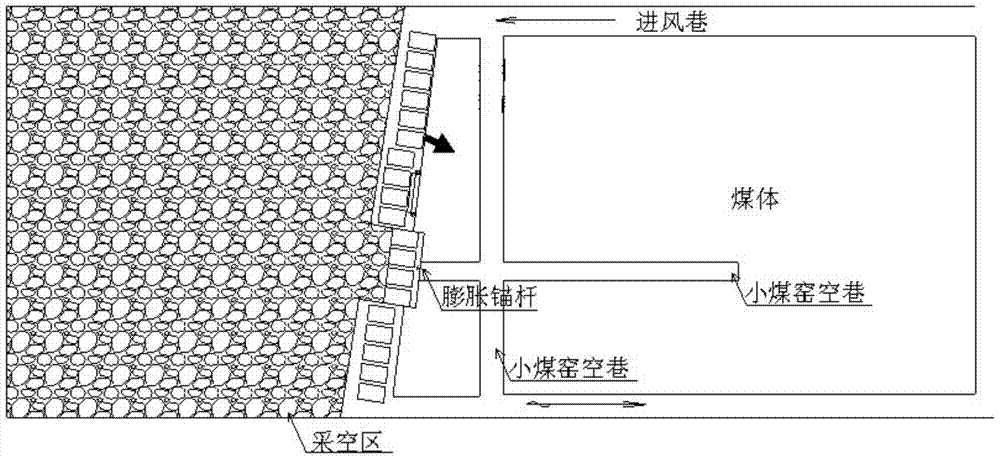

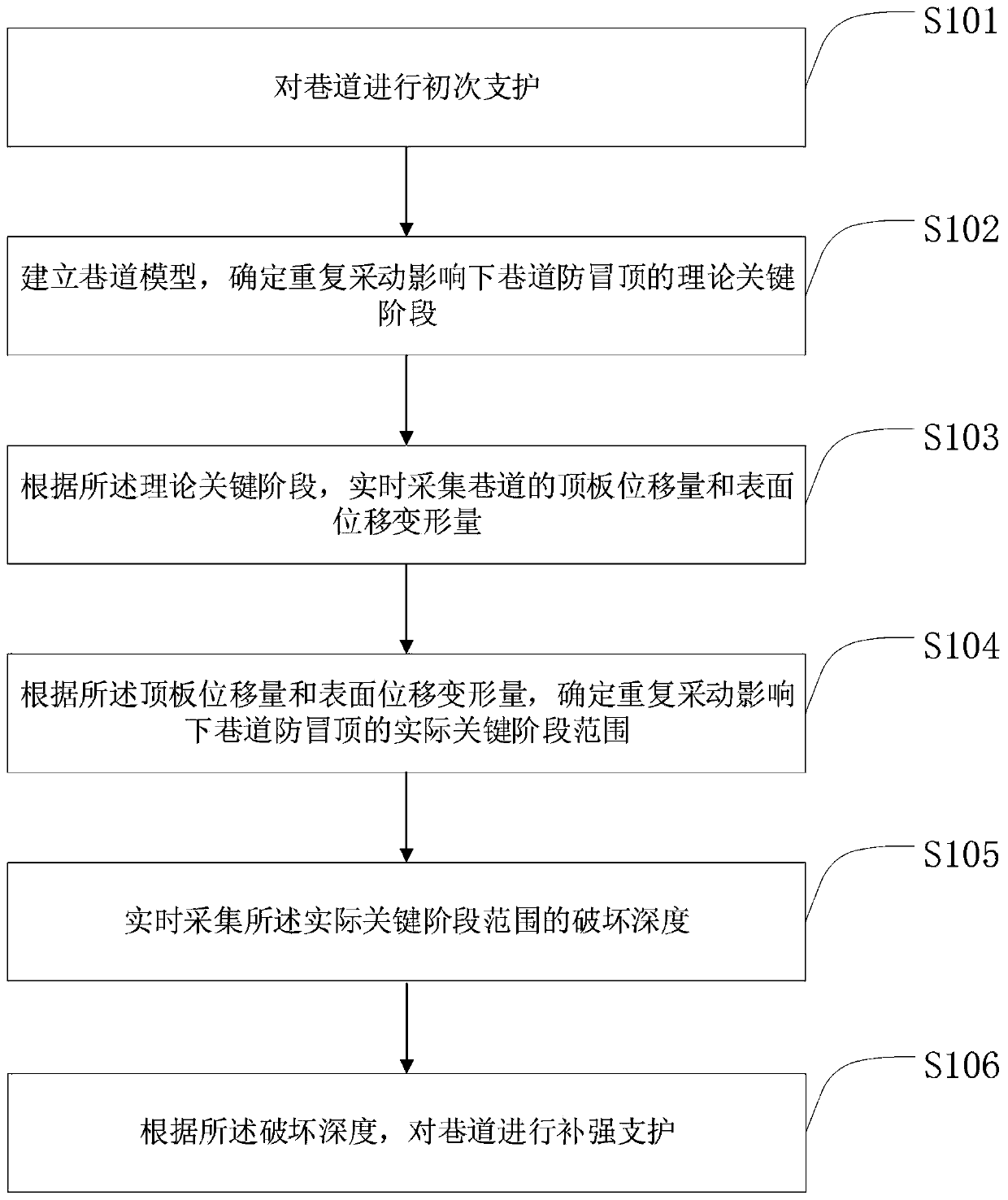

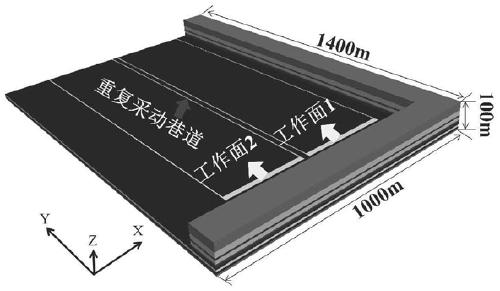

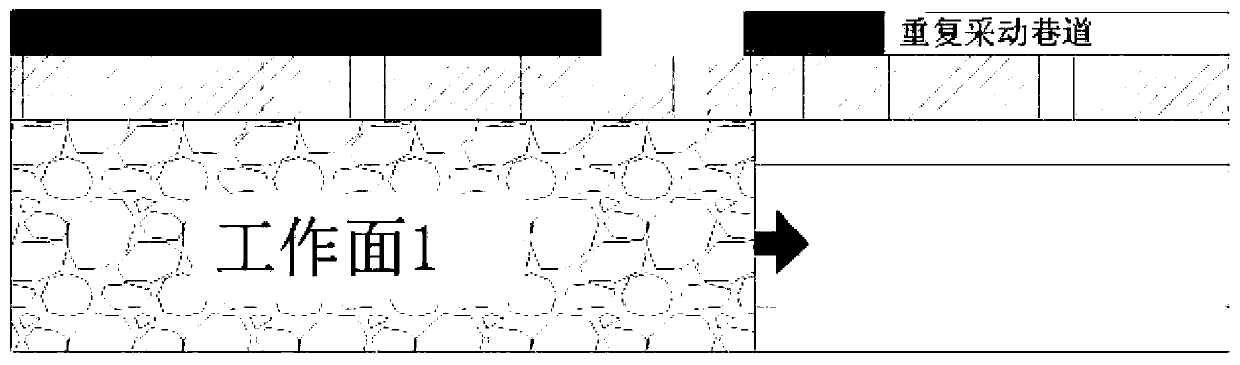

Tunnel anti-roof-caving supporting method under influences of repeated mining

ActiveCN109505654APrevent roof fall accidentsLarge amount of deformationMining devicesUnderground chambersEngineeringSurface displacement

The invention provides a tunnel anti-roof-caving supporting method under influences of repeated mining. The method includes the steps of primarily supporting a tunnel, establishing a tunnel model, determining the tunnel anti-roof-caving theoretical key stage under the influences of repeated mining, collecting top plate displacement and surface displacement deformation of the tunnel in real time, determining the tunnel anti-roof-caving actual key stag range under the influences of repeated mining according to the top plate displacement and surface displacement deformation, collecting the breakage depth of the actual key stage range in real time, and conducting reinforced supporting on the tunnel according to the breakage depth. By means of the tunnel model, the tunnel anti-roof-caving theoretical key stage under the influences of repeated mining is obtained; in combination with the top plate displacement and surface displacement deformation, the actual key stage range is obtained; the reinforced supporting is conducted on the tunnel in the actual key stage range, roof caving accidents of the tunnel under the influences of repeated mining can be effectively avoided, and the tunnel maintains safe and stable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

Mining drivage shielding support for coal mine

The invention relates to the technical field of supports, in particular to a mining drivage shielding support for coal mine. The mining drivage shielding support for coal mine comprises a base, a topbeam and a crawler device. One ends of multiple first fulcrum rods are hinged to the left side of the base, one ends of multiple second fulcrum rods are hinged to the right side of the base, the middles of the first fulcrum rods and the second fulcrum rods are hinged, the other ends of the first fulcrum rods are hinged to one ends of the second fulcrum rods above the first fulcrum rods, one ends of the second fulcrum rods are hinged to one ends of the first fulcrum rods above the second fulcrum rods, and the middles of the first fulcrum rods above the second fulcrum rods and the second fulcrumrods are hinged. The mining drivage shielding support has the advantages of being simple in structure, convenient and safe to operate, good in supporting performance, easy to apply and popularize andthe like, puking accidents can be effectively avoided, the safety of the coal mining operation is guaranteed, a roof is not likely to deviate during supporting through guide rods, first hydraulic cylinders are evenly arranged at intervals, it can be effectively avoided that several portions are stressed excessively, the top beam is not prone to deformation, and supporting is firm and safe.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

