Patents

Literature

62 results about "Coal shovel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coal shovel is a shovel designed for shoveling coal, coke or similar fuels, and on occasions does a double duty removing ash from the fireplace, firebox or furnace. A large coal shovel is used by the fireman of a coal-fired steam locomotive unless an automatic stoker is used.

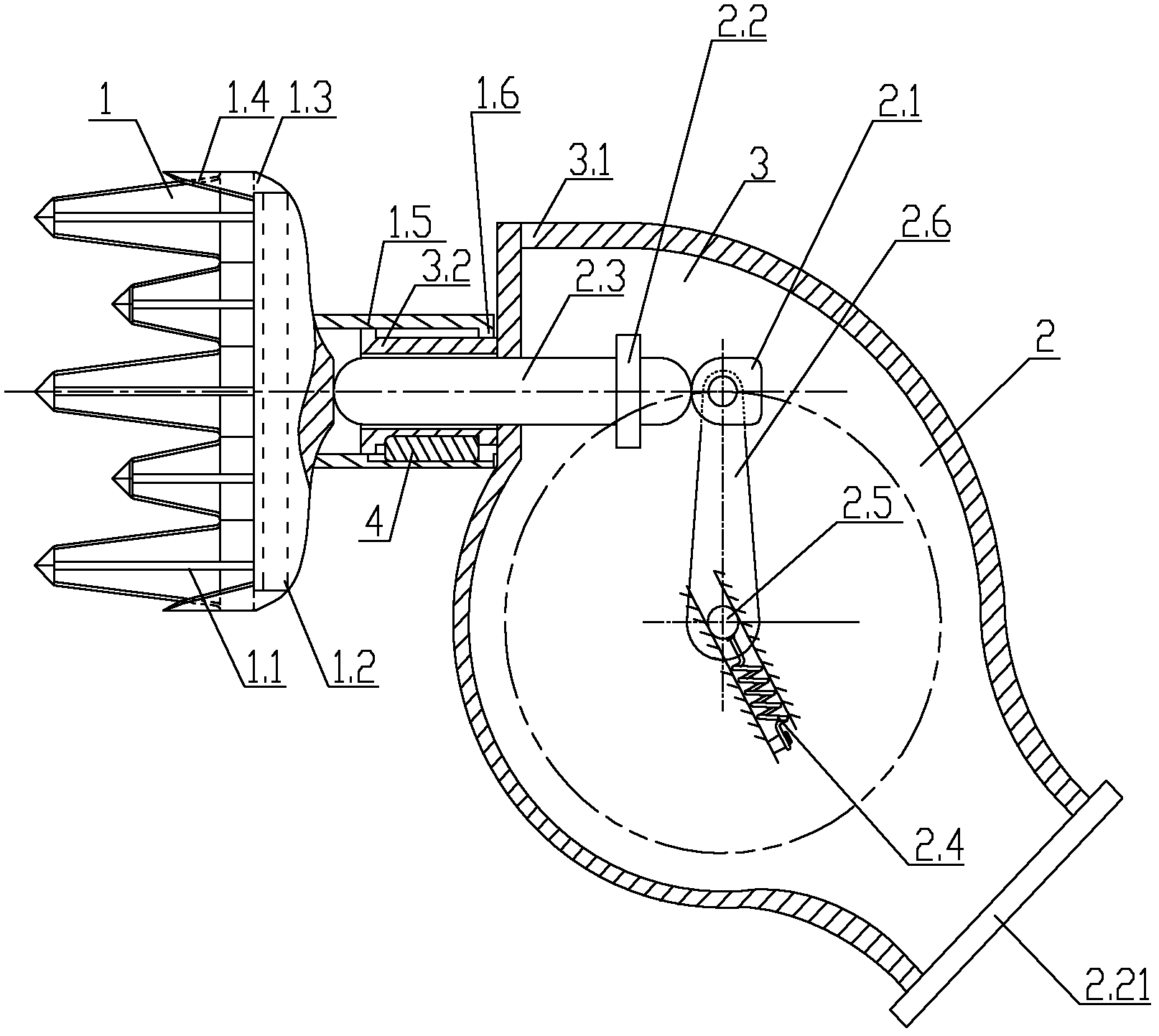

High-efficiency blocking coal shovel

The invention relates to coal mining equipment and specially, relates to a high-efficiency blocking coal shovel. The high-efficiency blocking coal shovel comprises a shovel body. The shovel body comprises a frame. The high-efficiency blocking coal shovel also comprises an impulsion shovel mechanism. The impulsion shovel mechanism comprises a shovel head and an impulsion device. The shovel head comprises shovel teeth and a fixing part. The shovel teeth are installed on the fixing part. A rear part of the fixing part is provided with an impulsion stroke guiding mechanism. The impulsion stroke guiding mechanism is sildingly connected to a guiding sleeve. The guiding sleeve is arranged on the impulsion device and / or the frame. The impulsion device impacts the impulsion stroke guiding mechanism. Only through one impulsion process, the shovel head can complete both coal falling and surface cleaning. The impulsion shovel mechanism is arranged on the shovel body. The shovel body drives the whole high-efficiency blocking coal shovel to walk. Coal mined by the high-efficiency blocking coal shovel is not broken fully. The high-efficiency blocking coal shovel has a high blocking rate and low power consumption, produces a small quantity of coal dust, provides a good work environment, realizes continuous coal mining, synchronously completes both coal falling and surface cleaning, and saves a mass of energy.

Owner:刘素华

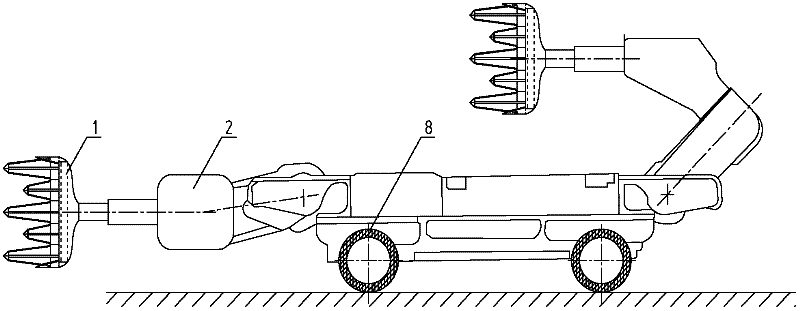

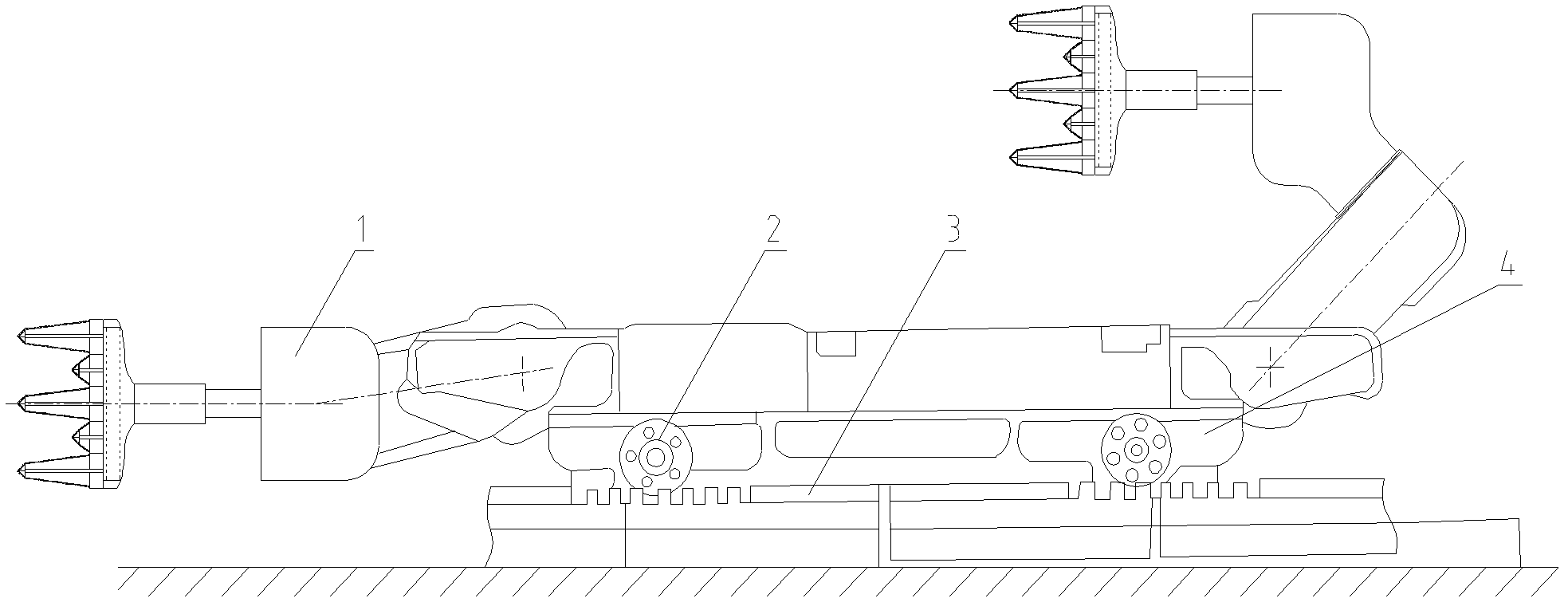

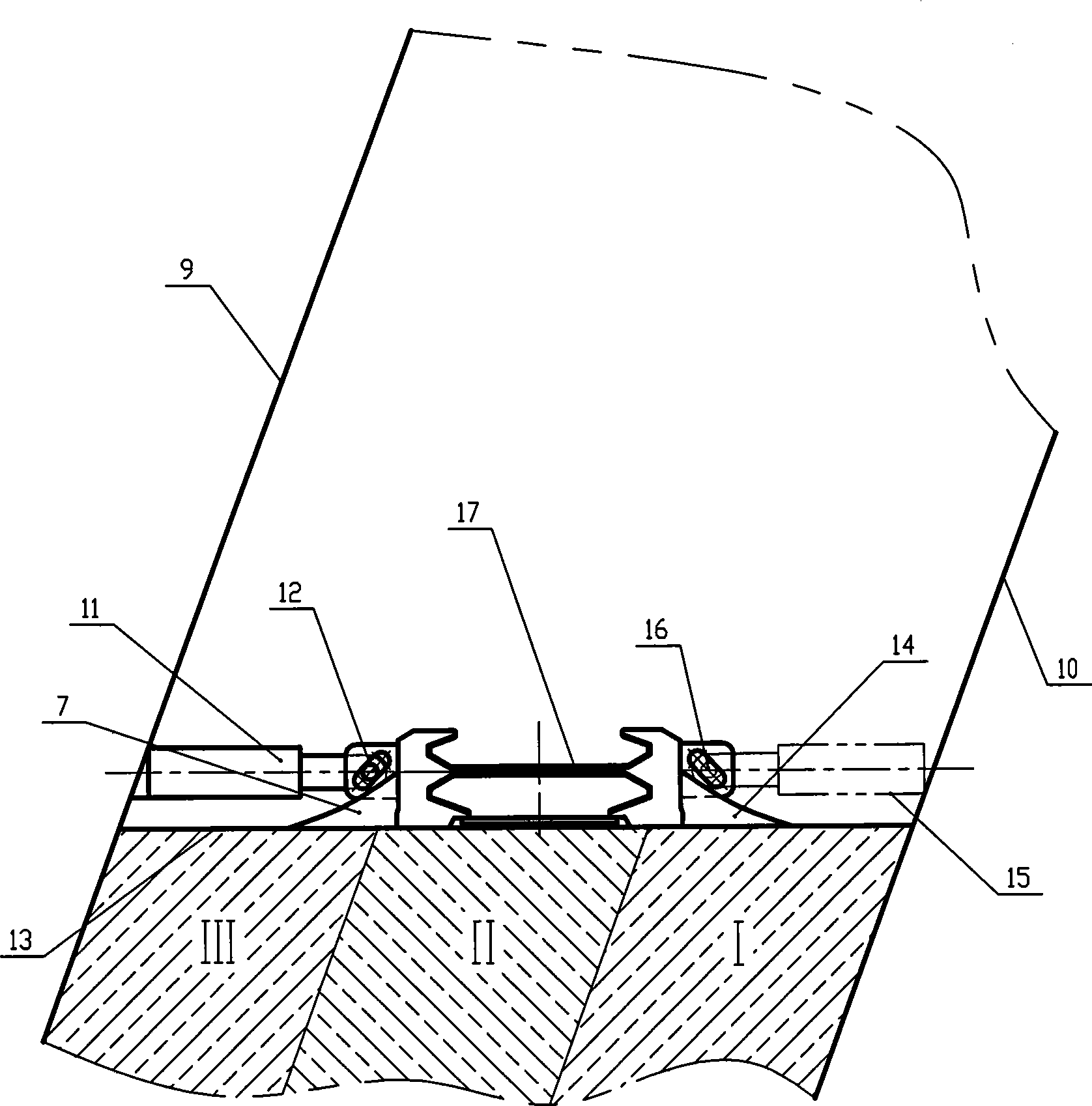

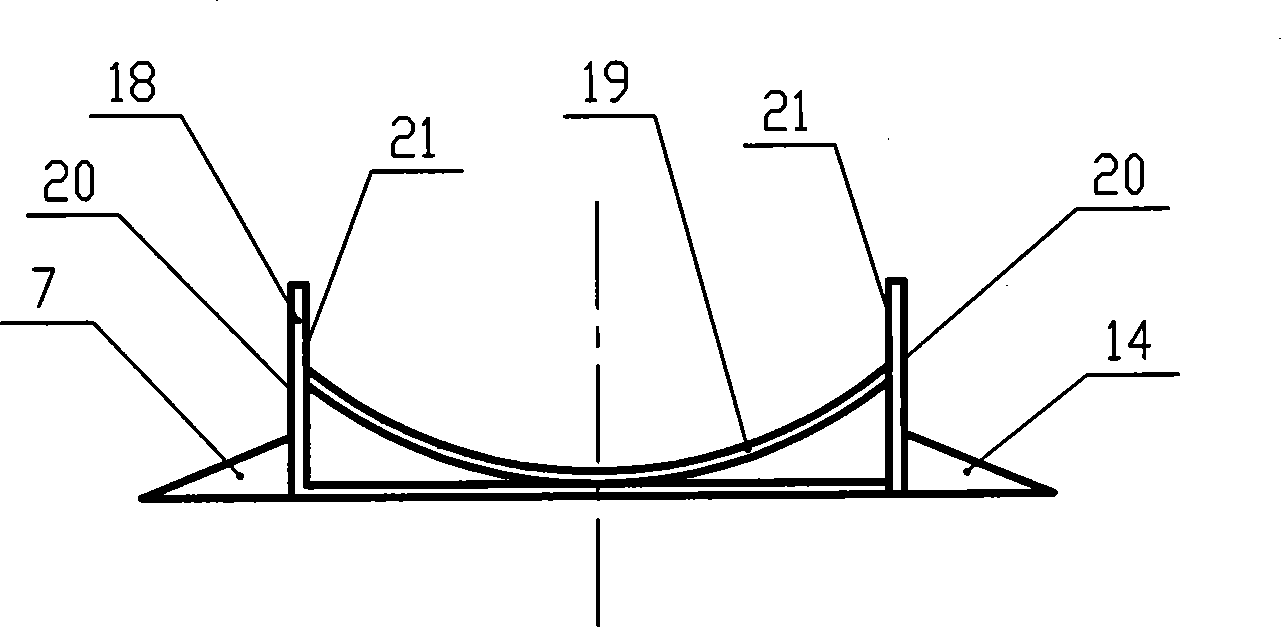

Cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology

ActiveCN101798925AReduce cutting powerReduce electricity costsUnderground miningSlitting machinesControl systemElectrical control

The invention discloses a cutting head type shortwall coal-winning machine and comprehensive mechanized coal mining technology. A tunneller type cutting device is used, and the coal-winning machine is a hydromechatronics coal-winning machine which is in electric traction, electrically drags a cutting head, carries out hydraulic drive to change a cutting arm pitch angle and swings inside and outside the working face. The coal-winning machine mainly comprises a machine body, a cutting device, a travelling mechanism, a coal shovelling device, an auxiliary device, an auxiliary hydraulic system and an electrical control system. The coal-winning technology uses technical equipment, such as a coal-winning machine, a hydraulic support, a scraper conveyor, an elevating conveyor, a breaker, a crossheading belt, an advance support hydraulic support and the like. The technical flow is as follows: the coal-winning machine retracts to the working surface tail, a scraper-trough conveyer is pushed tocoal wall, coal is cut to the machine head, the machine is retracted, coal is cleaned, and the support is pulled. The coal-winning machine has compact structure, small volume and weight, strong adaptability and convenient installation and transportation, can solve a series of problems of four low, three high, two long and one poor in small and medium coal mining technology and provides matching coal mining technology.

Owner:闫振东

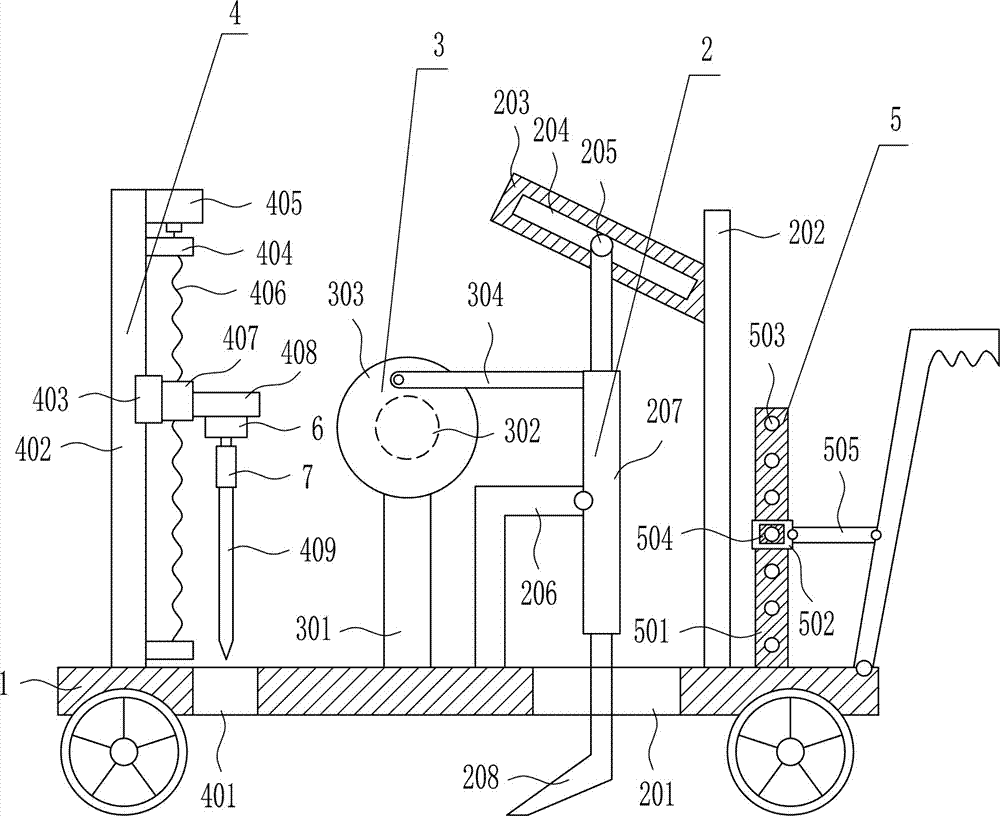

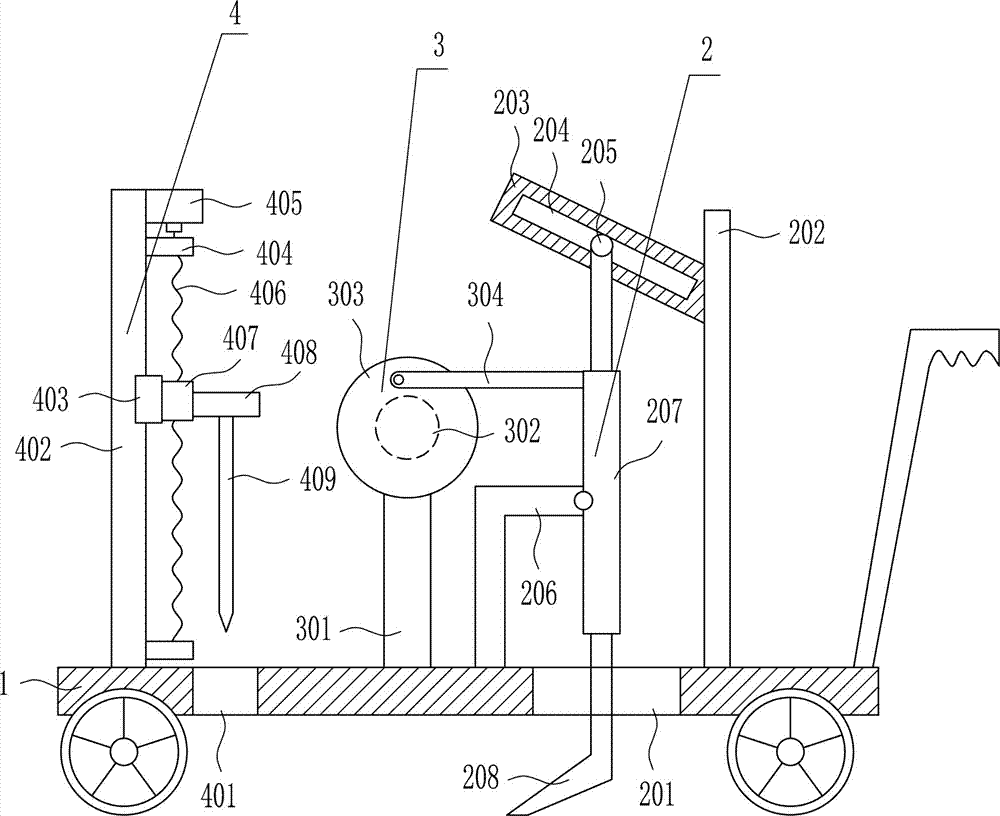

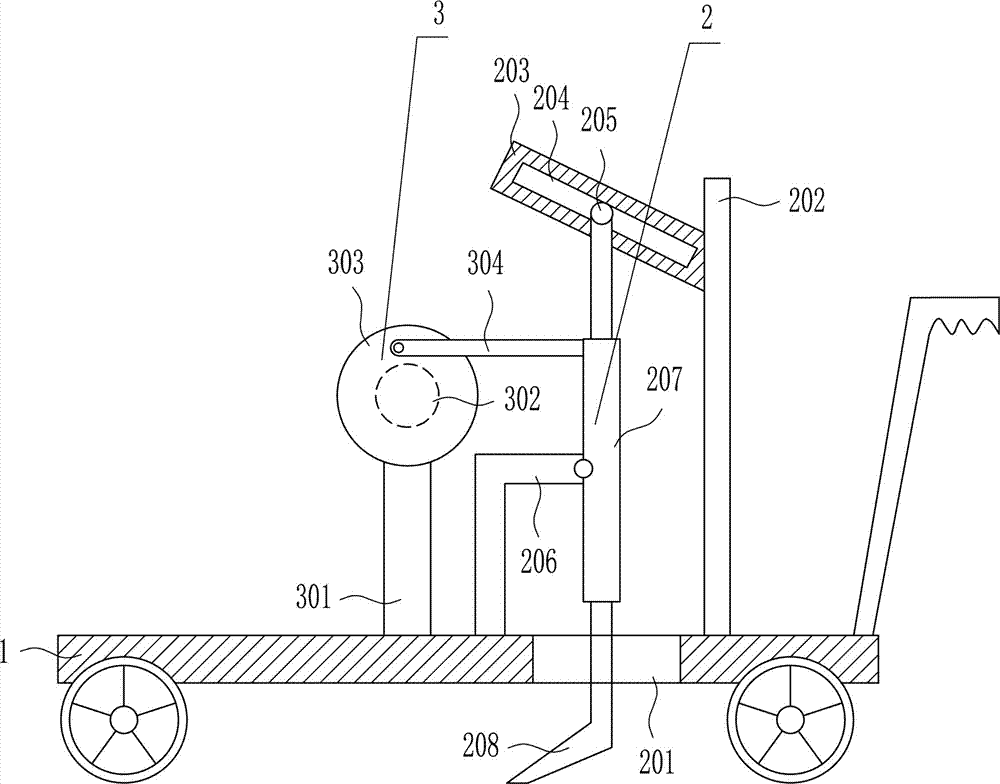

Snow shoveling device for highway traffic

The invention belongs to the technical field of highway traffic, and particularly relates to a snow shoveling device for highway traffic. The invention aims at solving the technical problem of providing the snow shoveling device for highway traffic with the advantages that the work intensity can be reduced; the snow shoveling speed can be accelerated; the snow shoveling efficiency can be improved. In order to solve the technical problem, the invention provides the snow shoveling device for highway traffic. The snow shoveling device for highway traffic comprises a trolley and the like, wherein the top of the trolley is provided with a snow shoveling device; a driving device is arranged on the top of the trolley at the left side of the snow shoveling device. Through the driving device, the snow shoveling device can be driven to fast shovel the snow, so that the manual snow shoveling on the road by a coal shovel is not needed; therefore the effects of reducing the work intensity, accelerating the snow shoveling speed and improving the snow shoveling efficiency are achieved.

