Excavating and shoveling buffer transmission device of lump coal shovel

A technology of transmission device and coal scraper, which is applied in the fields of mine excavation, mining, and tunnel excavation. It can solve the problems of large power consumption, waste of resources, and high cost, and achieve the goals of increasing power transmission capacity, stable gear transmission, and improved meshing degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

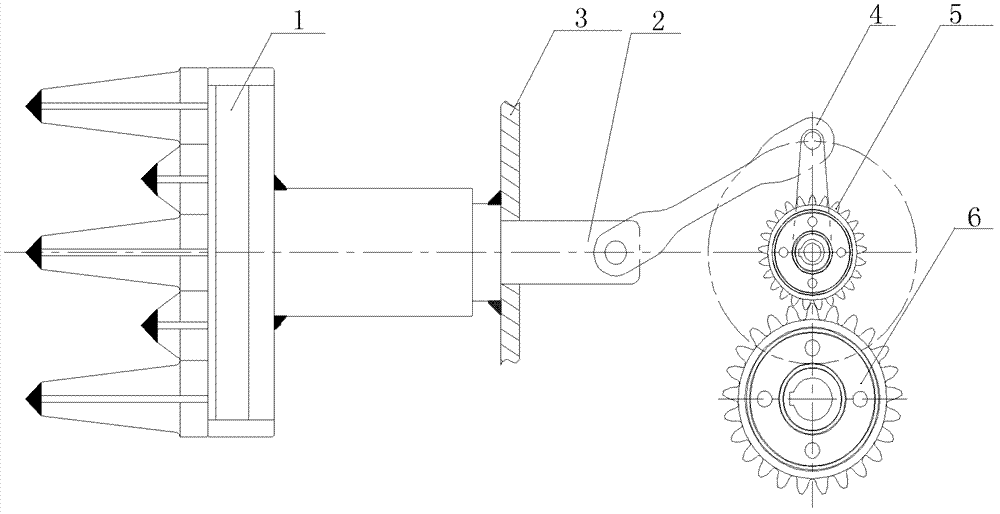

[0028] figure 1 It is the excavation shovel buffer transmission device of the lump coal shovel described in embodiment 1. The device includes a driving gear 6, a driven gear 5 and a gear mounting frame 9, and the driving gear 6 and the driven gear 5 are installed on the gear mounting frame 9. The driving gear 6 is connected with the power input shaft 8, and the power input shaft 8 is connected with the driving device through a winding coupling, and the power input shaft and the driving device are kept concentric through the winding coupling. The driven gear 5 is connected with the power output shaft 7 , and the other end of the power output shaft 7 is connected with the connecting rod 4 . A guide rod 2 is connected to the rear of the excavation shovel 1 , and the guide rod 2 is connected to a power output shaft 7 through a connecting rod 4 .

[0029] The driving gear 6 and the driven gear 5 both adopt cylindrical spur gears, and the meshing mode between the two gears is exte...

Embodiment 2

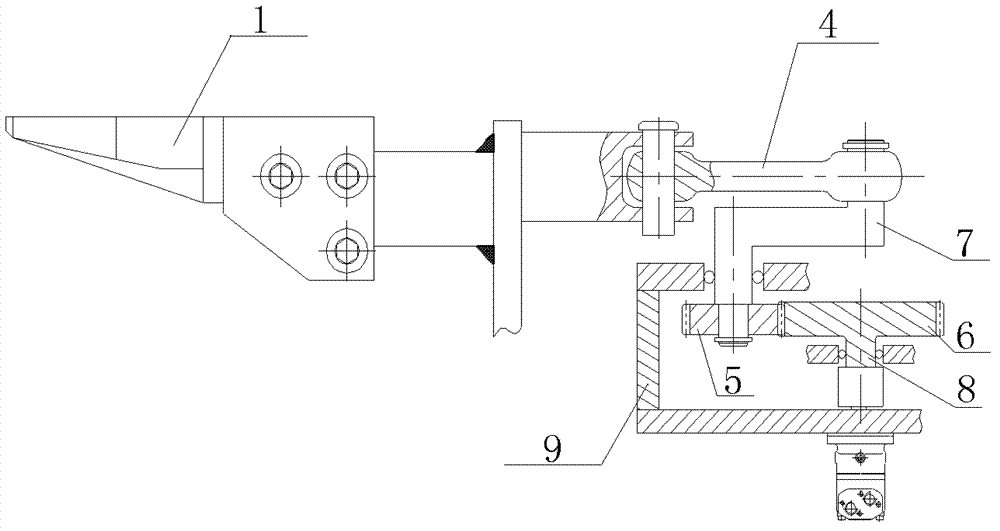

[0033] figure 2 It is the excavation and shovel buffer transmission device of the block coal shovel described in embodiment 2. The difference from Embodiment 1 is that the driving gear 6 in this embodiment is arranged on one side of the driven gear 5, and the driven gear 5 is installed on the power output shaft at this time.

[0034] Others are with embodiment 1.

Embodiment 3

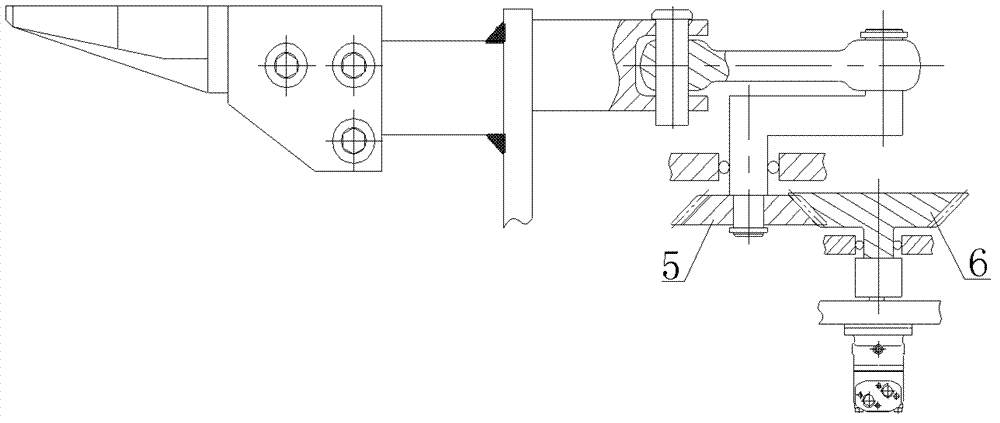

[0036] image 3 It is the excavation shovel buffer transmission device of the block coal shovel described in embodiment 3. The difference from Embodiment 2 is that the driving gear 6 and the driven gear 5 in this embodiment are conical spur gears.

[0037] Others are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com