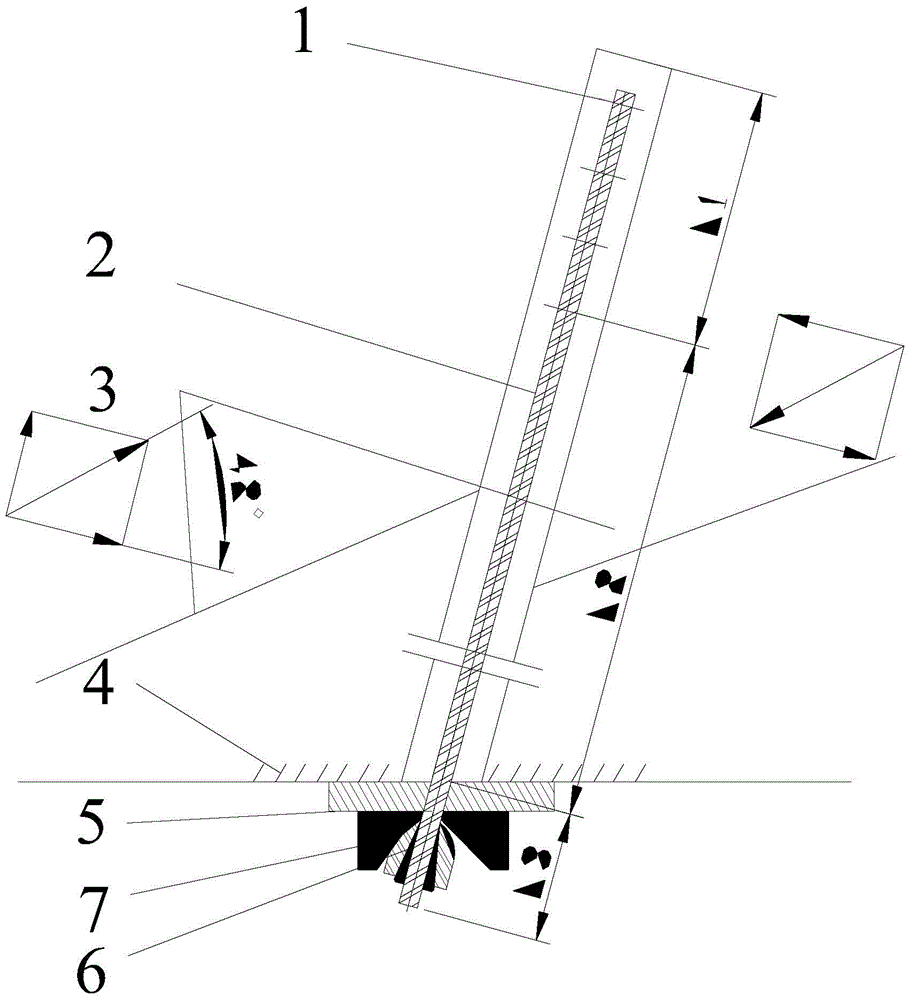

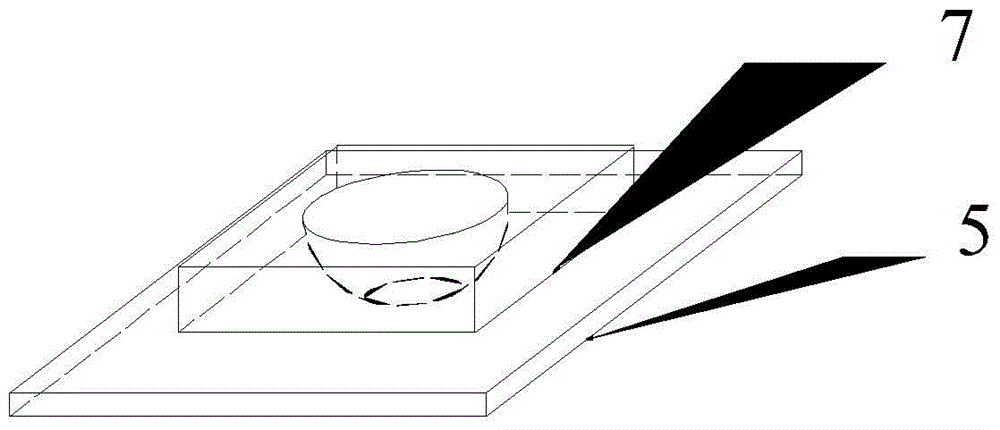

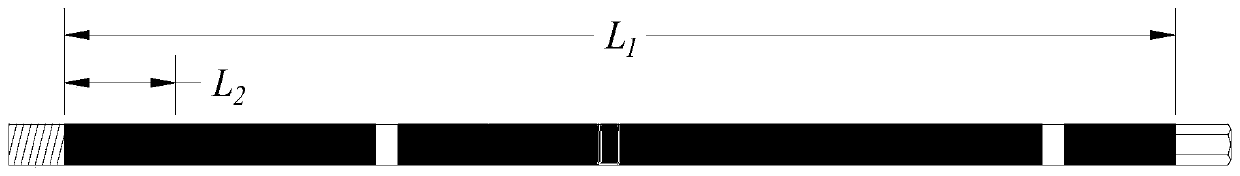

Novel sphere type anchor rope applicable to faults and other geological structure damaged sections

InactiveCN104594930AAvoid shear damageImprove shear resistanceAnchoring boltsGeological structureTransverse shear

The invention discloses a novel sphere type anchor rope applicable to faults and other geological structure damaged sections and belongs to the field of anchor ropes for retaining and protecting in underground works, such as mine engineering. The novel sphere type anchor rope is used for solving the problem that the existing anchor ropes are prone to shear failure. The novel sphere type anchor rope disclosed by the invention comprises an anchor rope body, a pallet, a spherical-groove steel backing plate and a sphere type anchor rope locking device, wherein a spherical groove is formed in the spherical-groove steel backing plate and is bigger than the anchor rope locking device, and the contact between the sphere type anchor rope locking device and the spherical-groove steel backing plate is spherical contact, so that the anchor rope locking device can rotate in the groove. When rock formations or broken rock blocks of the faults and other geological structure damaged sections undergo mutual staggering, the anchor rope body bears a great shear force, the sphere type anchor rope locking device is deflected at a certain angle in the spherical groove of the spherical-groove steel backing plate, and meanwhile, the anchor rope body is also deflected at a certain angle along with the staggering of the rock formations, so that the transverse shear force stressed by the anchor rope body is reduced, the damage to the anchor rope caused by shearing is avoided, and the shear resistance of the anchor rope is improved.

Owner:ANHUI UNIV OF SCI & TECH

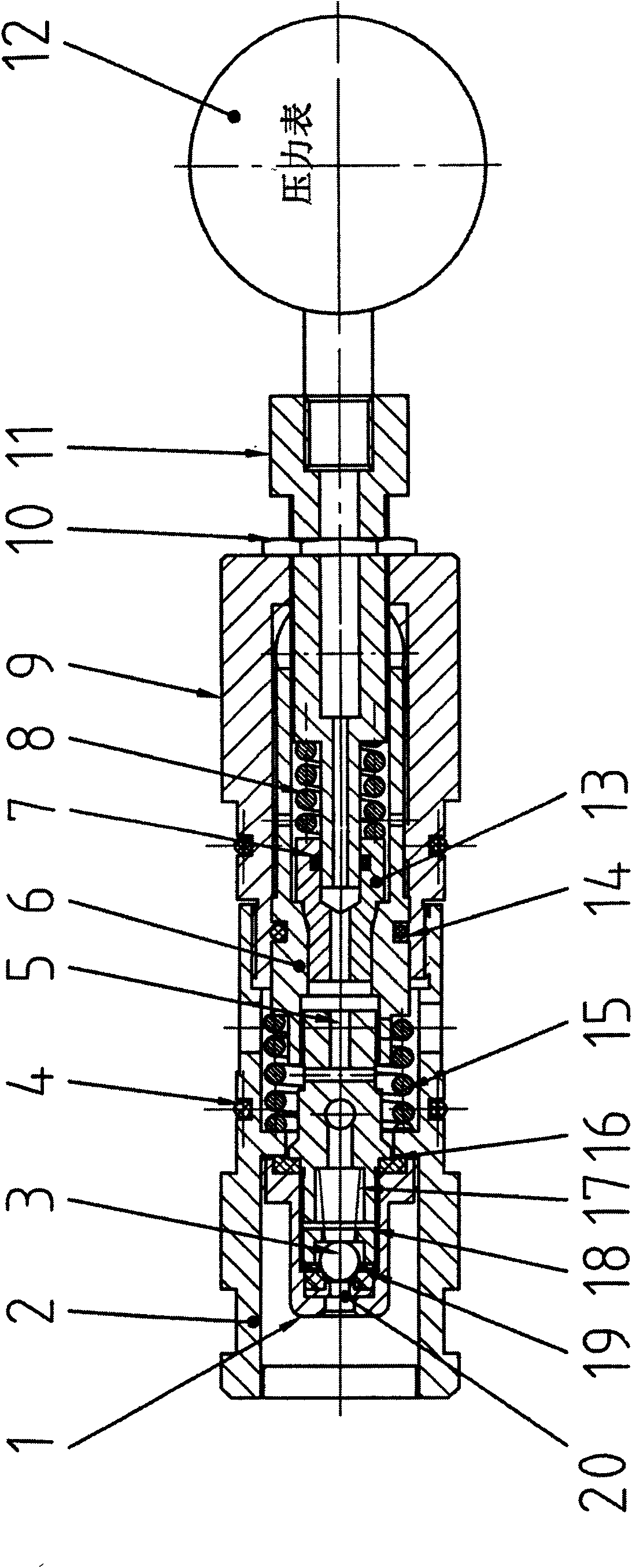

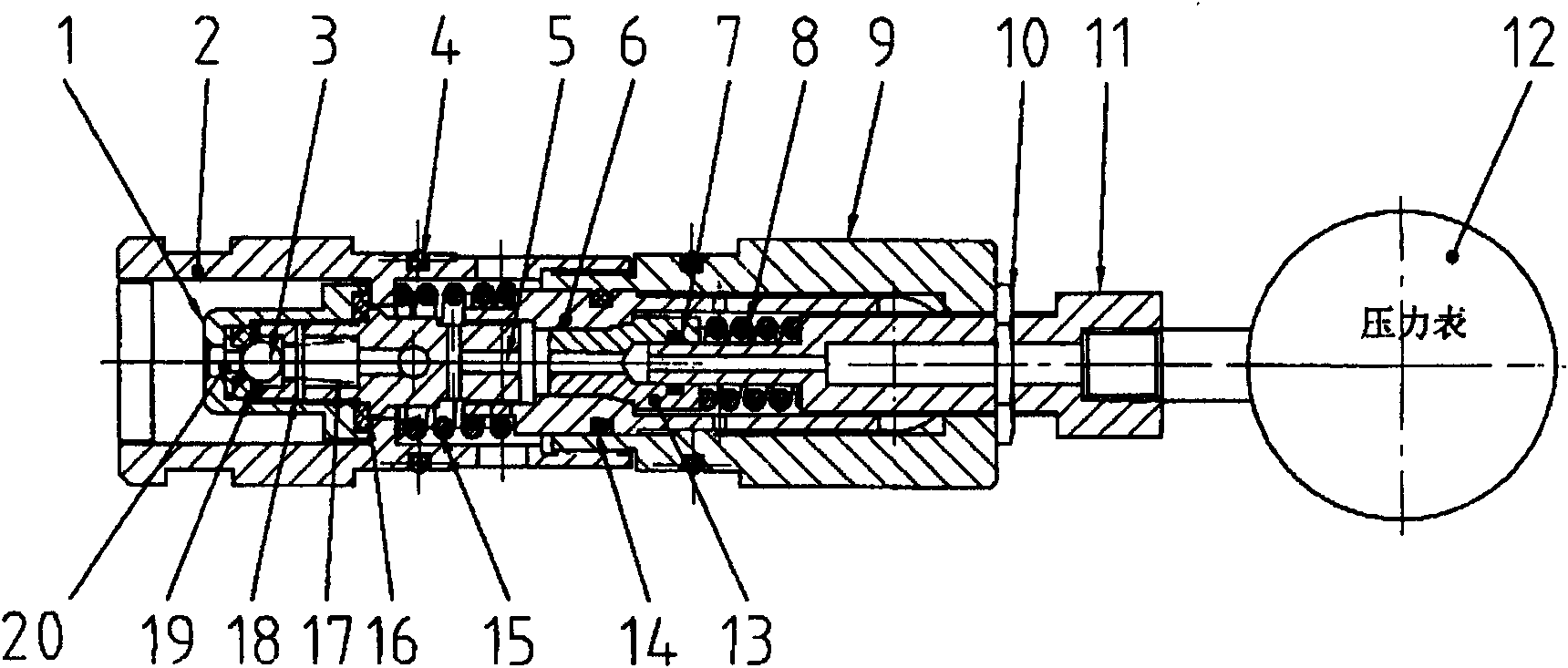

Four-purpose valve for single hydraulic prop

The invention relates to a four-purpose valve for a mine single hydraulic prop, which has the functions of fluid injection, unloading, hyperpressure drainage and pressure display, and guides the pressure of hydraulic fluid inside the single hydraulic prop to a pressure gauge through a connecting screw, a valve bush, a safety valve seal slider, an O-shaped ring and a fluid guiding pipe, and thus, the pressure gauge can constantly display the pressure inside a hydraulic cavity of the single hydraulic prop during supporting, workers can conveniently find out pressure loss phenomenon caused by the internal leakage of a sealing face of the single hydraulic prop, and the occurrence frequency of roof collapse accidents during coal mining is reduced. Meanwhile, the hyperpressure drainage part of the four-purpose valve is the sealing face of a safety valve, which is formed by a conical surface of one section of an inner bore of the valve bush, with certain angle, and a spherical surface of the safety valve sealing slider; and a hyperpressure unloading device of the four-purpose valve, composed of the valve bush, the safety valve sealing slider, a safety valve spring and the fluid guide pipe, has greater drainage capability when larger rock burst occurs and can be used for preventing the rock burst from damaging the single hydraulic prop.

