Patents

Literature

59results about How to "Improve power transmission performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

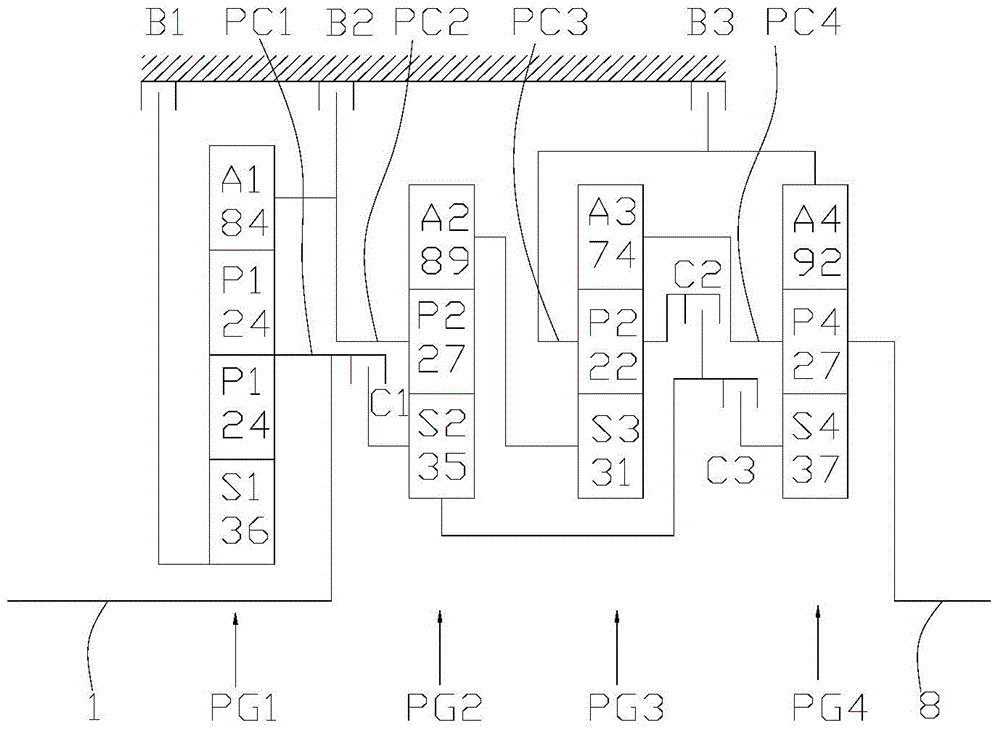

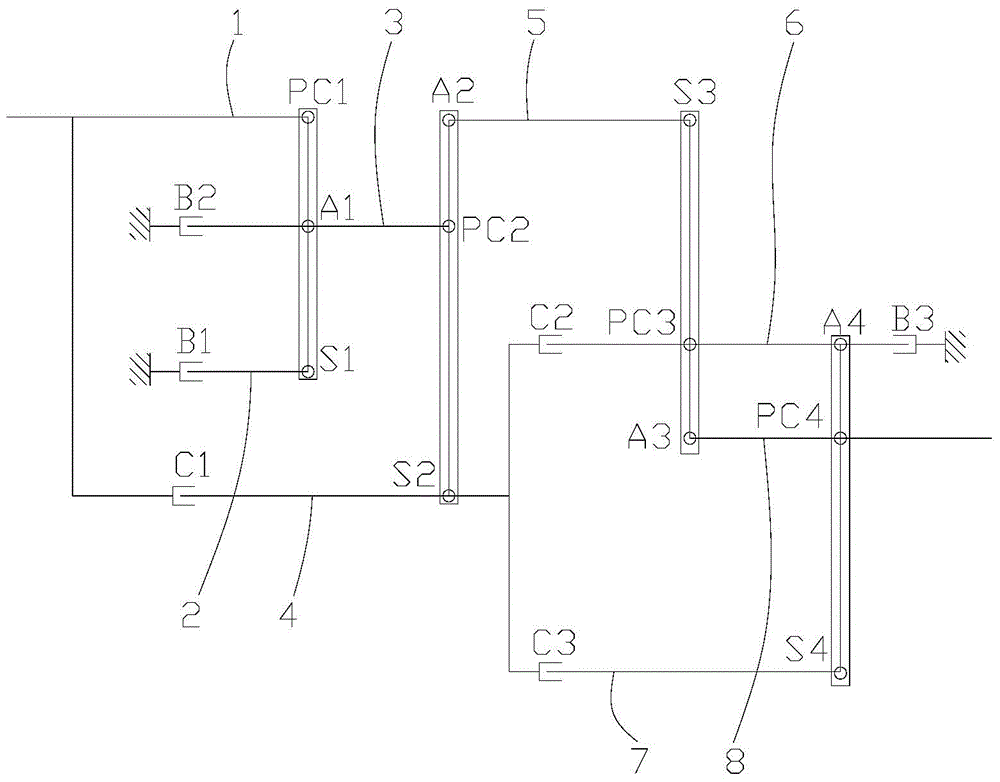

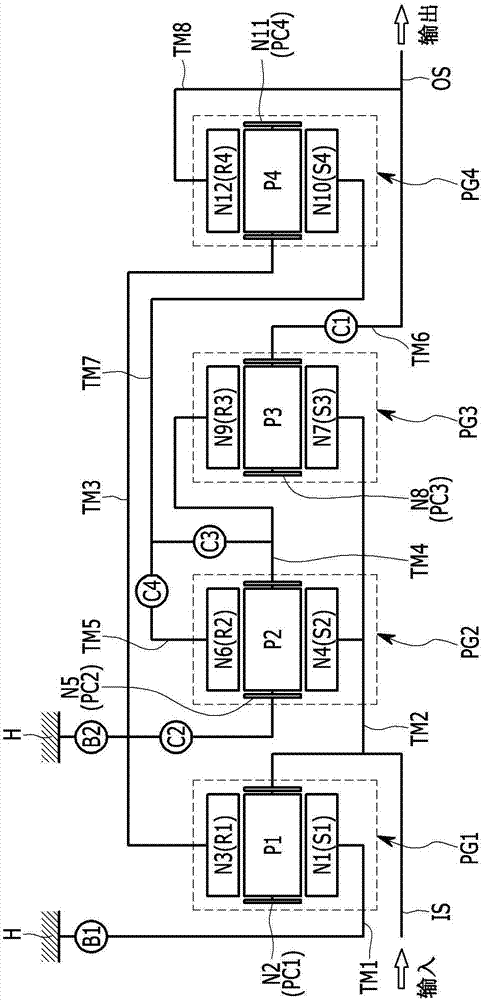

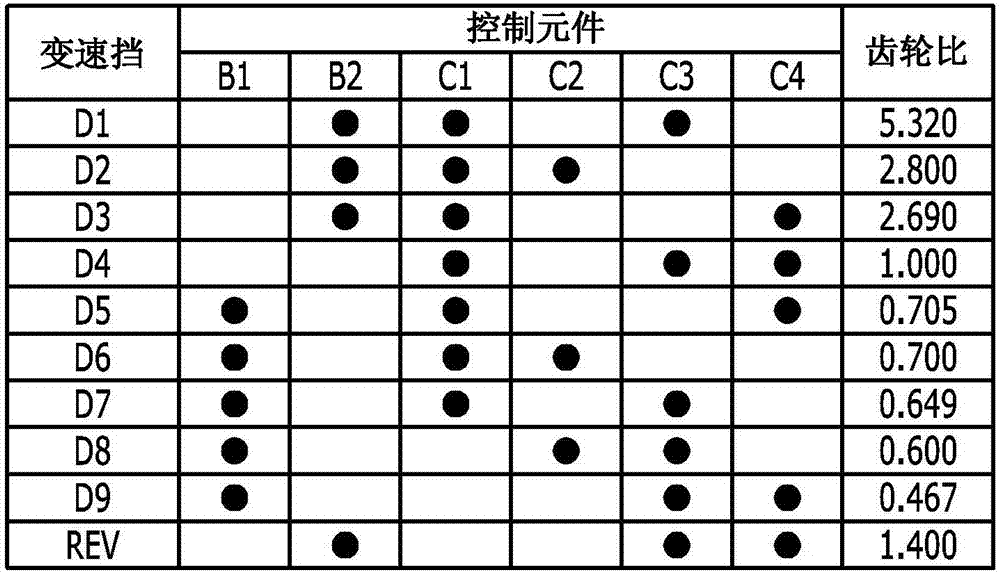

Multi-gear transmission and planetary gear train thereof

ActiveCN104896038AShorten the lengthMeet the durabilityToothed gearingsTransmission elementsAutomatic transmissionGear wheel

