Top-shoveling and bottom-cutting type full-seam mining fully-mechanized coal mining method for extrasoft thick coal seam

A technology of thick coal seam and full height mining, applied in the field of full-height fully mechanized mining with shovel top and bottom cutting type in extremely soft and thick coal seams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

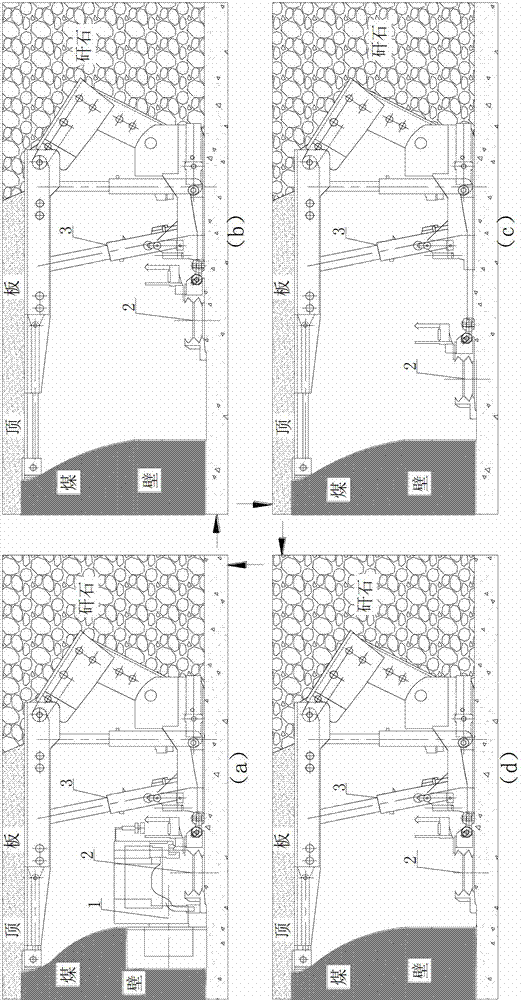

[0018] The very soft and thick coal seam shoveling top and cutting bottom type one-time mining full-height fully mechanized mining method of the present invention comprises the following steps:

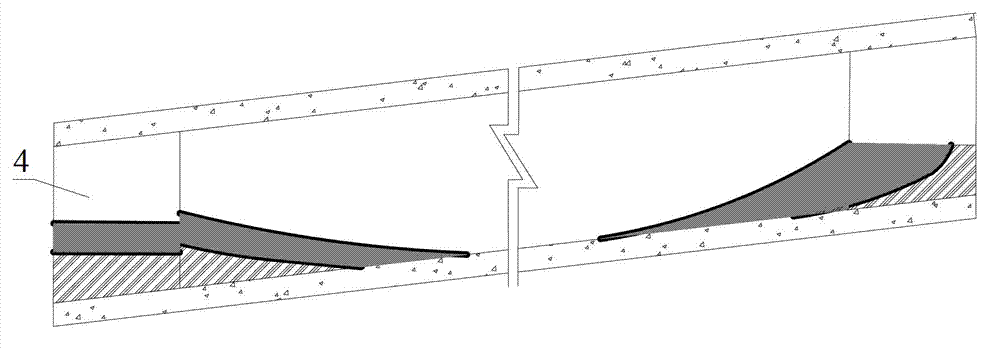

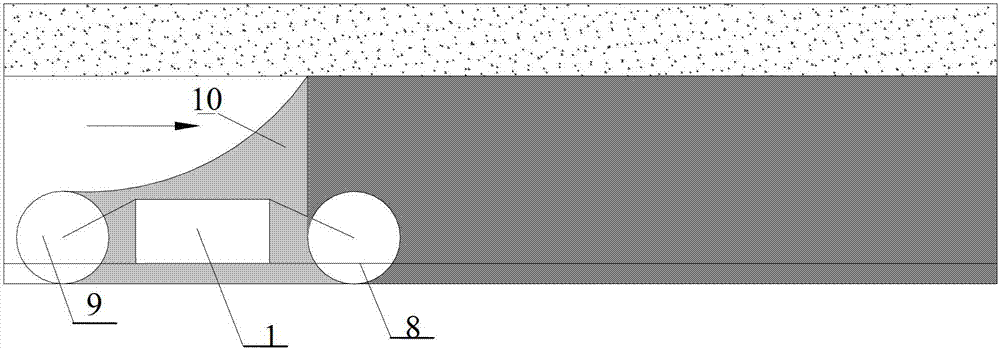

[0019] The mining roadway is excavated along the top of the coal seam, and the overlapping method of the working face and the coal seam is oblique lapping, that is, according to the daily advance rate, the bottom coal is artificially lifted along the advancing direction of the working face in the transport level roadway of the fully mechanized mining face with large mining height4 ~6m, the bottom coal bottom slope is less than 10°, which is used as a way to overlap the mining roadway and the working face and to recover the bottom coal at the end, as follows figure 1 shown.

[0020] During the mining proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com