Owner:王翠兰

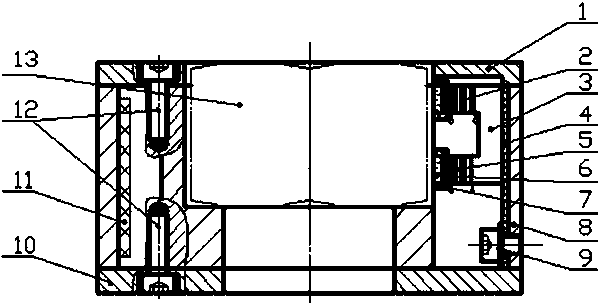

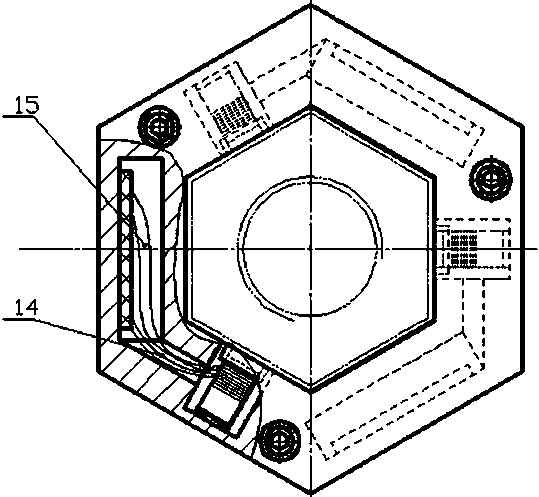

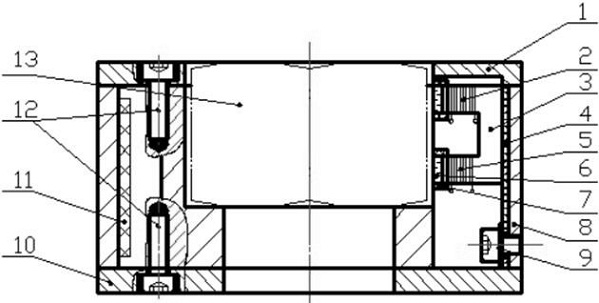

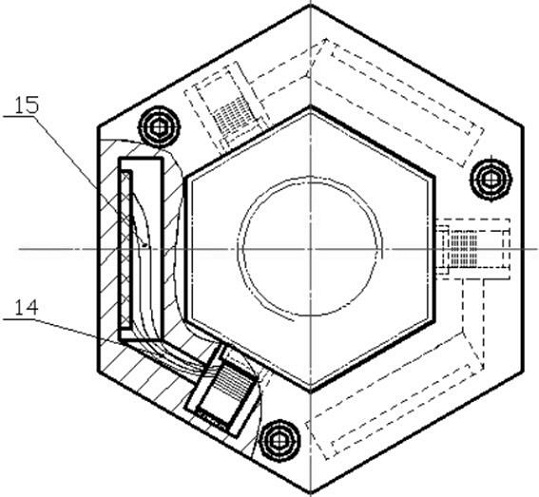

Detection device and detection method for axial force of anchor rod

InactiveCN109238517APrevent landslidesPrevent roof fallForce measurement by measuring magnetic property varationAxial forceEngineering

The invention discloses a detection device and a detection method for the axial force of an anchor rod. An integrated structure of the device is a regular hexagonal prism; an upper end cover and a lower end cover are respectively connected with a protective shell through fastening screws; a plurality of two-pole U-shaped magnetic cores are uniformly disposed at an outer side of an anchor rod fastening nut; the two-pole U-shaped magnetic cores are located in a space encircled by the upper end cover, the lower end cover and the protective shell; silicon rubber sleeves are sleeved on two magneticpoles of the two-pole U-shaped magnetic cores; a magnetic fluid is filled in each of the silicon rubber sleeves; a circuit slot is disposed in the space encircled by the upper end cover, the lower end cover and the protective shell; a control circuit is disposed in the circuit slot; a wire led from the control circuit passes through the circuit slot to wind an excitation coil and a detection coilto upper and lower ends of the two-pole U-shaped magnetic cores; elastic sheets are disposed at outer sides of the two-pole U-shaped magnetic cores; and the elastic sheets are fixed on an inner wallof the protective shell. The detection device and the detection method for the axial force of the anchor rod are used for detecting the axial force of the anchor rod, the collapse and cave-in of a topplate are avoided, a top plate support parameter is provided, and a reliable technical parameter is provided for support design of a laneway layout and safety monitoring of the top plate.

Owner:TAIYUAN UNIV OF TECH

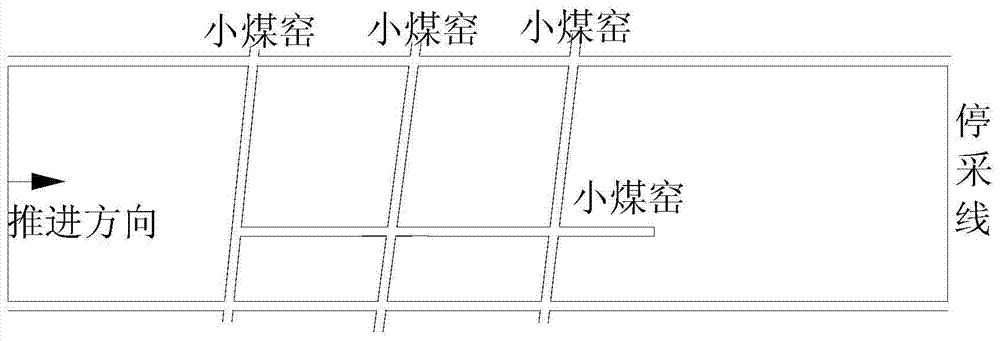

The Mining Method of Small Coal Kiln Roadway Crossing Complicated Crossing at Working Face

ActiveCN105673013BImprove roof conditionsSafe and efficient production environmentUnderground miningSurface miningEngineeringMechanical engineering

The invention discloses an exploiting method for a working face to pass through cross and complex small coalpit tunnels. An arrangement direction of the working face is adjusted manually according to the following steps: the arrangement direction is adjusted 30 meters away from the small coalpit, a tail propels in advance, the tail supports scraper conveyers, and a head does not support scraper conveyers; the head and the tail propel simultaneously, but the head propels in advance, so that the arrangement direction of the working face is changed again; when the small coalpit is nearly exposed during propelling, the working face is leveled, an expansion anchor pole is anchored to a coal wall. The method can effectively prevent generation of roof fall accidents near the small coalpit, so that production inconvenience due to working face coal wall caving is eliminated. Safety and high efficiency of production environment on the working face which passes through the small coalpit is guaranteed.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

A roadway anti-roof fall support method under the influence of repeated mining

ActiveCN109505654BPrevent roof fall accidentsLarge amount of deformationMining devicesUnderground chambersStructural engineeringGeotechnical engineering

The invention provides a tunnel anti-roof-caving supporting method under influences of repeated mining. The method includes the steps of primarily supporting a tunnel, establishing a tunnel model, determining the tunnel anti-roof-caving theoretical key stage under the influences of repeated mining, collecting top plate displacement and surface displacement deformation of the tunnel in real time, determining the tunnel anti-roof-caving actual key stag range under the influences of repeated mining according to the top plate displacement and surface displacement deformation, collecting the breakage depth of the actual key stage range in real time, and conducting reinforced supporting on the tunnel according to the breakage depth. By means of the tunnel model, the tunnel anti-roof-caving theoretical key stage under the influences of repeated mining is obtained; in combination with the top plate displacement and surface displacement deformation, the actual key stage range is obtained; the reinforced supporting is conducted on the tunnel in the actual key stage range, roof caving accidents of the tunnel under the influences of repeated mining can be effectively avoided, and the tunnel maintains safe and stable.

Owner:INNER MONGOLIA UNIV OF SCI & TECH +1

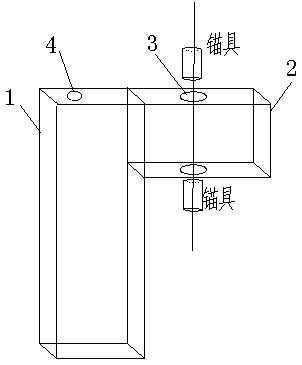

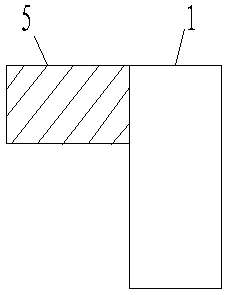

Temporary supporting forepoling bar suspension device of full anchor-cable supporting roadway and application

ActiveCN109630169ANot destroyedExit normallyMine roof capsAnchoring boltsManufacturing technologyEngineering

The invention relates to a temporary supporting forepoling bar suspension device of a full anchor-cable supporting roadway and application. The device is characterized in that the suspension device isin an inverted L shape and comprises a longitudinal plate and a transverse plate, an anchor device penetrating hole is formed in the transverse plate, a threaded hole is formed in the top of the longitudinal plate, and a safe baffle plate is arranged on the inner side of the transverse plate, and the length and width of the safe baffle plate are same as those of the transverse plate; according tothe device, each forepoling bar utilizes two temporary supporting forepoling bar suspension devices of the full anchor-cable supporting roadway. The device is simple in manufacturing technology, flexible in operation and high in adaptability, it can be ensured that after coal cutting (blasting), the full anchor-cable supporting roadway can be effectively supported temporarily, by adopting the suspension device, an original anchor cable which has reached the pre-tightening state does not need to be dismantled, and it is avoided that due to dismantling of the anchor cable, anchoring fails, theempty roof phenomenon occurs again, and the roof falling accident is caused.

Owner:XINWEN MINING GROUP

Fully mechanized mining recovery technology with large mining height and large mining height in complex thick coal seam with large dip angle structure

ActiveCN110273686BImprove stabilityGuarantee unimpededUnderground miningSurface miningStructural engineeringMachine

The invention relates to a coal mining technology, and discloses a fully mechanized mining recovery technology with a large mining height and a complex thick coal seam with a large dip angle structure. This process retains the uncut section to feed the knife, and through the supporting effect of the uncut section, the empty roof area is reduced to prevent the occurrence of roof fall accidents. The combination of cutting sections can further improve the stability of the entire working face, and ensure the unimpeded pedestrian passage of the end bracket and tail frame; moving the hydraulic support twice can solve the problem that the hydraulic support cannot be pushed to a cutting depth at one time, and ensure that the scraper conveyor can Push it in place to maintain the safe operation of the equipment.