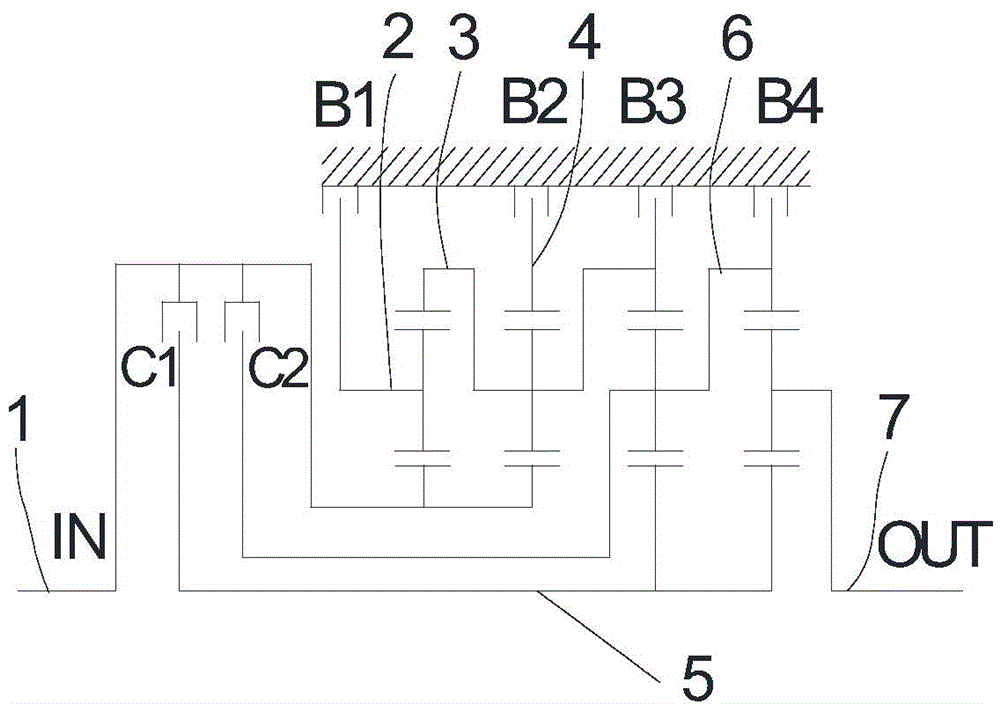

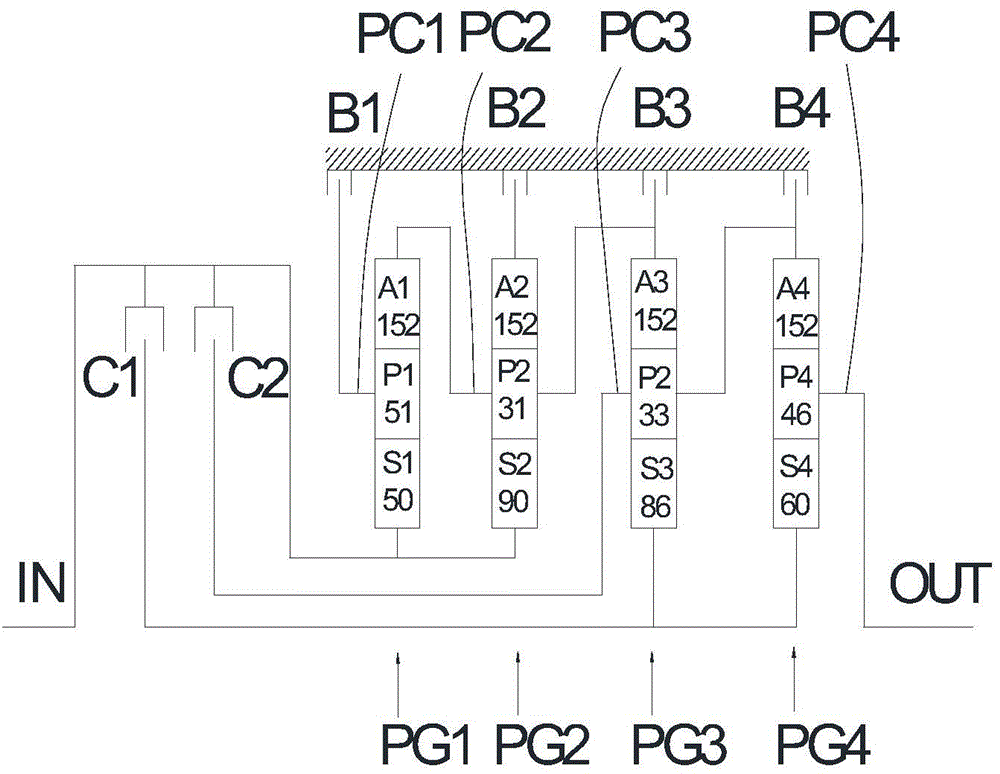

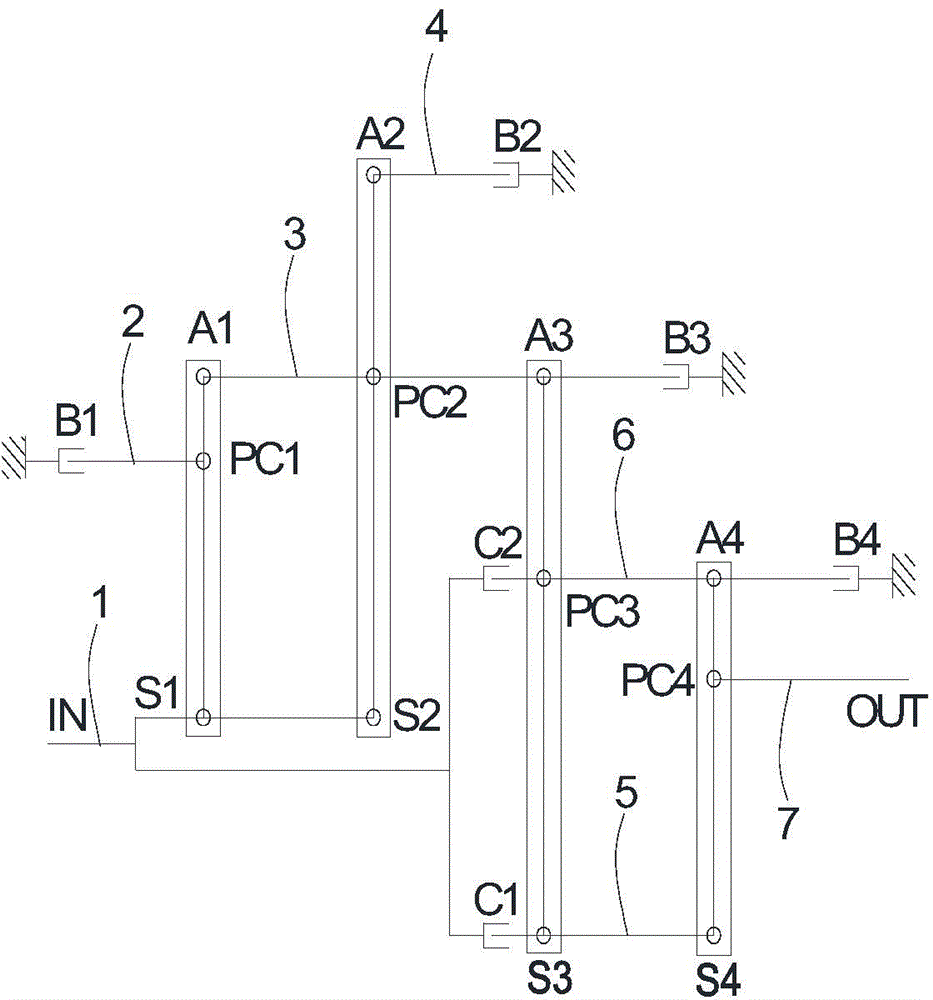

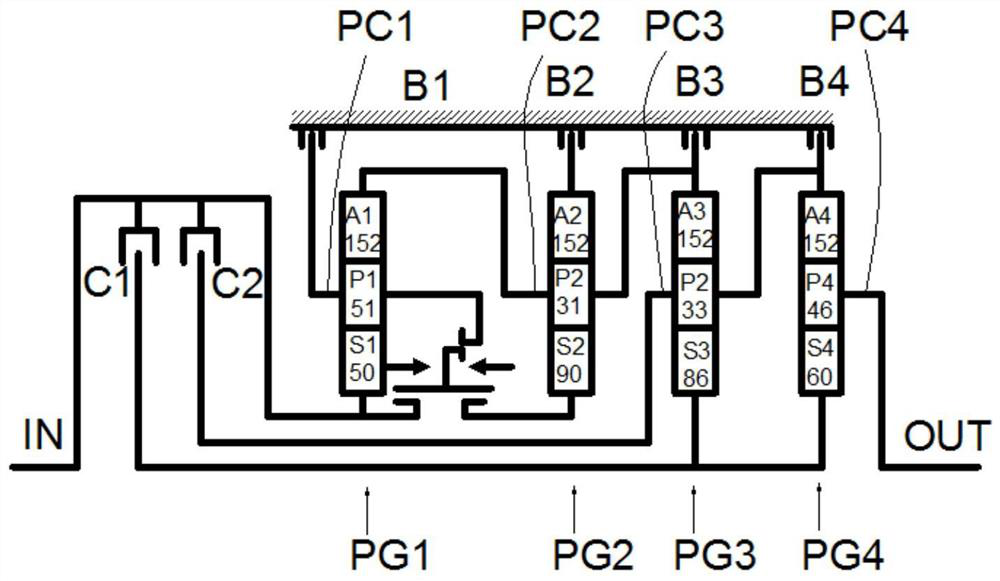

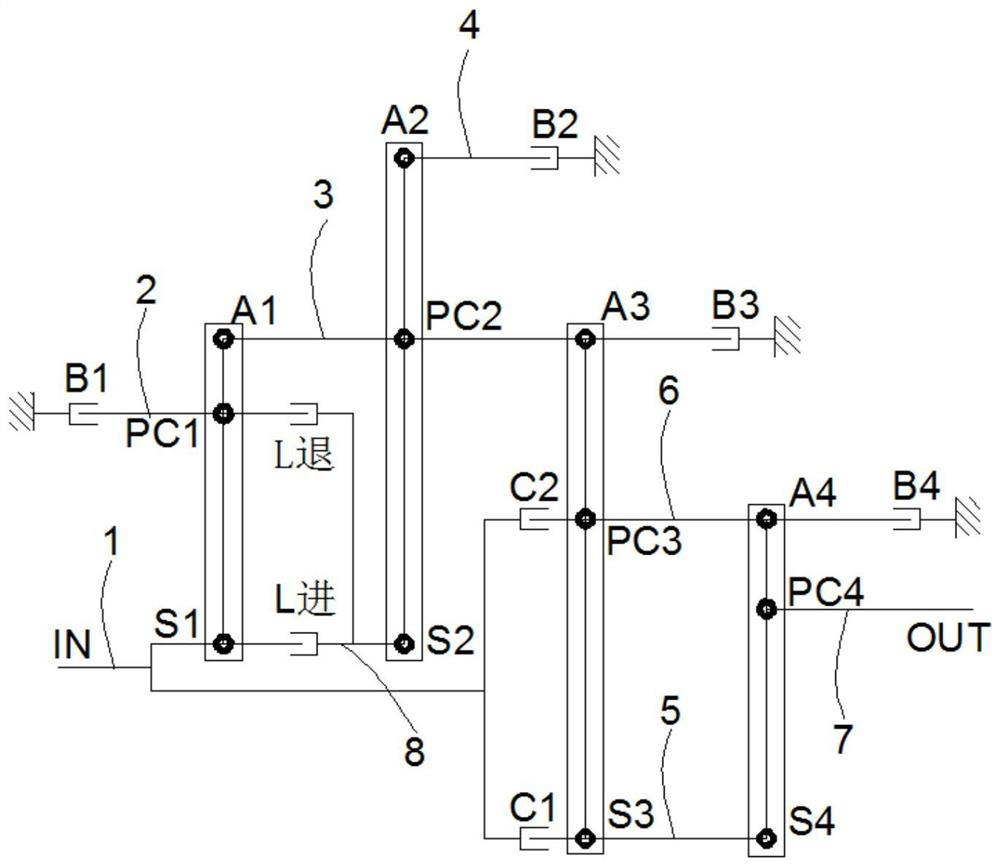

The invention discloses a planetary gear train to be used for a multi-gear transmission. At least nine available forward gears and at least one available reverse gear can be obtained. The planetary gear train comprises a first planet row, a second planet row, a third planet row and a fourth planet row. Each planet row comprises a sun gear, a planet carrier and a gear ring. Components and connection members of the planet rows can form seven rotation elements. A gear shifting component comprises two clutches and four brakes. The clutches are arranged among the selected rotation elements of the rotation elements, and the brakes are arranged between the selected rotation elements of the rotation elements and fixing parts. The planetary gear train has more gears and optimal speed ratio, the power transmission performance and the fuel economy of the cars can be improved apparently, and the planetary gear train is short, compact in overall design, capable of meeting requirements of cars for transmission durability, power transmission efficiency, size, costs and the like well. The invention further discloses an automatic transmission with the planetary gear train.