Owner:浙江东民科技有限公司

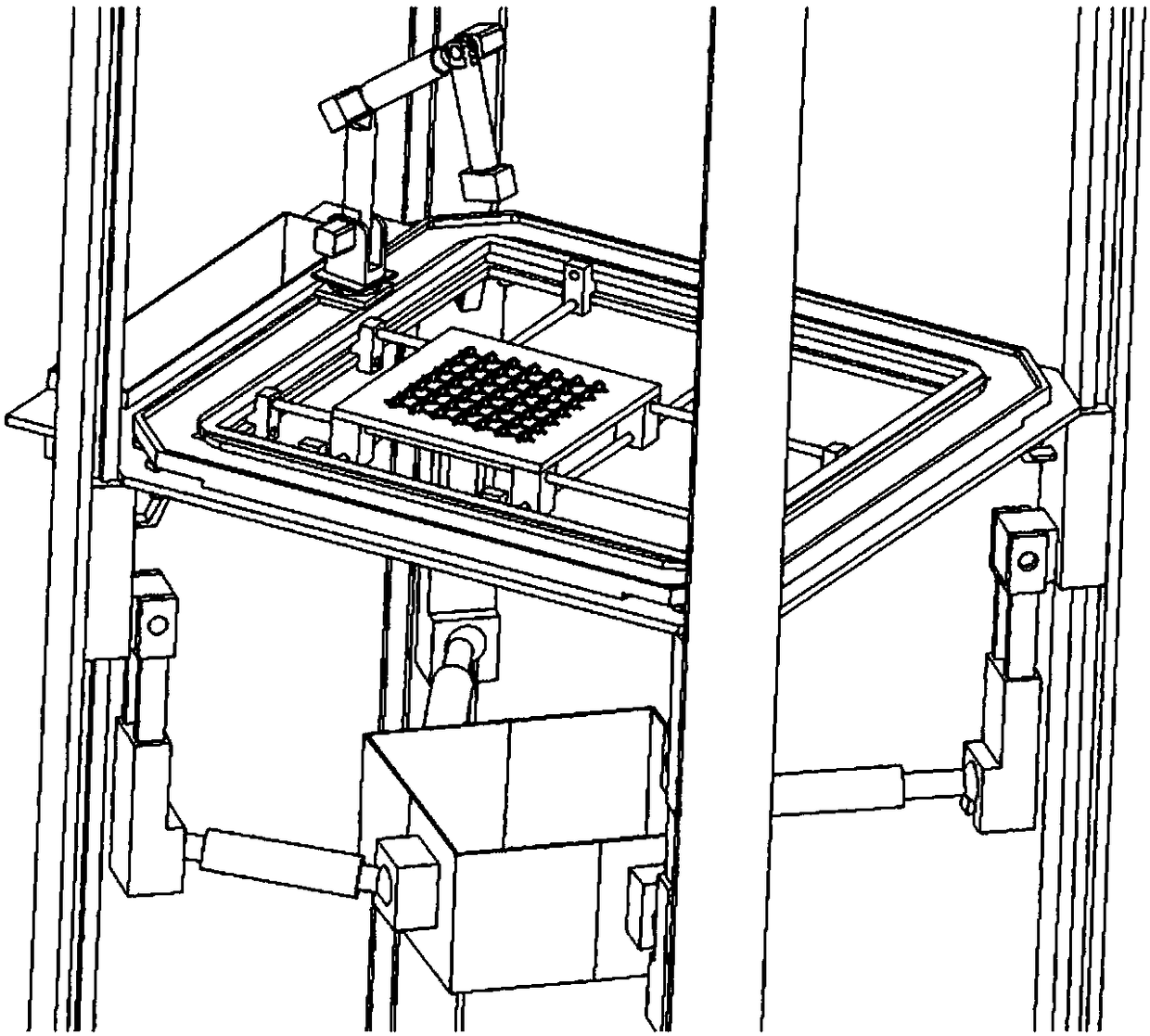

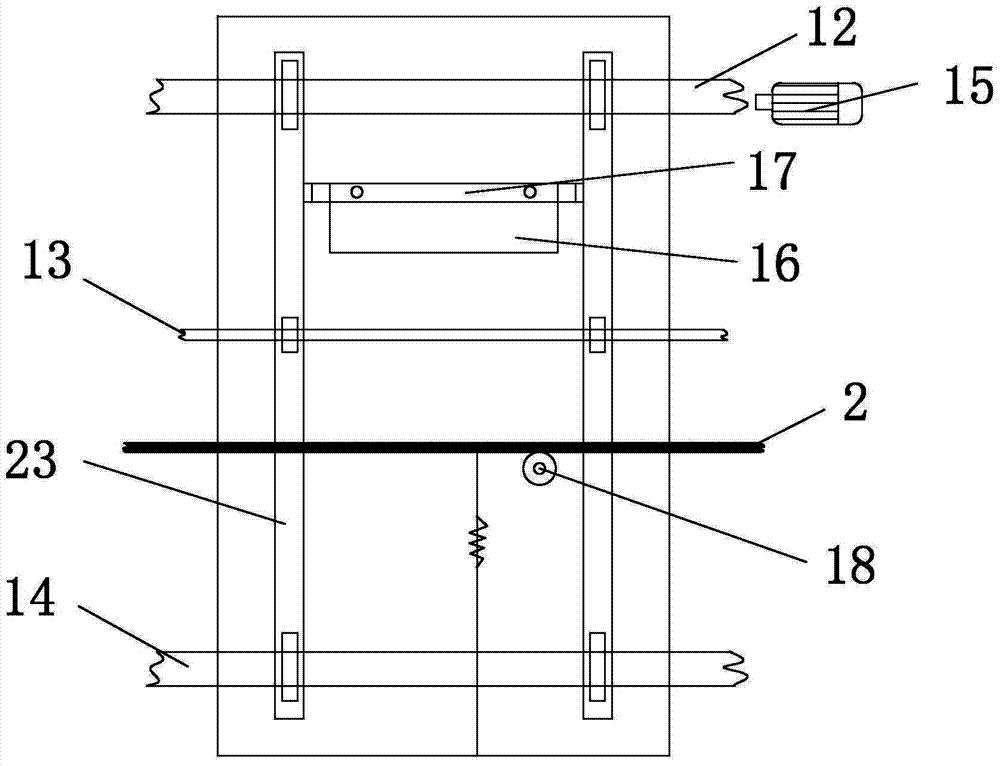

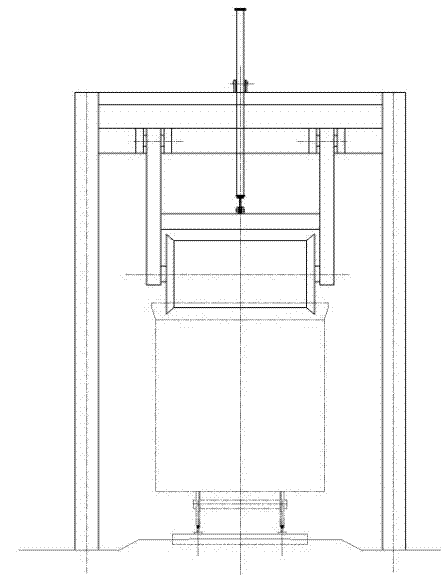

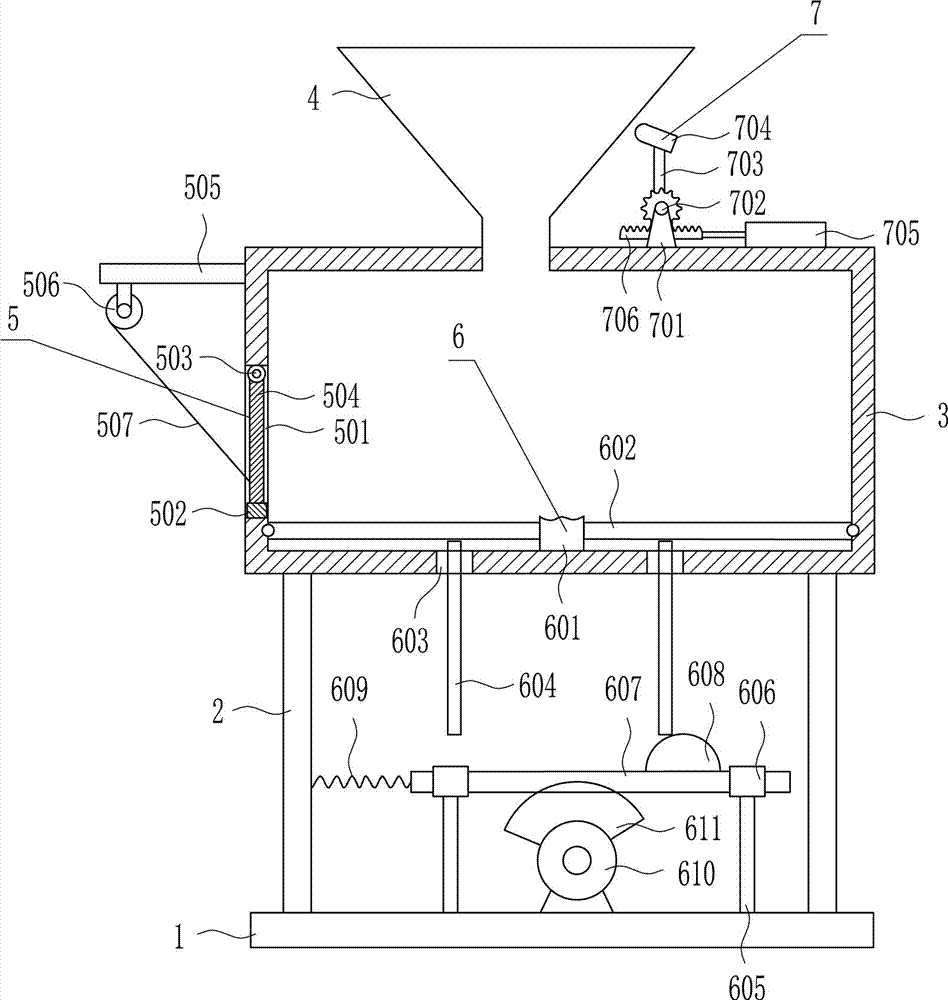

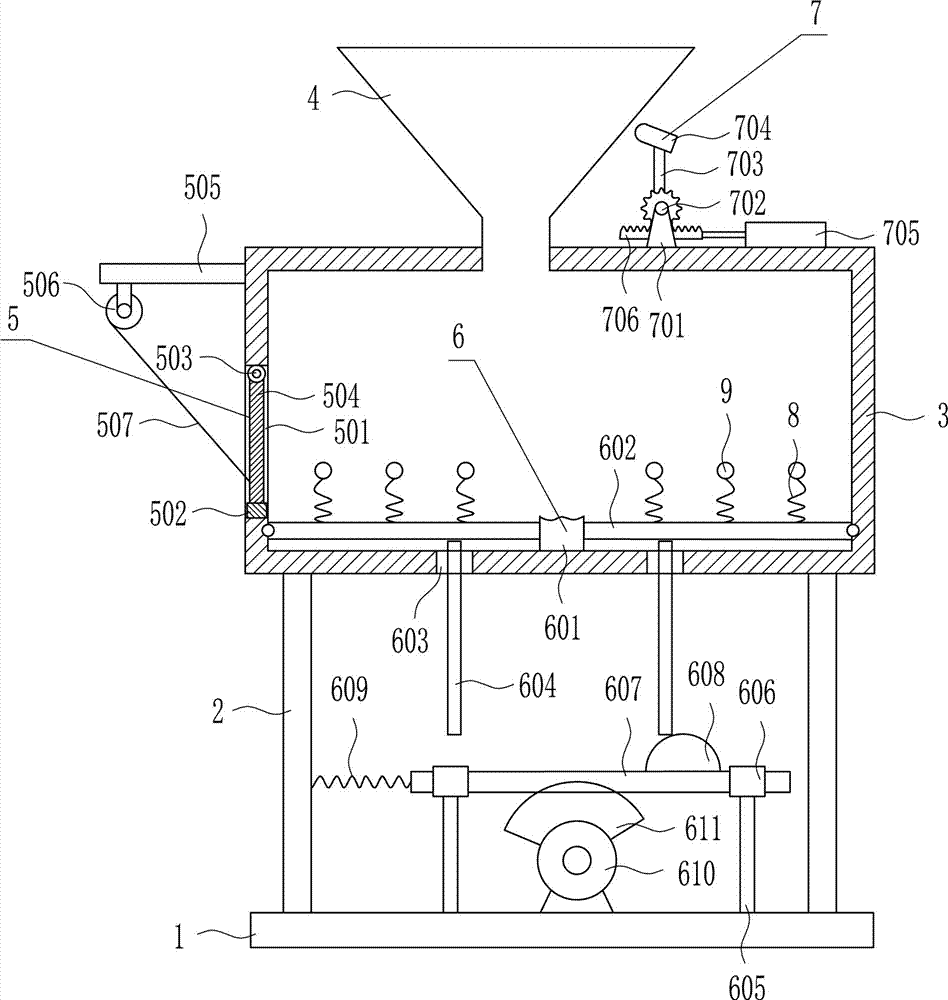

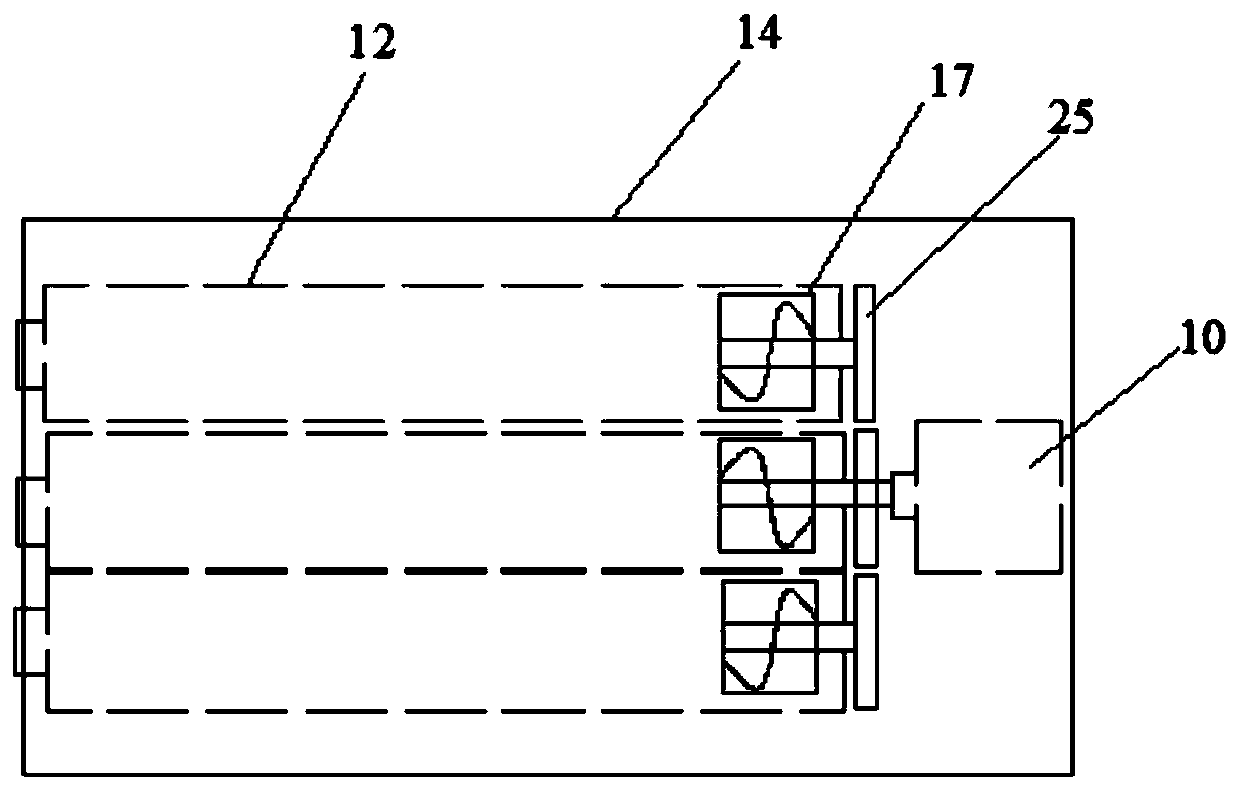

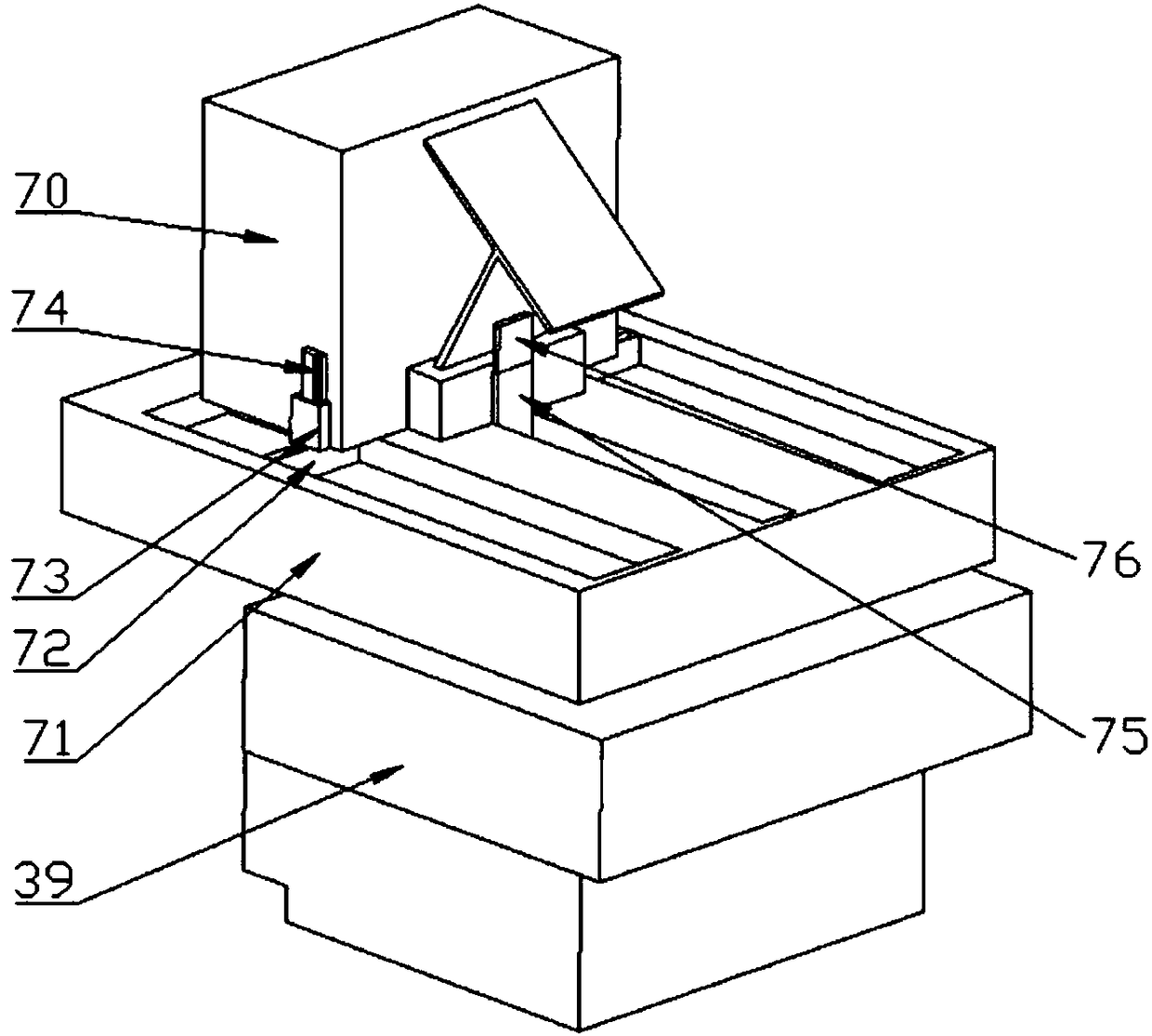

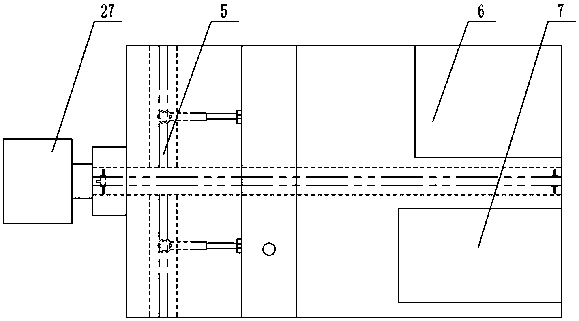

Top coal gangue interface recognition test system

ActiveCN108534975AStrong expandabilitySave spaceVibration testingShock testingDrop impactPilot system

The invention relates to a top coal gangue interface recognition test system comprising a base, a coal gangue particle impact vibration test device, a simulating coal flow coal gangue drop impact testdevice. The coal gangue particle impact vibration test device comprises a vibration table device, a bracket assembly, a coal release device and a high-speed camera component. The coal release devicereleases the coal gangue particles to the vibration table device. The high-speed camera component obtains instantaneous image information that the coal gangue particles drop on the vibration table device. The simulating coal flow coal gangue drop impact test device includes a simulating coal flow drop device, a coal gangue transport device, a coal shovel device and a top coal hydraulic support working group. Subsequently, a simulating coal pressure loading device and coal flow buckle device perform a simulating coal flow coal gangue drop impact test on the top coal hydraulic support working group. The test system can realize the vibration plate test of single-particle, multi-particle, group-particle coal gangue impact simulation, can also simulate the actual drop of the top coal, and can effectively obtain the data of the top coal drop test.

Owner:SHANDONG UNIV OF SCI & TECH

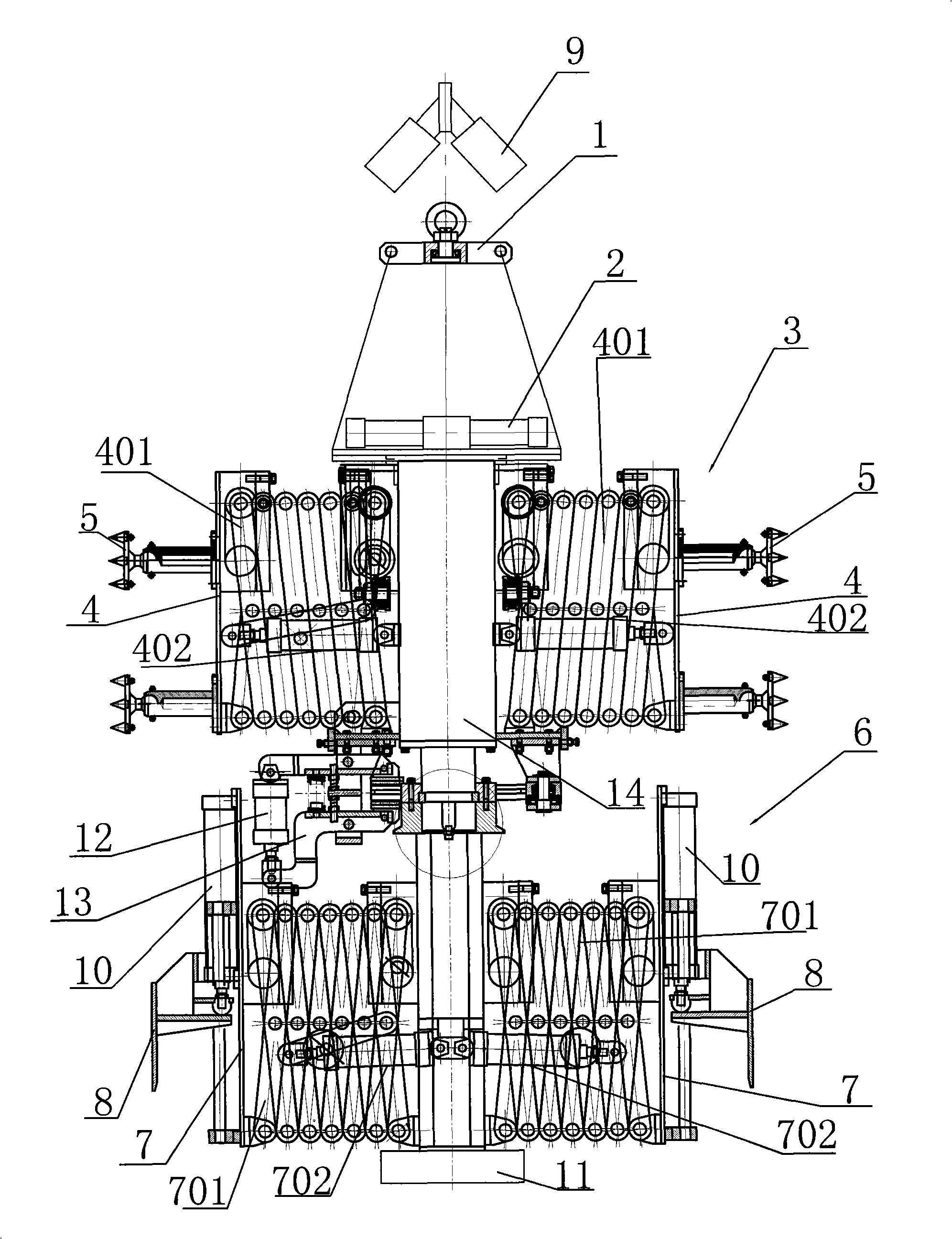

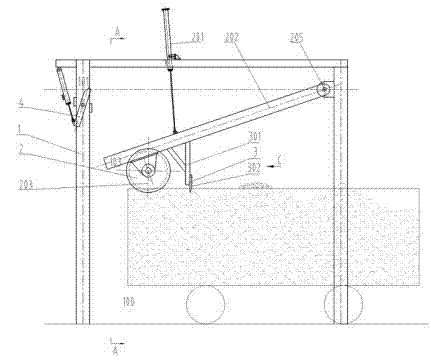

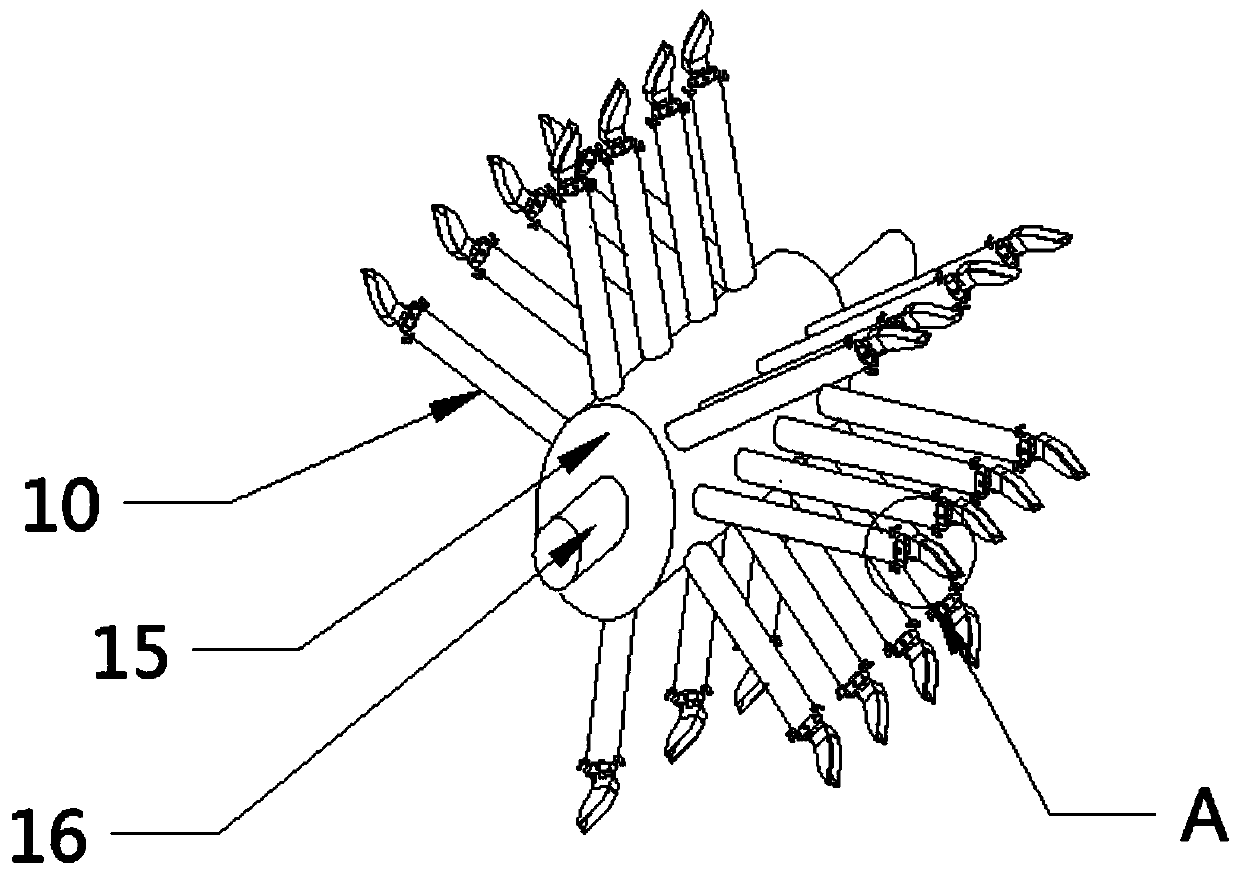

Underground coal bunker cleaning robot

InactiveCN101526007AMechanizationSave manpower and material resourcesMine roof supportsWinding mechanismsEngineeringMaterial resources