Owner:SICHUAN CHUANMEI HUARONG ENERGY CO LTD

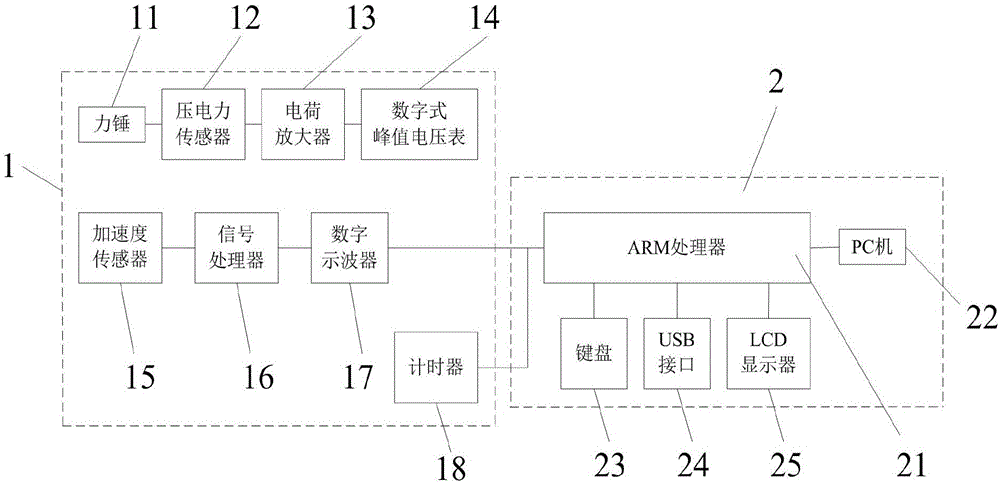

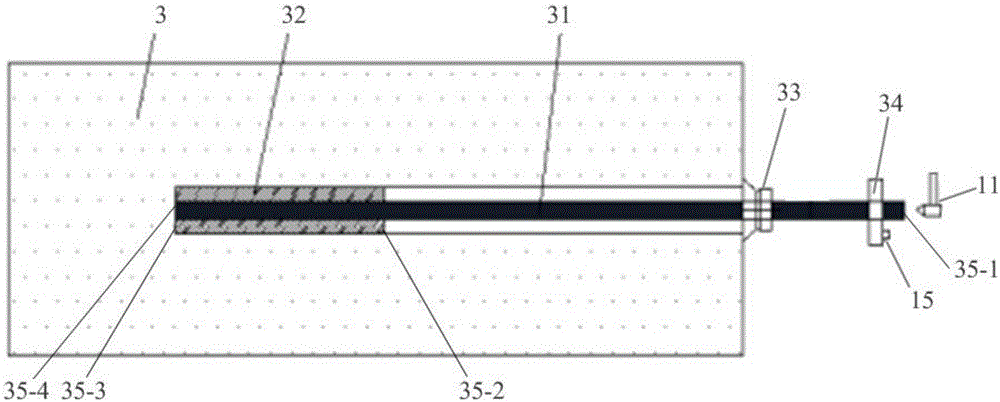

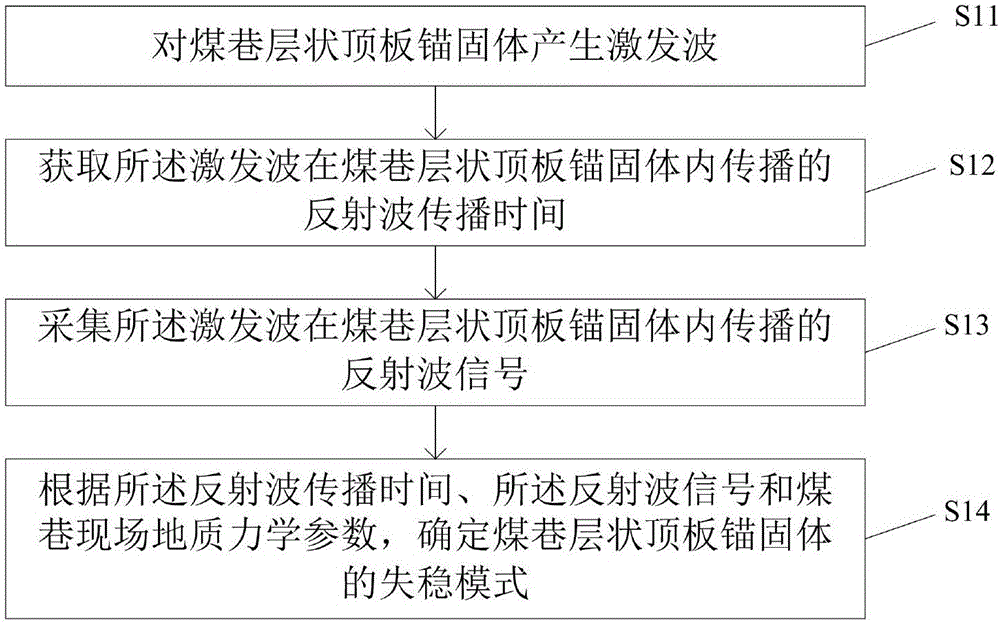

Coal roadway stratified roof anchorage body instability mode detector and control method thereof

InactiveCN106770651AImprove accuracyMeet safety explosion-proof requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesAccelerometerInstability

The invention discloses a coal roadway stratified roof anchorage body instability mode detector, and relates to the technical field of coal mine safety. The detector is used for solving the problem of poor nondestructive detection effect of coal roadway stratified roof anchorage bodies in the prior art. The detector comprises: an exciting hammer used for exciting a coal roadway stratified roof anchorage body to generate excitation waves; an accelerometer used for acquiring a reflection wave signal of the excitation waves propagated in the coal roadway stratified roof anchorage body and sending the reflection wave signal to an ARM processor; a timer used for acquiring the reflection wave propagation time of the excitation waves propagated in the coal roadway stratified roof anchorage body and sending the reflection wave propagation time to the ARM processor; and the ARM processor used for determining the instability mode of the coal roadway stratified roof anchorage body according to the reflection wave signal, the reflection wave propagation time and the onsite geologic mechanical parameters of coal roadway. The invention also discloses a control method of the coal roadway stratified roof anchorage body instability mode detector.

Owner:SHANXI DATONG UNIV

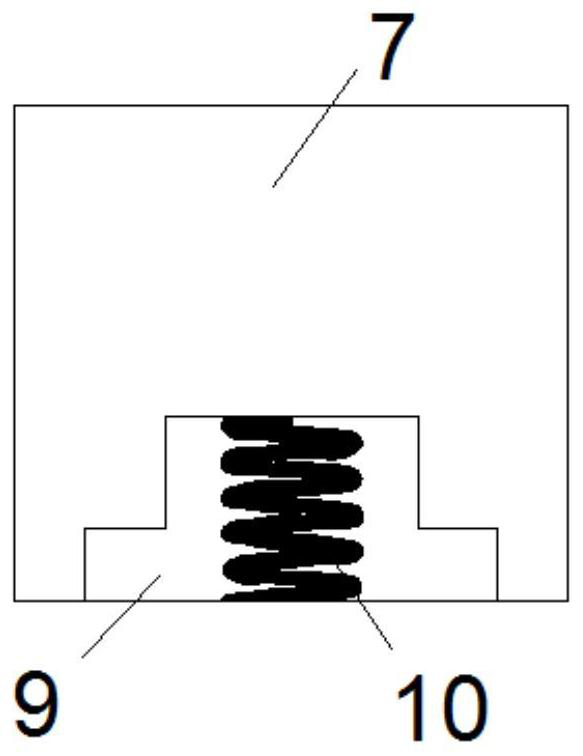

Unit type constant-resistance elastic yielding anti-impact hydraulic support and working method thereof

The invention discloses a unit type constant-resistance elastic yielding anti-impact hydraulic support which is composed of a support top beam, a support base, two hydraulic stand columns and a safetyvalve and is characterized by further comprising an energy storage device installed on the support base. When the static pressure of a top plate and a bottom plate of a roadway is greater than 40 Mpa, the safety valve is automatically opened to discharge part of emulsion for unloading; when an impact dynamic pressure of the top plate of the roadway is greater than 41.5 Mpa, impact energy is stored in a pressure spring, and the support is prevented from being broken and toppled; and when the top plate rebounds after the impact energy is released, the energy of the pressure spring is released along with the rebounding of the top plate, the emulsion is promoted to return to a liquid cavity of the hydraulic stand columns, and hydraulic jacks return to an original retraction state.

Owner:张治高

A mine fiber grating roof detachment monitoring device and monitoring method

ActiveCN103528530BRealize online measurementPrevent roof fall accidentsMining devicesTesting machinesFiberGrating

Owner:CHINA UNIV OF MINING & TECH

A Novel Bolt Pullout Resistance Alarm Instrument and Its Application Method

ActiveCN103422890BAlarm in timePrevent roof fall accidentsMining devicesAnchoring boltsButton batteryEngineering

The invention discloses a novel anchor rod pulling resistance alarm. The novel anchor rod pulling resistance alarm comprises a pressure sensor box, a sensor rod, a light-emitting diode and a sounder, wherein the pressure sensor box sends out a signal, the signal is transmitted to the light-emitting diode and the sounder through the sensor rod, the pressure sensor box is annular and is provided with a central hole whose size is 18-22 mm, the sounder and the light-emitting diode are provided with a sealing waterproof device, and a button cell is arranged inside the pressure sensor box and is used for supplying power to the sounder and the light-emitting diode. The novel anchor rod pulling resistance alarm monitors the pulling resistance of an anchor rod in real time and gives an alarm before danger, thereby guiding people to take related maintenance measures in advance, preventing the anchor rod from being pulled broken and avoiding roof collapse accidents.

Owner:SHANDONG UNIV

Integral laying method for artificial roof

PendingCN114776347ASolve technical problemsStable supportProtective coversArchitectural engineeringWorking environment

The invention provides an overall laying method for an artificial roof. The overall laying method comprises the following steps that a first wood crib is formed along a crossheading top plate in a sleeper stacking and inserting mode for top sealing; a plurality of first I-shaped steel are arranged below the first wood crib at intervals, and the first I-shaped steel is suspended and fixed to a crossheading top plate through first anchor cables to form a first false top layer; the metal net is laid below the second false top layer to form the artificial false roof structure, the first false top layer formed by the wooden sleeper, the first I-shaped steel and the first anchor cable is fixedly connected with the gate road to form a whole, and the second false top layer is arranged below the first false top layer, so that a support is convenient to support, obvious deformation and displacement do not occur in the operation period, and the working efficiency is improved. The safety is greatly improved, the occurrence of roof fall accidents is effectively avoided, and the safety and reliability of the working environment are ensured.

Owner:扎赉诺尔煤业有限责任公司

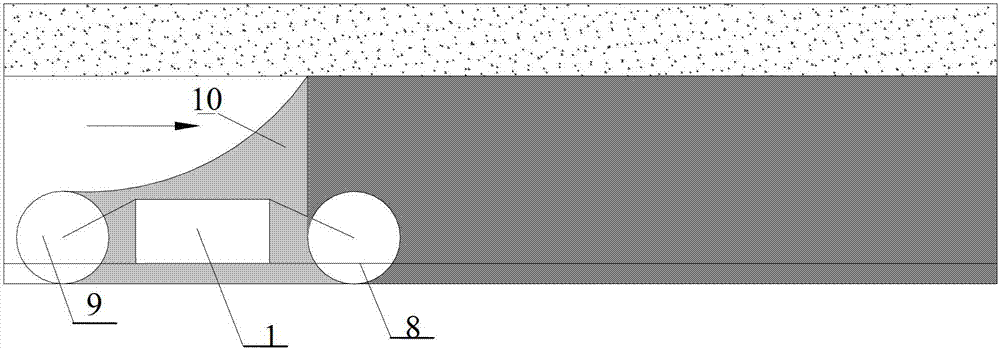

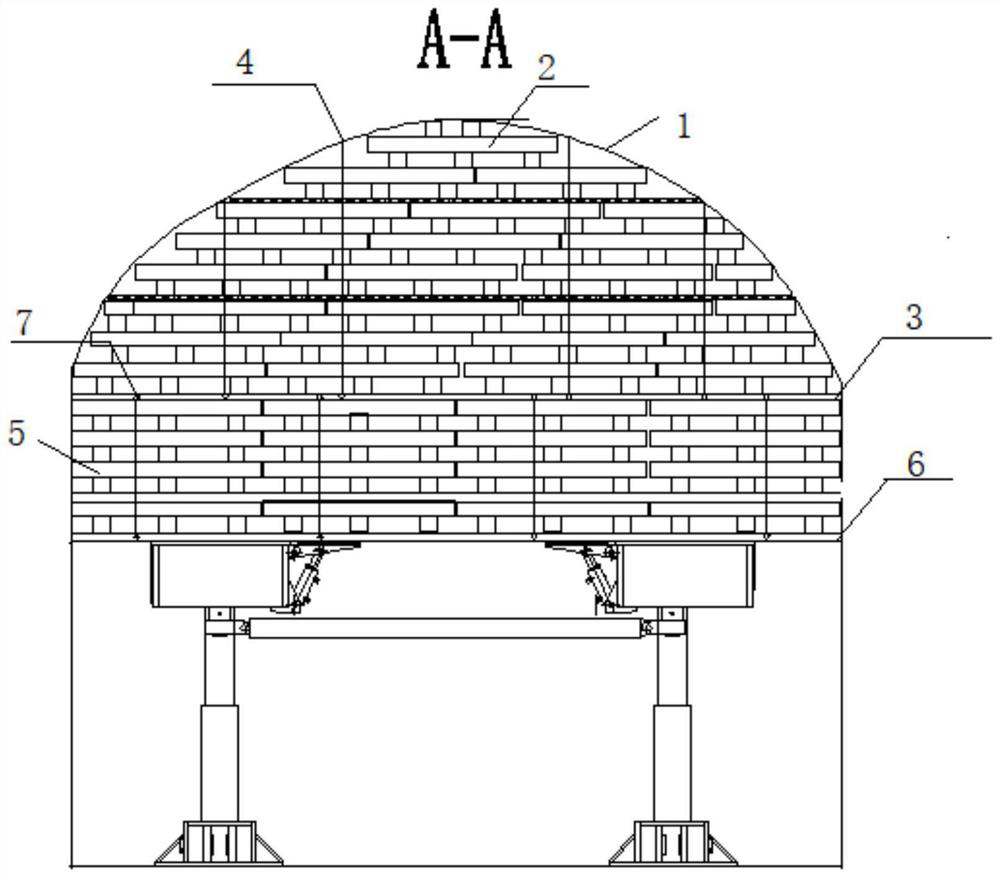

Movable mining tunneling arch-shaped flexible shield support for coal mine

PendingCN113669097AReduce stressAvoid destructionMine roof supportsMining engineeringStructural engineering

The invention discloses a movable mining tunneling arch-shaped flexible shield support for a coal mine. The movable mining tunneling arch-shaped flexible shield support comprises a base and a crawler device installed at the bottom of the base; the two ends of the top of the base are connected with a top beam through two hydraulic props; the two ends of the top beam are connected with the tops of the two hydraulic props in a groove mode respectively; the top beam is in an arch shape and is bent towards the direction of a goaf area; a cushion block is fixed to the lower end of the top beam; the higher end of the top beam and the cushion block are provided with groove type limiting holes; and the tops of the two hydraulic props are connected with the two groove type limiting holes through springs respectively. The movable mining tunneling arch-shaped flexible shield support can be used for supporting and shielding a large number of rock blocks collapsed in the goaf area, has a good effect on rock blocks with broken top plates, and has good applicability to inclined and steeply inclined mining tunneling projects; the hydraulic props can buffer impact force generated when the rock blocks roll down, roof caving accidents can be effectively prevented, and the safety of mining operation is guaranteed; and the movable mining tunneling arch-shaped flexible shield support has the advantages of being good in supporting performance, easy to apply and popularize and the like, and has good practicability.