Owner:SHAANXI FAST GEAR CO

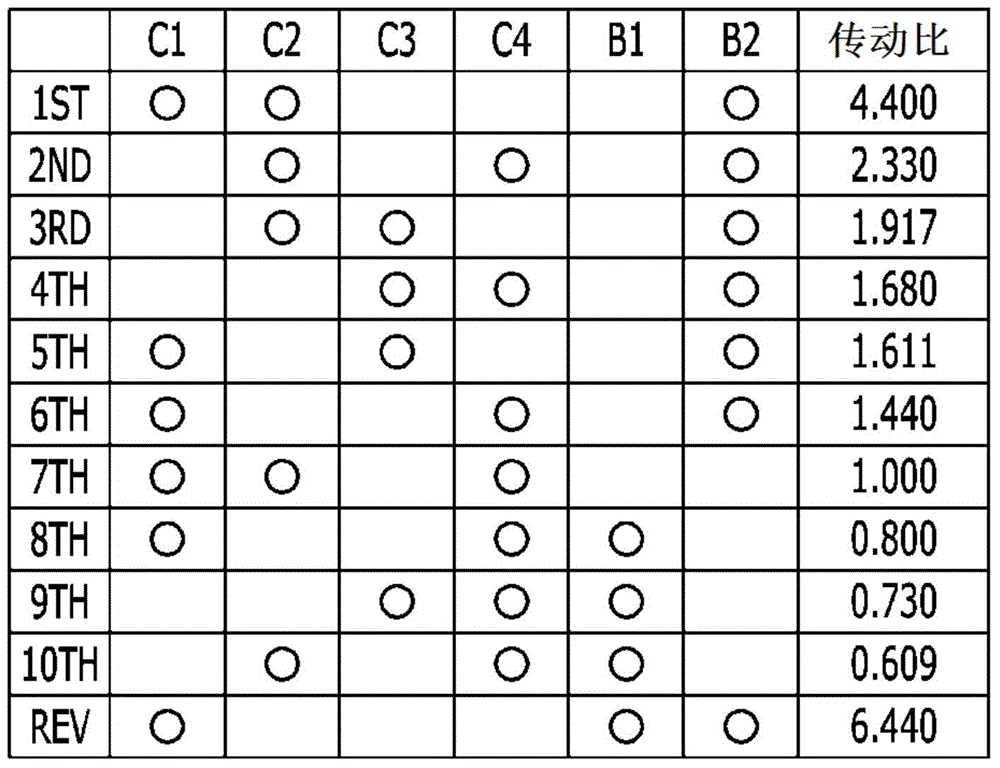

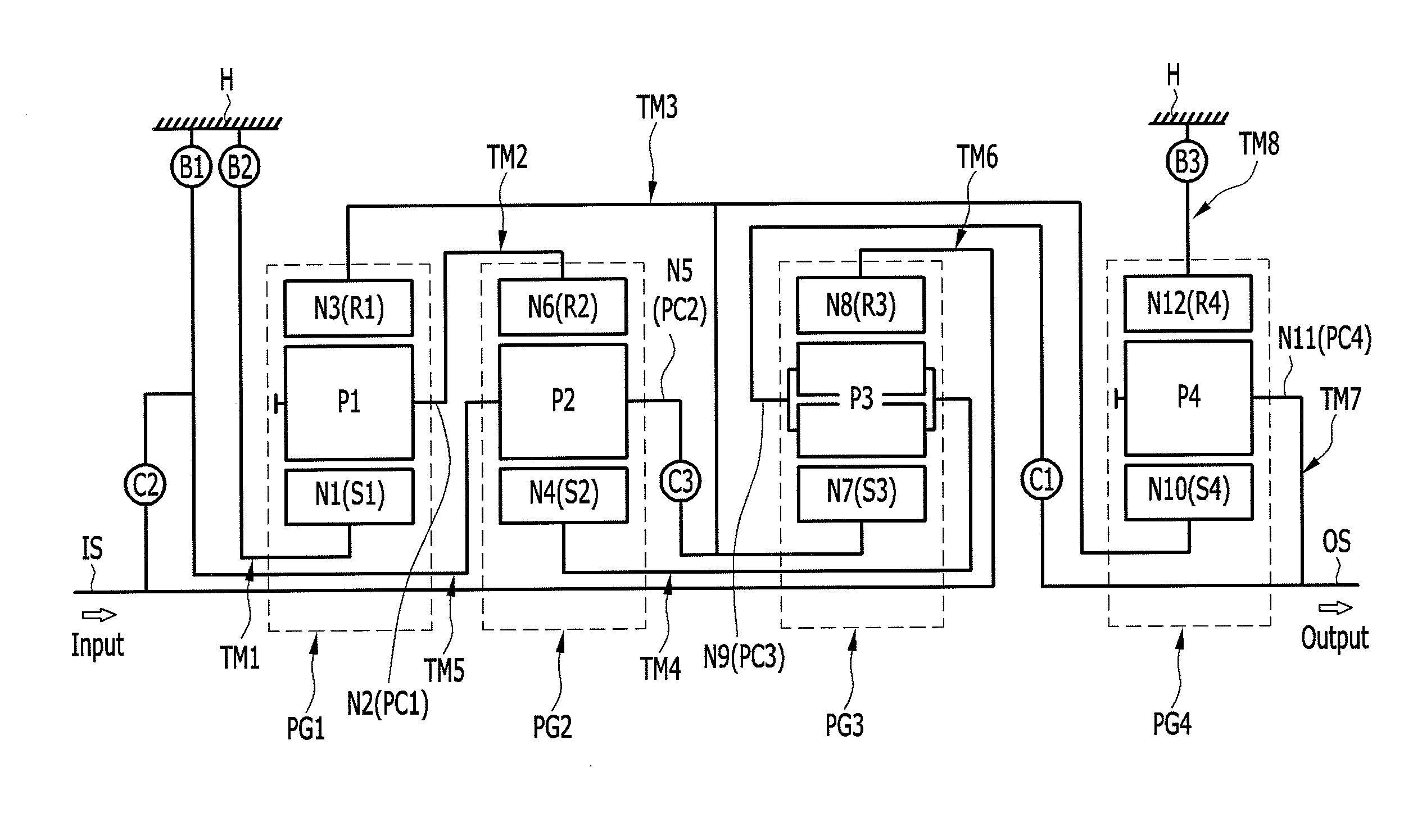

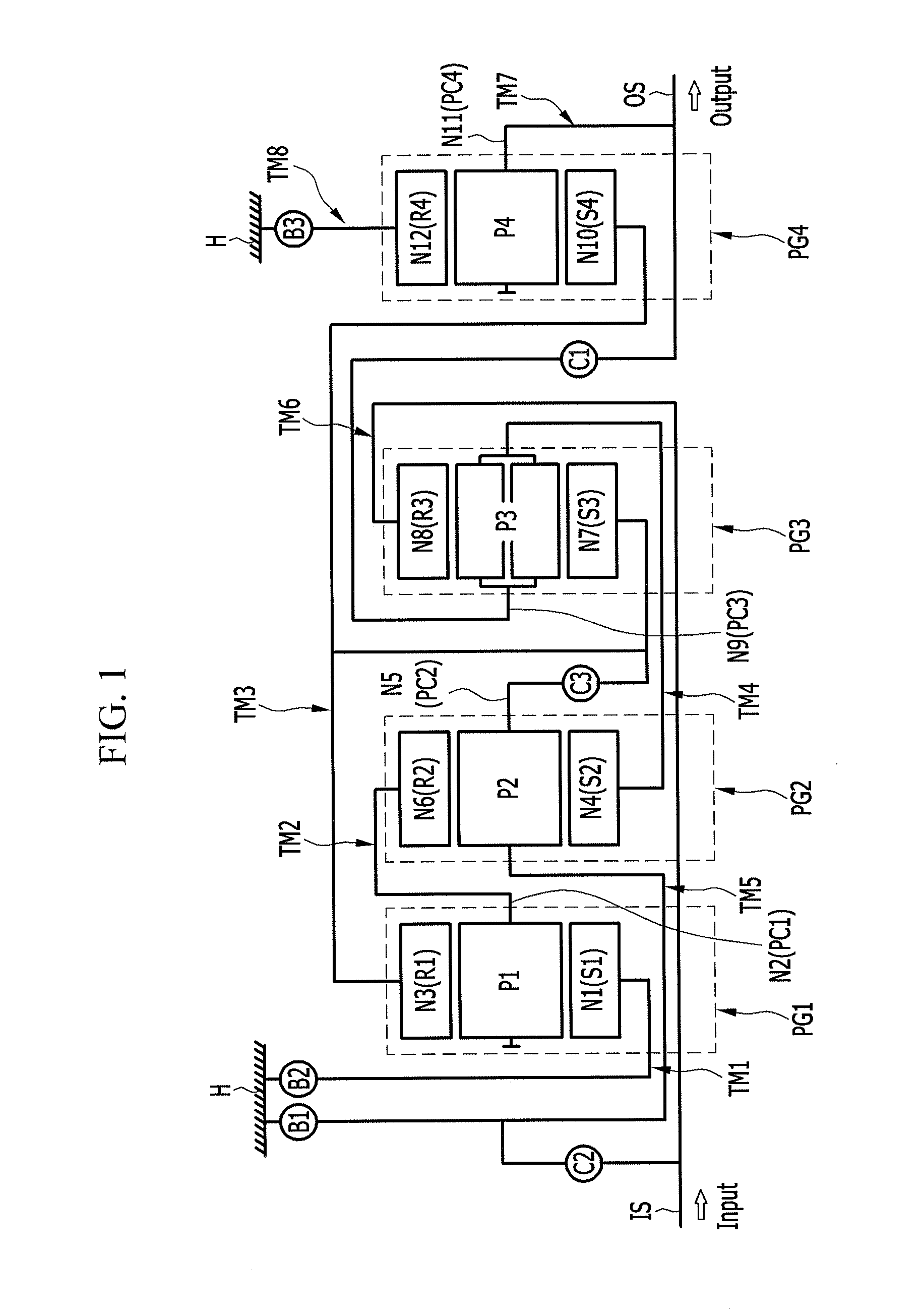

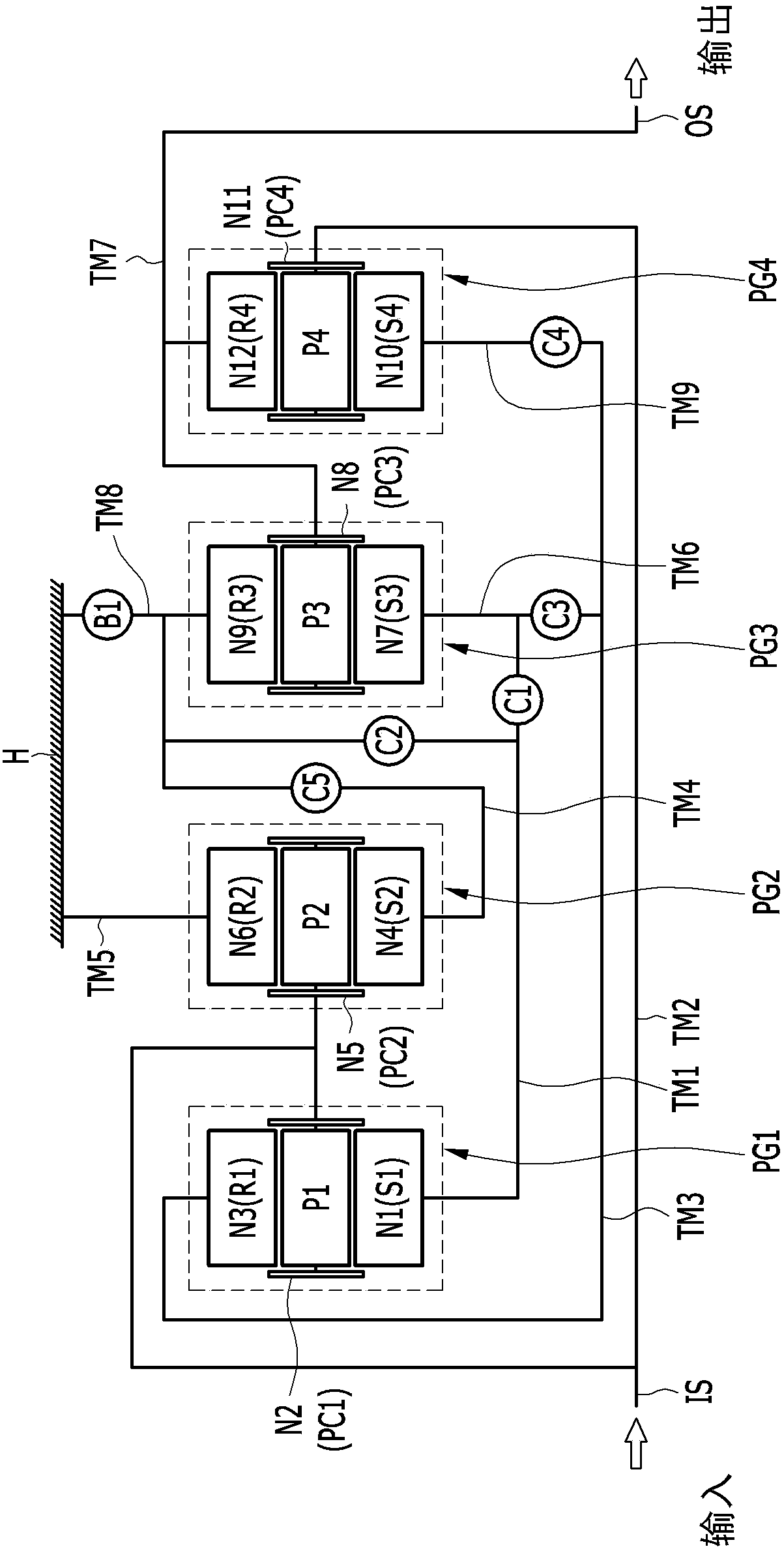

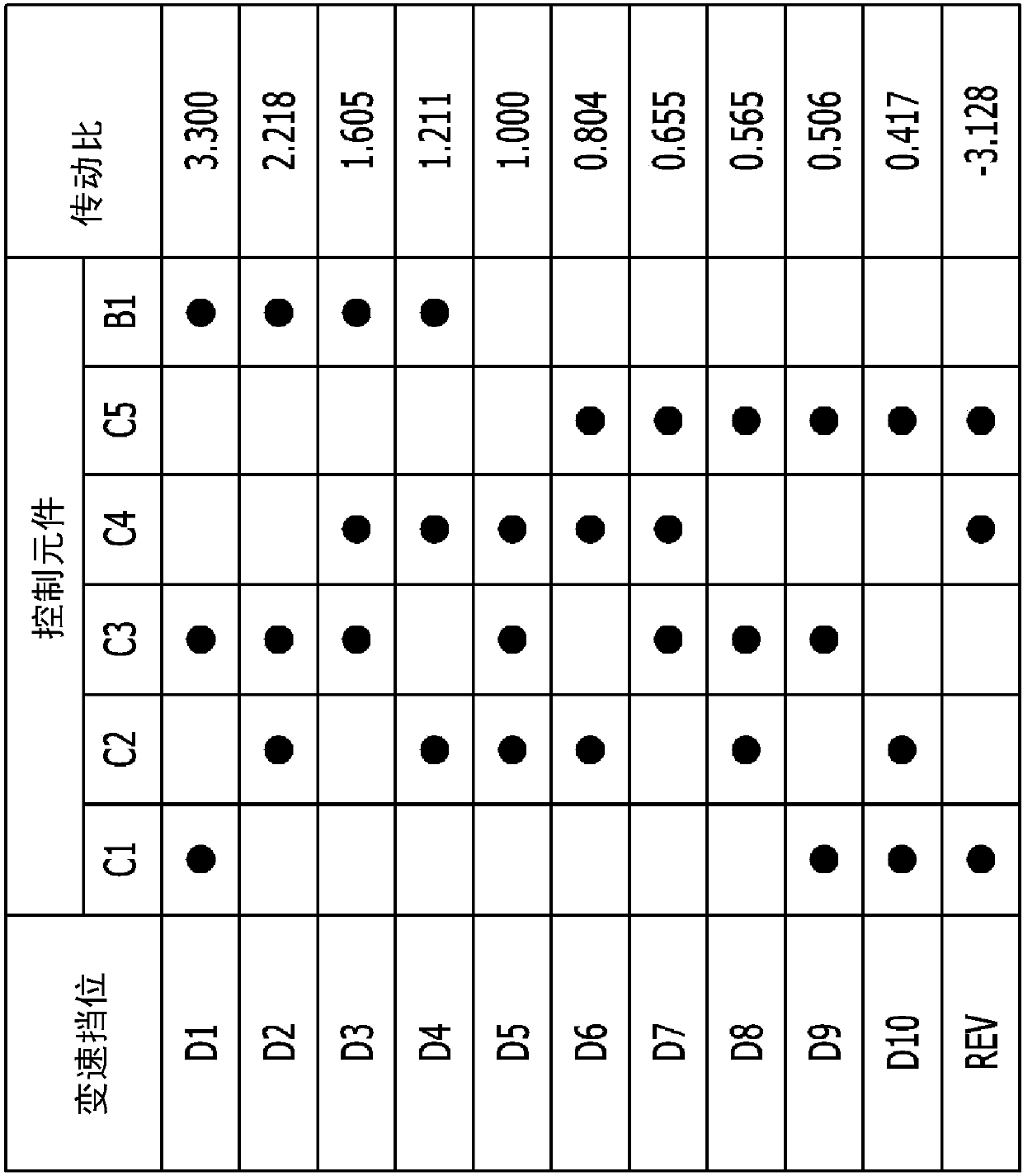

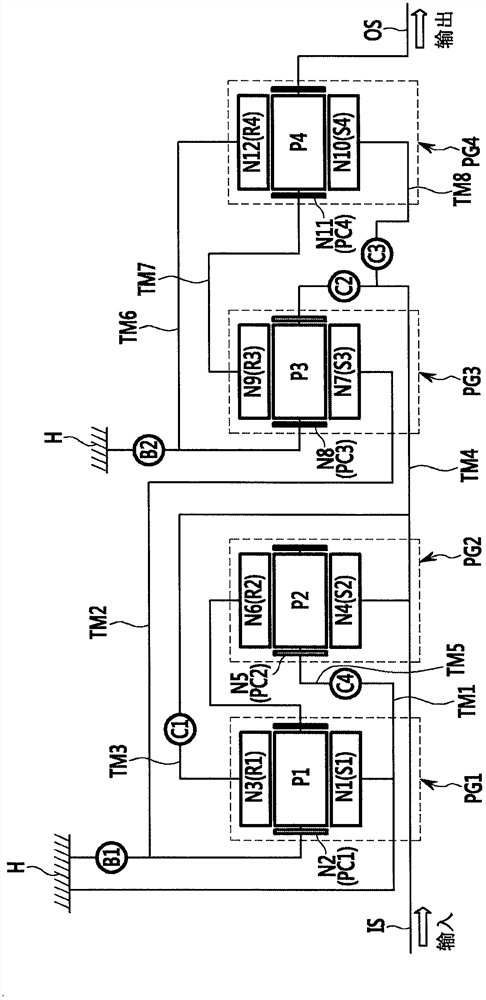