The invention discloses an underground coal bunker cleaning robot which comprises a suspension mechanism, a driving mechanism, an upper position mechanism, a lower position mechanism and at least one camera, wherein the suspension mechanism is connected with a traction rope of a hoist device arranged outside the coal bunker; the driving mechanism is used for driving the upper position mechanism and the lower position mechanism to respectively rotate and swing; the upper position mechanism is used for supporting the wall of the coal bunker to position and is provided with at least two elastic transverse supporting arms, and the free ends of the transverse supporting arms are provided with contact parts with sharp objects; the lower position mechanism is used for shoveling coagulum of the wall of the coal bunker and is provided with at least two elastic transverse operating arms, and the free ends of the transverse operating arms are provided with coal shovels which can reciprocate upwards and downwards; and the camera is used for shooting the on-site situation of the wall of the coal bunker and is connected with a monitor arranged outside the coal bunker. An operator can only correspondingly operate the underground coal bunker cleaning robot by an electric control system, and the like outside the coal bunker to complete cleaning tasks of the vertical walls and a lower shrinking hole of the whole underground coal bunker, thus manpower and material resources are reduced to realize the mechanization of underground coal bunker cleaning.

Owner:SHANDONG UNIV OF SCI & TECH

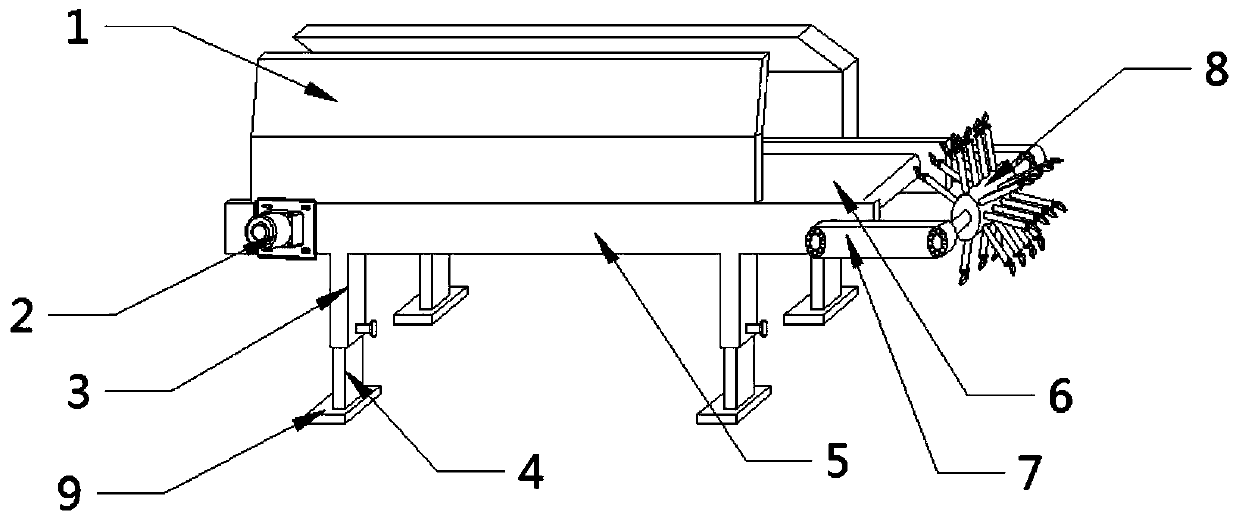

Belt sticky coal removing and recycling machine

The invention discloses a belt sticky coal removing and recycling machine which comprises a base, a rack arranged on one side of the base, and a fallen coal recycling transmission mechanism installed on the rack. The base is located below a lower belt of a belt conveyor, the upper end of the base is opened, the lower end of the base is closed, and a fallen coal bunker and a sticky coal cleaner are arranged in the base. A fallen coal containing cavity communicated with the fallen coal bunker is formed in the rack. The fallen coal recycling transmission mechanism comprises drive chain wheels installed on the rack, driven chain wheels opposite to the drive chain wheels in position, and a drive portion driving the driving chain wheels to rotate. Chains are arranged between the drive chain wheels and the driven chain wheels in a sleeved mode, the drive chain wheels are two in number, the driven chain wheels are two in number, correspondingly, the chains are two in number, and a coal shovel is arranged between the two chains. The belt sticky coal removing and recycling machine can be used for automatically removing sprinkled coal and effectively reducing the phenomena of belt deviation, equipment abrasion, machine tail roller blocking and the like caused by the sprinkled coal, and the maintenance cost of equipment is greatly cut down.

Owner:SHANDONG UNIV OF SCI & TECH

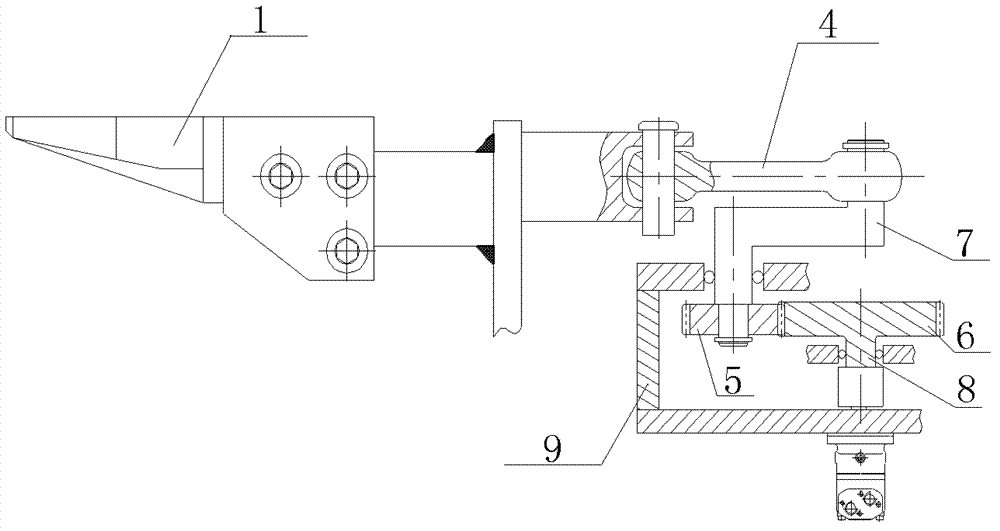

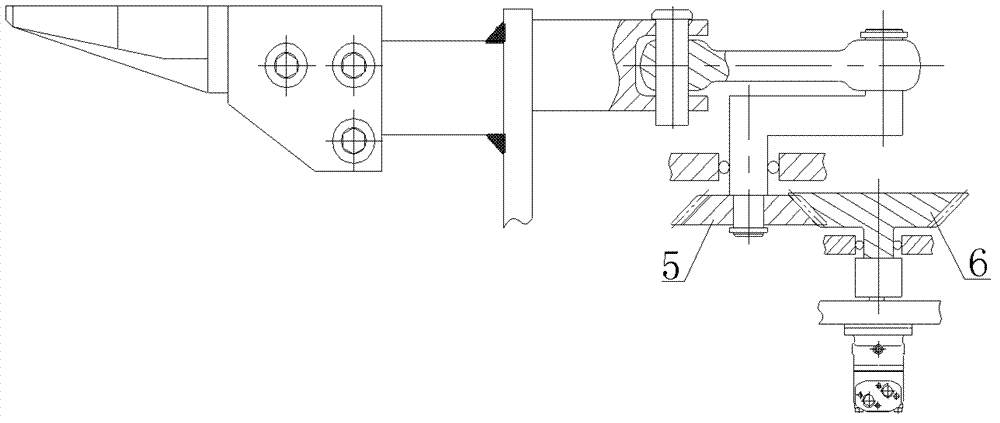

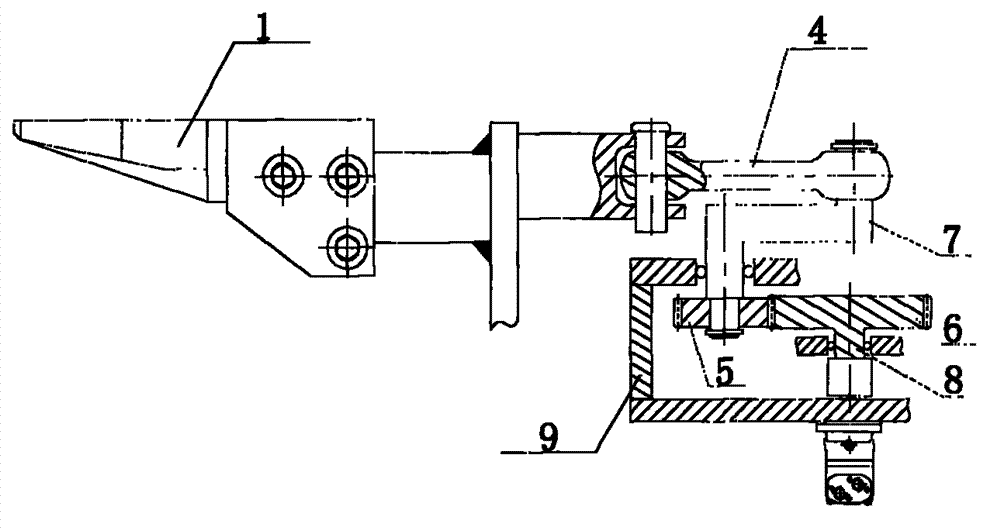

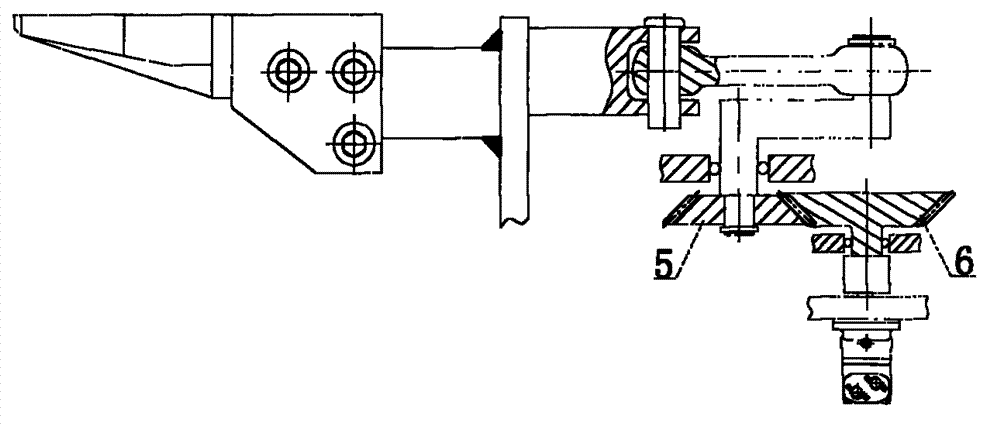

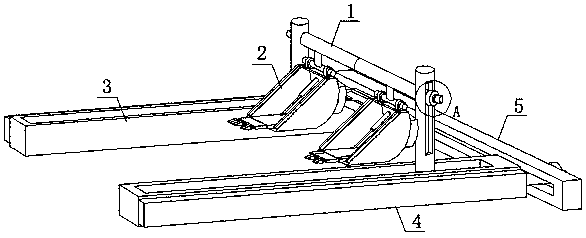

Excavating and shoveling buffer transmission device of lump coal shovel

The invention belongs to the fields of mineral extraction, mining tunneling and tunnel excavation, and particularly relates to an excavating and shoveling buffer transmission device of a lump coal shovel. The device comprises a driving gear, a driven gear and a gear mounting rack, wherein the driving gear and the driven gear form a clearance fit; the driven gear is connected with a power output shaft; and the clearance between the driving gear and the driven gear absorbs the amount of deformation during the work of the power output shaft. Thus, the vibration of the body of the device is prevented, so that the excavating and shoveling work is smooth, and the coal mining process is improved, thereby bringing great benefits to coal mine production.

Owner:刘素华

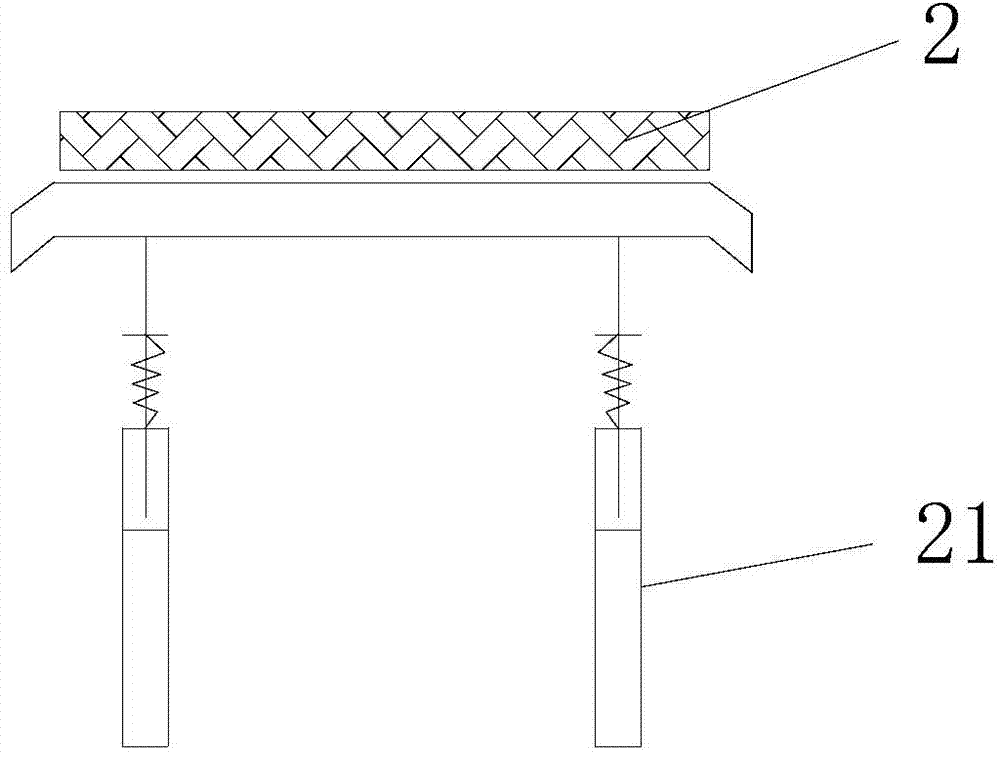

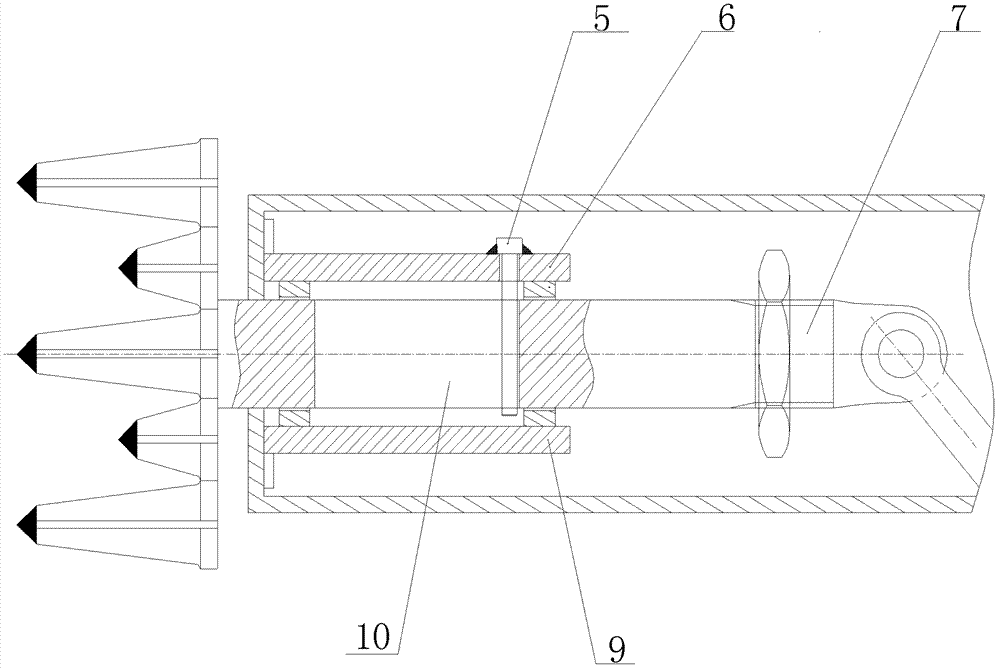

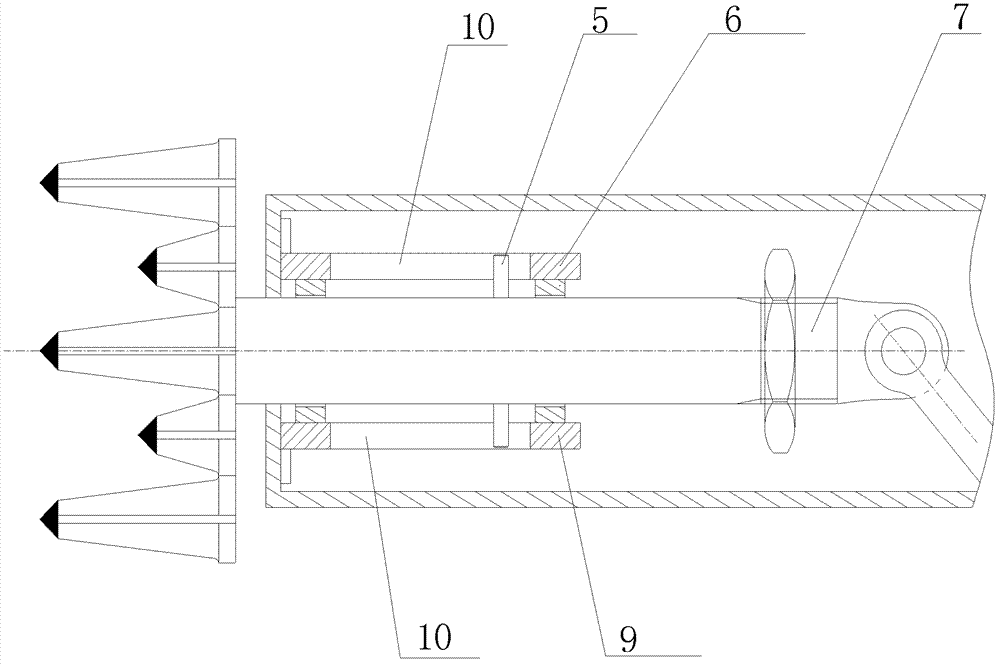

Efficient blocking coal shoveling device

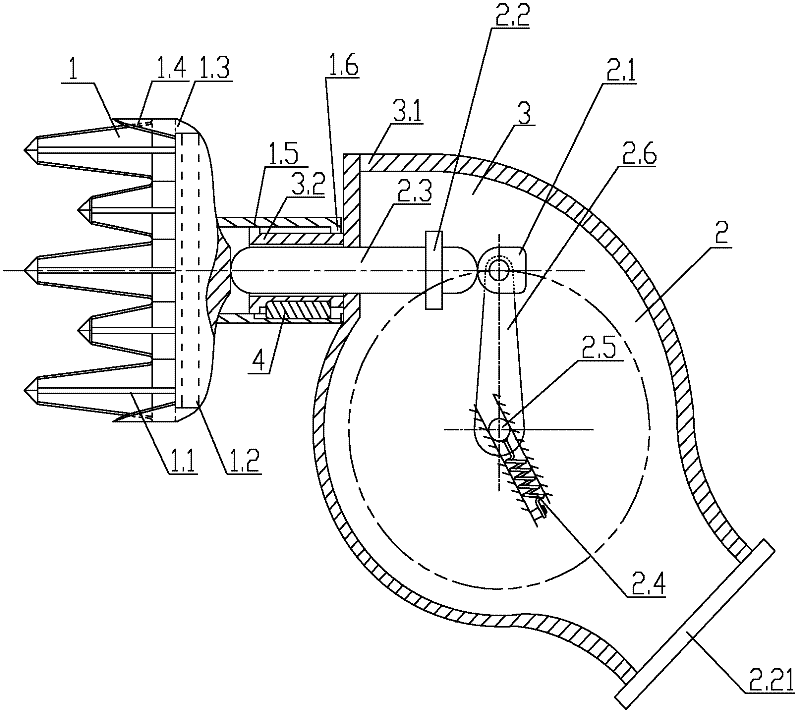

ActiveCN102678111AImprove efficiencyExtended service lifePropulsionSurface cleaningWorking environment

The invention relates to mine coal extraction equipment and specifically relates to an efficient blocking coal shoveling device. The coal shoveling device comprises a device body and an impact shovel mechanism, wherein the device body comprises a rack, the impact shovel mechanism comprises a shovel head and an impacting device, the shovel head includes shovel teeth and a fixing part, the shovel teeth are installed on the fixing part, an impact stroke guide rod is arranged on the rear portion of the fixing part and is in a sliding connection with a guide sleeve, the guide sleeve is arranged on the impacting device and / or the rack, the impacting device can impact the impact stroke guide rod, an impacting action enables the shovel head to have a one-time completion of a coal blanking and a surface cleaning, and the impact shovel mechanism is arranged on the device body which drive a whole device to move. By means of the efficient blocking coal shoveling device, extracted coals are not subjected to a sufficient crushing, so that blocking material rate is high, power consumption and coal dusts are small, work environment is good, a continuous coal extraction and the one-time completion of the coal blanking and the surface cleaning are achieved, and a large amount of energy is saved.