Owner:LIAONING TECHNICAL UNIVERSITY

A detection device and detection method for the axial force of a bolt

InactiveCN109238517BPrevent landslidesPrevent roof fallForce measurement by measuring magnetic property varationMagnetic polesHemt circuits

The invention discloses a detection device and a detection method for the axial force of an anchor rod. An integrated structure of the device is a regular hexagonal prism; an upper end cover and a lower end cover are respectively connected with a protective shell through fastening screws; a plurality of two-pole U-shaped magnetic cores are uniformly disposed at an outer side of an anchor rod fastening nut; the two-pole U-shaped magnetic cores are located in a space encircled by the upper end cover, the lower end cover and the protective shell; silicon rubber sleeves are sleeved on two magneticpoles of the two-pole U-shaped magnetic cores; a magnetic fluid is filled in each of the silicon rubber sleeves; a circuit slot is disposed in the space encircled by the upper end cover, the lower end cover and the protective shell; a control circuit is disposed in the circuit slot; a wire led from the control circuit passes through the circuit slot to wind an excitation coil and a detection coilto upper and lower ends of the two-pole U-shaped magnetic cores; elastic sheets are disposed at outer sides of the two-pole U-shaped magnetic cores; and the elastic sheets are fixed on an inner wallof the protective shell. The detection device and the detection method for the axial force of the anchor rod are used for detecting the axial force of the anchor rod, the collapse and cave-in of a topplate are avoided, a top plate support parameter is provided, and a reliable technical parameter is provided for support design of a laneway layout and safety monitoring of the top plate.

Owner:TAIYUAN UNIV OF TECH

Detection method of roadway roof rock Platts coefficient while drilling based on sound level meter

The invention discloses a method for detecting while drilling the Platts coefficient of roadway roof rock based on a sound level meter, aiming at the problem of detecting while drilling the Platts coefficient, which is an important rock mechanics index affecting the roof anchoring support scheme of coal mines, in the roadway. Drill holes of Φ32~42mm on the top plate. A bearing-type drilling-while-drilling device with a sound level meter probe is installed behind the drill bit. The method combined with the reading of the scale drill pipe is used to test the drilling volume of different depths during the drilling process. The decibel value, combined with the standard library of rock Platts coefficient of 0.3 to 20 established in the laboratory, by comparing the decibel value of the in-situ rock drilling volume in the roadway, the Platts coefficient of the rock within the drilling range of the roadway roof can be quickly obtained, and the drilling process can be calculated. Harmful noises are transformed into beneficial sound sources, enabling detection while drilling technology. It is suitable for the detection of Platts coefficient of typical sedimentary rocks such as sandstone, shale and mudstone in coal measure strata while drilling. It has the advantages of convenient on-site use, simple operation, low labor intensity and no influence on normal production.

Owner:CHINA UNIV OF MINING & TECH

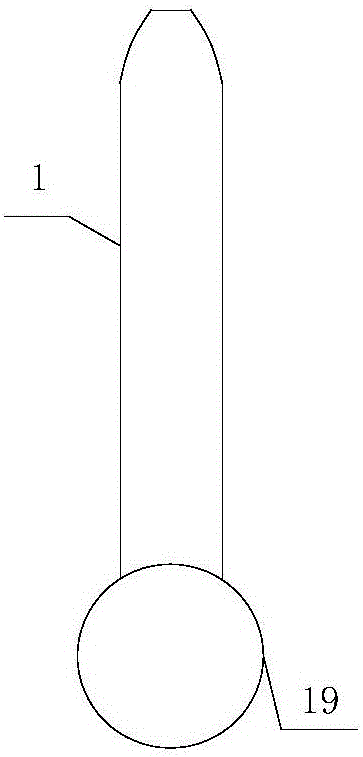

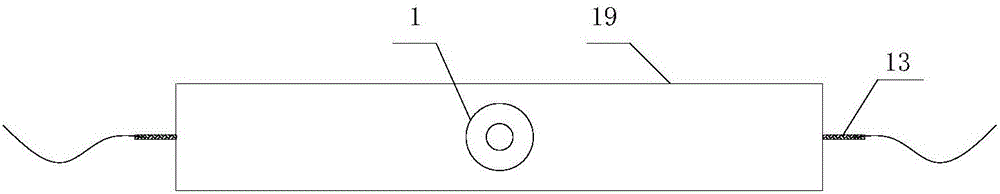

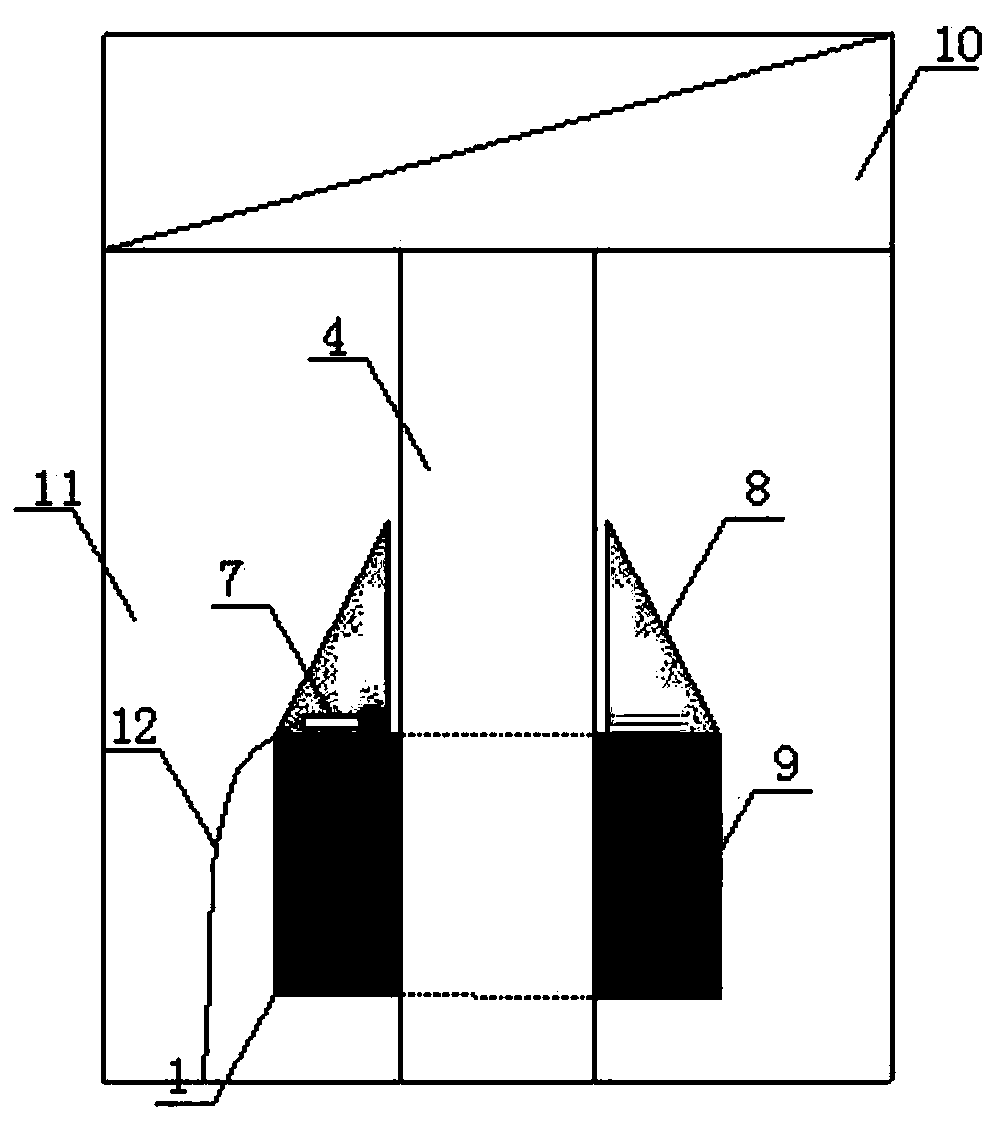

Roof separation layer observation teaching device and application method under the joint support of anchor rod and anchor cable

InactiveCN105096728BSimple working principleSymptoms of research instabilityEducational modelsLithologyComputer module

A teaching device for observing the separation layer of the roof under the joint support of anchor rods and cables and its use method, mainly including a retractable anchor rod, a base point anchor, a casing, an outer measuring cylinder, an inner measuring cylinder, steel strands, and a retractable anchor cable 1. Rigid plastic formation module; the hard plastic formation modules are connected together by steel strands, and the surface of each hard plastic formation module is coated with standardized formation filling patterns to represent different lithological formations. The modules can move each other to simulate the separation phenomenon. The retractable anchor rod and the retractable anchor cable are installed in the hard plastic formation module. The plastic formation module is connected to the steel frame, and the up and down movement of the hard plastic formation module is controlled by the gear and the steel strand connected by the handle of the long rod, demonstrating the change process of the roof separation layer. The demonstration device has a simple structure and can fully demonstrate the mechanism of the combined support of bolts and cables and the working principle of the roof separation instrument.

Owner:CHINA UNIV OF MINING & TECH

Quantitative design method of roadway support based on the size of plastic zone of surrounding rock

ActiveCN108062439BPrevent roof fall accidentsSupport parameters are scientific and reasonableGeometric CADMining devicesSite monitoringArchitectural engineering

The invention discloses a roadway support quantitative design method based on the size of the plastic zone of the surrounding rock, comprising the following steps: step 1, calculating and determining the radius R of the plastic zone of the surrounding rock of the roadway; step 2, classifying the surrounding rock of the roadway according to the calculation result; Step 3, according to the roadway surrounding rock classification results, carry out targeted support parameter design for different types of surrounding rock; Step 4, modify and adjust the support parameters according to the site monitoring feedback information. The support parameters designed in the present invention based on the size of the plastic zone are scientific and reasonable. On the basis of obtaining the radius of the plastic zone of the roadway and the geometric characteristic index of the boundary, the surrounding rock of the roadway is classified with the radius of the plastic zone as the main index, so as to classify different types of rocks. Surrounding rock is designed with pertinent support parameters to ensure the scientificity and economy of roadway support design; the invention can prevent roadway roof fall accidents for roadway support.