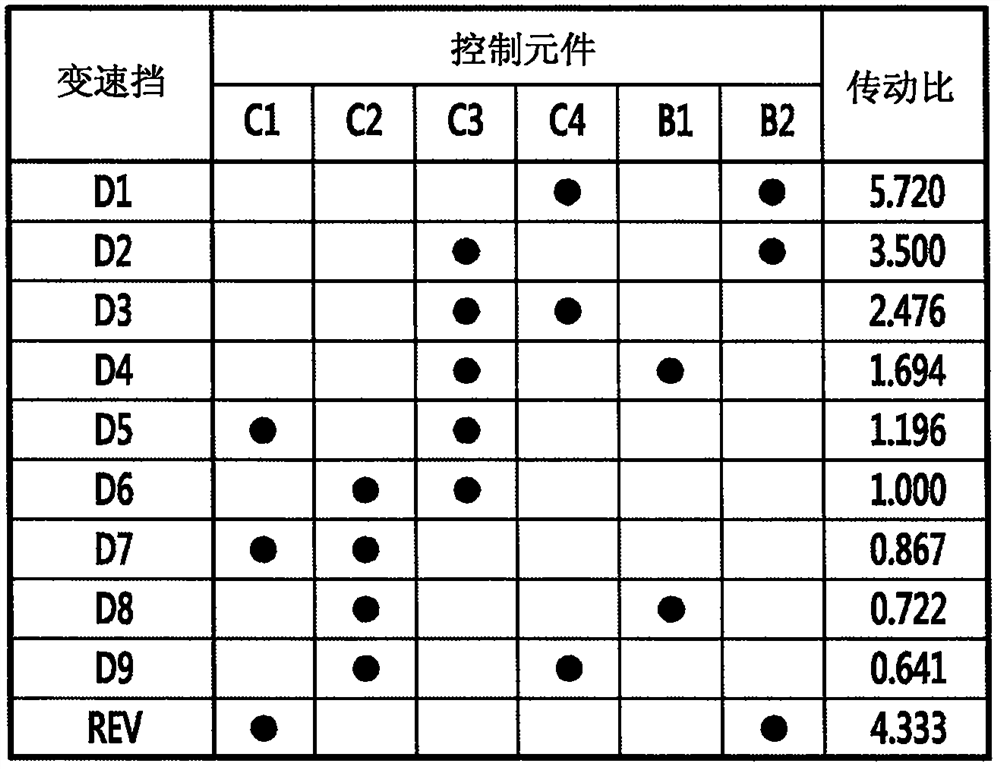

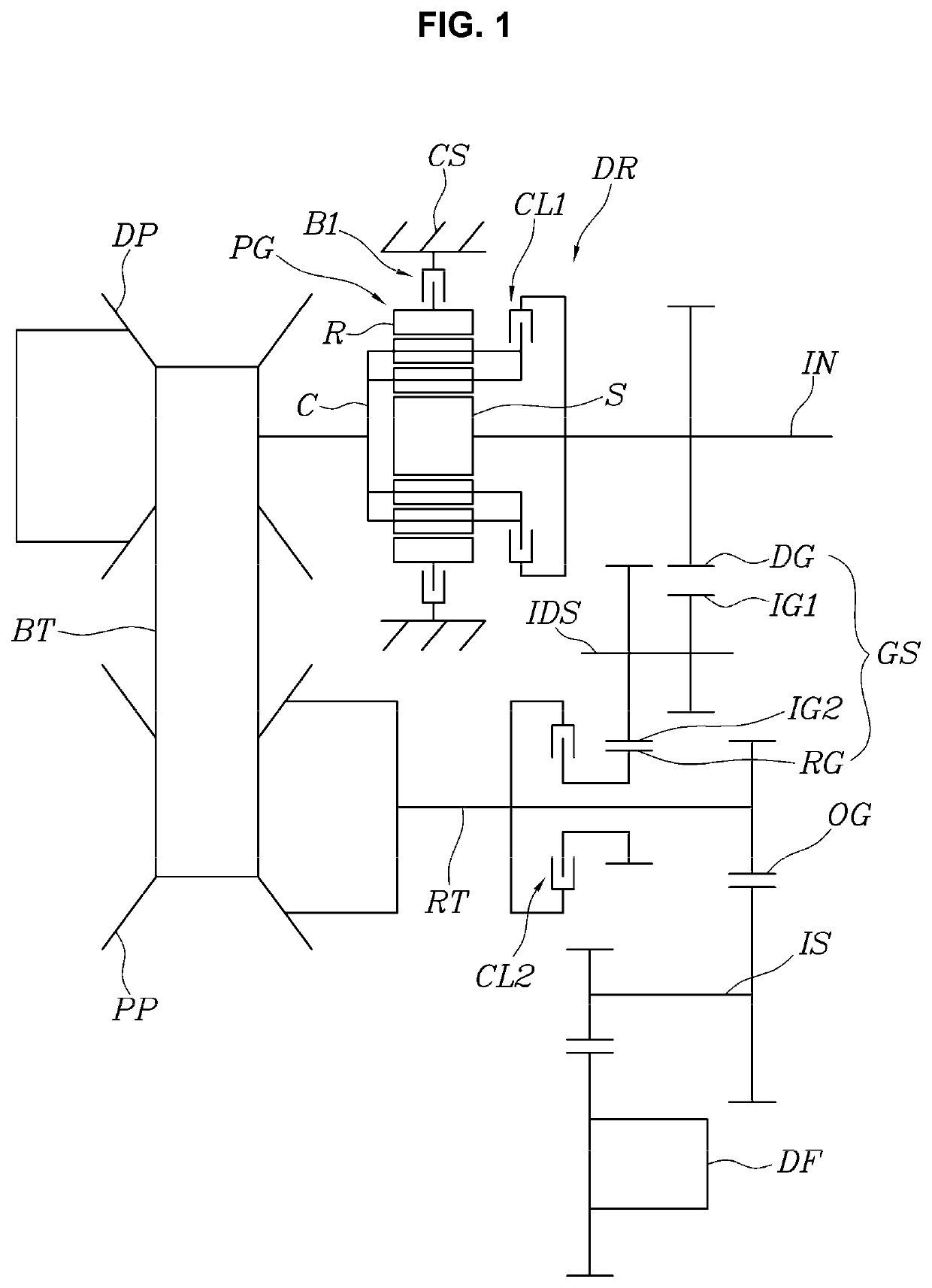

Planetary gear train of automatic transmission for vehicle

ActiveCN105697675AImprove economyImprove power transmission performanceToothed gearingsTransmission elementsAutomatic transmissionGear wheel