Owner:刘素华

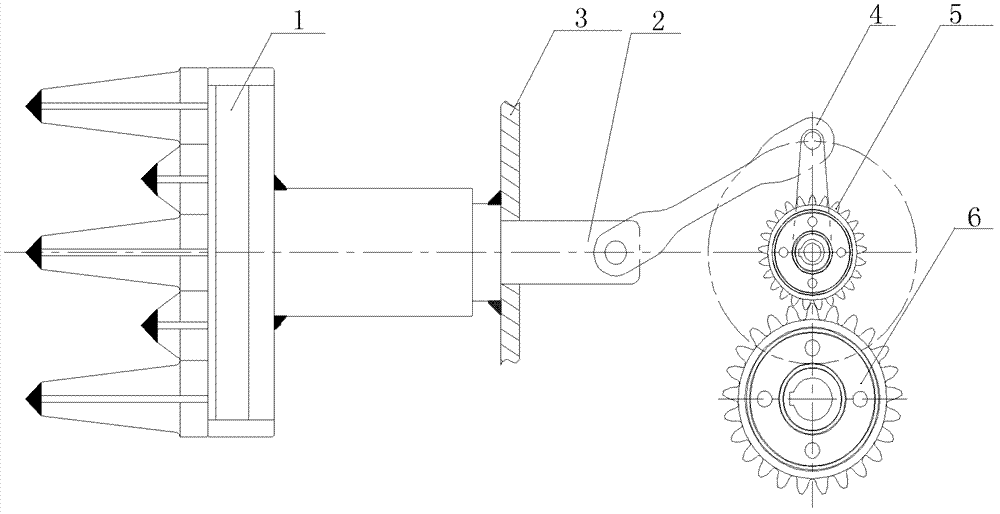

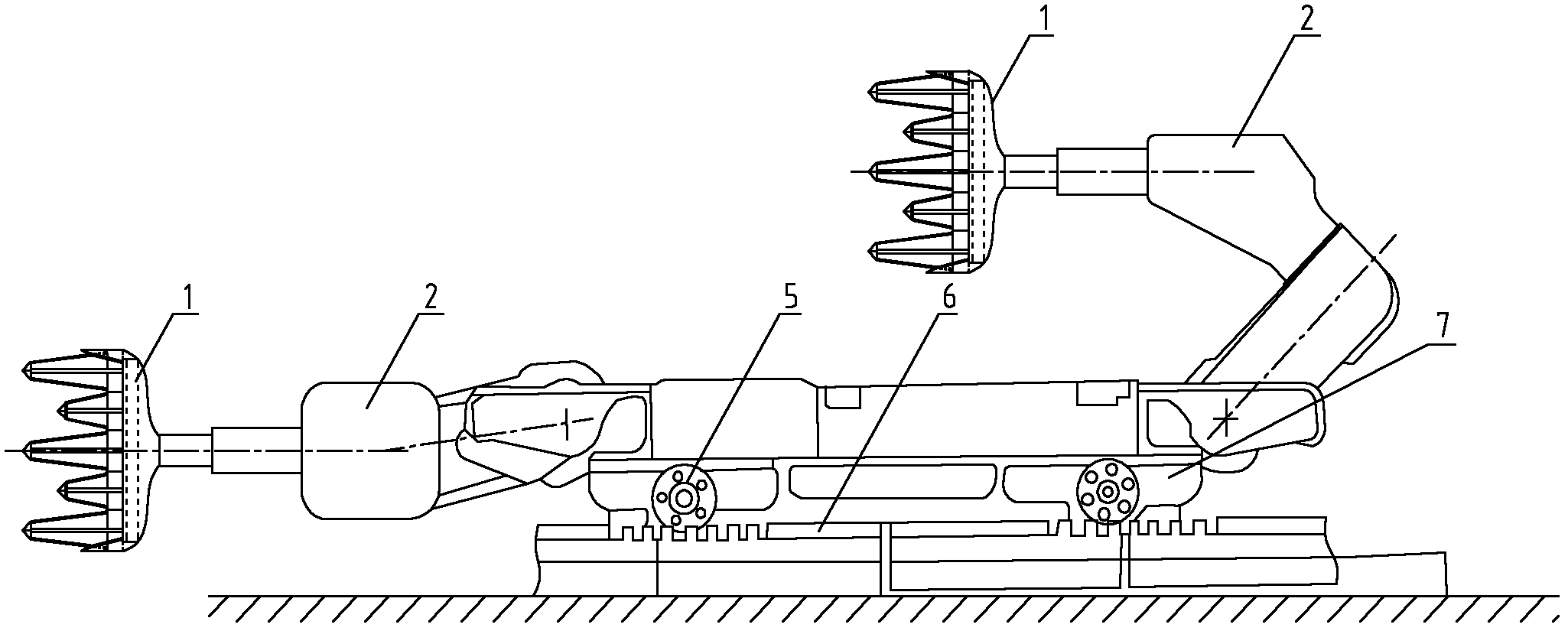

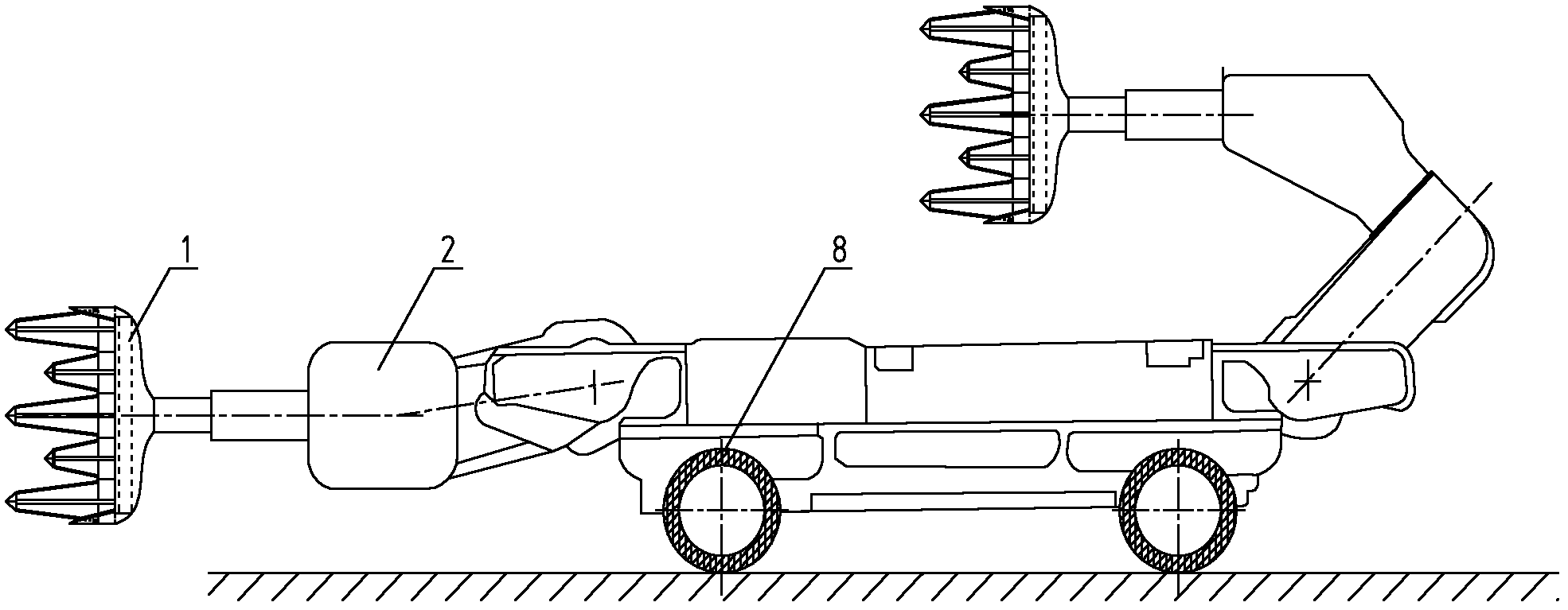

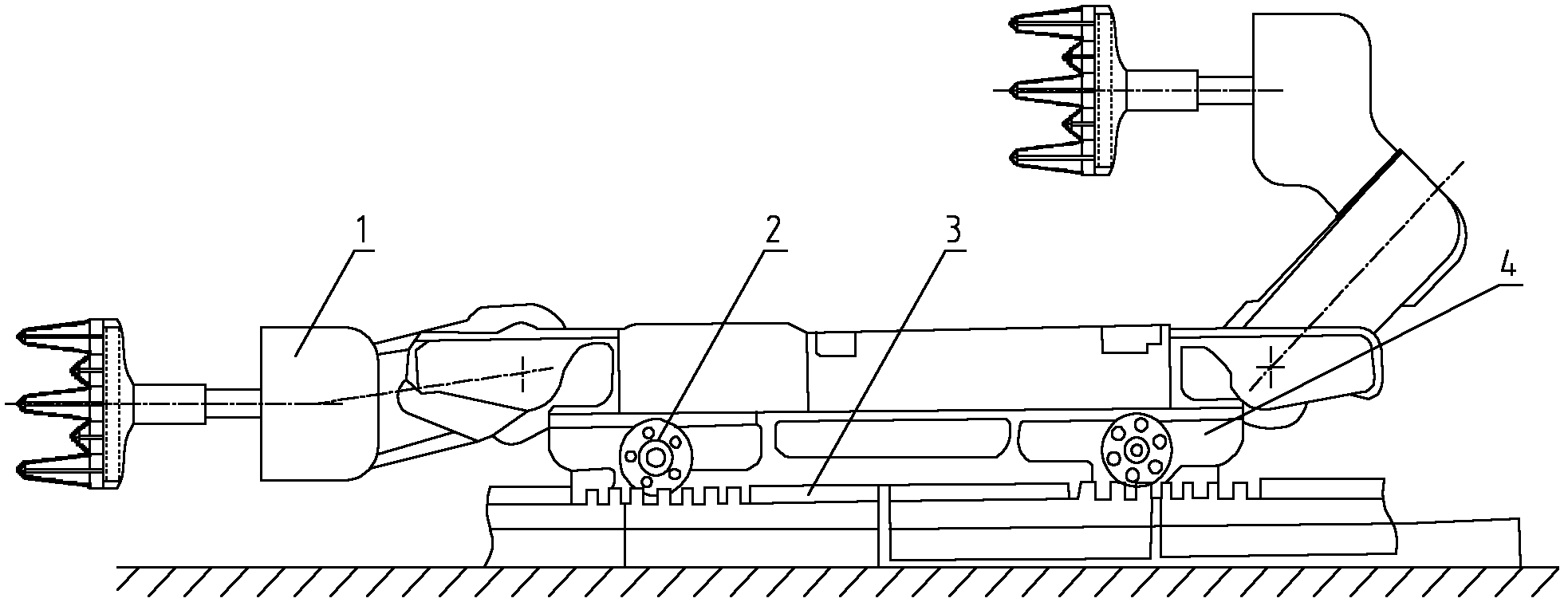

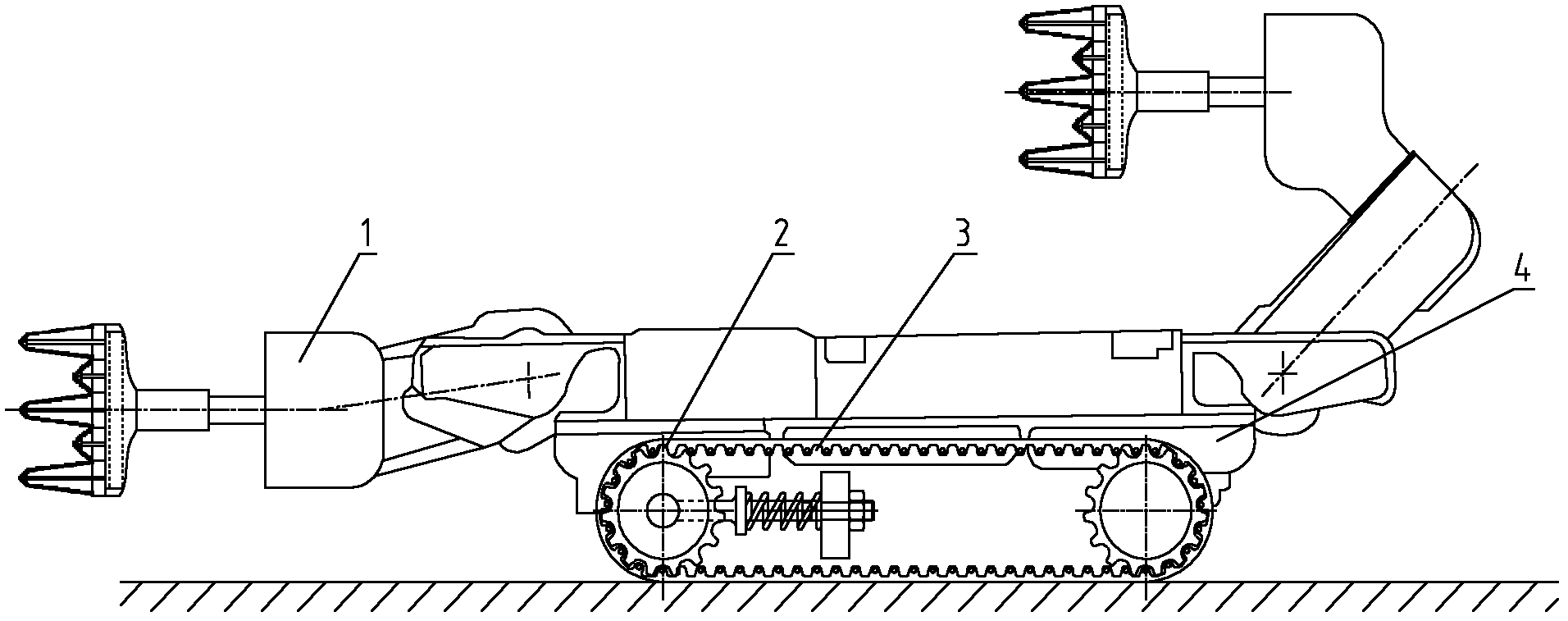

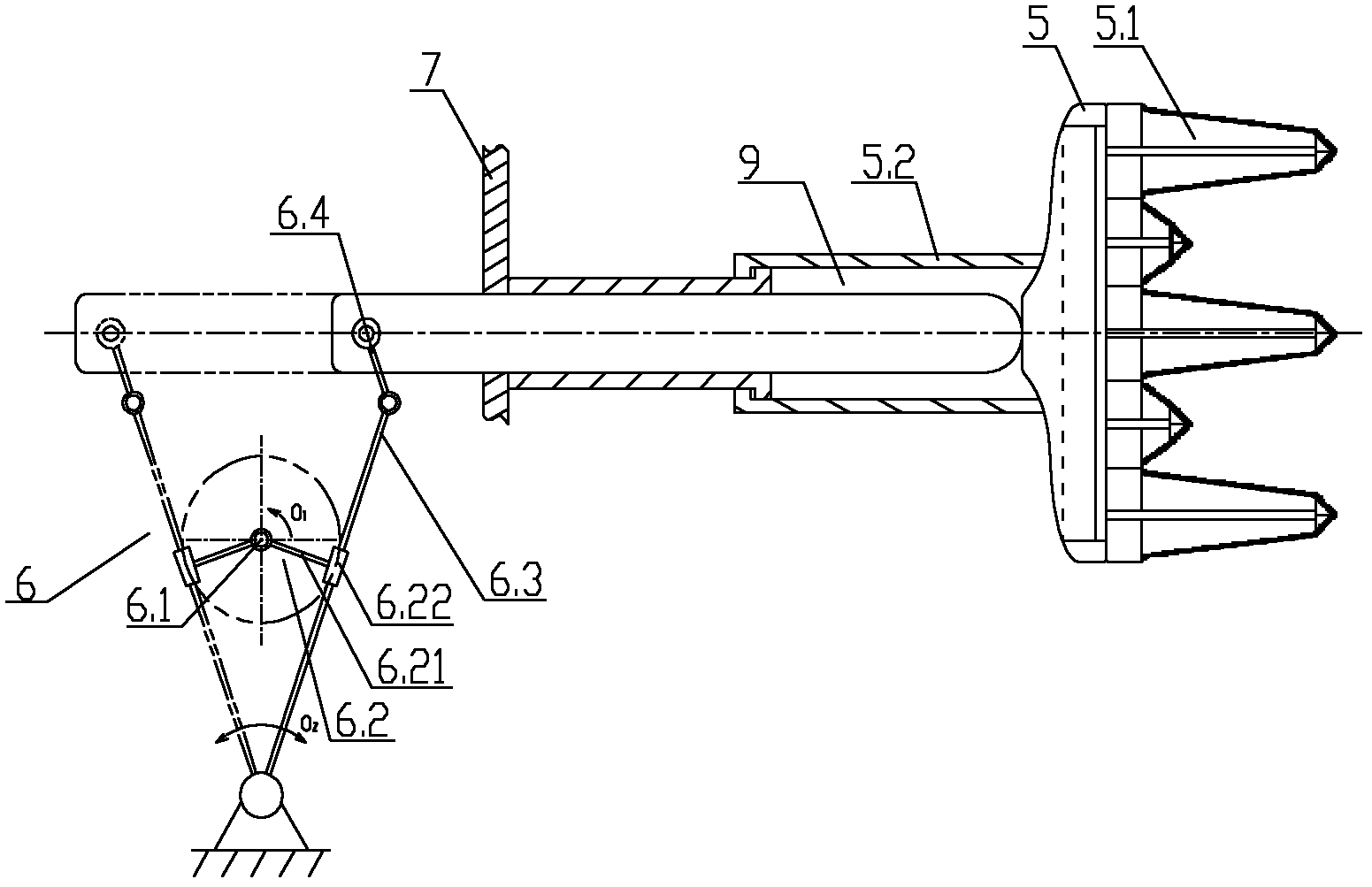

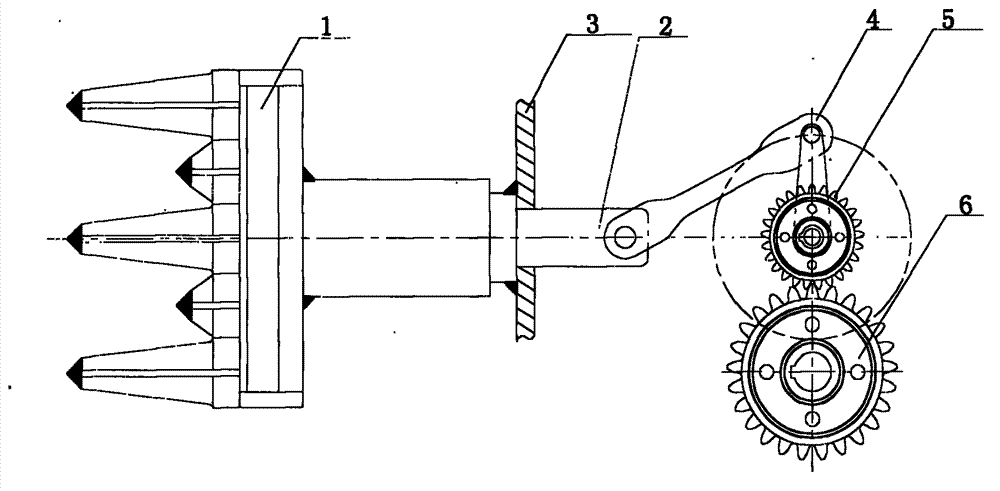

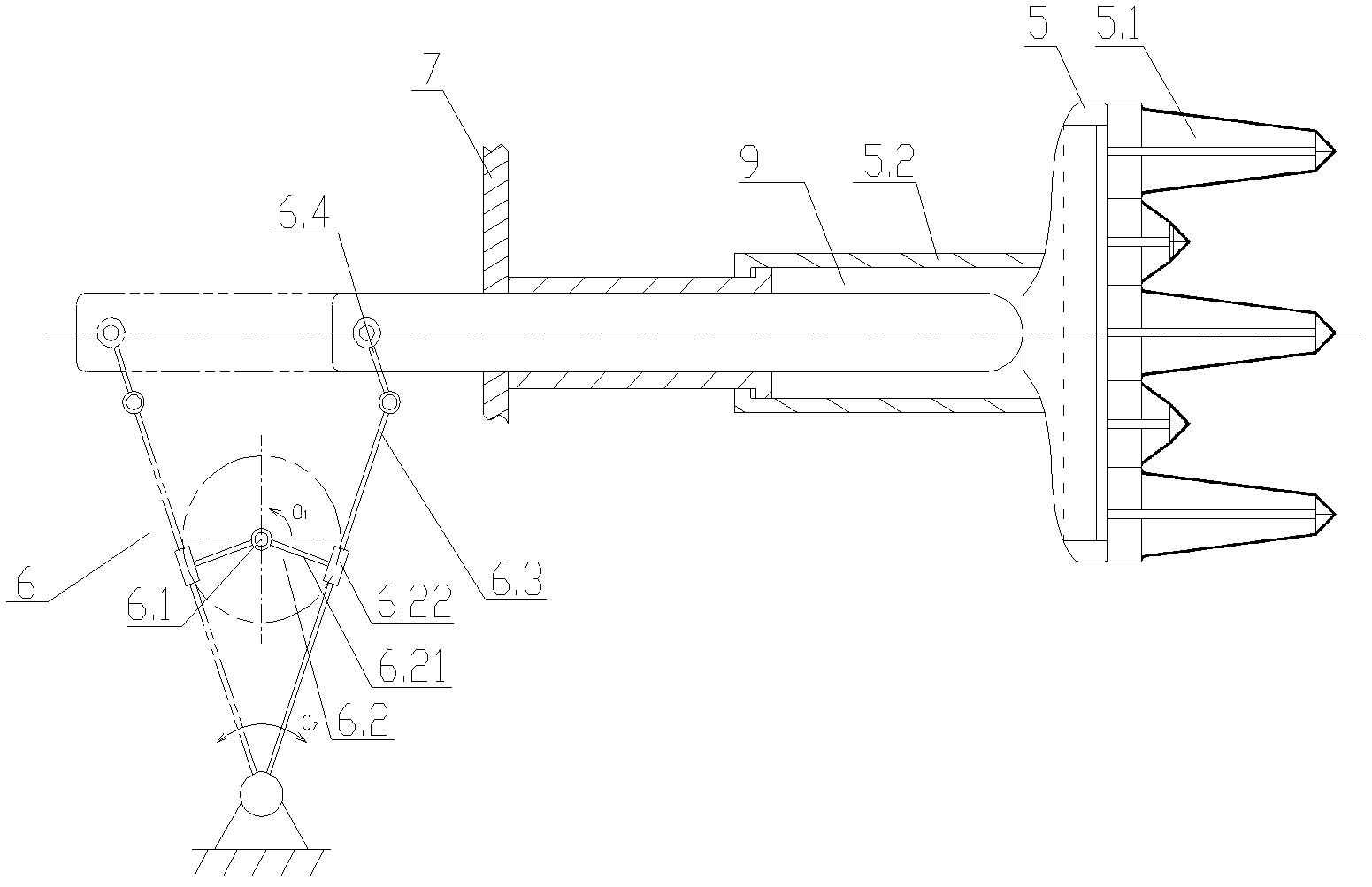

Swing rod link direct-impact coal shoveling machine

The invention belongs to the coal mining field, and especially relates to a swing rod link direct-impact coal shoveling machine. The coal shoveling machine comprises a machine body and a rotary force changed-to-linear impact force impact shoveling device arranged on the machine body, wherein the machine body and / or the rotary force changed-to-linear impact force impact shoveling device are / is provided with a guiding mechanism; the rotary force changed-to-linear impact force impact shoveling device comprises impact shoveling mechanisms and a rotary force changed-to-linear impact force mechanism; each of the impact shoveling mechanism comprises a shoveling head and a stroke rod; the movement direction of the stroke rod is in parallel with the movement direction of the shoveling head; the stroke rods are guided by the guiding mechanism; the rotary force changed-to-linear impact force mechanism comprises a rotary part and swing rods; the rotary part comprises rotary handles, a disc wheel and / or a gear; one ends of the rotary handles are connected with a rotary shaft, and the other ends of the rotary handles drive the swing rods to move; the swing rods are single rods or are provided with straightening connection rods; and one ends of the swing rods are fixed, and the other ends of the swings rod make the stroke rods straightly move back and forth along the guiding mechanism.

Owner:刘素华

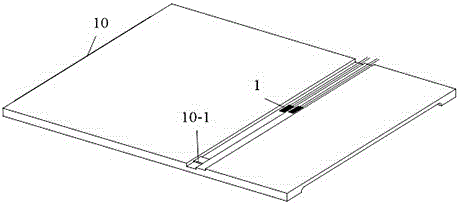

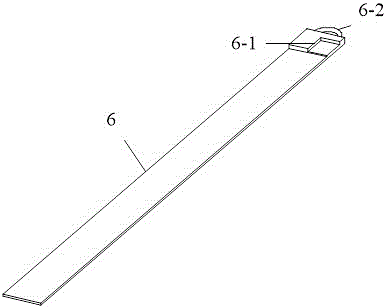

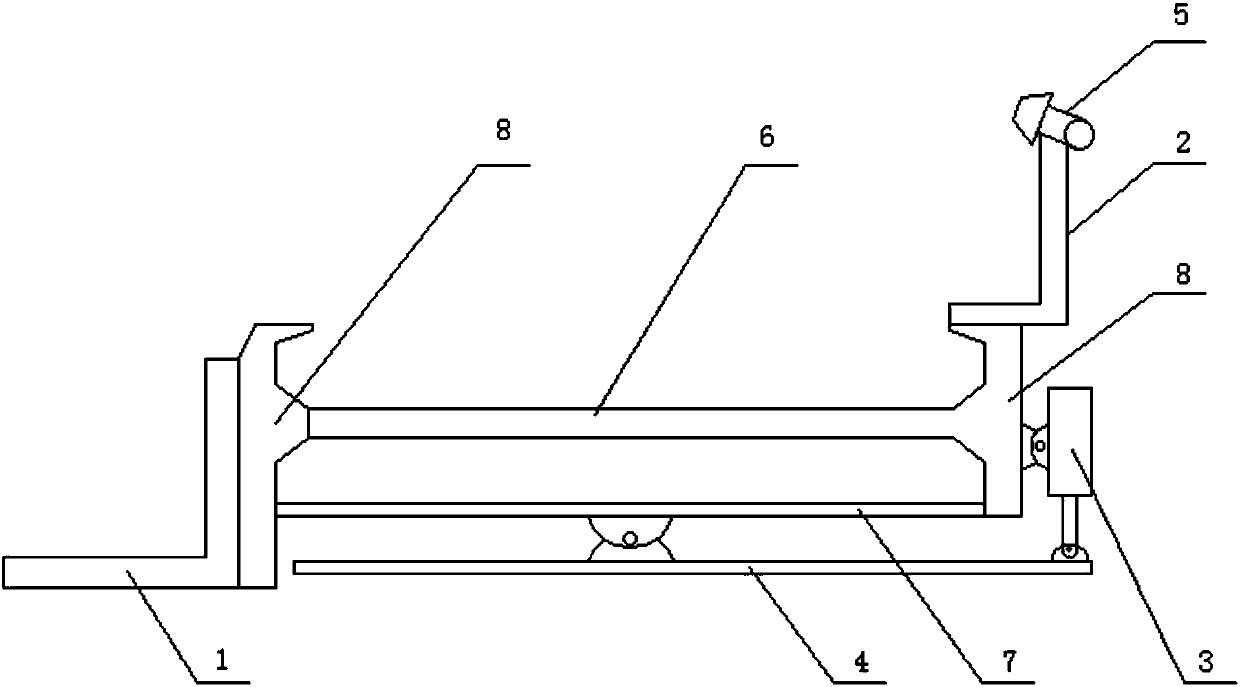

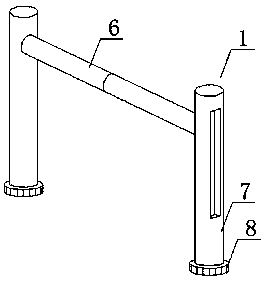

Float coal cleaning device and coal mining device

The invention relates to the technical field of coal mine machinery, in particular to a float coal cleaning device and a coal mining device. The float coal cleaning device comprises a rail groove body, a coal shoveling plate assembly and a pushing and moving device, wherein the rail groove body is provided with a coal storage groove and used for collection of float coal, a cleaning rail is arranged in the rail groove body, the coal shoveling plate assembly is arranged on the rail groove body along the cleaning rail in a sliding mode and used for cleaning and collecting of the float coal in the coal storage groove, and the pushing and moving device is arranged in the rail groove body and used for pushing and moving the coal shoveling plate assembly to slide along the cleaning rail. The float coal cleaning device and the coal mining device are simple in structure, low in cost, and capable of cleaning the float coal through other power drive. According to the float coal cleaning device, the problems of large working intensity and low efficiency of manual cleaning of the float coal can be effectively solved.