Owner:XIAN UNIV OF SCI & TECH

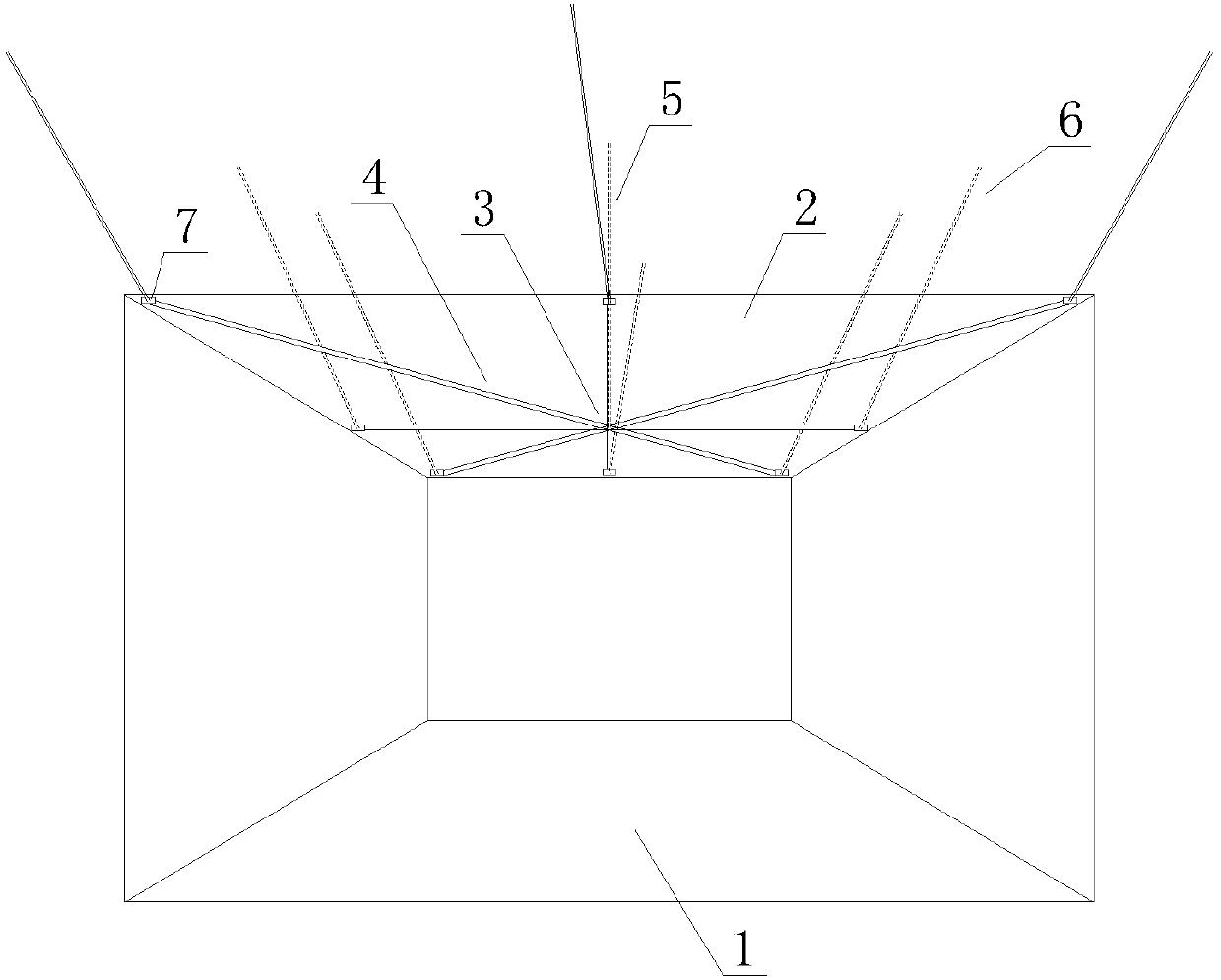

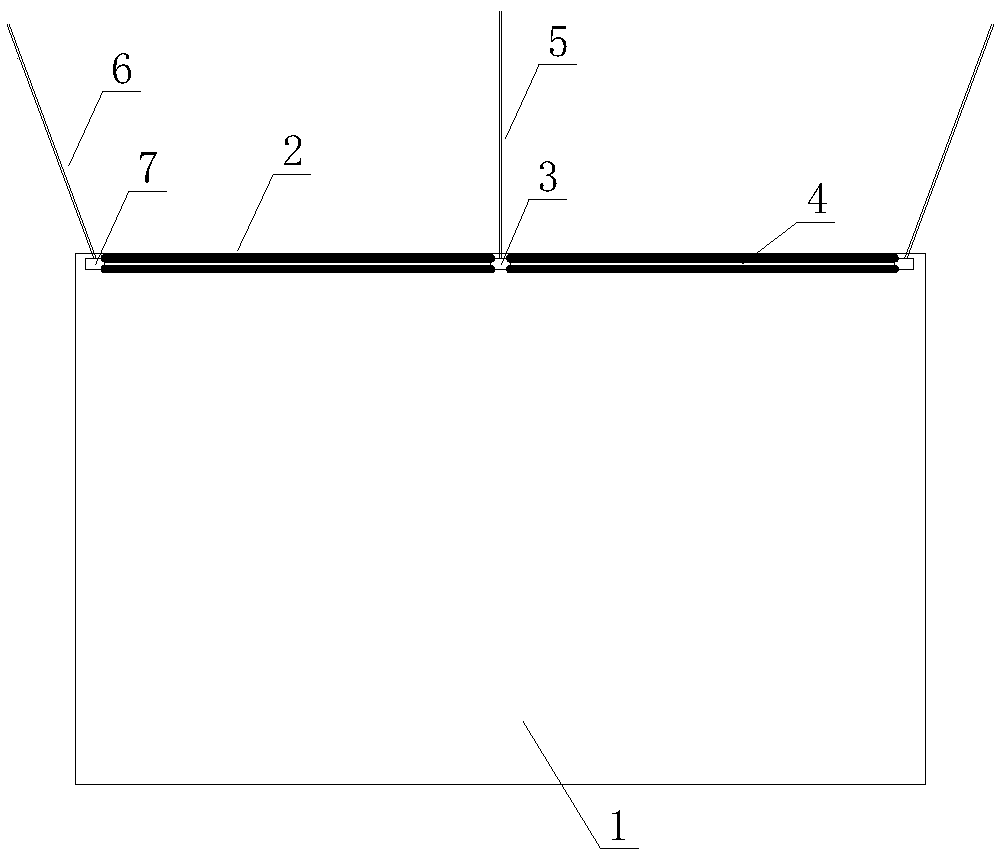

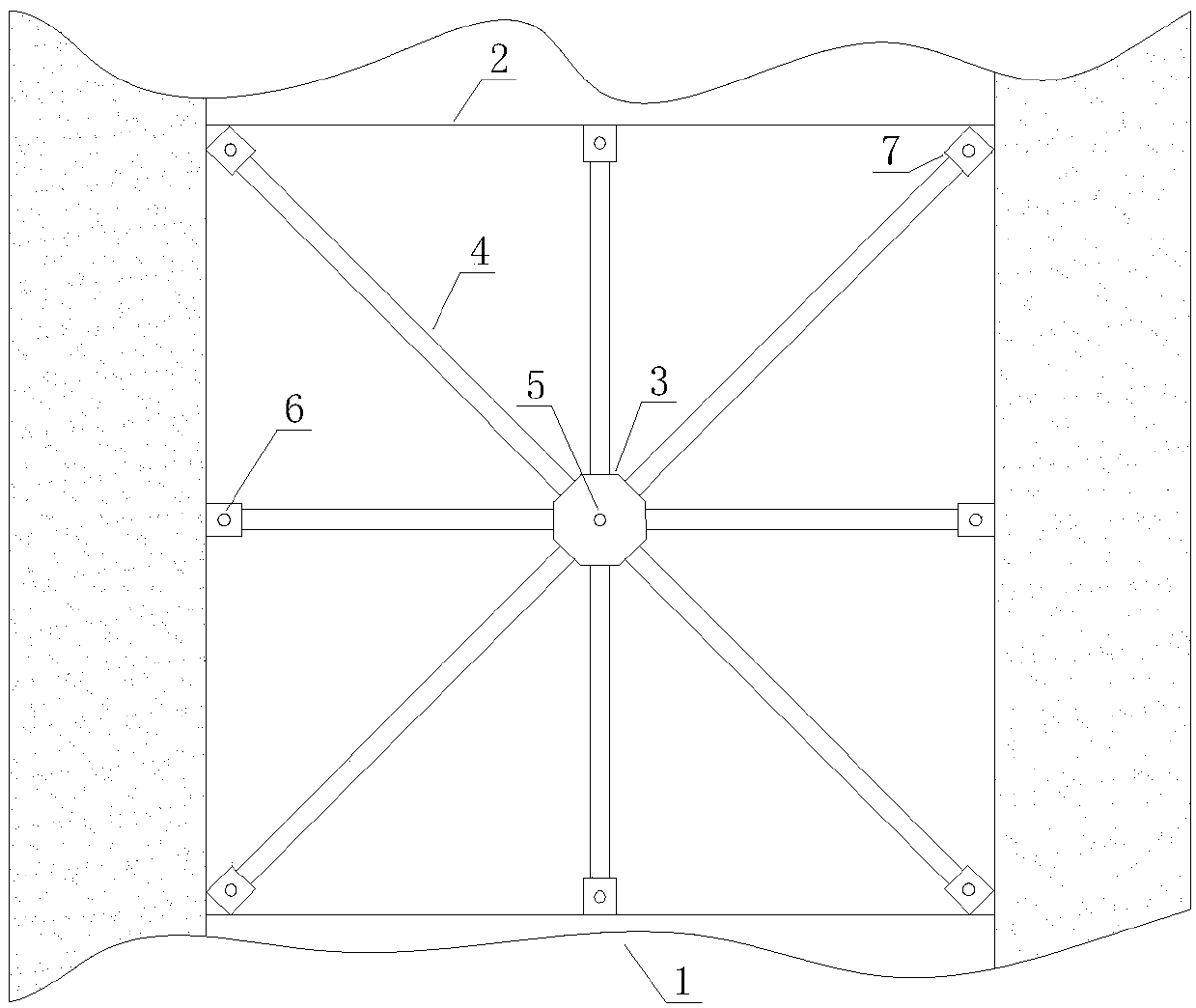

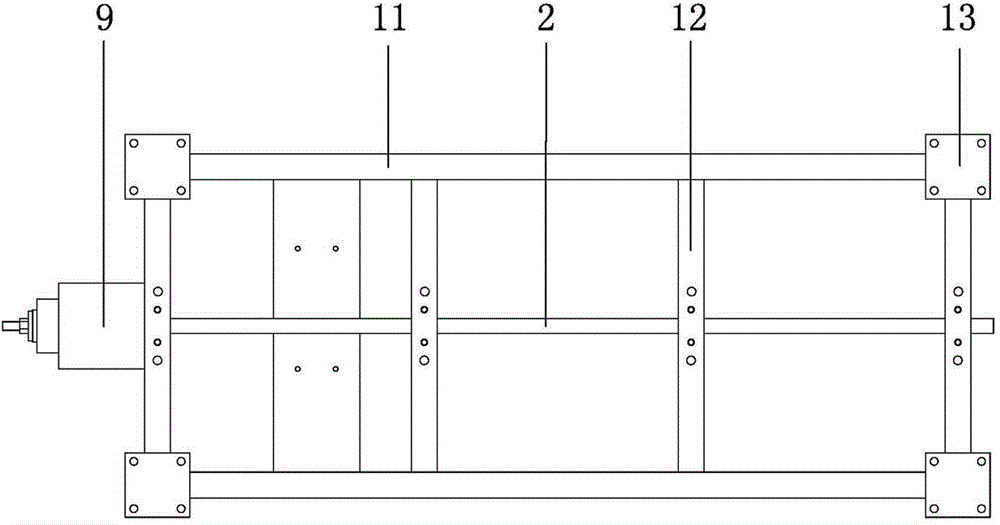

A large-scale support method and support device for roadway truss anchor cables

ActiveCN108150186BImprove the state of stressImprove stabilityUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a large-range supporting method for roadway truss anchor cables and a supporting device. The large-range supporting method for the roadway truss anchor cables comprises the steps that the vertical anchor cable and the multiple inclined anchor cables are anchored in a vertical drilled hole and a plurality of inclined drilled holes in a roadway roof correspondingly; multiplepairs of telescopic trusses are connected in a combined mode through a truss combining member, and the truss combining member is anchored through the vertical anchor cable, and the multiple pairs of telescopic trusses are anchored through the multiple inclined anchor cables correspondingly, so that large-range supporting of the roadway roof is formed; and in the supporting process, horizontal extrusion stress of each pair of telescopic trusses can be adjusted by controlling extending and retracting of the telescopic trusses according to the magnitude of horizontal applied force generated by horizontal motion of the roadway roof, and the horizontal extrusion stress is made to balance the horizontal applied force so as to adapt to or restrain horizontal extrusion dislocation or loosening expansion deformation of the roadway roof. A large-range extrusion stress area can be formed above the surface of the roadway roof, and large-range stable supporting of the roadway roof is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