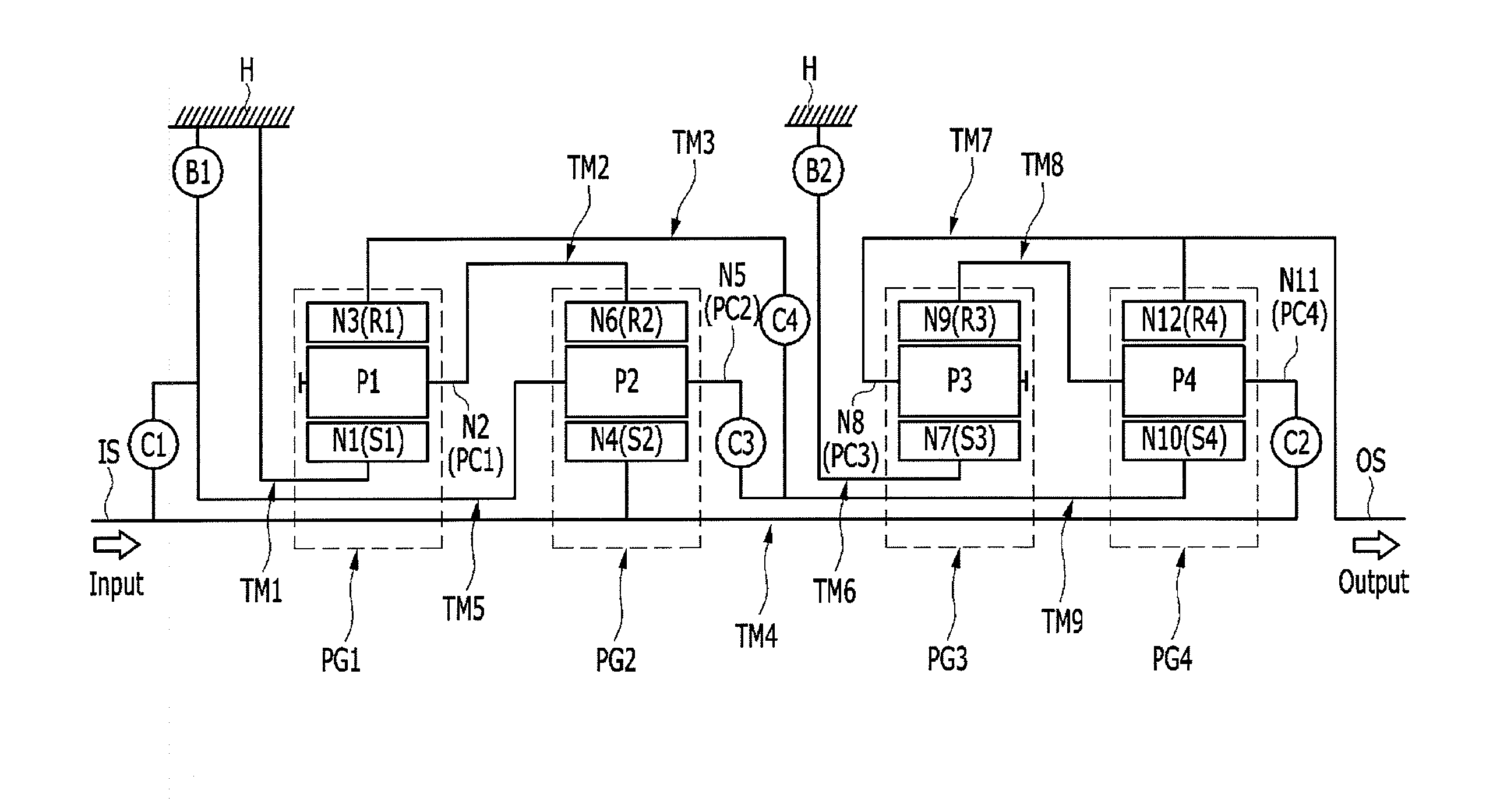

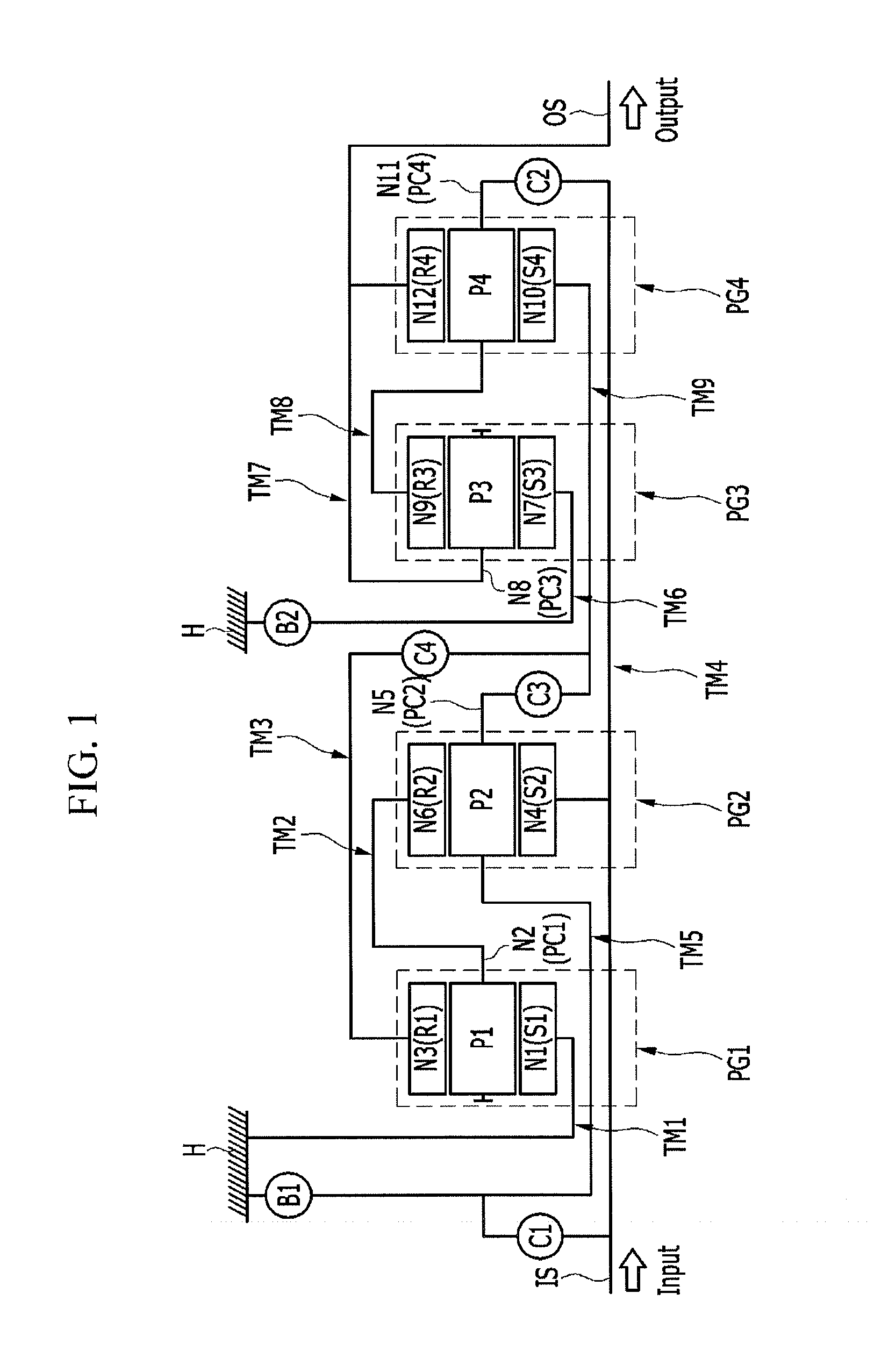

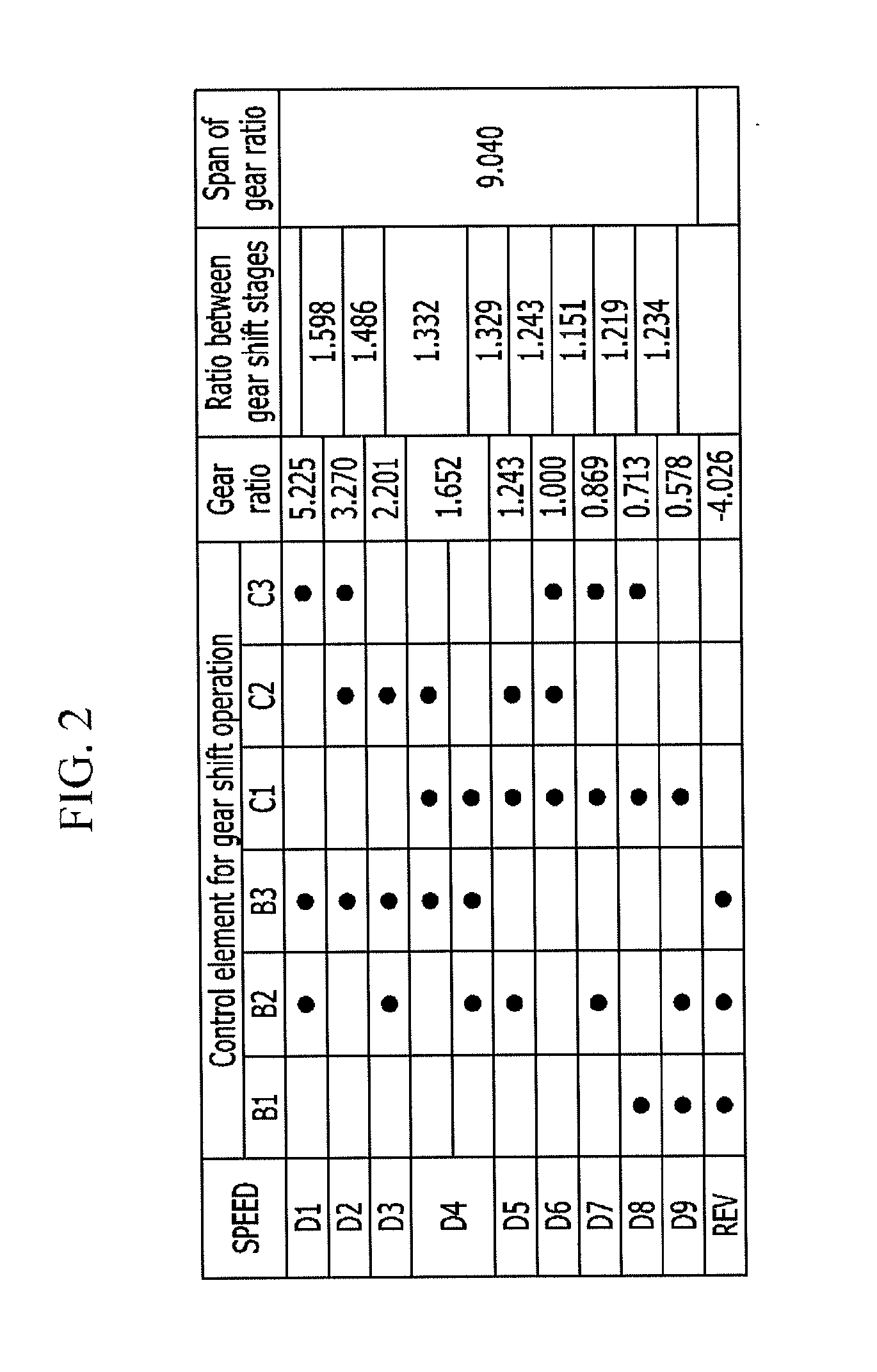

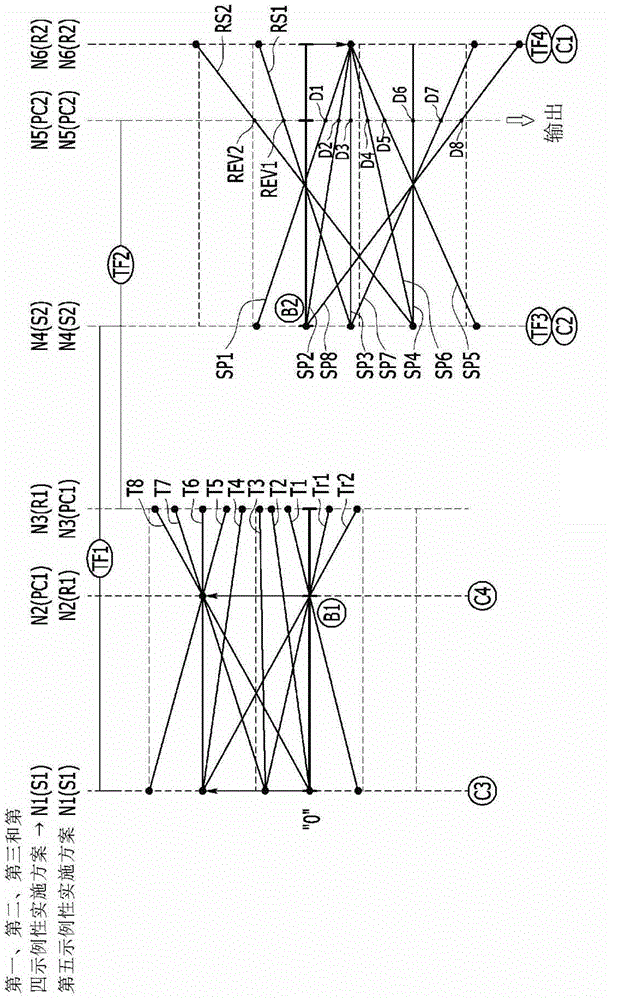

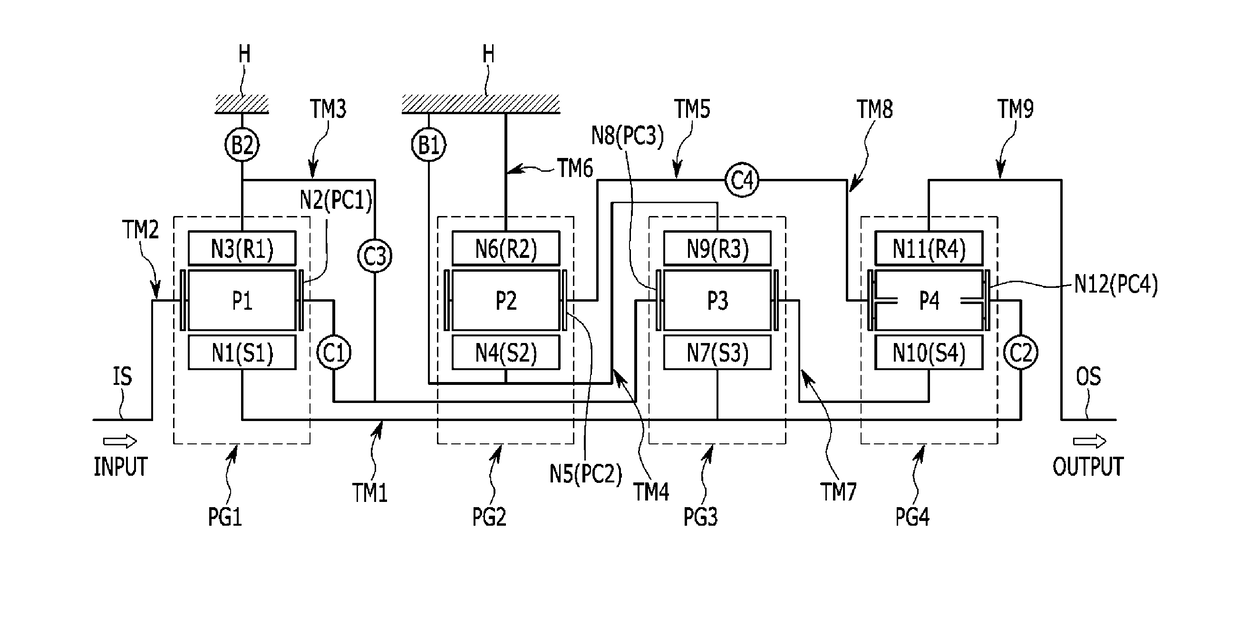

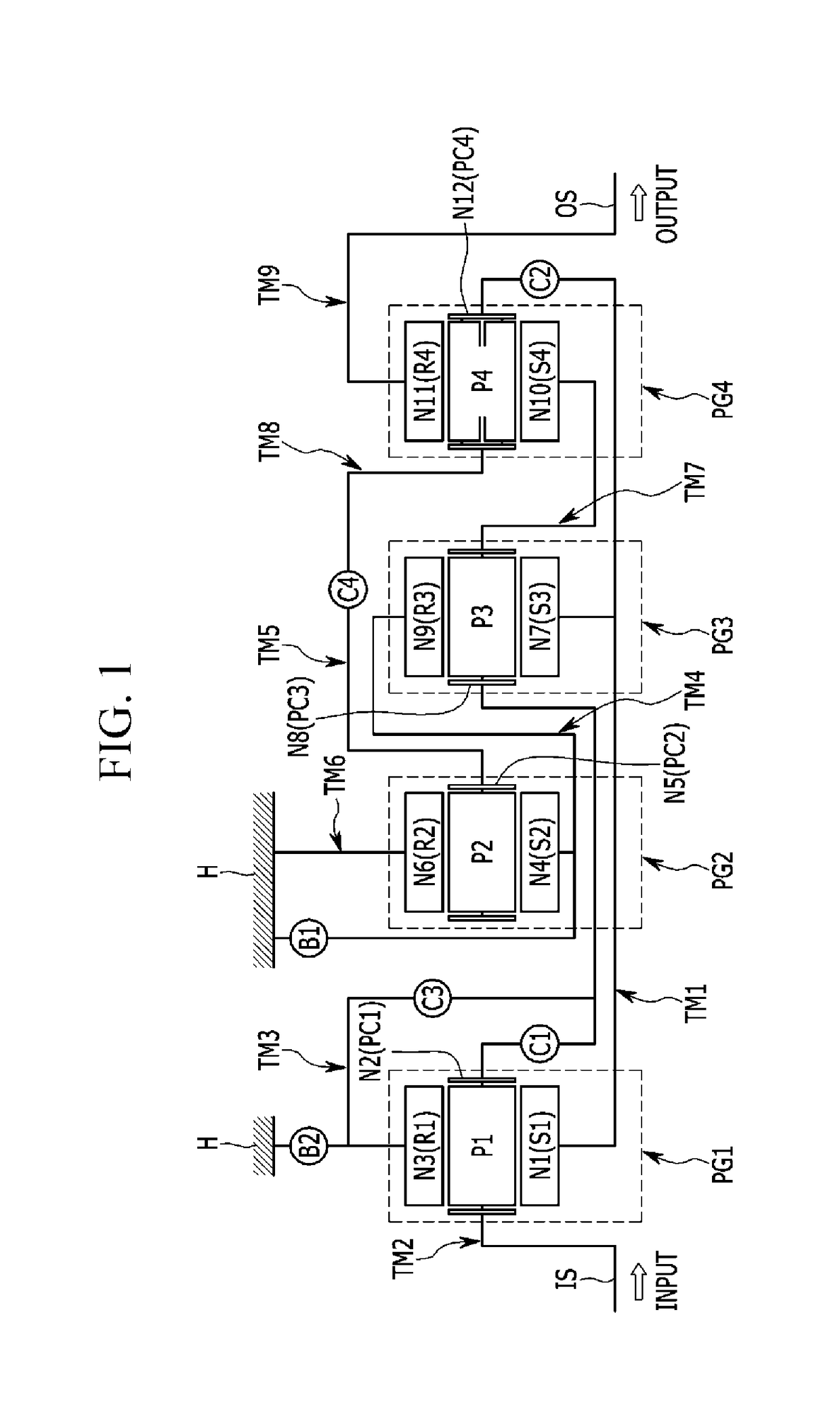

A planetary gear train of an automatic transmission for a vehicle may include an input shaft receiving torque of an engine, an output shaft outputting changed torque, a first planetary gear set including a first sun gear, a first planet carrier, and a first ring gear, a second planetary gear set including a second sun gear, a second planet carrier, and a second ring gear, a third planetary gear set including a third sun gear, a third planet carrier, and a third ring gear, a fourth planetary gear set including a fourth sun gear, a fourth planet carrier, and a fourth ring gear, a first rotation shaft, a second rotation shaft, a third rotation shaft, a fourth rotation shaft, a fifth rotation shaft, a sixth rotation shaft, a seventh rotation shaft, and an eighth rotation shaft.