Owner:SANY HEAVY EQUIP

Material leveling and compacting device of compartment

InactiveCN103043459ASmall running resistanceAvoid lostLoading/unloadingMechanical engineeringIndustrial engineering

The invention relates to a material leveling and compacting device of a compartment. The material leveling and compacting device of the compartment comprises a rack body, a leveling and compacting mechanism, and a self-lock mechanism, wherein the rack body is arranged above the compartment; the leveling and compacting mechanism is arranged on the rack body; one end of a landing gear of the leveling and compacting mechanism is hinged with the rack body through a revolving axle; the free end is suspended on the rack body through a cylinder; the position when a flat roller works is adjusted by adjusting the elongation of the cylinder; the pressure of the flat roller on the material is adjusted by adjusting the pressure of the cylinder; the free end of the landing gear of the leveling and compacting mechanism is supported by a retainer plate of the self-lock mechanism; a flat coal shovel of which the length is smaller than the width of internal part of the compartment is arranged in front of a flat idler of the leveling and compacting mechanism; and the bottom part of the flat coal shovel is higher than that of the flat roller. The material leveling and compacting device, which is safe and practical, and convenient to operate, of the compartment capable of adjusting the pressure of the roller, automatically locking reliably in a non-working state and preventing the landing gear from falling off is provided by the invention.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

Fertilizer stirring device for garden fertilizer applying

InactiveCN107258182AImprove mixing efficiencyEasy to useShaking/oscillating/vibrating mixersTransportation and packagingAgricultural engineeringCoal shovel

The invention relates to a device for garden fertilizer applying, in particular to a fertilizer stirring device for garden fertilizer applying, which aims at solving the technical problem of providing a fertilizer stirring device for garden fertilizer applying with the advantages of shortening of time, decreasing of labor intensity, improving of mixing efficiency and convenience in use. To solve the technical problem, the fertilizer stirring device for the garden fertilizer applying comprises a base and the like, wherein the left side and right side of the top part of the base are vertically connected with support plates through bolts; the top parts of the two support plates are connected with a mixing box through bolts; a material discharging hopper is arranged at the top part of the mixing box; a material discharging device is arranged at the lower part of the left side of the mixing box; a mixing device is arranged in the mixing box. The fertilizer mixing device has the advantages that the fertilizer in the mixing box can be mixed through continuous vertical swinging, and the mixing of the fertilizer by a worker using a coal shovel is not needed.

Owner:泉州市欣百亚智能科技有限公司

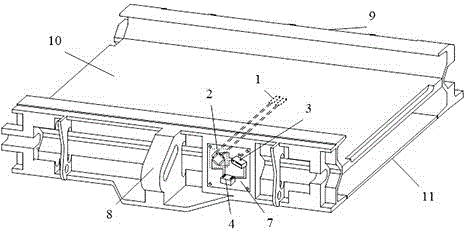

Scraper conveyor load monitoring device and chain tension estimation method

ActiveCN106829391AEliminate the effects of strainEasy to monitorConveyorsControl devices for conveyorsHydraulic cylinderTransverse groove

The invention discloses a scraper conveyor load monitoring device. The scraper conveyor load monitoring device comprises strain gauges, a half bridge circuit, a wireless signal transmitter, a power supply, a wireless signal receiver, a strain gauge retaining plate, pushing slide side channel steel, coal shoveling side channel steel, a middle plate, a bottom plate, a drive shaft and a hydraulic cylinder, wherein the middle plates is provided with two parallel transverse grooves, and the strain gauges are transversely adhered to the parallel transverse grooves. The invention further provides an on-load section chain tension estimation method. The method is characterized in that a signal is output through the half bridge circuit, the signal is wirelessly transmitted to a remote control center, the load of each middle groove of a scraper conveyor is calculated according to advance load calibration and a linear interpolation method to obtain the difference of chain tension on two sides of the middle grooves, and on-load section chain tension distribution is calculated according to drive shaft torque and hydraulic cylinder pressure. The scraper conveyor load monitoring device and the on-load section chain tension estimation method have the advantages that the device is convenient in distributed load monitoring, on-load section chain tension can be estimated easily, a sensor is less prone to failure, sensor positioning is easy, the power supply can be replaced easily, and the like.

Owner:CHINA UNIV OF MINING & TECH

Excavating and shoveling buffer transmission device of blocking coal shovel

The invention belongs to the field of mining, mine tunneling and tunnel excavating, and particularly relates to an excavating and shoveling buffer transmission device of a blocking coal shovel. The excavating and shoveling buffer transmission device comprises a driving gear, a driven gear and a gear installation rack, wherein the driving gear and the driven gear are in clearance matching, the driven gear is connected with a power output shaft, and the deformation of the power output shaft during the working of the power output shaft can be absorbed by clearances between the driving gear and the driven gear. According to the excavating and shoveling buffer transmission device disclosed by the invention, the vibration of a device body is prevented, the excavating and shoveling work is stabilized, the mining technology is increased, and great benefit is brought for coal mine production.

Owner:刘素华

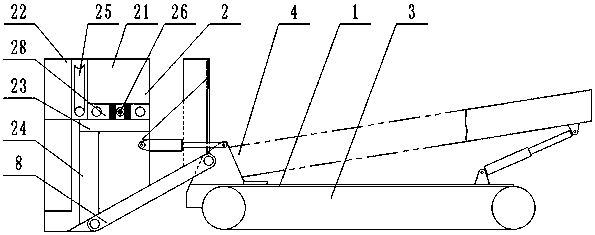

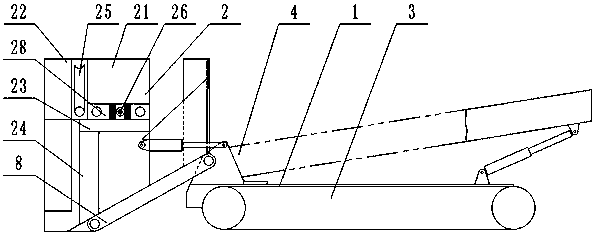

Movable mine coal conveyor

InactiveCN109573638AEasy to transportThe principle is simpleConveyorsLoading/unloadingEngineeringMechanical engineering

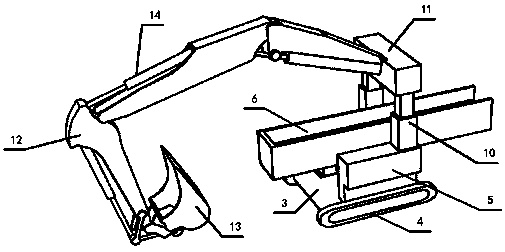

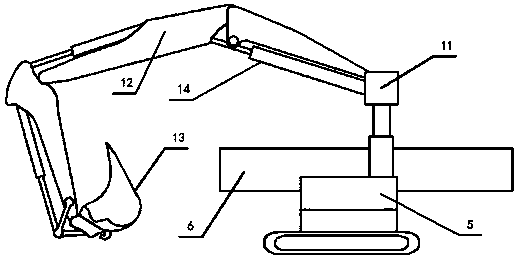

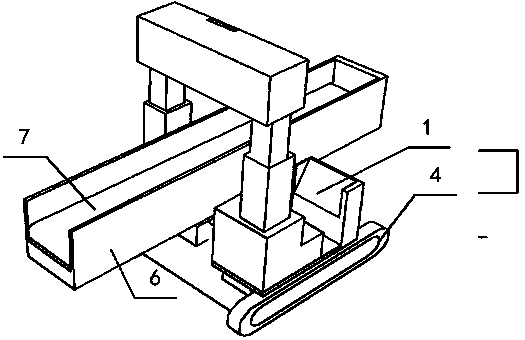

The invention discloses a movable mine coal conveyor. The movable mine coal conveyor comprises an operation bin, a base plate, a conveying device, a coal-shoveling device platform and a bucket, wherein the west part of the operation bin is fixedly connected with an operation bin base, the operation bin base is connected to the base plate, the two sides of the base plate are fixedly connected withtracks, an engine is arranged on the upper part of the left side of the base plate, a conveying device is arranged between the operation bin and the engine, a conveying belt is mounted at the bottom end inside the conveying device, an inclined rotating shaft is arranged in the middle of the bottom end of the conveying device, the end, away from the conveying device, of the inclined rotating shaftis connected with a conveying device lifting rod, the coal-shoveling device platform is mounted on the upper side of a coal-shoveling device lifting column, a movable arm is mounted on the front partof the coal-shoveling device platform, the bucket is hinged to the front part of the movable arm, and an oil cylinder is connected between the movable arm and the coal-shoveling device platform. The movable mine coal conveyor is provided with a moving module, a coal-shoveling module and a conveying module, lots of coal can be conveyed conveniently and quickly, and the effect of labor saving is achieved.

Owner:徐州市三成铸业有限公司

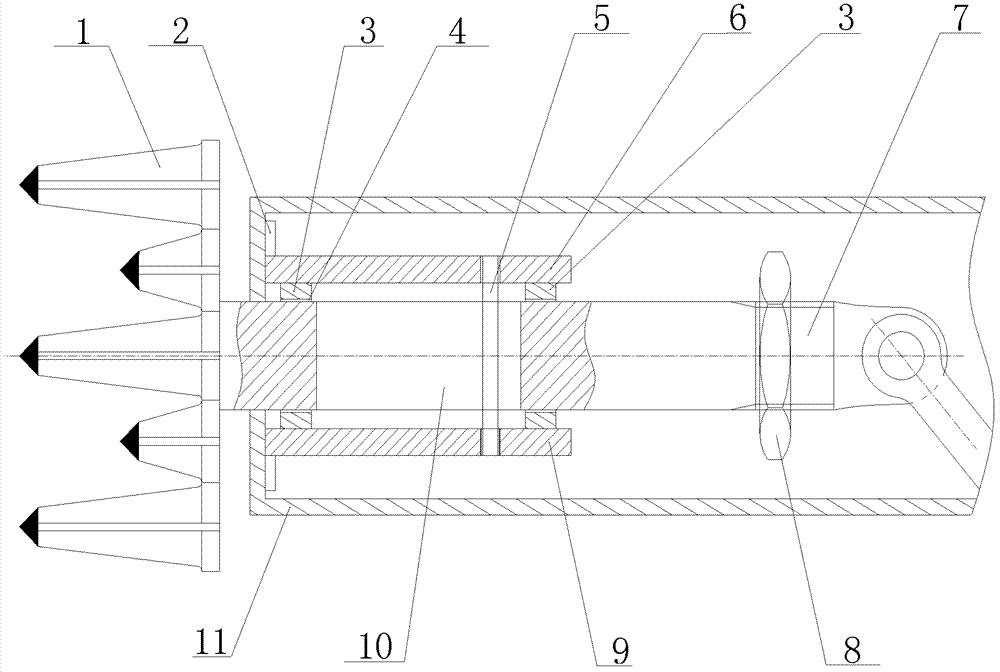

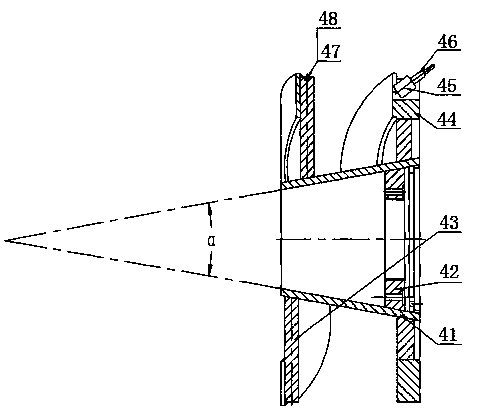

Digging and shovel impacting guide device of blocked coal shoveling machine

ActiveCN102953731AReduce contact areaReduce frictional resistanceSlitting machinesPulp and paper industryCoal

The invention relates to the field of mine digging and particularly relates to a digging and shovel impacting guide device of a blocked coal shoveling machine. The device comprises a fixing base and a connecting flange; the device further comprises guide ring fixing plates, an anti-rotating bolt and at least more than two guide rings; an upper guide ring fixing plate and a lower guide ring fixing plate are mounted on the two sides of a digging and shovel impacting guide rod; the guide rings are fixedly arranged between the upper guide ring fixing plate and the lower guide ring fixing plate; and one end of the anti-rotating bolt penetrates through the center of the digging and shovel impacting guide rod. According to the digging and shovel impacting guide device of the blocked coal shoveling machine, the stress of digging and shovel impacting of the blocked coal shoveling machine is uniform, the vibration is small, the work is stable, the operation is simple, the utilization is flexible, the service life is long and the digging and shovel impacting guide device is easy to realize; and the combined efficiency of mine production is improved.

Owner:刘素华

Opencast coal mining machine capable of effectively crushing coal briquettes and usage thereof

InactiveCN108361035AFine particleAvoid cloggingOpen-pit miningGrain treatmentsCoal briquetteEngineering

The invention provides an opencast coal mining machine capable of effectively crushing coal briquettes and usage thereof, which relate to the technical field of machinery. The opencast coal mining machine comprises a coal mining machine body, a coal-crushing roller power box is arranged on one side of a coal-crushing roller, the coal-crushing roller power box is connected with a main power case through a connecting arm, a hydraulic piston rod is arranged on the bottom of the coal-crushing roller power box, fan-shaped stirring blocks are arranged on the surface of a coal-shoveling bucket, a stirring tank is arranged at one side of the fan-shaped stirring blocks, a conveyer belt is arranged at one side of the stirring tank, a control room is electrically connected with the main power case, the coal-crushing roller power box, the fan-shaped stirring blocks, a rotary motor and travelling pedrails are all electrically connected with the control room, and the hydraulic piston rod is electrically connected with the coal-crushing roller power box. The opencast coal mining machine is an opencast coal mining machine which can effectively crush coal briquettes; since the stirring tank is arranged, coal briquettes can be rolled and crushed by stirring disks in the stirring tank, consequently, the opencast coal mining machine can effectively ensure that coal briquette particles getting intoa coal outlet passage are fine, and thereby coal briquette blockage is prevented; and the invention has high popularization and application value.

Owner:湖州悉匠汽车服务有限责任公司

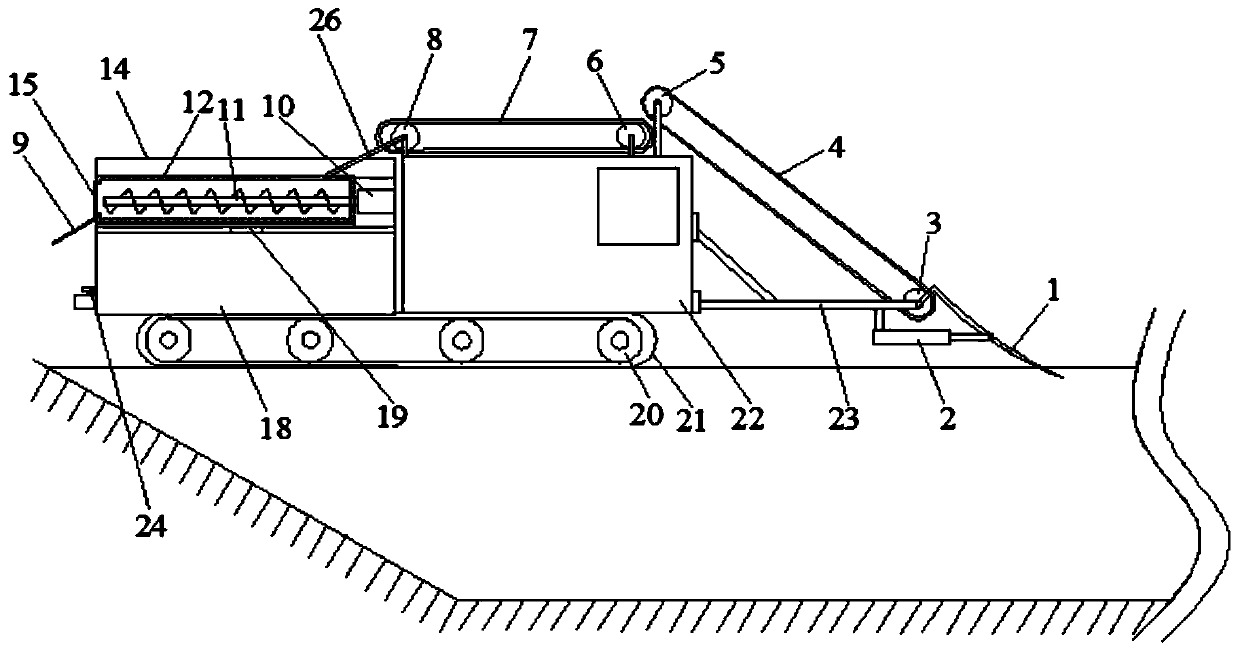

Coal mine underground sump dredging device

InactiveCN111255003AImprove dredging efficiencySoil-shifting machines/dredgersWater storage tankEnvironmental engineering

The present invention relates to the technical field of sump dredging, and discloses a coal mine underground sump dredging device. The device comprises a motor vehicle provided with a coal shoveling mechanism, a transportation mechanism, an extrusion drainage mechanism and a water storage tank; when the motor vehicle runs, the coal shoveling mechanism is driven to shovel up coal slime, the transportation mechanism is used for transporting the shoveled coal slime to the extrusion drainage mechanism, the transportation mechanism is connected with the coal shoveling mechanism, and the transportation mechanism is arranged at the front part of the motor vehicle and extends to the upper side of the back part; the extrusion drainage mechanism is used for performing extrusion drainage on the coalslime, and the extrusion drainage mechanism is arranged on the lower side of the back part of the motor vehicle; and the water storage tank is used for storing water drained after the coal slime is extruded, the water storage tank is arranged on the lower side of the back part of the motor vehicle, and the water storage tank is positioned below the extrusion drainage mechanism and communicates with the extrusion drainage mechanism. According to the coal mine underground sump dredging device, multiple functions of coal shoveling, transporting and extruding are integrated in the motor vehicle, thereby improving the sump dredging efficiency and saving time and labor.

Owner:HEILONGJIANG UNIV OF TECH

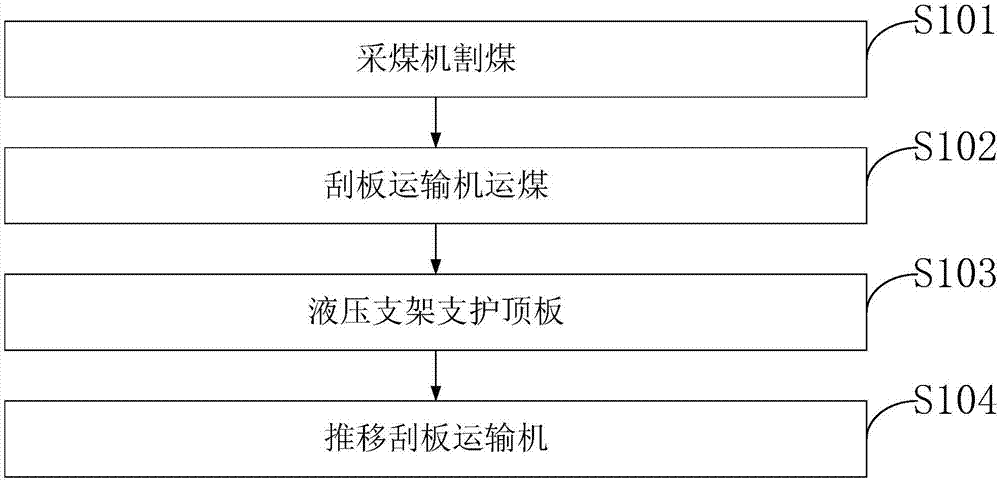

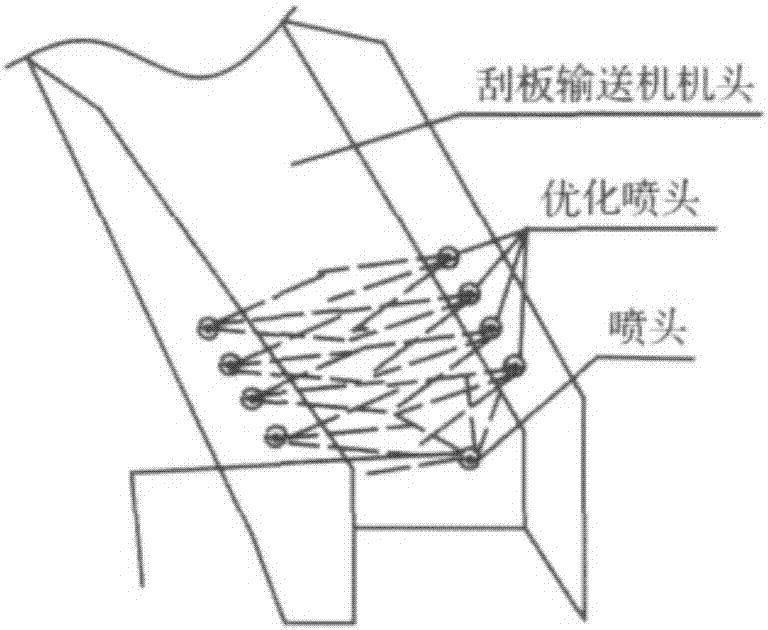

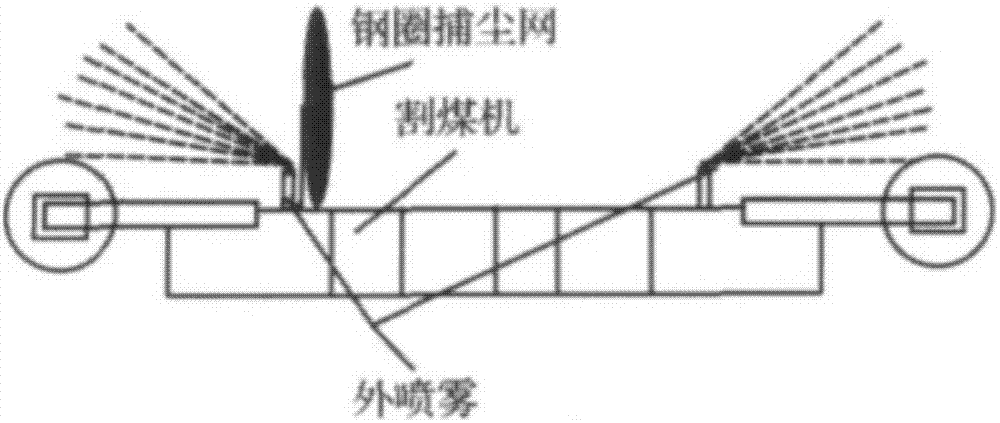

Coal mining method and roof management method

InactiveCN107575227ASafe and Efficient MiningPromote recoveryMining devicesUnderground miningMineralogyCoal shovel

The invention belongs to the technical field of coal mines and discloses a coal mining method and a roof management method. The coal mining method comprises the steps that comprehensive mechanized coal mining of a single medium-thick coal seam full-seam mining inclined longwall retreating type full caving method is conducted on a working face, specifically, coal is cut through coal mining machines, the coal is transported through a scraper conveyor, a roof is supported through hydraulic supports, and the scraper conveyor is pushed to be moved; the coal mining machines are used for bidirectional coal cutting, rollers automatically rotate to crush the coal through cutting teeth, and unit roller blades and a coal shoveling plate of the conveyor are used for automatically loading the coal intothe scraper conveyor; inclined cutting feed is conducted on the ends of the two sides to cut the triangular coal; and in the production process, coal mining is conducted according to the sequence ofcoal cutting, support moving and scraper conveyor pushing. The problem that the dust proof effect is poor in coal mining is solved.