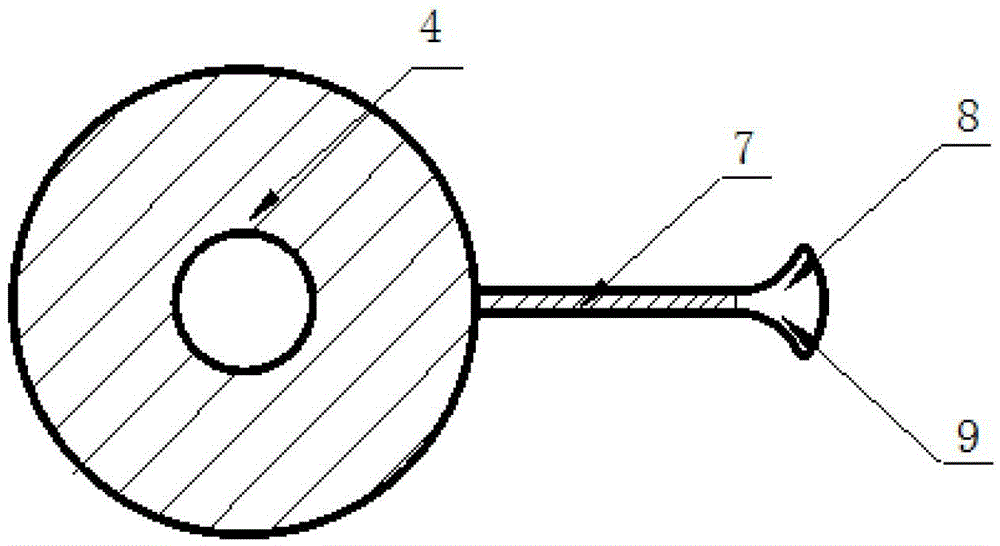

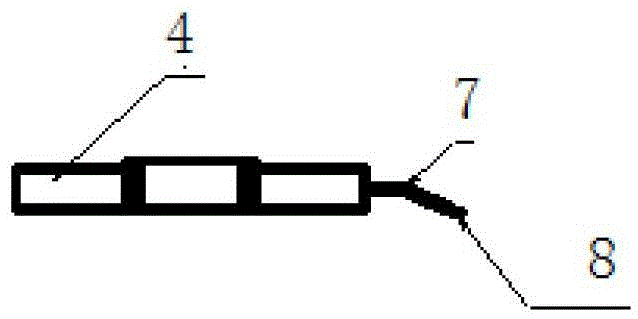

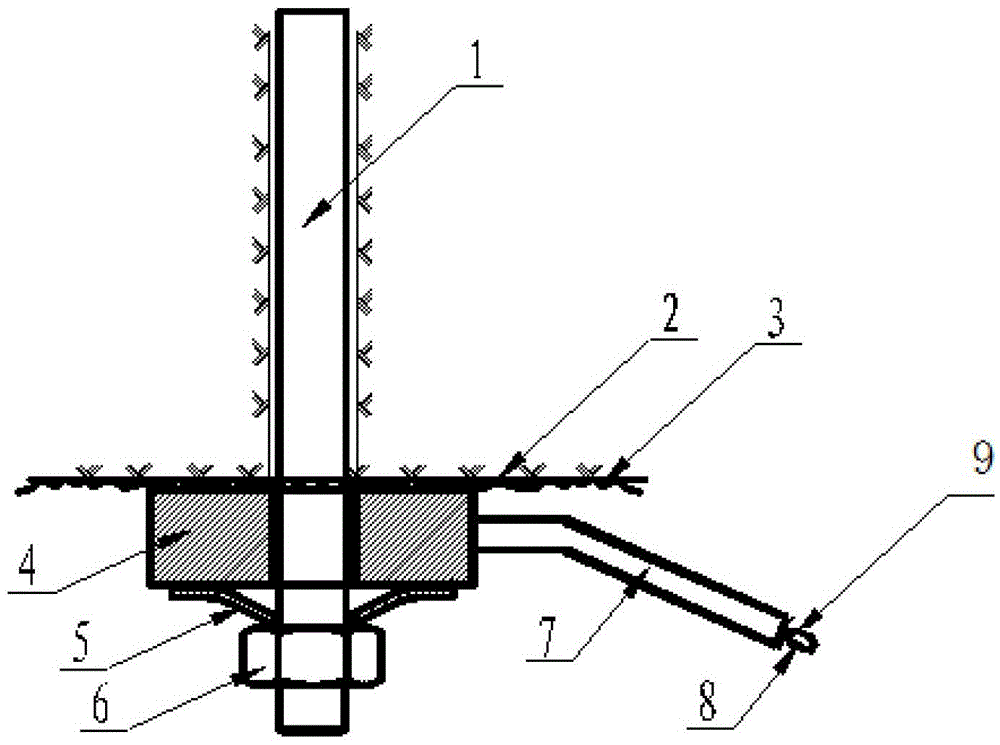

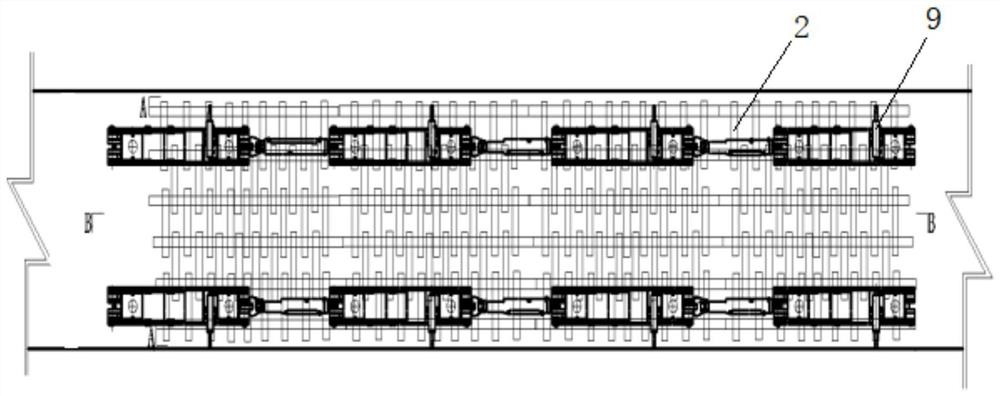

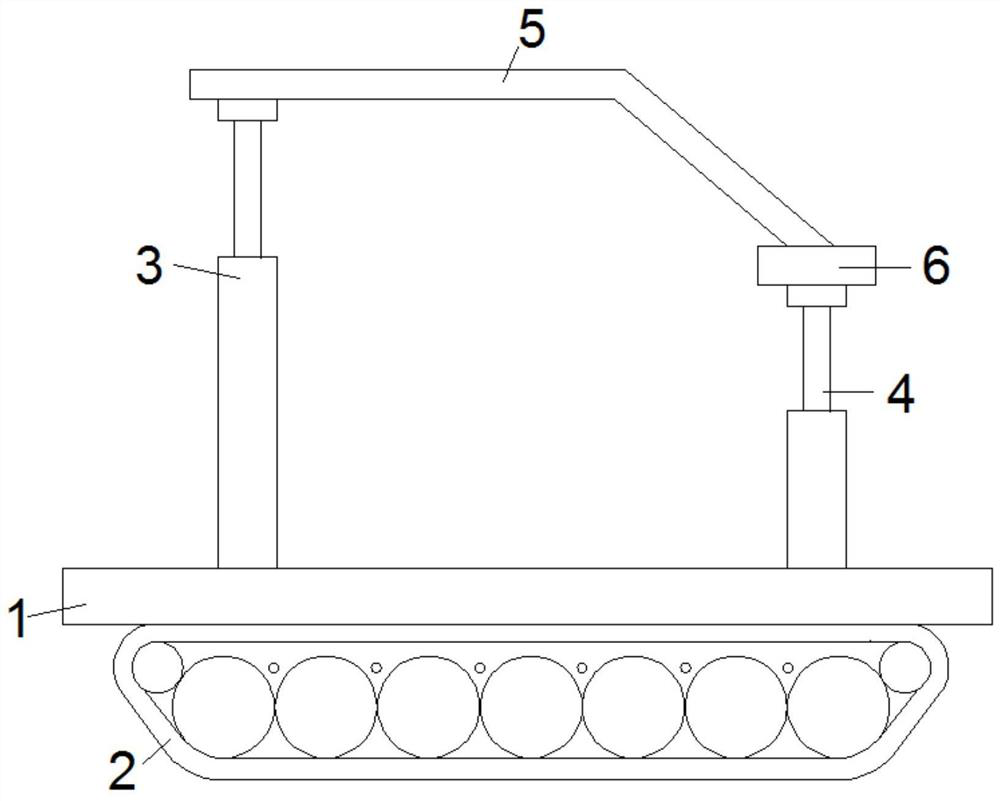

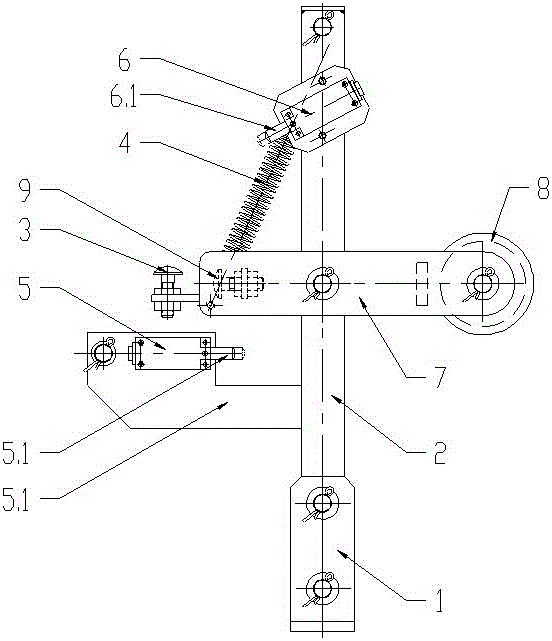

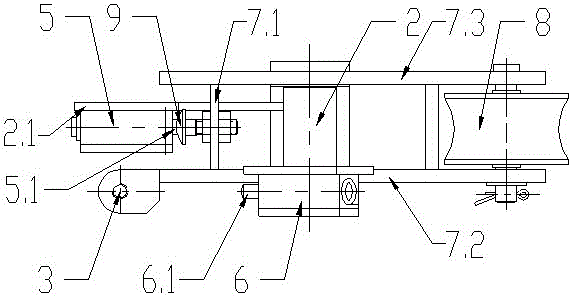

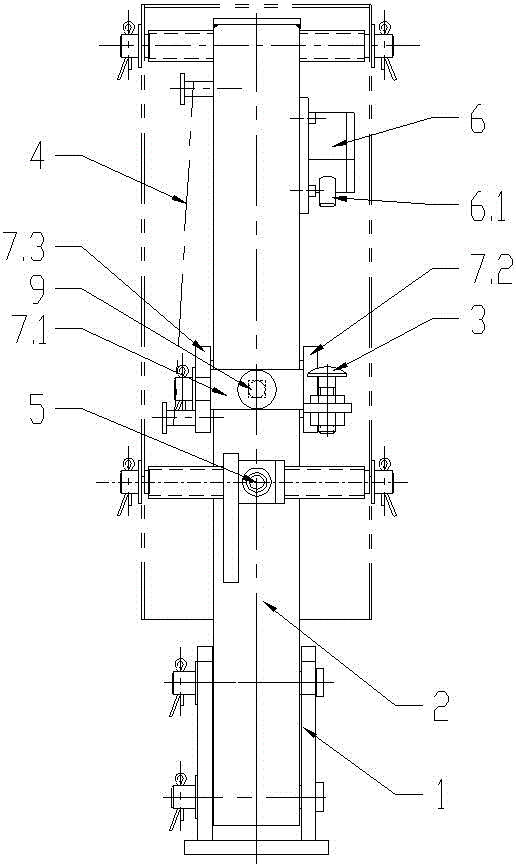

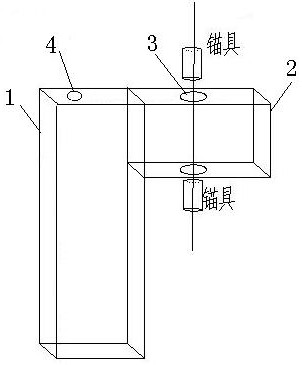

lift height limiter

The invention relates to a lifting height limiter comprising a vertical rod (2), a tension spring (4) and a link (7). The right end of the link (7) is provided with a pulley (8), the middle of the link (7) is hinged to the middle of the vertical rod (2), the left end of the link (7) is provided with an upper contact block (3) and a lower contact block (9), the upper end of the vertical rod (2) is connected to the left end of the link (7) through the tension spring (4), the lower portion of the vertical rod (2) is provided with a lower limiter unit (5) matching with the lower contact block (9), and the upper portion of the vertical rod (2) is provided with an upper limiter unit (6) matching with the upper contact block (3). According to the lifting height limiter, the link matches with the upper and lower limiter units, the dual-protection effect is provided, and the cage roof fall accident is avoided effectively.