Owner:HYUNDAI MOTOR CO LTD

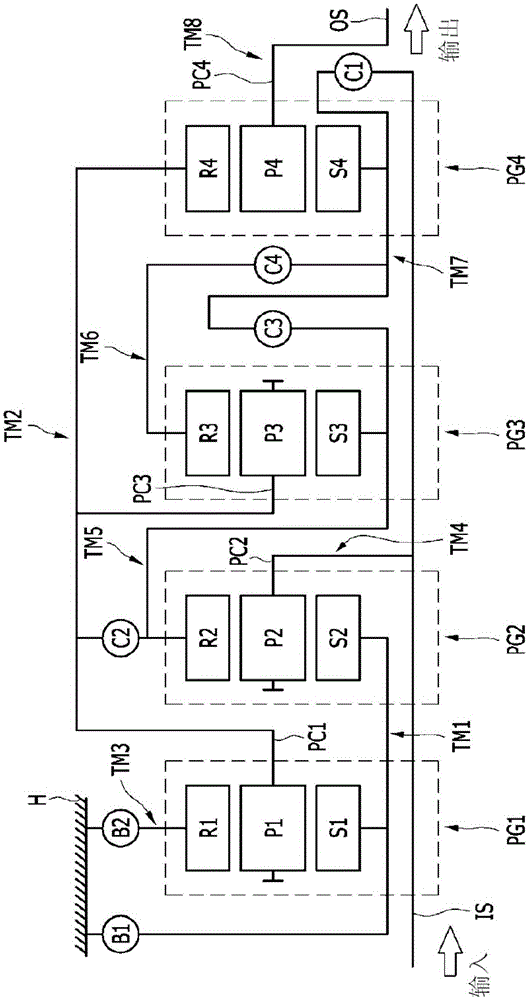

Planetary gear train of automatic transmission for vehicle

InactiveCN105697687AImprove economyImprove power transmission performanceToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention relates to a planetary gear train of an automatic transmission for a vehicle. The planetary gear train may include an input shaft receiving torque of an engine, an output shaft outputting changed torque, a first planetary gear set, a second planetary gear set, a third planetary gear set, a fourth planetary gear set, a first rotation shaft selectively connected to a transmission housing, a second rotation shaft, a third rotation shaft selectively connected to the transmission housing, a fourth rotation shaft directly connected to the input shaft, a fifth rotation shaft, a sixth rotation shaft, a seventh rotation shaft selectively connected to the input shaft, and selectively connected to the fifth rotation shaft or the sixth rotation shaft, and an eighth rotation shaft directly connected to the output shaft.

Owner:HYUNDAI MOTOR CO LTD

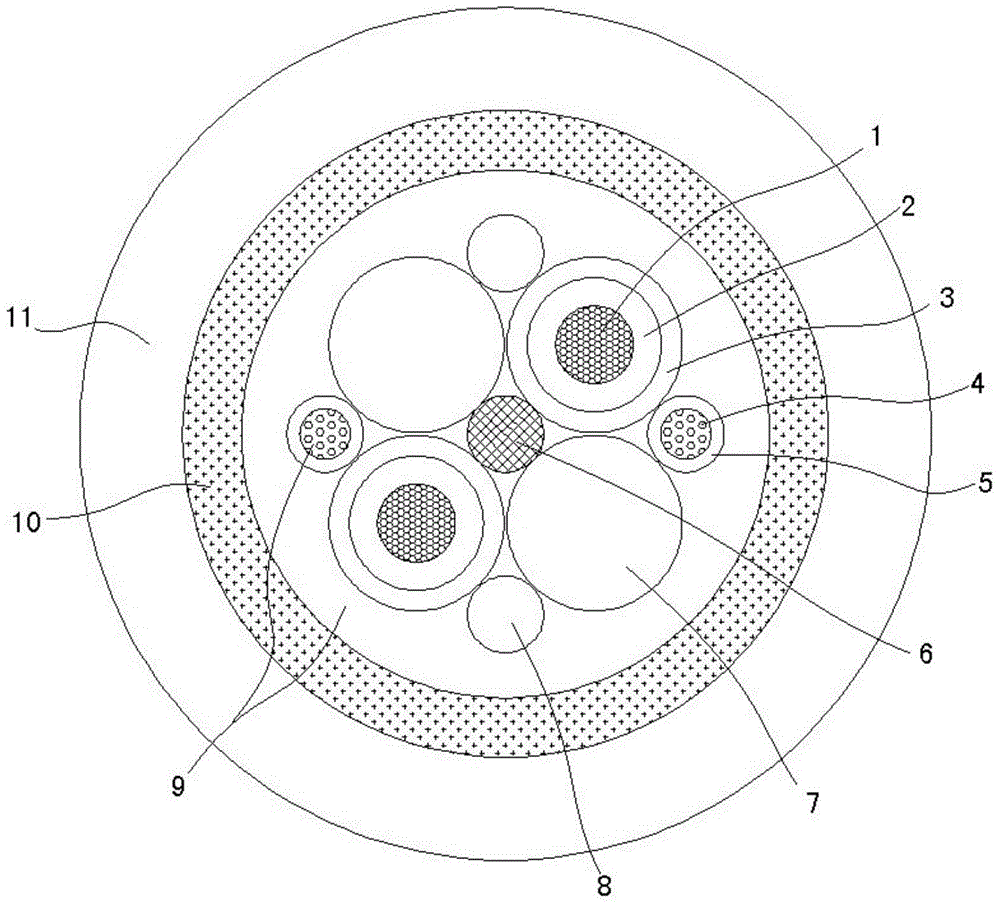

Graphene composite optical cable

InactiveCN103824646AIncrease ampacityImprove power transmission performanceInsulated cablesCommunication cablesCarrying capacityEngineering

Disclosed in the invention is a graphene composite optical cable comprising a twisted core, a metal protection layer coating the outside of the twisted core, and an outer sheath layer coating the outside of the metal protection layer. The twisted core includes a center reinforced element arranged at the center of the twisted core, cable cores, and large-diameter fillers, wherein the cable cores and the large-diameter fillers are distributed uniformly at the circumferential surface of the center reinforced element by a staggered way; and small-diameter fillers and optical cable cores are arranged at the externally tangent portions of the cable cores and the large-diameter fillers. And the small-diameter fillers and optical cable cores are arranged at the externally tangent portions of the cable cores and the large-diameter fillers by a staggered way; and the cable cores, the large-diameter fillers, the small-diameter fillers, and the optical cable cores are twisted along the circumferential direction of the center reinforced element. The provided graphene composite optical cable has the following beneficial effects: the design is reasonable; the structure is simple; the power transmission efficiency and the carrying capacity are improved; the construction and maintenance costs are lowered; and the cable can be popularized conveniently.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

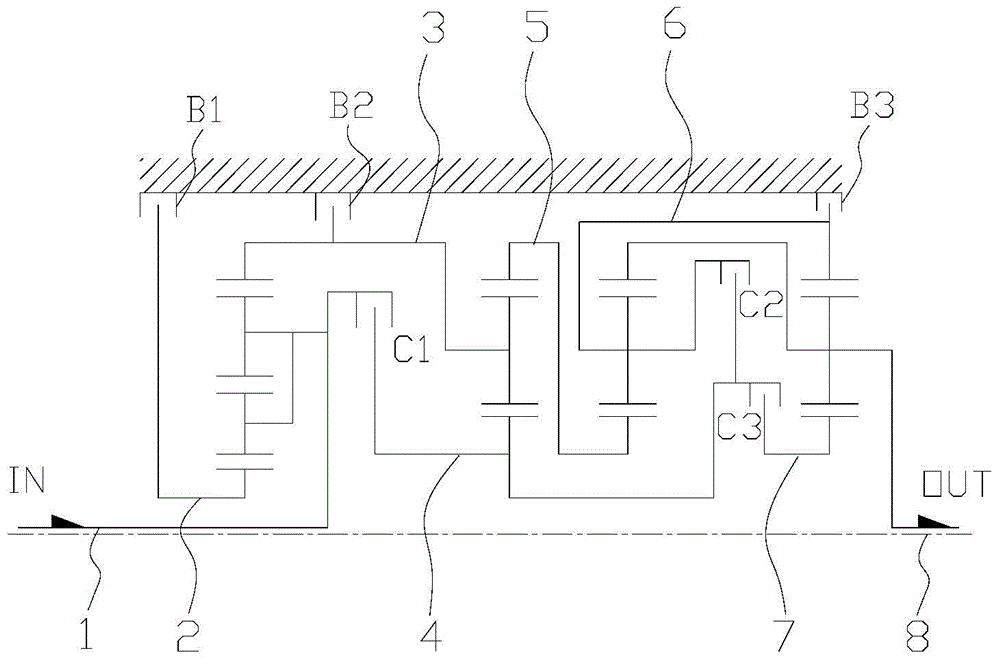

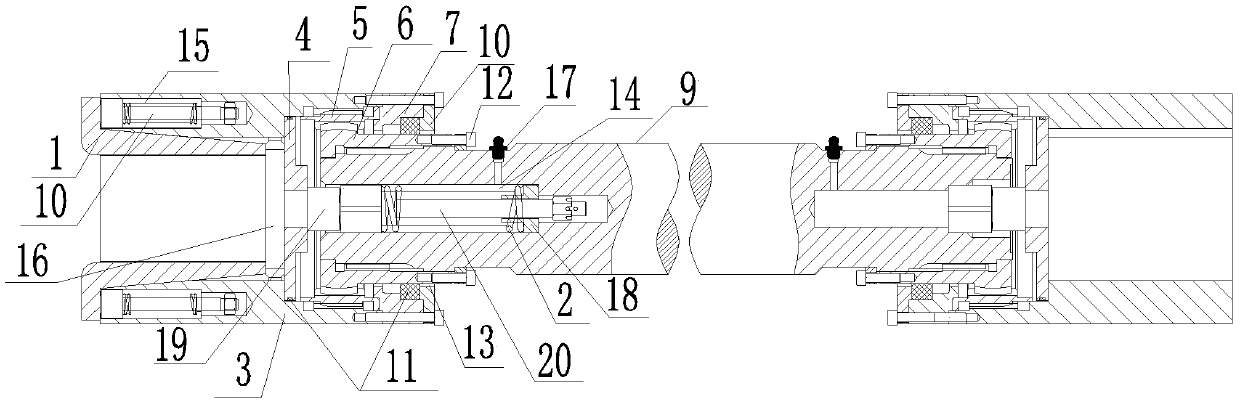

Automatic transmission and planetary gear train thereof

ActiveCN105485271AImprove power transmission performanceImprove fuel economyToothed gearingsGearing detailsAutomatic transmissionGear wheel

The invention discloses a planetary gear train used for an automatic transmission. At least eight forwarding gears and at least two reversing gears can be obtained, and the planetary gear train comprises a first planet row, a second planet row, a third planet row and a fourth planet row. Each planet row is provided with a sun gear, a planetary frame and a gear ring; eight rotating bodies can be jointly formed by assemblies of the planet rows and connecting components; a gear shifting assembly comprises three clutches and three brakes, and the clutches are arranged between selected rotating bodies in the rotating bodies; and the brakes are arranged between the selected rotating bodies in the rotating bodies and fixing parts. The planetary gear train can have more gears and the more optimized speed ratio; the power transmission performance and the fuel economy of a vehicle can be obviously improved, the length is shorter, the whole design is more compact, and the requirements of the vehicle for durability, the power transmission rate, the size, the cost and the like of the transmission can be met well. The invention further discloses the automatic transmission provided with the planetary gear train.