Owner:HEILONGJIANG UNIV OF TECH

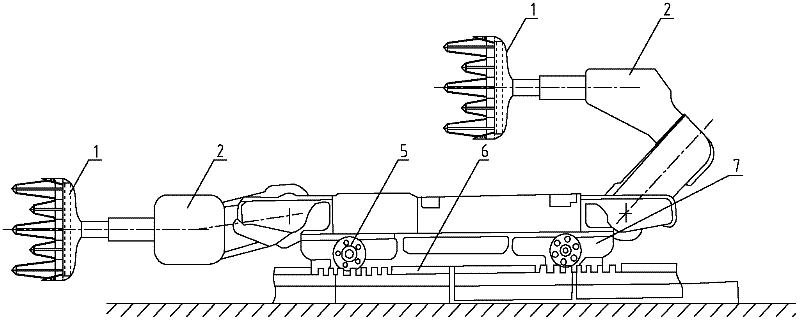

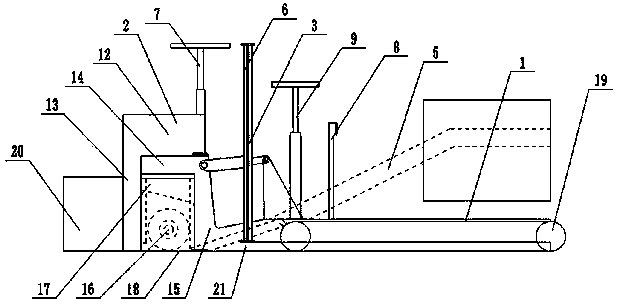

Swing rod transmission direct-impact coal shoveling machine

ActiveCN102828749AReduce shear forceAvoid damageDriving meansPropulsionReciprocating motionEngineering

The invention belongs to the coal mining field, and especially relates to a swing rod transmission direct-impact coal shoveling machine. The machine comprises a machine body and a rotary force changed-to linear impact force impact shoveling device arranged on the machine body, wherein the machine body and / or the rotary force changed-to linear impact force impact shoveling device are / is provided with a guiding mechanism; the rotary force changed-to linear impact force impact shoveling device comprises a rotary mechanism, a swing rod mechanism and impact shoveling mechanisms; each of the impact shoveling mechanism comprises shoveling heads and an impact shoveling stroke part; the shoveling heads are arranged on the front ends of the impact shoveling stroke parts; the impact shoveling stroke parts are in parallel with the movement directions of the shoveling heads; the impact shoveling stroke parts are guided by the guiding mechanism; the rotary mechanism drives the swing rod mechanism to move back and forth; the swing rod mechanism drives the impact shoveling stroke parts to impact back and forth; and the shoveling heads impact back and forth to impact coal and clear surfaces. The machine enables damages of the reaction force to the machine body and a power mechanism during the impact coal mining of the impact shovels to be substantially reduced, and the service life of a coal mining machine to be improved.

Owner:刘素华

Adjustable middle chute

InactiveCN110386411AImprove coal shoveling efficiencyReduce generationConveyorsCleaningHydraulic cylinderEngineering

The invention relates to a middle chute, and particularly relates to an adjustable middle chute for coal conveying in the coal seam mining process. According to the adjustable type middle chute, through arranging a hydraulic cylinder and a support plate, the angle of the middle chute is adjustable, so that the coal shoveling through a coal shoveling plate is facilitated, thus preventing the situation that a bottom plate is deviated during the propelling process of the middle chute so as to affect coal transportation efficiency. The adjustable middle chute comprises the hydraulic cylinder and the support plate, wherein a first end of the chute is fixedly provided with the coal shoveling plate, the top end of a second end of the chute is fixedly provided with a fixing coal baffler plate, thebottom of the chute is hinged with the support plate, the middle of the second end of the chute is hinged with the hydraulic cylinder, a push rod of the hydraulic cylinder is hinged with the supportplate, and the top of the fixing coal baffler plate is fixedly provided with a nozzle which inclines towards the coal wall side.

Owner:王锐垚

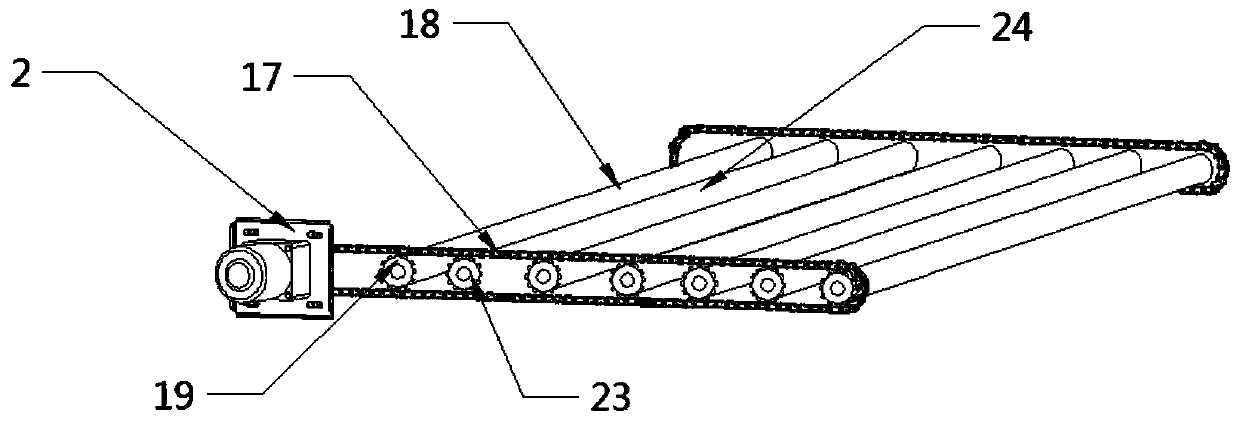

Conveyor

InactiveCN104343451ASolve the problem of flying straight down and hurting peopleEliminate the feeling of being in the abyssSlitting machinesUnderground transportCoal briquetteEngineering

The invention discloses a conveyor for a coal-mine underground vertical-layer coal-mining working face. The conveyor comprises a machine head part, a machine tail part, a chute, an accessory and a push unit, and is characterized in that coal shoveling plates which can bidirectionally push the conveyor to shovel coal are arranged at the two sides of the conveyor; and a component which is connected with the push unit and can be used for bidirectionally pushing the conveyor is arranged on the conveyor. By adopting the structure, the pushing direction of the conveyor does not push toward the direction of the coal wall along a bottom plate like a long wall coal mining working face but pushes toward the direction of a top plate or a bottom plate along the coal wall. The coal wall with various shapes and gradients can be artificially made according to requirements under the feet of operators, so that the feel like standing upon the edge of an abyss in the steep dip long wall working face is eliminated, and the problem that coal briquettes fly swiftly downwards in the working face with the gradient of 60 degrees or more and hurt people is completely solved to ensure that multi-point parallel operation becomes possible.