Owner:江阴市星联起重设备安装有限公司

A full-anchor cable-supported roadway temporary support front beam suspension device and its application

ActiveCN109630169BNot destroyedExit normallyMine roof capsAnchoring boltsManufacturing technologyClassical mechanics

The invention relates to a temporary supporting forepoling bar suspension device of a full anchor-cable supporting roadway and application. The device is characterized in that the suspension device isin an inverted L shape and comprises a longitudinal plate and a transverse plate, an anchor device penetrating hole is formed in the transverse plate, a threaded hole is formed in the top of the longitudinal plate, and a safe baffle plate is arranged on the inner side of the transverse plate, and the length and width of the safe baffle plate are same as those of the transverse plate; according tothe device, each forepoling bar utilizes two temporary supporting forepoling bar suspension devices of the full anchor-cable supporting roadway. The device is simple in manufacturing technology, flexible in operation and high in adaptability, it can be ensured that after coal cutting (blasting), the full anchor-cable supporting roadway can be effectively supported temporarily, by adopting the suspension device, an original anchor cable which has reached the pre-tightening state does not need to be dismantled, and it is avoided that due to dismantling of the anchor cable, anchoring fails, theempty roof phenomenon occurs again, and the roof falling accident is caused.

Owner:XINWEN MINING GROUP

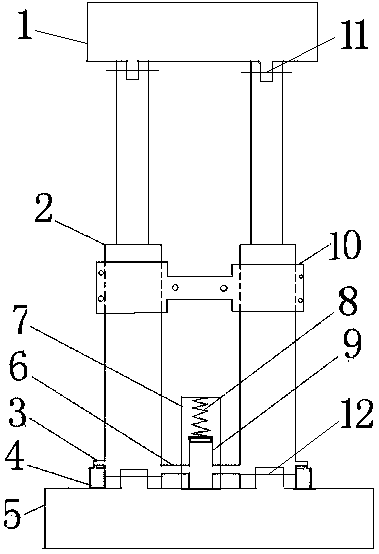

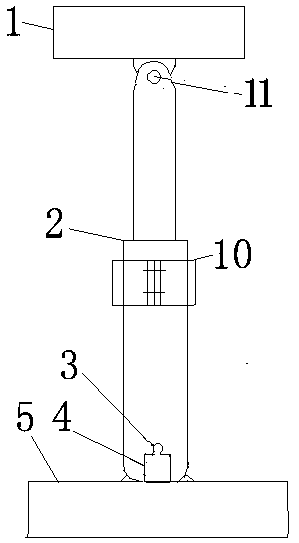

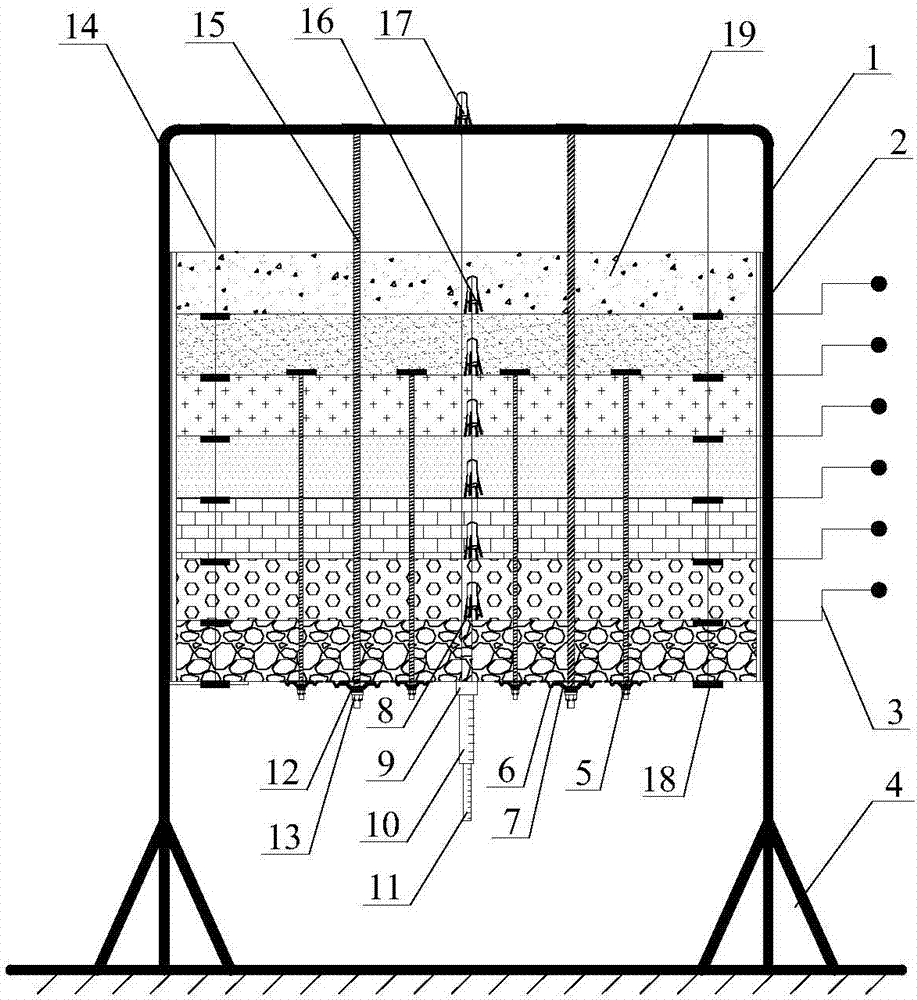

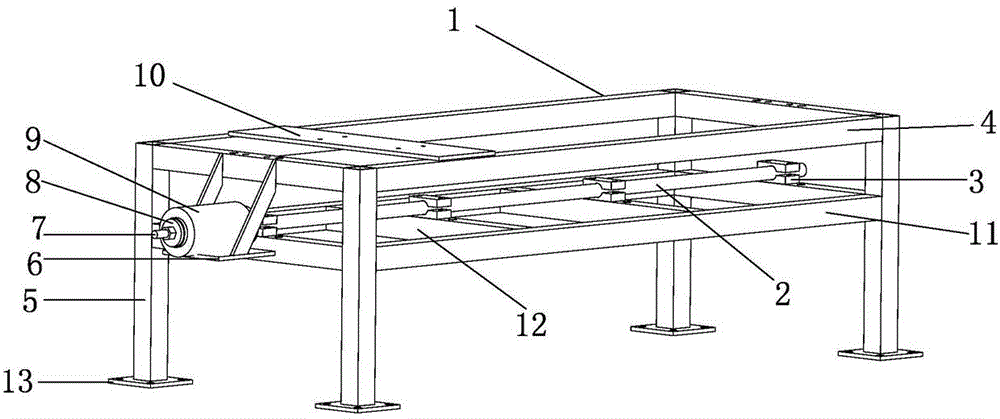

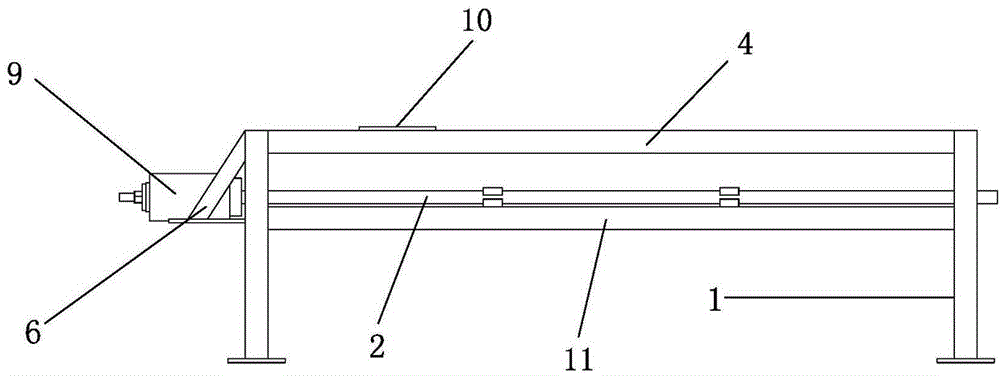

Anchor force test simulation comprehensive experimental device

ActiveCN103728077BPrevent roof fall accidentsNovel and reasonable structureUsing mechanical meansApparatus for force/torque/work measurementTest fixtureSteel tube

The invention relates to a device for an anchor rod anchoring force testing simulating comprehensive experiment. The device can effectively solve the problem that time and labor are wasted and the accuracy rate is low simultaneously in the prior art. The technical scheme is that the device comprises a machine frame, a steel pipe, an anchor rod and an annular oil cylinder. The machine frame is formed by supporting legs, an upper frame and a lower frame. The four supporting legs are respectively welded to four corners of both a horizontal upper frame and a horizontal lower frame, an oil cylinder mounting plate is installed in the front of the machine frame, the annular oil cylinder is installed on the oil cylinder mounting plate, a support is installed on the upper frame, a hand pump and a digital display meter are installed on the support, the steel pipe is fixed on the lower frame through a clamping plate, one end of the anchor rod is anchored in the steel pipe, the other end of the anchor rod penetrates through the center of the annular oil cylinder, and the anchor rod extends out of one end of the annular oil cylinder and is fixed through a baffle at the end of the annular oil cylinder. The device is low in cost and high in accuracy rate and greatly improves working efficiency, top plate roof collapse accidents on the working site are effectively avoided, and the device is innovation for anchor rod anchoring force testing devices.

Owner:HENAN POLYTECHNIC UNIV

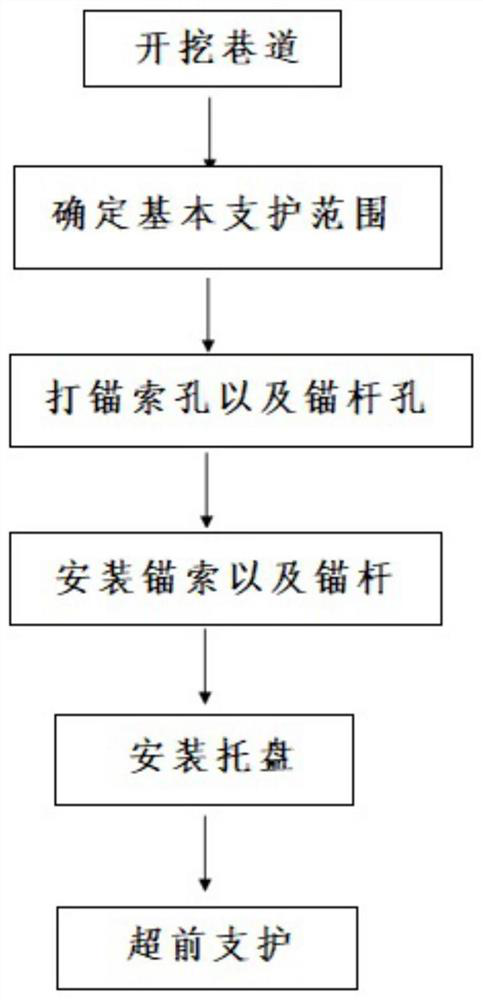

Coal mine tunnel supporting method

PendingCN114017083APrevent roof fall accidentsImprove the support effectAnchoring boltsCoal miningMining engineering

The invention relates to a coal mine roadway supporting method. The coal mine roadway supporting method comprises the following steps that S1, a roadway is excavated; S2, an impact danger area is determined, and then it is determined that the basic supporting range is 200-250 m in front of a current working face; S3, anchor cable holes and anchor rod holes are drilled in the impact danger area and the non-impact danger area correspondingly; S4, anchor cables and anchor rods are installed in the anchor cable holes and the anchor rod holes correspondingly, and top ends of the anchor cables and top ends of the anchor rods penetrate through the coal seam in the roadway and are fixed to the bedrock layer; S5, the anchor cables and the anchor rods are fixed through the trays, and basic supporting is completed; and S6, advance supporting is carried out to support a top plate of the roadway, and the advance support range is 200-250m in front of the current working face. According to the method, the basic supporting range and the advance supporting range are expanded, the ranges can cover the affected area in the coal mining process, and the roof caving accident can be effectively prevented. In addition, in the basic support, the anchor rods and the anchor cables are directly fixed to the firm bedrock layer, and support stability can be further improved.

Owner:山西中煤担水沟煤业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com