Owner:西安双特智能传动有限公司

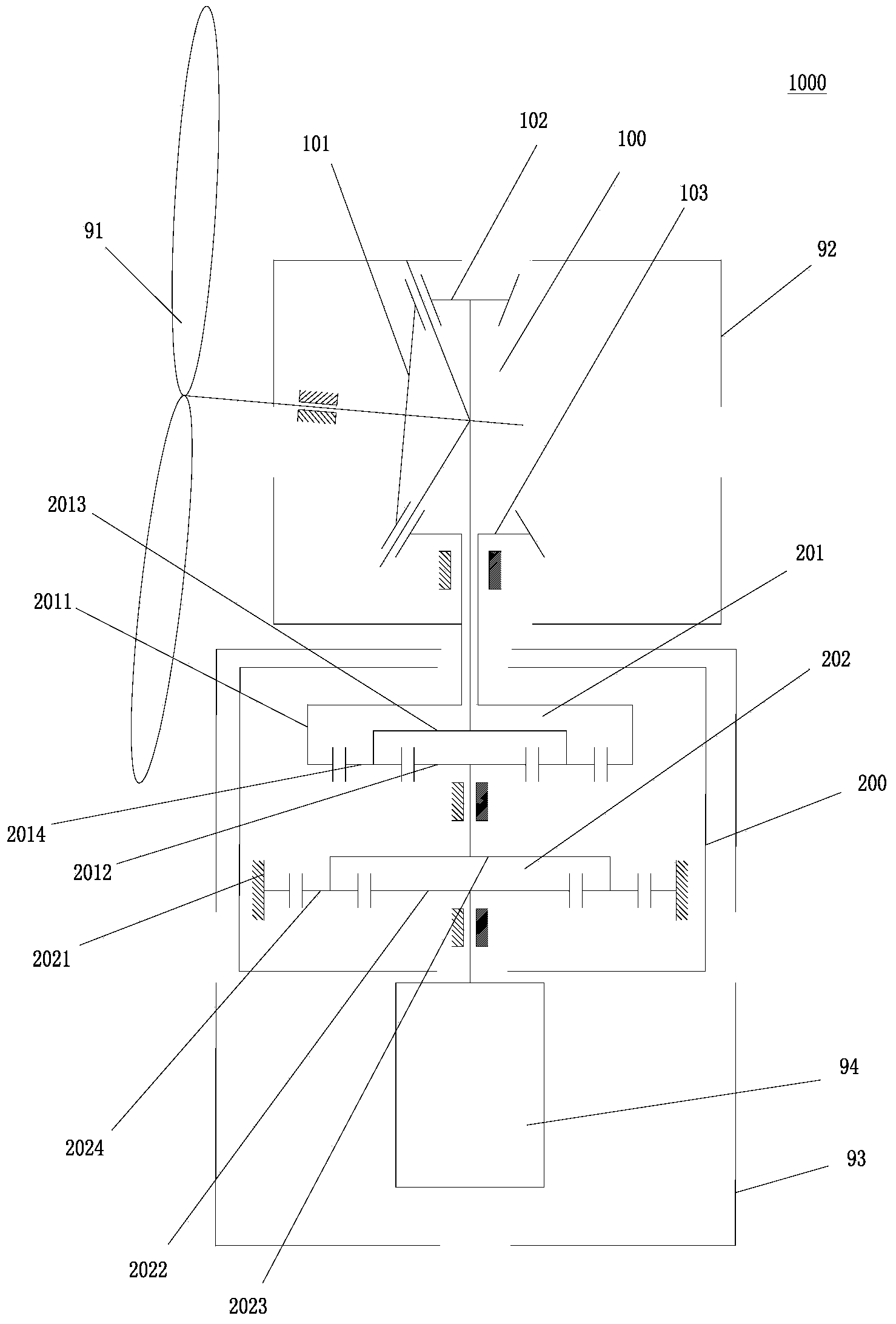

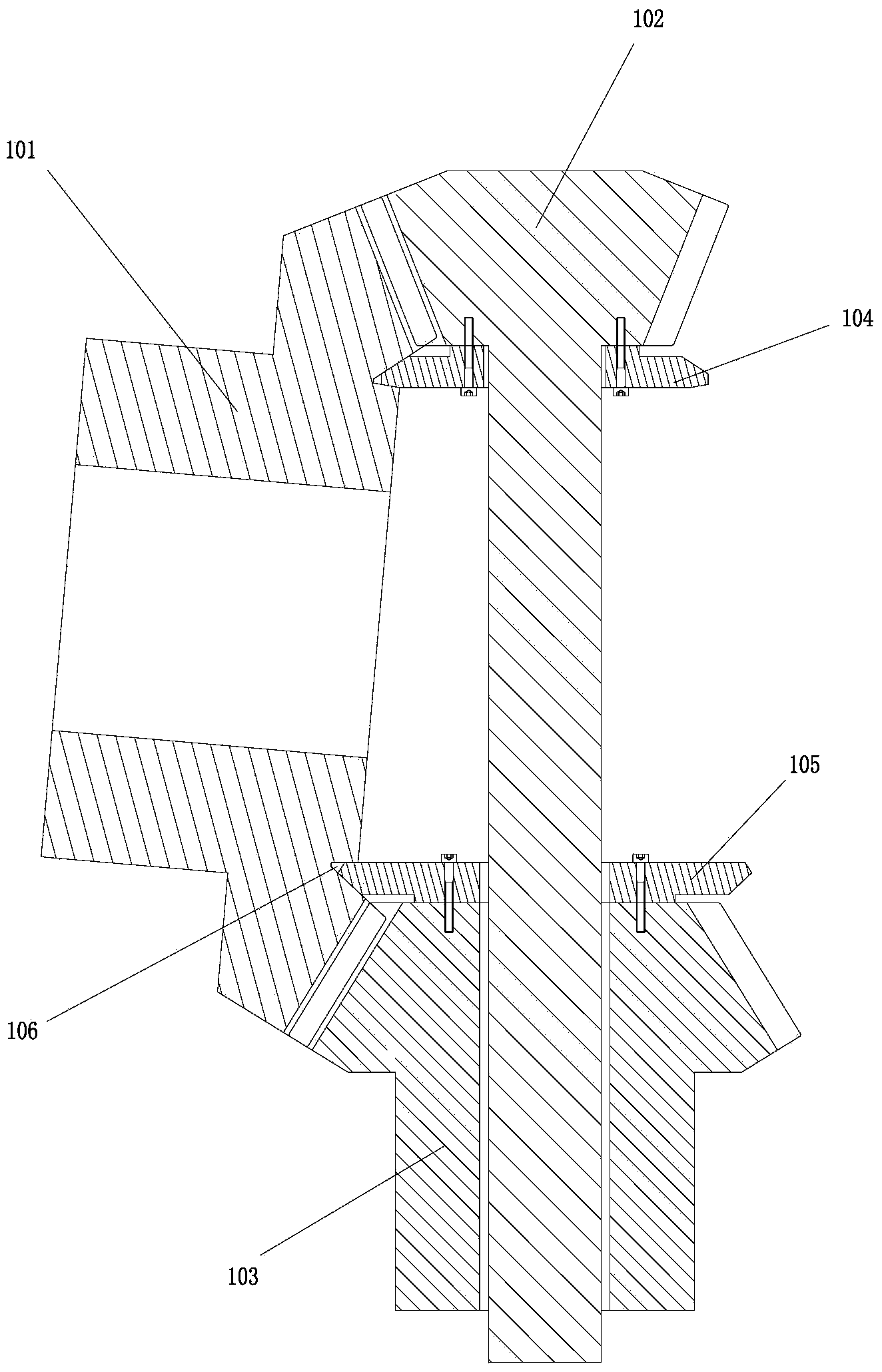

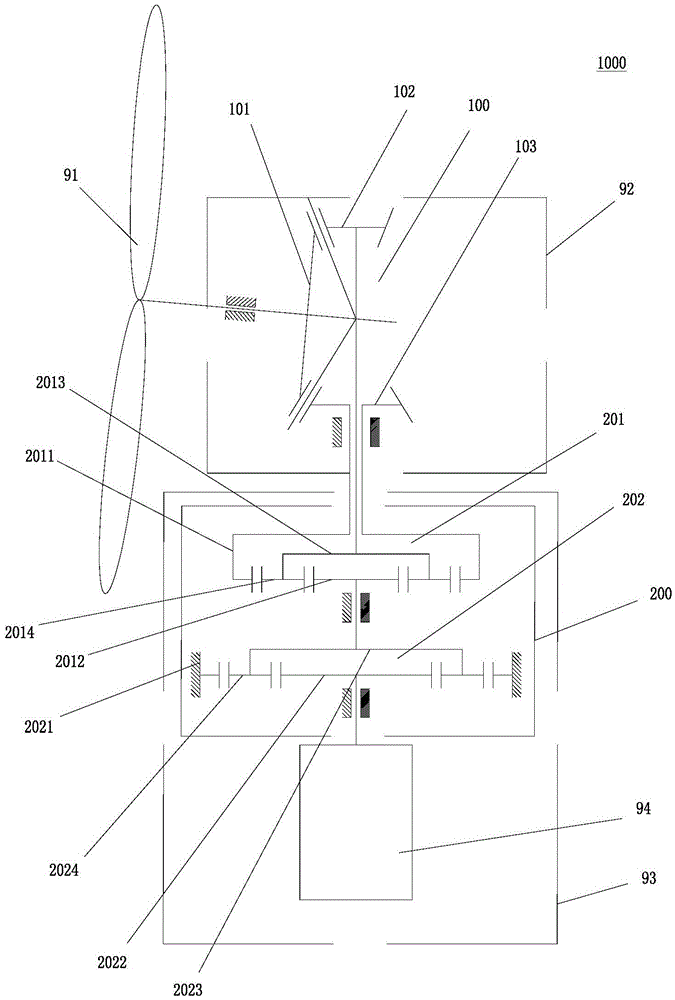

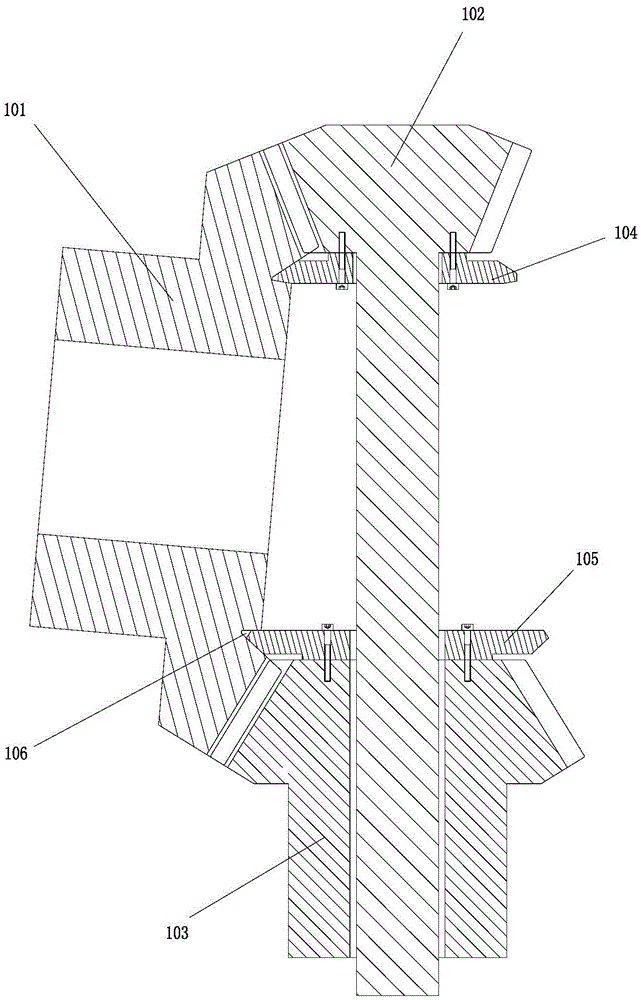

Transmission structure for wind driven generator

InactiveCN103835892ALow failure rateImprove reliabilityToothed gearingsWind energy generationFailure rateImpeller

The invention relates to a transmission structure for a wind driven generator. The transmission structure is composed of a spiral bevel gear mechanism arranged in a generator cabin and a planetary gear gearbox arranged in a tower cylinder. An impeller of the wind driven generator is connected with an input shaft of the spiral bevel gear mechanism, an output shaft of the spiral bevel gear mechanism is connected with an input shaft of the a planetary gear gearbox, and an output shaft of the a planetary gear gearbox is connected with a rotary shaft of a generator set. The output shaft of the spiral bevel gear mechanism and the input shaft of the planetary gear gearbox are arranged coaxially and are identical to the axis direction of the tower cylinder. The transmission structure is low in failure rate, high in reliability and convenient to dismount and maintain, and accordingly, the maintenance cost of the transmission structure is reduced.