Owner:王洪伟

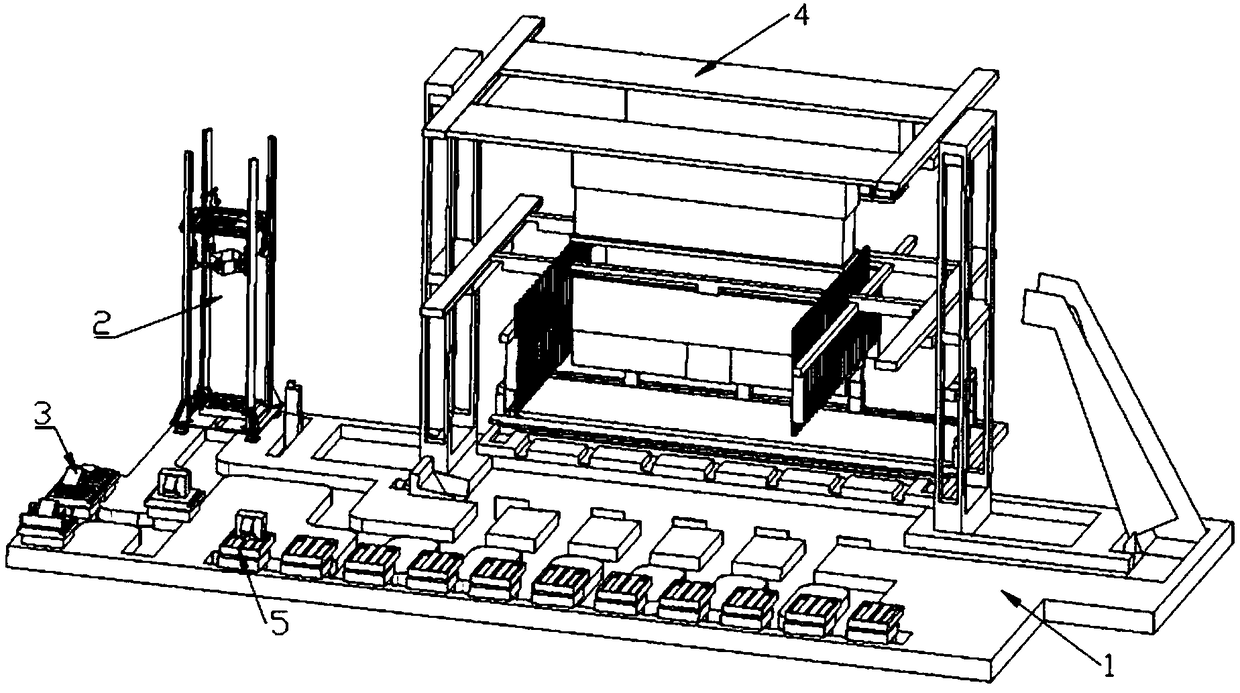

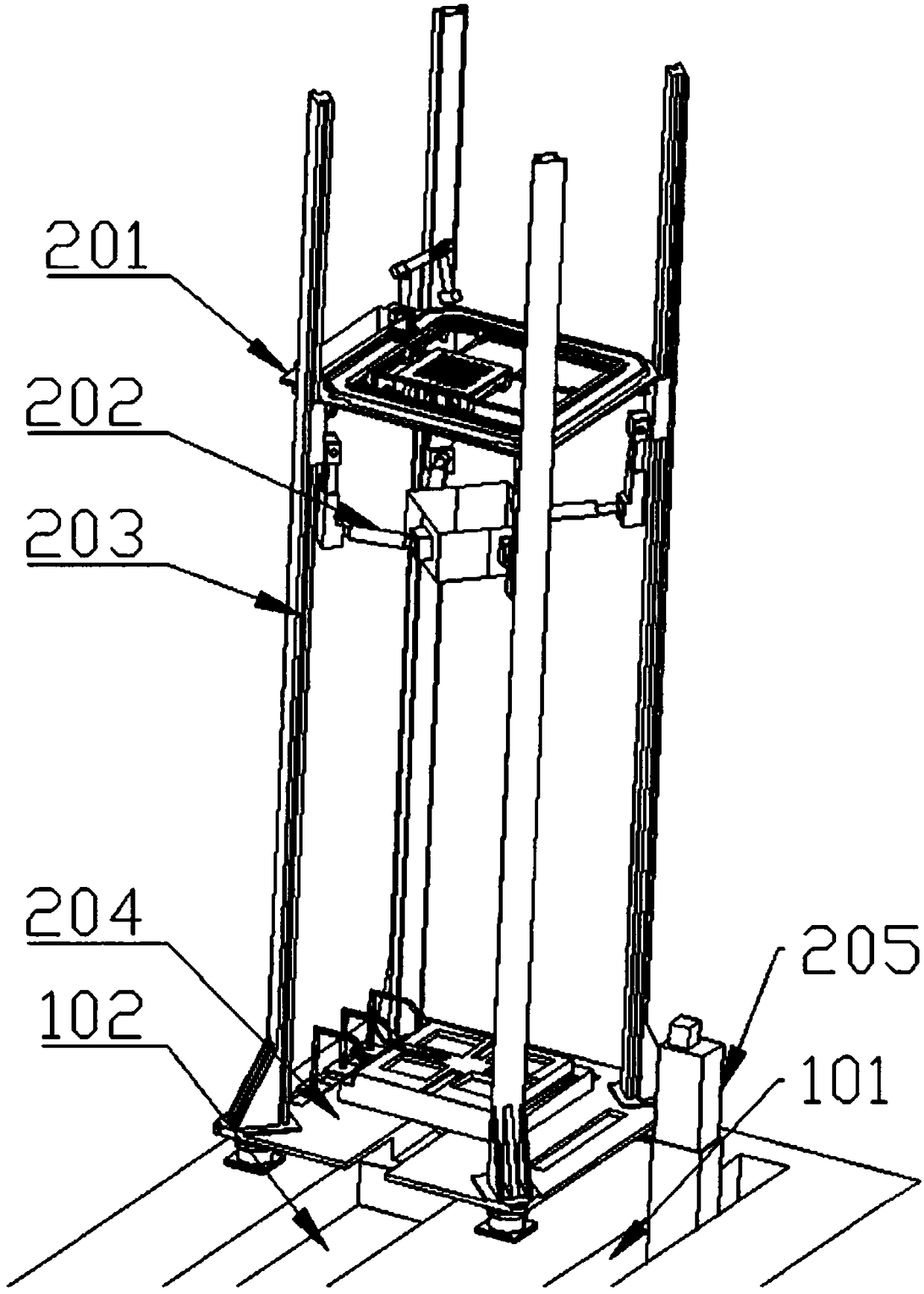

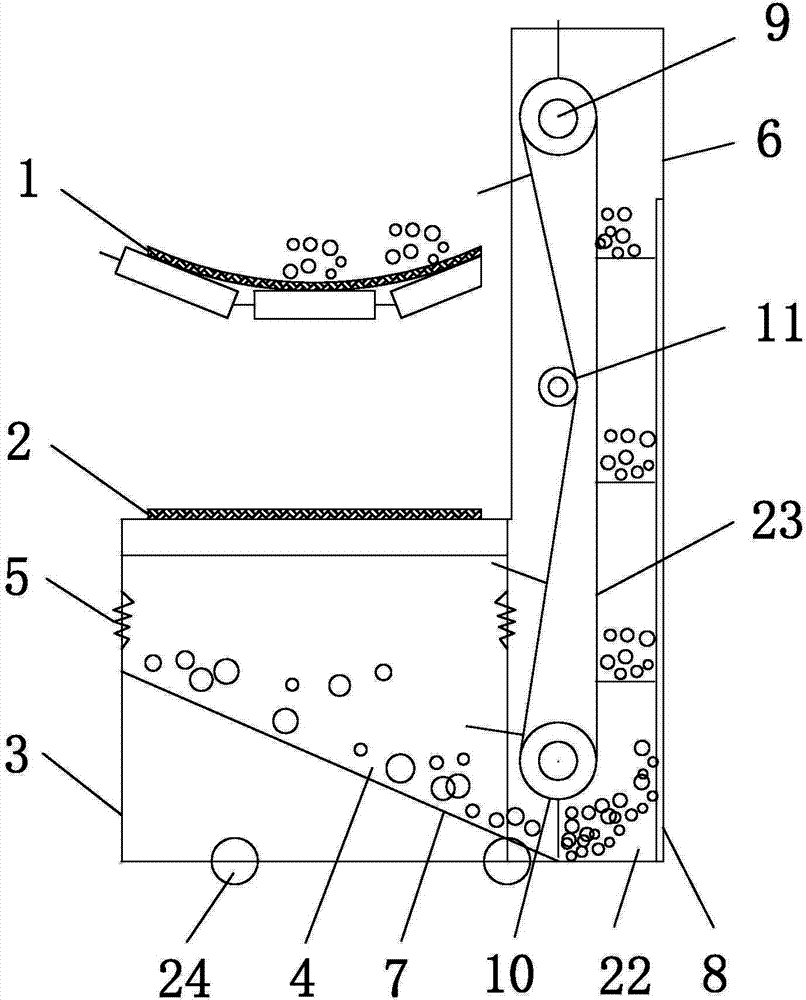

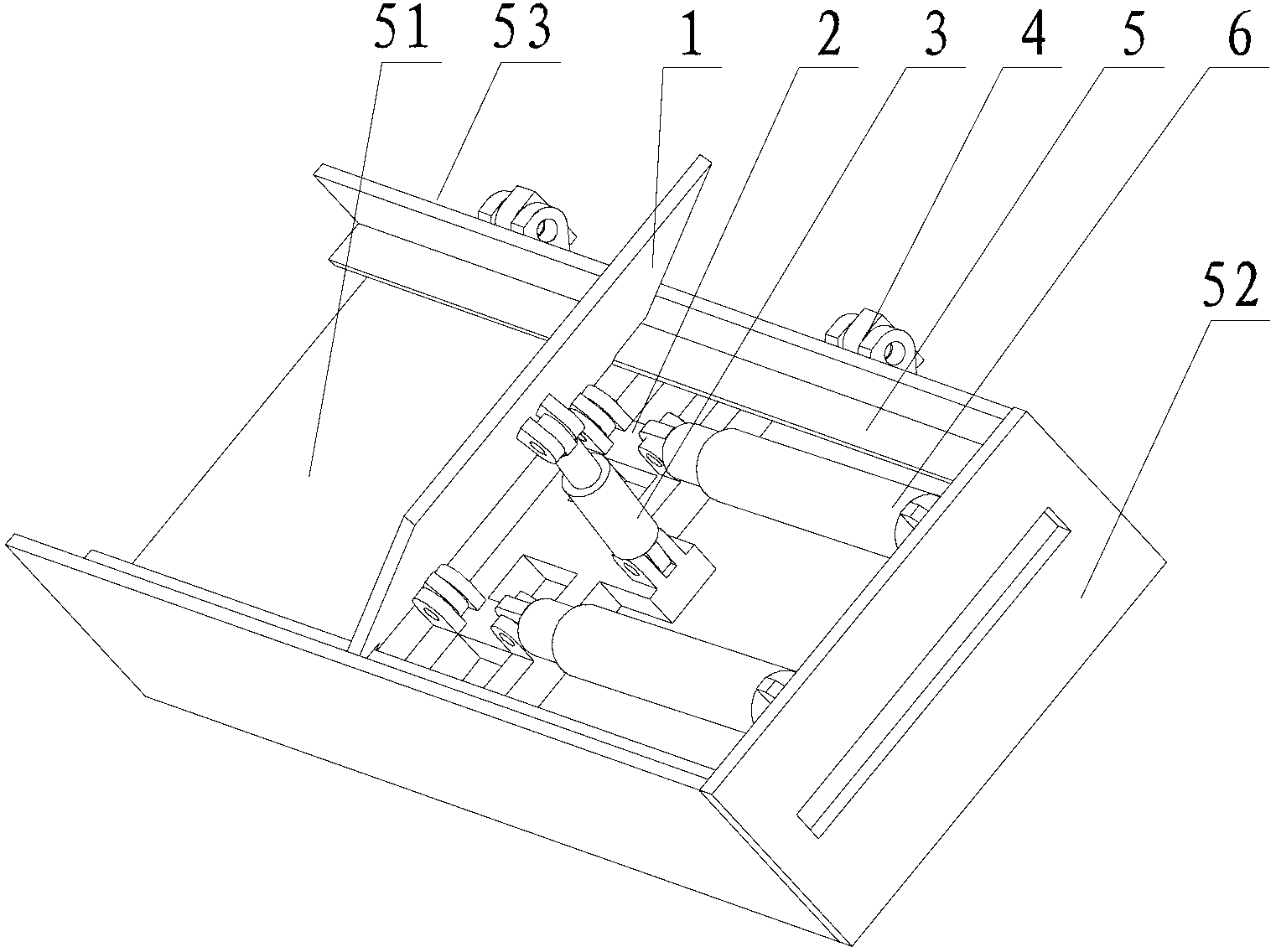

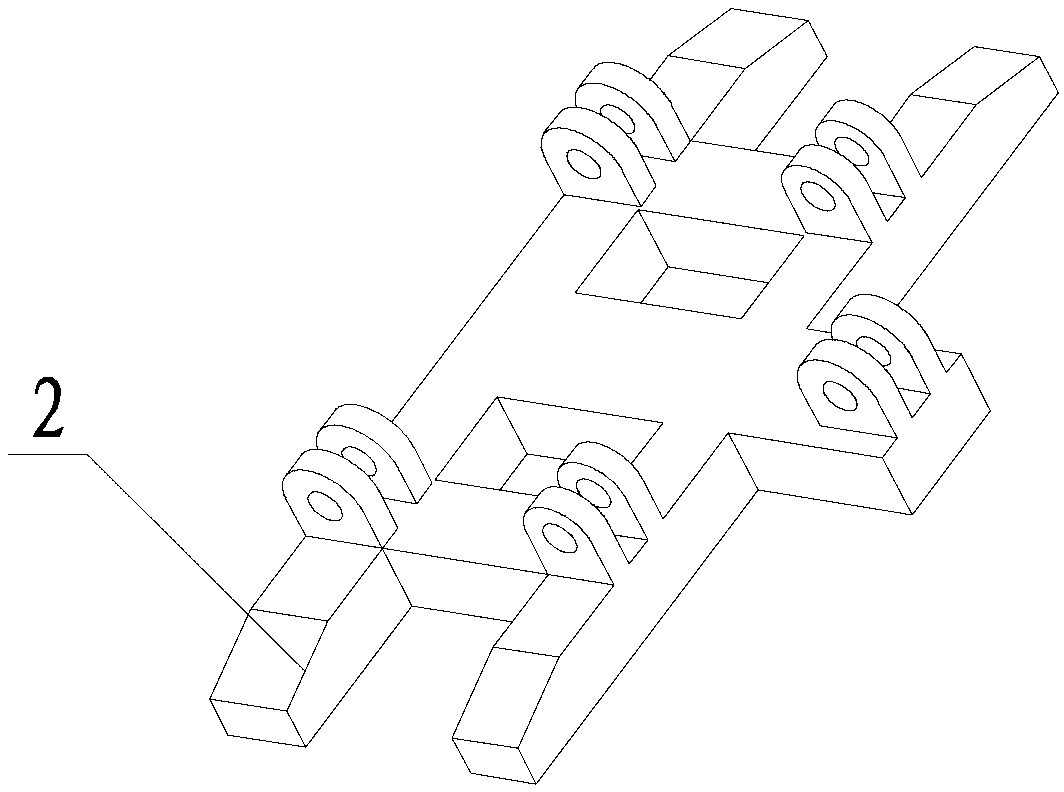

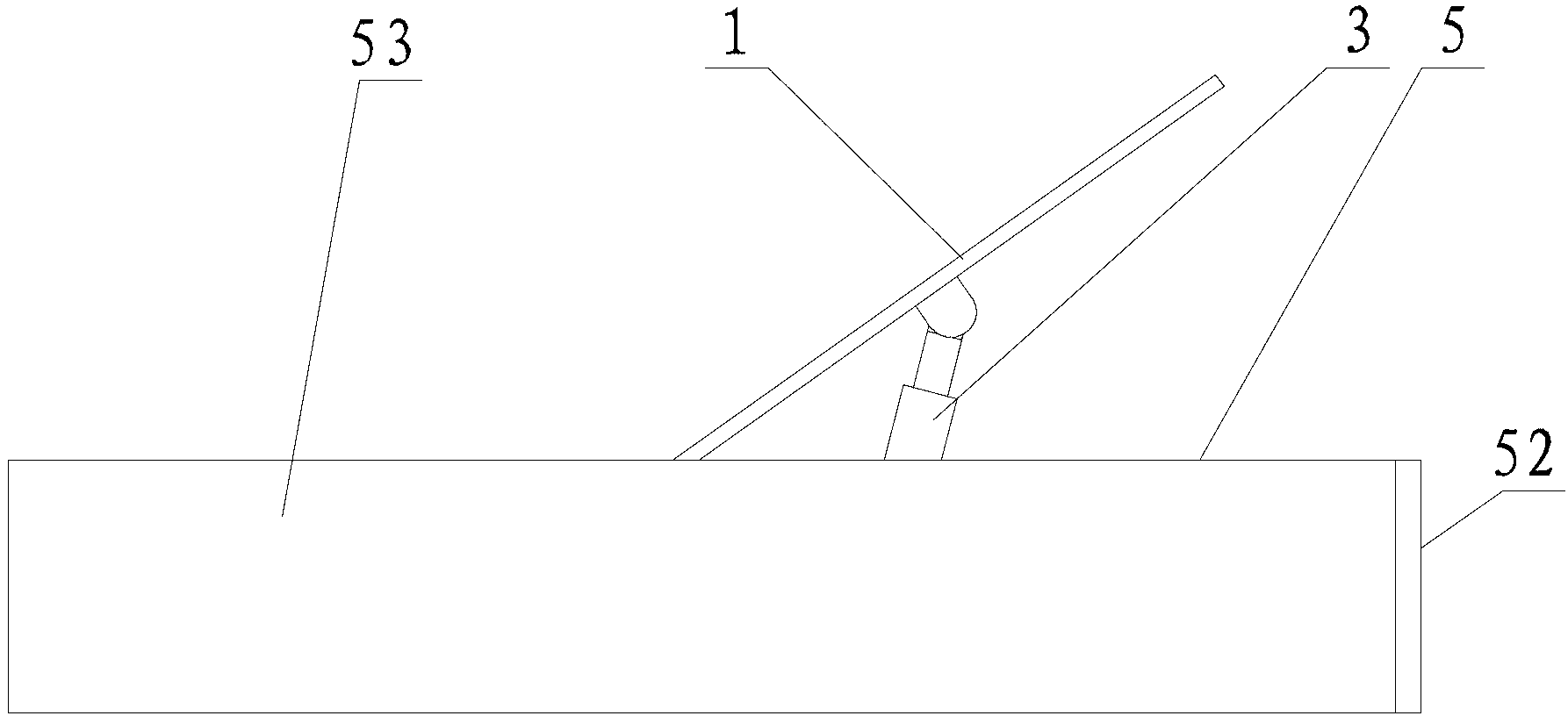

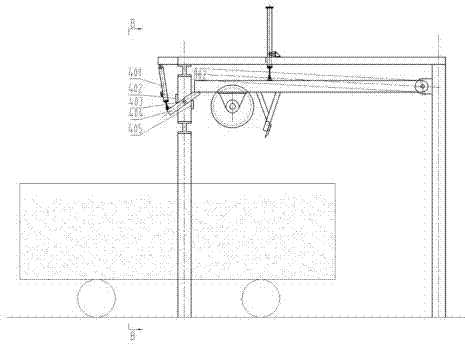

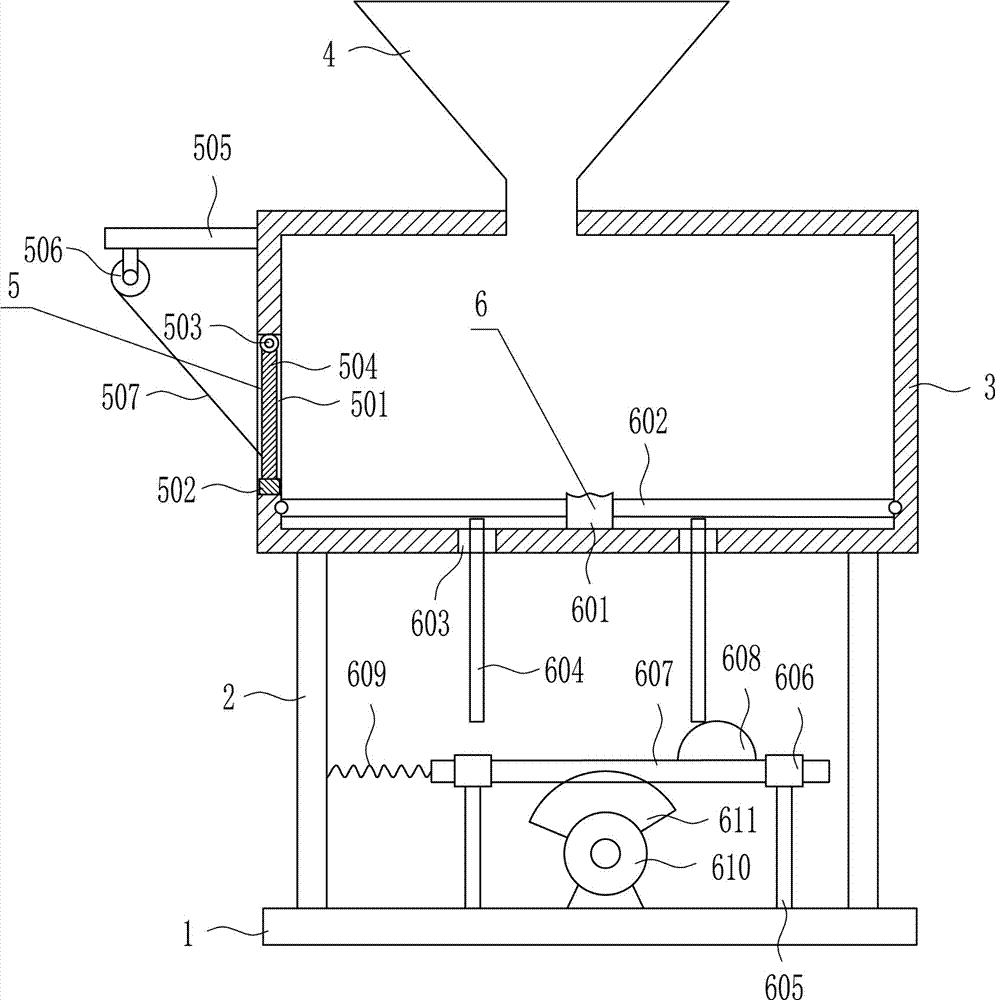

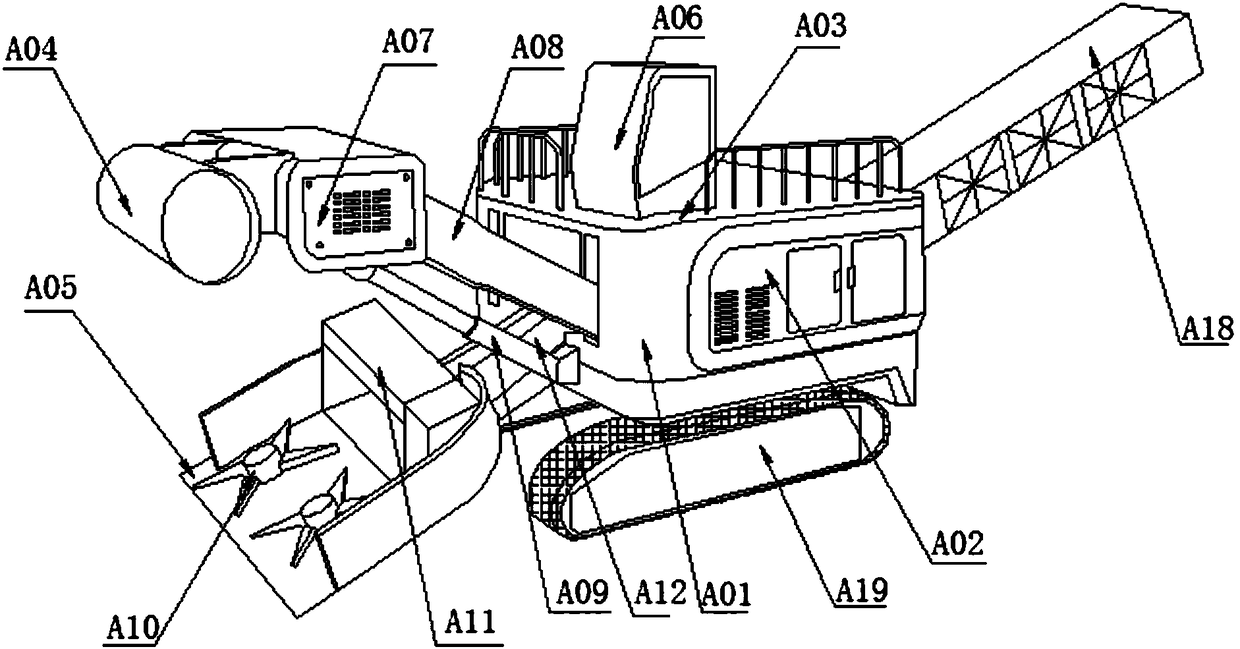

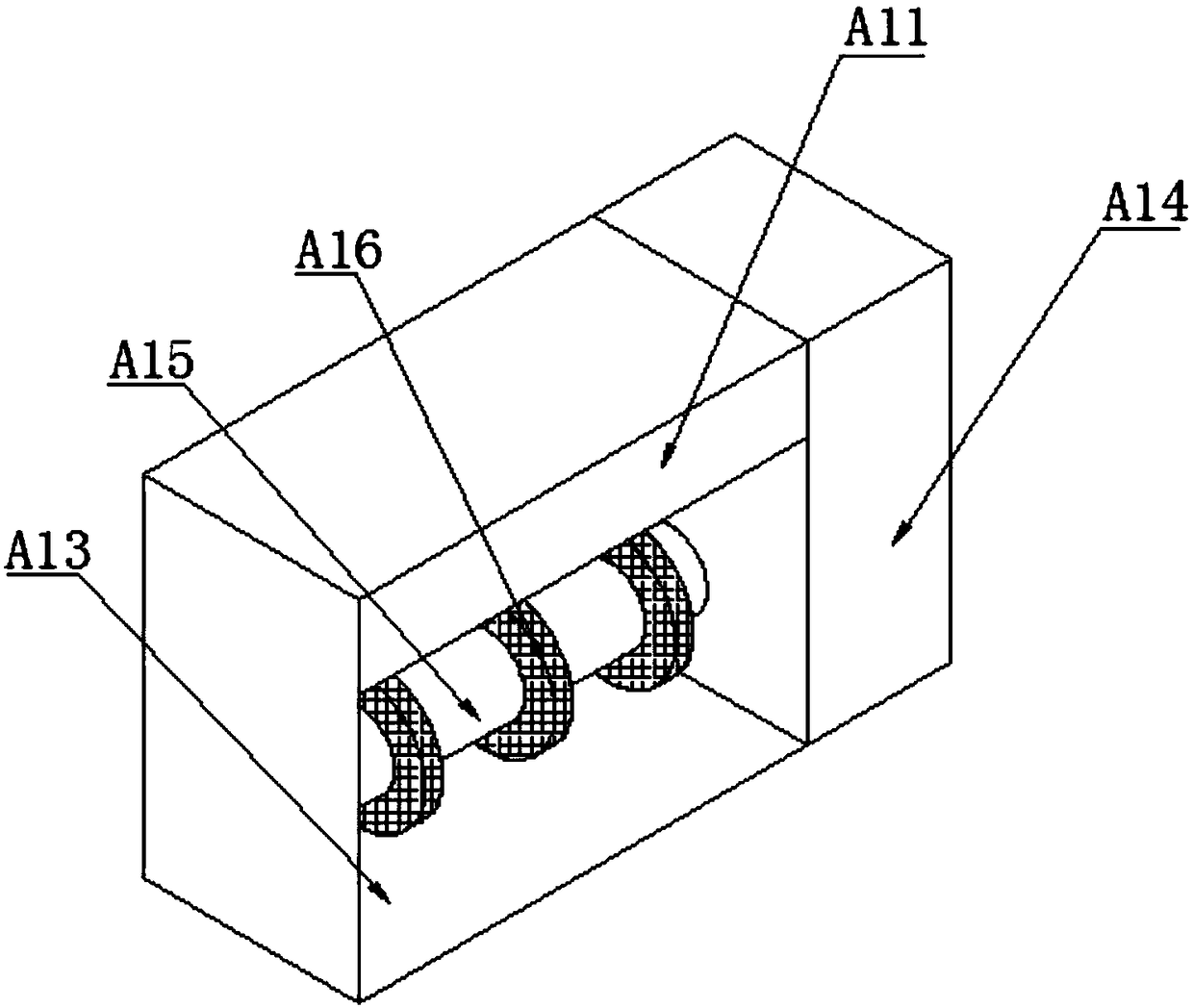

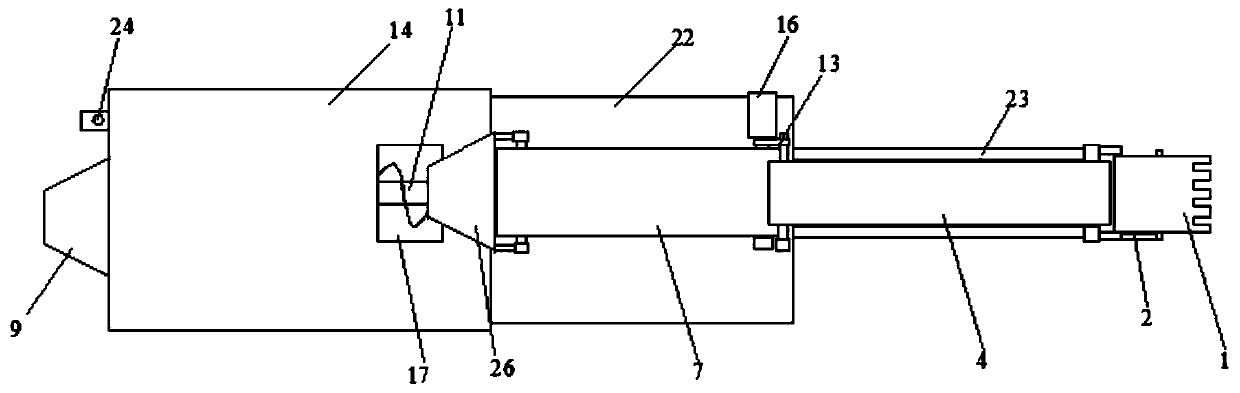

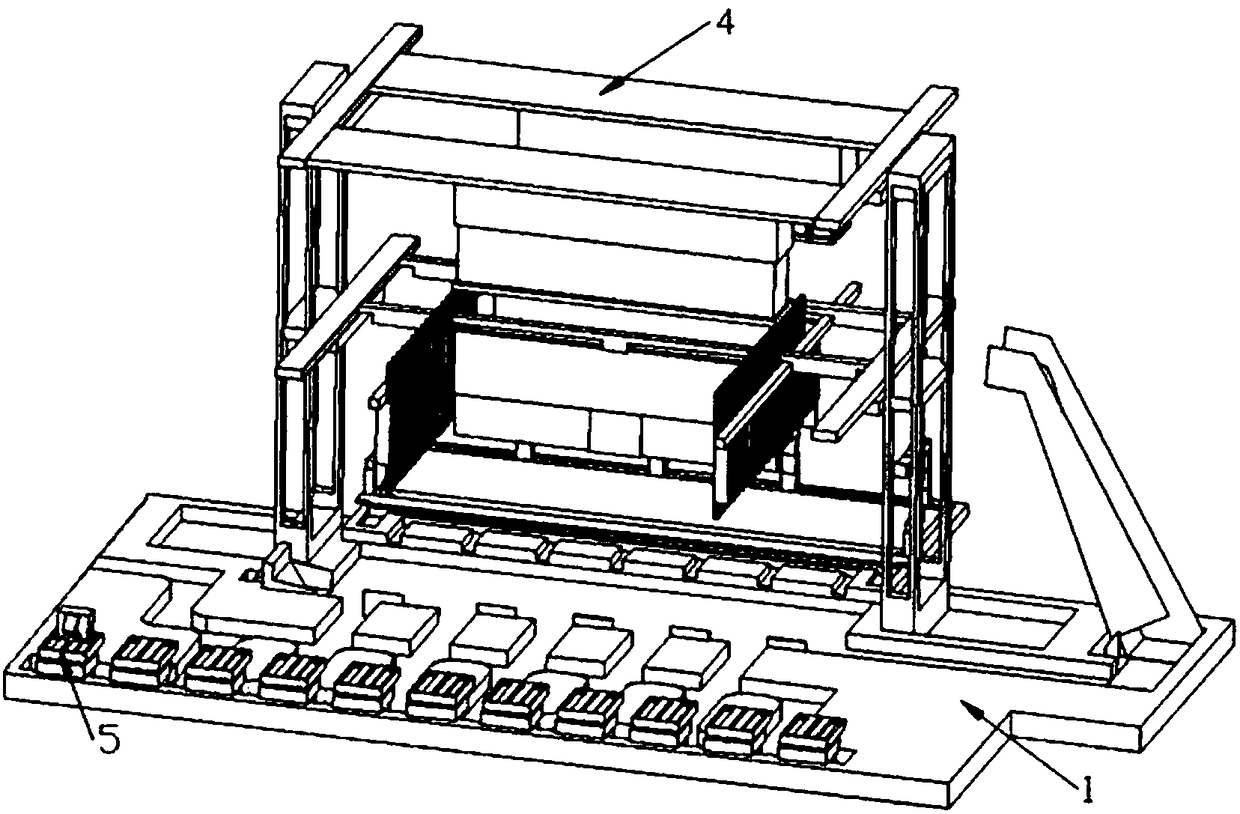

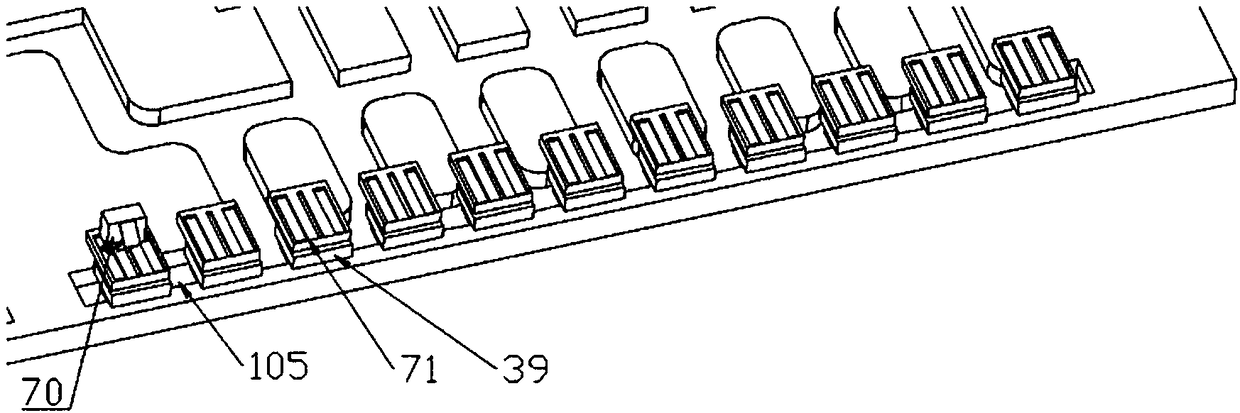

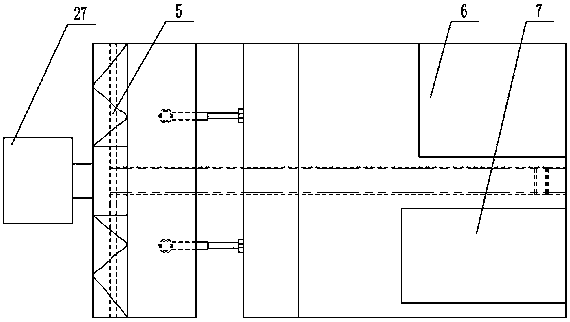

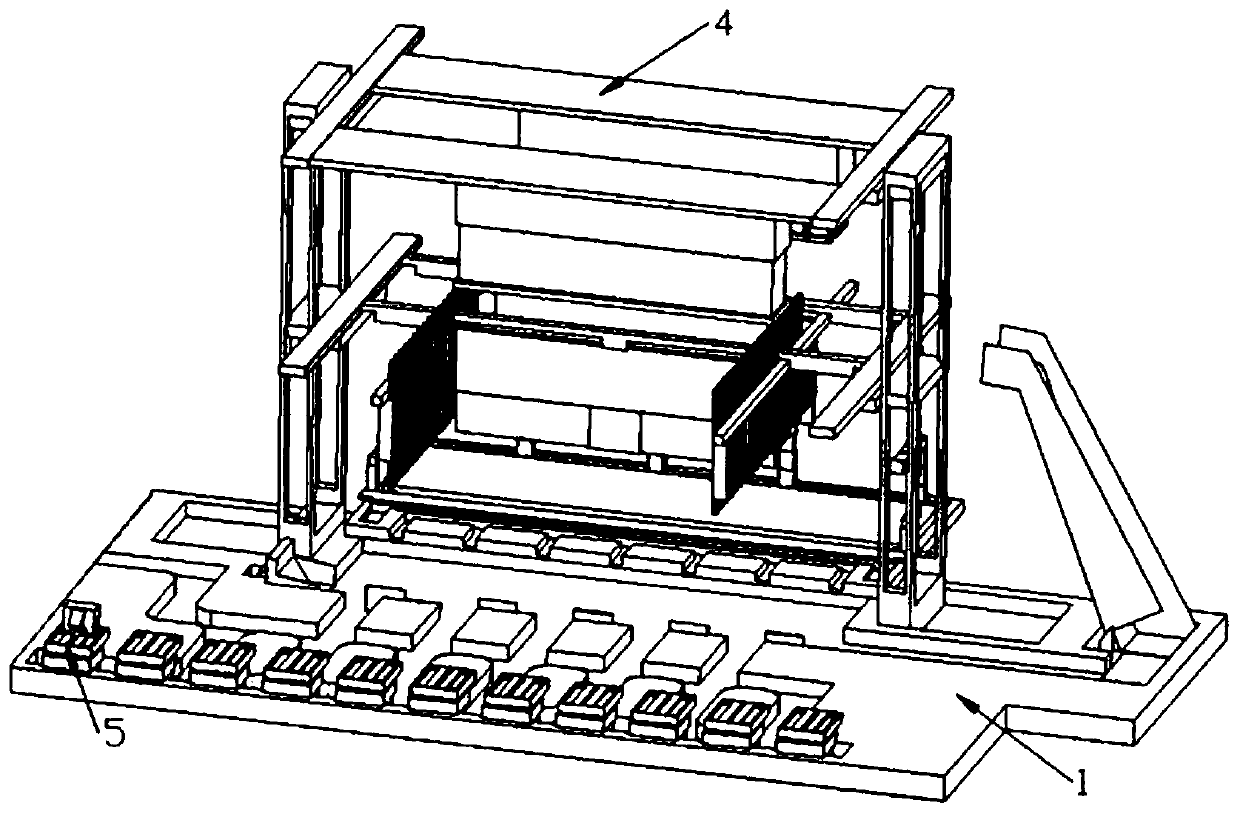

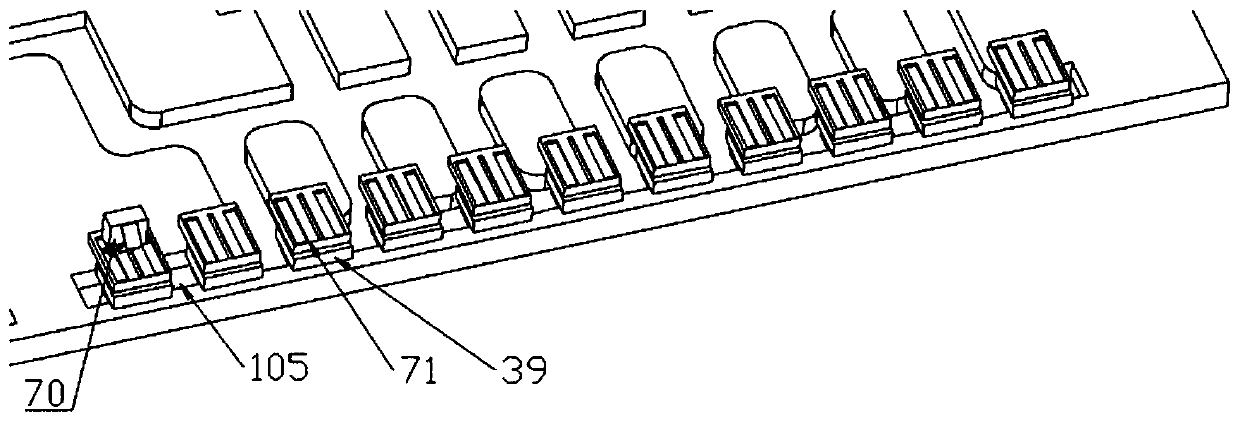

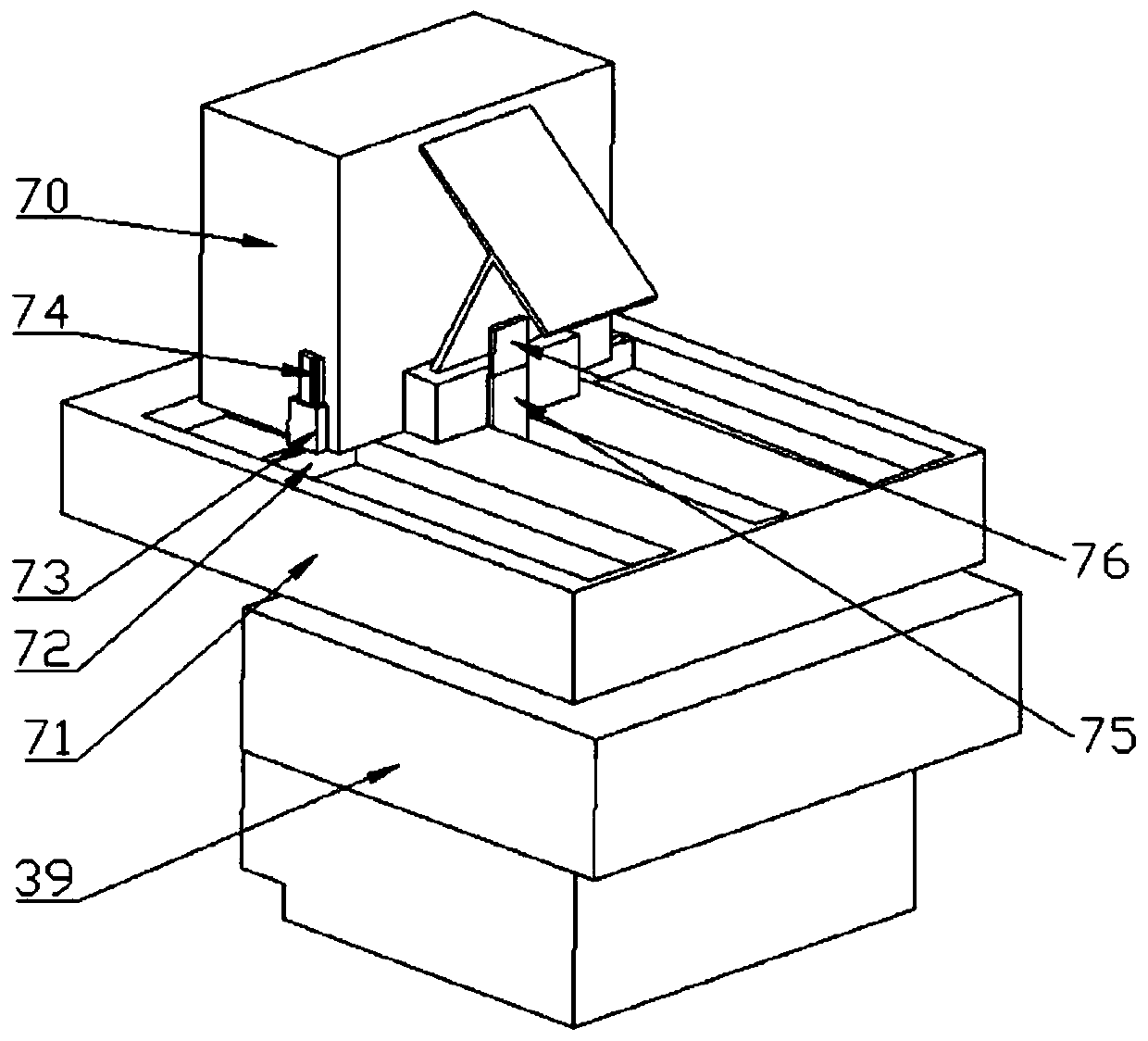

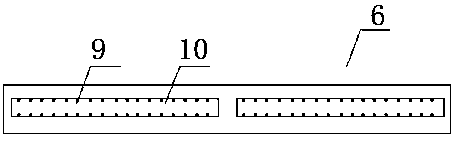

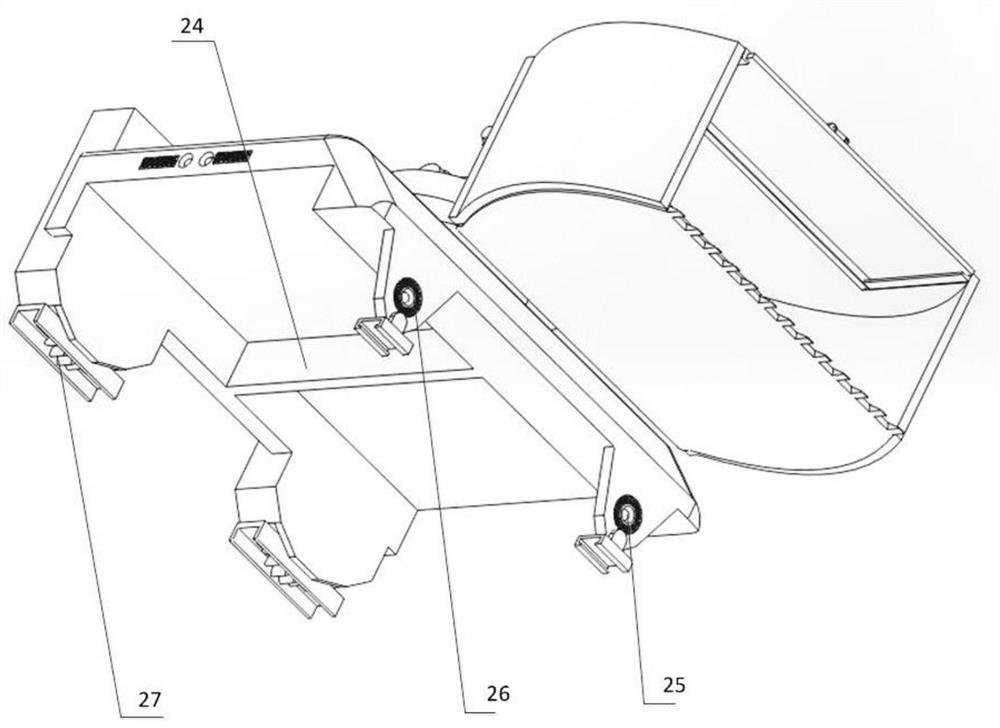

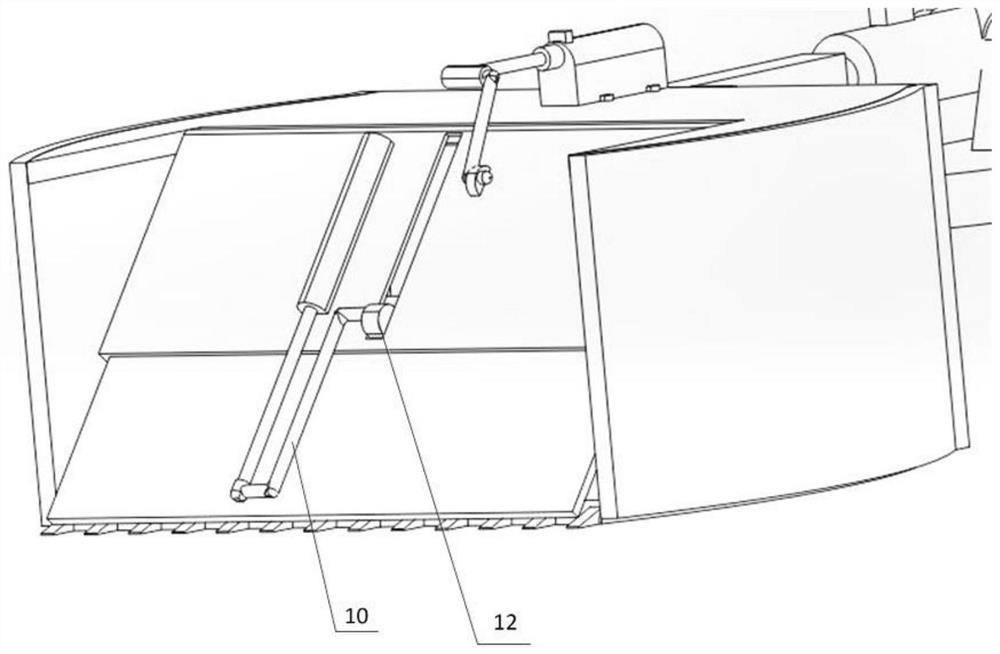

Caving coal simulation coal flow coal gangue drop impact test system and application thereof

ActiveCN108389493AEffective access to dataIngenious structural designEducational modelsDrop impactMining engineering

The invention relates to a caving coal simulation coal flow coal gangue drop impact test system and application thereof. The system comprises a base, and a simulation coal flow drop device, a coal gangue conveying device, a coal shoveling device and multiple caving coal hydraulic support working groups arranged on the base, wherein the simulation coal flow drop device comprises a simulation mine pressure loading device, a coal flow withholding device and a hydraulic support adjusting and placing device arranged from top to bottom; the coal shoveling device is used for pushing coal gangue particles after the test to the coal gangue conveying device; the coal gangue conveying device is used for conveying the coal gangue particles to the simulation coal flow drop device, and sequentially, through the simulation mine pressure loading device and the coal flow withholding device, a simulation coal flow coal gangue drop impact test is carried out on the caving coal hydraulic support working groups. The caving coal simulation coal flow coal gangue drop impact test system can simulate the actual drop of the caving coal, in match with the real hydraulic support groups, real coal caving signals can be simulated in a small range, data for the caving coal drop test can be acquired effectively, and a scientific basis is provided for a caving coal gangue interface.

Owner:SHANDONG UNIV OF SCI & TECH

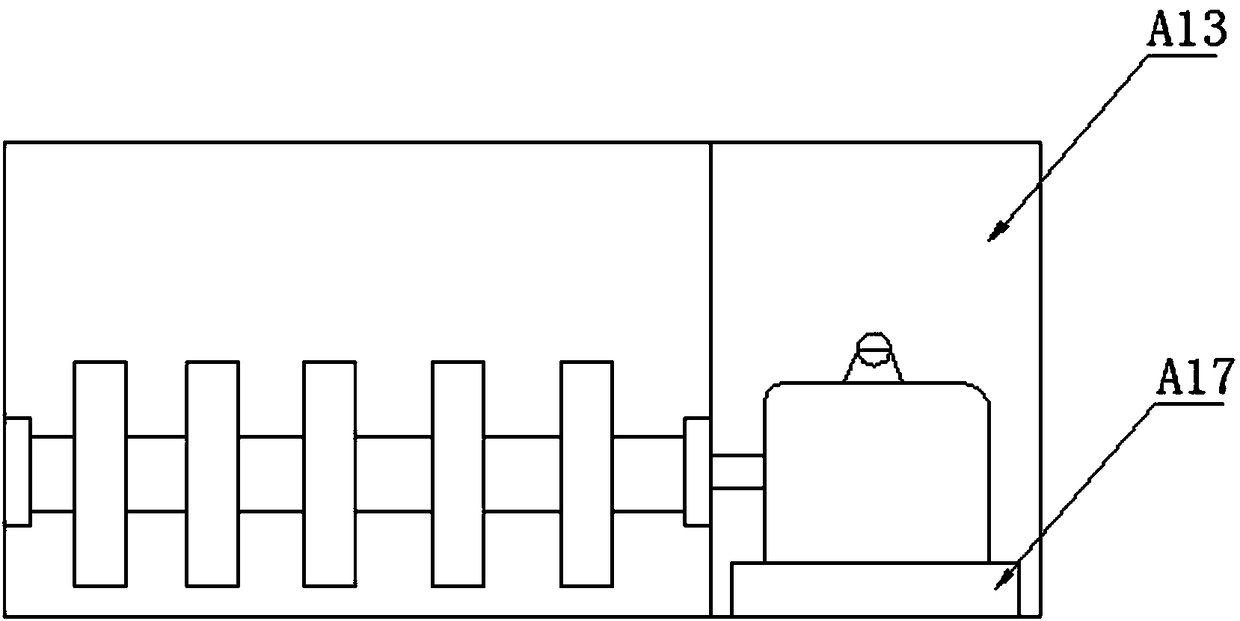

Efficient dust-prevention boiler feeding device

The invention discloses an efficient dust-prevention boiler feeding device, and belongs to the technical field of boiler feeding devices. A driving motor is started to drive a main rolling rod to rotate; the main rolling rod drives a conveying chain for transmission; the conveying chain drives a main transmission gear and a driven transmission gear to rotate so as to drive a driven rolling rod torotate; the main rolling rod and the driven rolling rod drive a conveying belt to move; meanwhile, a transmission module drives a coal shoveling module to rotate to realize coal shoveling cycles; shoveled coals are conveyed onto the conveying belt for conveying; the coals are conveyed to a carbon inlet of a boiler through the conveying belt, and the dust prevention is realized through side dustproof baffle plates; through automatic coal shoveling and conveying of the coals through automatic inputting of the coals onto the conveying belt, the problem of more dust caused by manual coal shovelingis prevented; the dust prevention is further realized through the side dustproof baffle plates; and through the design of electric conveying and coal shoveling, the labor force of workers is reduced,the working efficiency is improved, and both safety and stability are achieved.

Owner:芜湖市通达锅炉有限公司

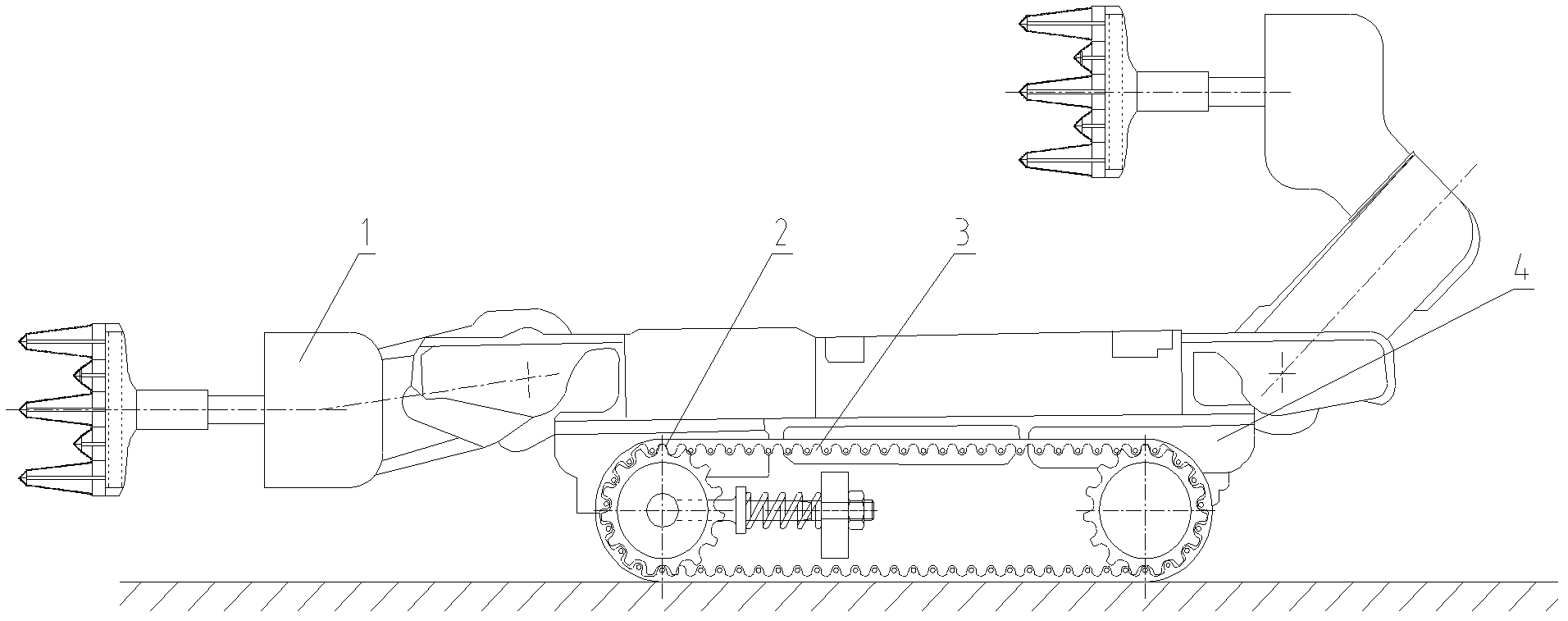

Crawler-type spiral roller coal collecting mechanism

The present invention overcomes the deficiencies in the prior art, and provides a crawler-type spiral drum coal collection mechanism, which can completely collect coal and overcome the problem of shedding; in order to solve the above technical problems, the technical solution adopted by the present invention is : A crawler-type spiral drum coal-collecting mechanism, comprising a coal-collecting mechanism body, a coal-collecting part and a crawler-type traveling part, the coal-collecting part is positioned at the front part of the coal-collecting mechanism body, and the crawler-type traveling part is arranged on the The bottom of the mechanism body, the top of the coal-collecting part is provided with a coal-shoveling plate, one end of the coal-shoveling plate is set on the body of the coal-collecting mechanism, and the bottom of the coal-shoveling plate is provided with a spiral drum for gathering coal. A scraper conveyor is installed in the middle of the coal-collecting mechanism body, and the scraper conveyor transports away the lump coal collected by the coal-collecting unit; the present invention can be widely used in the field of coal-collecting mechanisms.

Owner:CHANGZHI ZHONGRUI PRECISION BEARING MFGCO

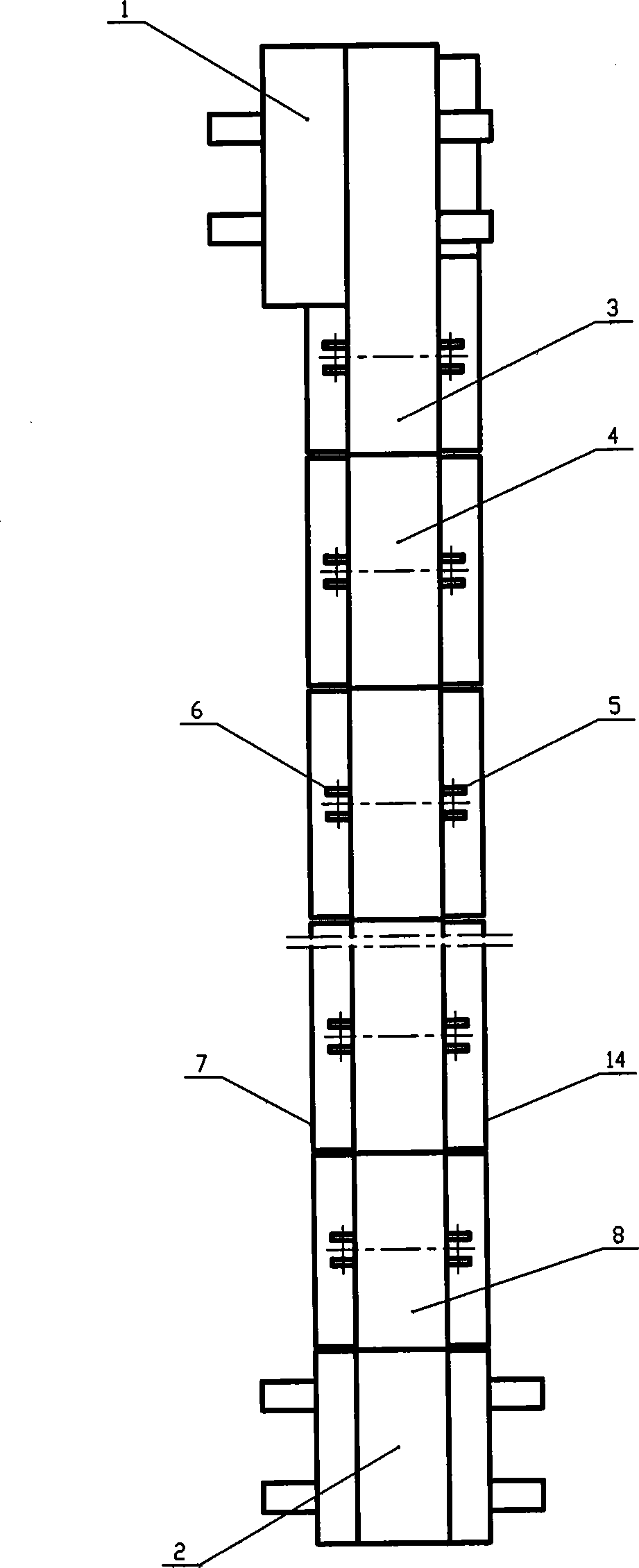

Digging and anchoring device for collecting coal by spiral drum

ActiveCN104358568ASimple structureLow costDriving meansAnchoring boltsBiochemical engineeringRock bolt

The invention discloses a digging and anchoring device for collecting coal by a spiral drum, belongs to the technical field of digging and anchoring devices, and solves the technical problems. The digging and anchoring device is simple in structure and convenient to popularize. The invention adopts the technical scheme as follows: the digging and anchoring device comprises a digging and anchoring device body, a cutting part, an anchor rod drill bit and a traveling part, wherein the cutting part is positioned at the front part of the digging and anchoring device body; the anchor rod drill bit is arranged on the digging and anchoring device body and positioned on the rear side of the cutting part; the traveling part is arranged at the bottom of the digging and anchoring device body; a coal shovel plate is arranged at the bottom of the cutting part; one end of the coal shovel plate is arranged on the digging and anchoring device body; the spiral drum used for collecting the coal is arranged on the coal shovel plate; a scraper conveyer is arranged in the middle of the digging and anchoring device body and used for conveying the coal collected by the spiral drum to a coal transport hopper. The digging and anchoring device can be widely applied to coal mining.

Owner:刘建德

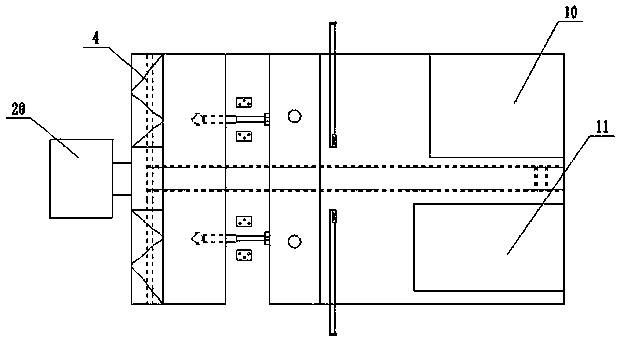

A top coal caving imitation coal flow gangue caving impact test system and its application

ActiveCN108389493BEffective access to dataIngenious structural designEducational modelsDrop impactMining engineering

The invention relates to a caving coal simulation coal flow coal gangue drop impact test system and application thereof. The system comprises a base, and a simulation coal flow drop device, a coal gangue conveying device, a coal shoveling device and multiple caving coal hydraulic support working groups arranged on the base, wherein the simulation coal flow drop device comprises a simulation mine pressure loading device, a coal flow withholding device and a hydraulic support adjusting and placing device arranged from top to bottom; the coal shoveling device is used for pushing coal gangue particles after the test to the coal gangue conveying device; the coal gangue conveying device is used for conveying the coal gangue particles to the simulation coal flow drop device, and sequentially, through the simulation mine pressure loading device and the coal flow withholding device, a simulation coal flow coal gangue drop impact test is carried out on the caving coal hydraulic support working groups. The caving coal simulation coal flow coal gangue drop impact test system can simulate the actual drop of the caving coal, in match with the real hydraulic support groups, real coal caving signals can be simulated in a small range, data for the caving coal drop test can be acquired effectively, and a scientific basis is provided for a caving coal gangue interface.

Owner:SHANDONG UNIV OF SCI & TECH

Ore transportation and ore discharging device for ore mining vehicle

InactiveCN109707379AFlexible connectionChange installation heightSlitting machinesElectric machineryEngineering

The invention discloses an ore transportation and ore discharging device for an ore mining vehicle. The ore transportation and ore discharging device comprises a moving frame, shoveling transportationhoppers, a first clamping and placing frame, a second clamping and placing frame, a clamping disc, a motor connecting ring, supporting and connecting posts, a first rolling gear ring, first clamp teeth, a first rolling cabin, a second rolling gear ring, a shoveling installing cabin, a first slide groove, a first locking ring, a first slide post, a second rolling cabin, a motor cabin, a second slide post, a second locking ring, second clamp teeth and a second slide groove. The ore transportation and ore discharging device has the beneficial effects that in the use process, a motor in the motorcabin drives the moving frame to integrally do forward and backward reciprocating movement through the first rolling gear ring, so that the two shoveling transportation hoppers arranged on the movingframe can perform normal coal shoveling transportation work; by sliding the second slide post of the clamping and placing frame in the second slide groove of the clamping disc, the space between thefirst and second clamping and placing frames is changed; therefore the device can perform more precise adaptive work on different ore mining vehicle hoppers; and the wide adaptation range is ensured.The operation of the device is convenient; and each component is flexibly connected.

Owner:李凤英

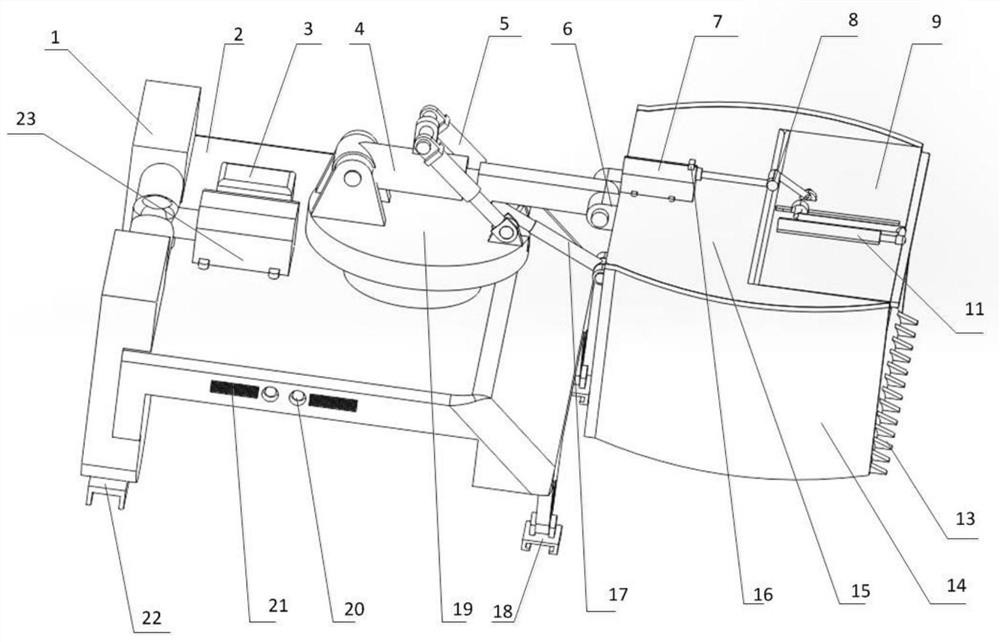

Mobile inspection type float coal cleaning system and working method thereof

ActiveCN112855142AImprove efficiencyEnsure safetySlitting machinesClosed circuit television systemsThermodynamicsControl system

The invention discloses a mobile inspection type float coal cleaning system and a working method thereof, and belongs to the field of coal mine underground float coal cleaning. The mobile inspection type float coal cleaning system comprises a vehicle body, and the vehicle body is provided with a sliding system, a machine vision and control system, a rotating system and a coal shoveling system; the sliding system is used for being matched with a scraper conveyor to achieve front-back movement of the vehicle body, the rotating system rotates front and back relative to the vehicle body, and the coal shoveling system is arranged on one side of the vehicle body and connected to the rotating system for shoveling coal; and the machine vision and control system comprises a PLC and a machine vision system which are connected to each other, and the PLC is connected to driving mechanisms of the sliding system, the rotating system and the coal shoveling system and used for controlling front-back movement of the vehicle body, left-right rotation of the coal shoveling system and coal loading and unloading actions of the coal shoveling system. The mobile inspection type float coal cleaning system can identify and automatically clean float coal at the place where excessive float coal is accumulated between the scraper conveyor and the coal wall working face and at the end of the scraper conveyor, the efficiency of the coal face is improved, and the safety of personnel is guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

Crawler-type T-shaped scraping plate machine coal collecting mechanism

The present invention overcomes the deficiencies in the prior art, and provides a crawler-type T-type scraper coal collection mechanism, which can completely collect coal and overcome the problem of shedding; in order to solve the above technical problems, the present invention adopts The technical solution is: a crawler-type T-shaped scraper coal-collecting mechanism, including a coal-collecting mechanism body, a coal-collecting part, and a crawler-type walking part. The coal-collecting part is located at the front of the coal-collecting mechanism body. The walking part is set at the bottom of the coal-collecting mechanism body, the top of the coal-collecting part is provided with a coal-shoveling plate, one end of the coal-shoveling plate is set on the coal-collecting mechanism body, and the lower part of the coal-shoveling plate is provided with a The T-shaped scraper machine, the middle part of the coal collection mechanism body is provided with a scraper conveyor, and the scraper conveyor transports away the lump coal collected by the coal collection part; the present invention can be widely used in the field of coal collection mechanism.

Owner:CHANGZHI ZHONGRUI PRECISION BEARING MFGCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com