Owner:BEIJING BUFFALO TRANSMISSION TECH +1

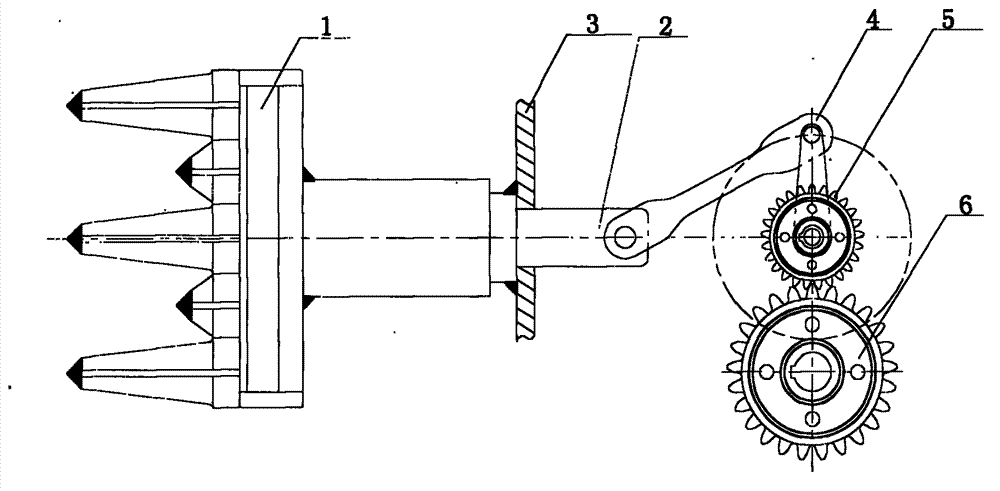

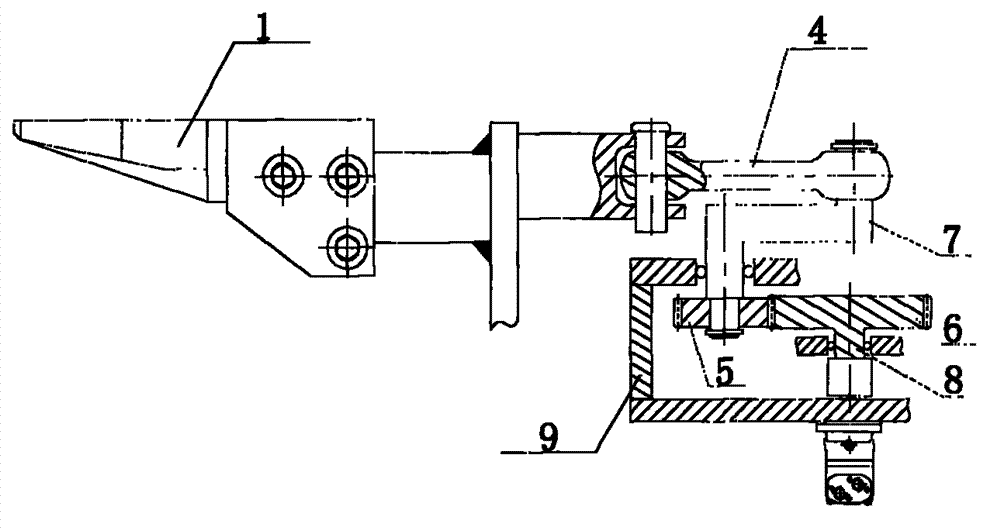

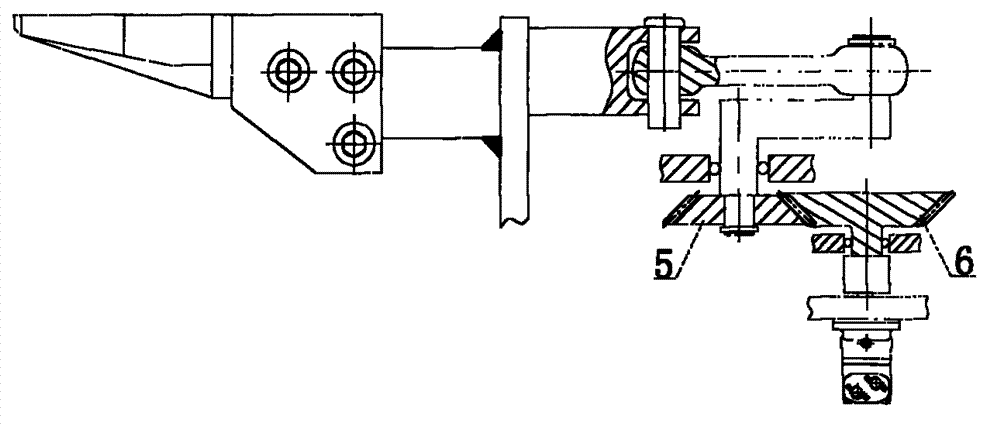

Excavating and shoveling buffer transmission device of blocking coal shovel

The invention belongs to the field of mining, mine tunneling and tunnel excavating, and particularly relates to an excavating and shoveling buffer transmission device of a blocking coal shovel. The excavating and shoveling buffer transmission device comprises a driving gear, a driven gear and a gear installation rack, wherein the driving gear and the driven gear are in clearance matching, the driven gear is connected with a power output shaft, and the deformation of the power output shaft during the working of the power output shaft can be absorbed by clearances between the driving gear and the driven gear. According to the excavating and shoveling buffer transmission device disclosed by the invention, the vibration of a device body is prevented, the excavating and shoveling work is stabilized, the mining technology is increased, and great benefit is brought for coal mine production.

Owner:刘素华

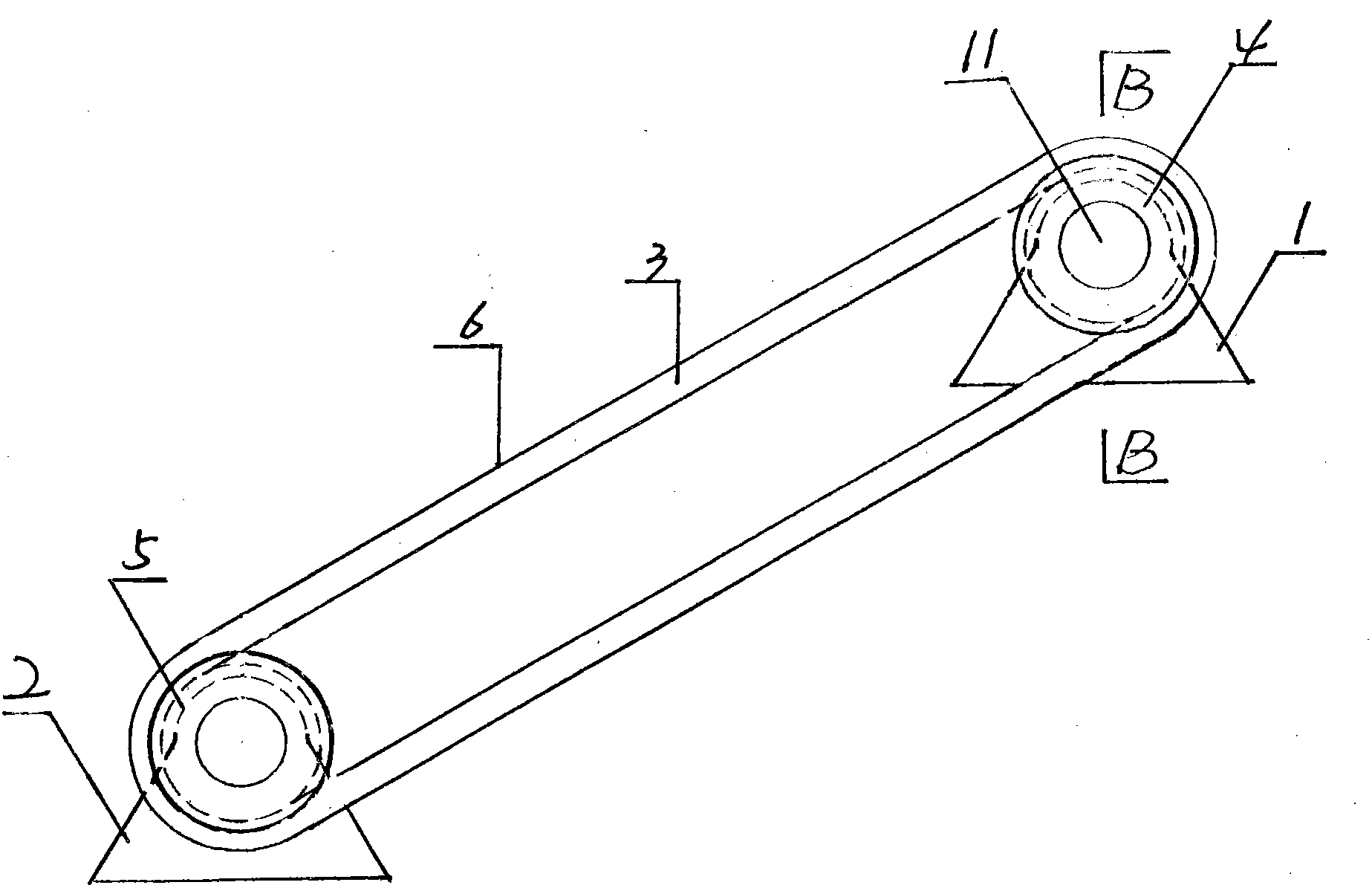

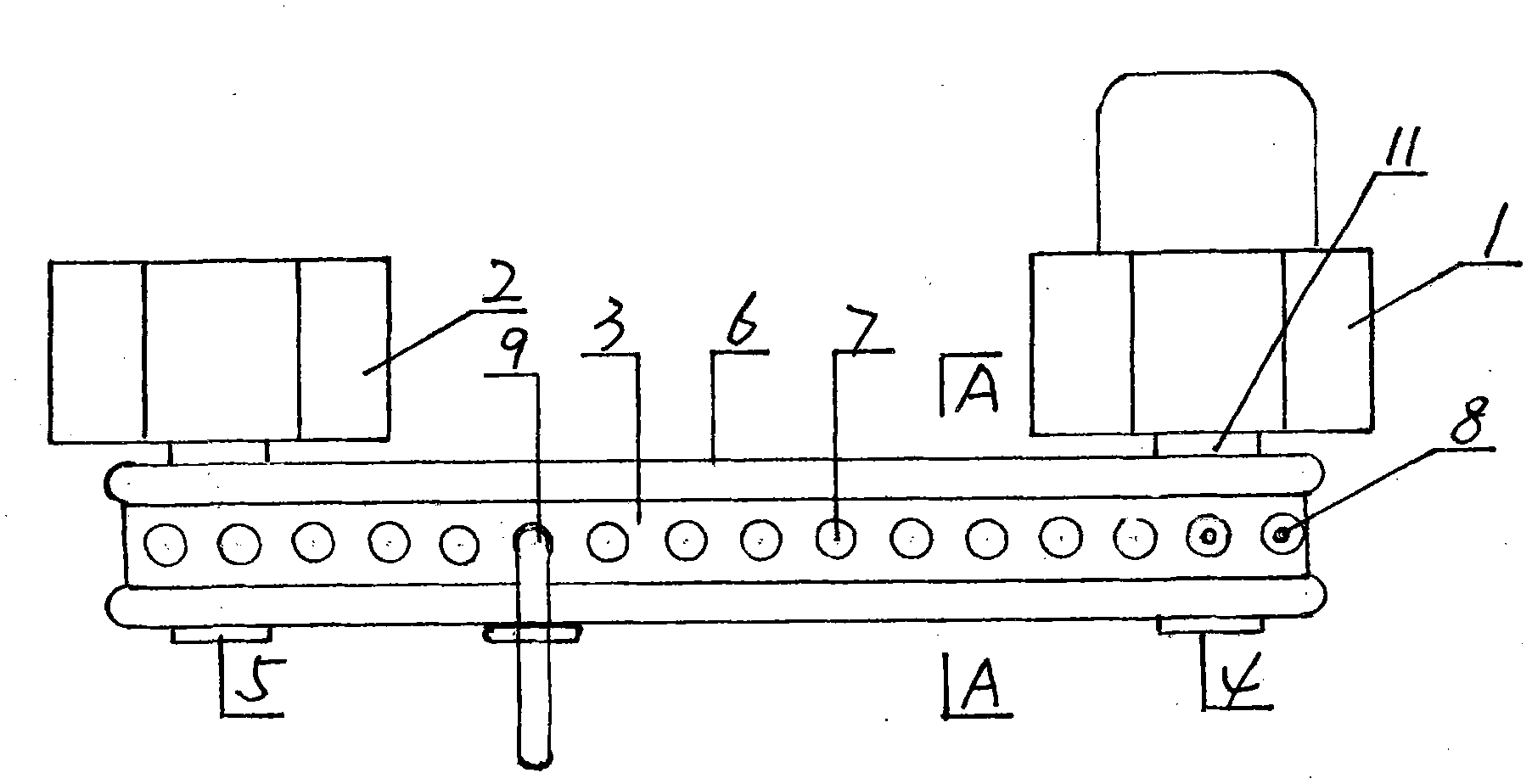

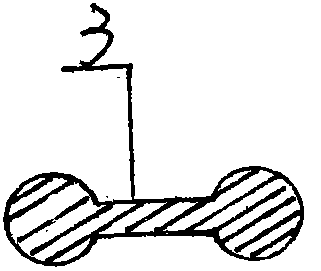

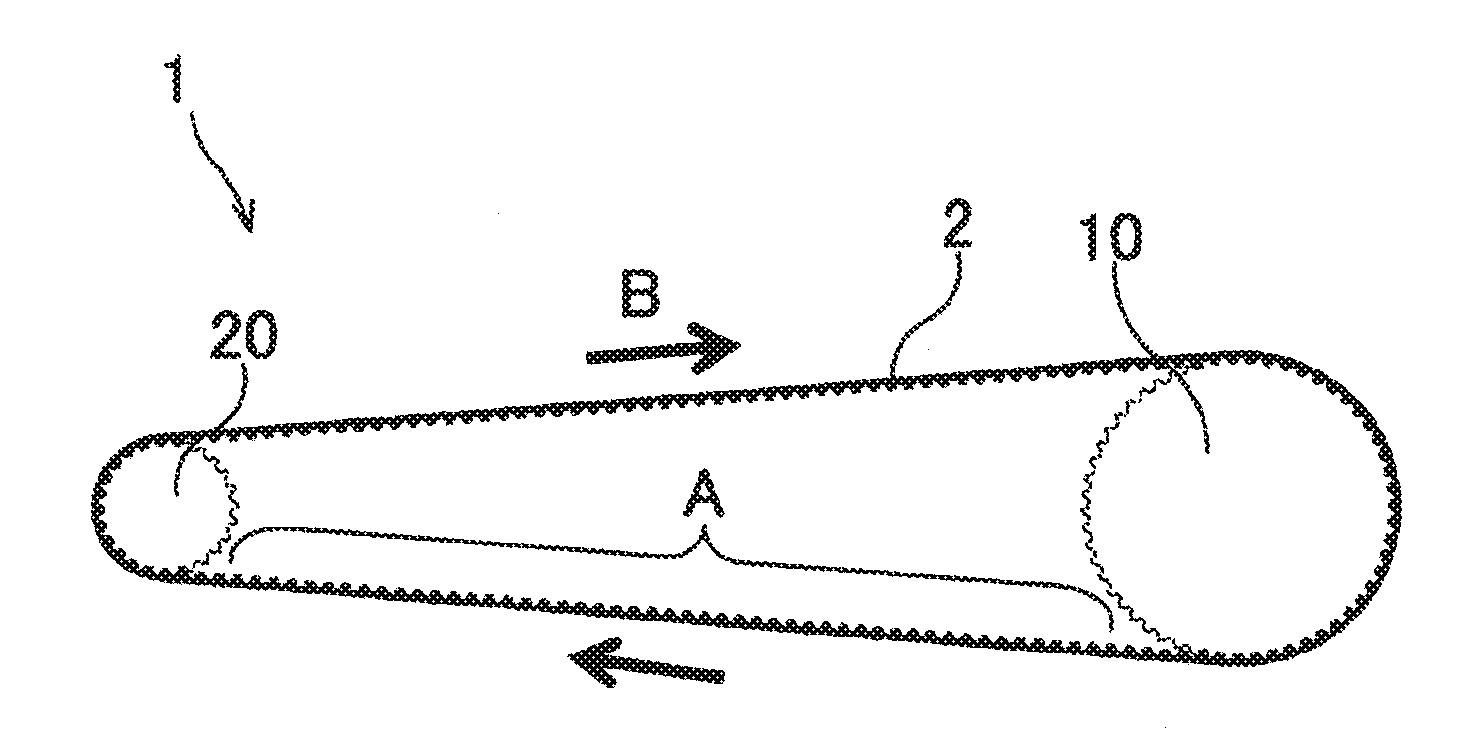

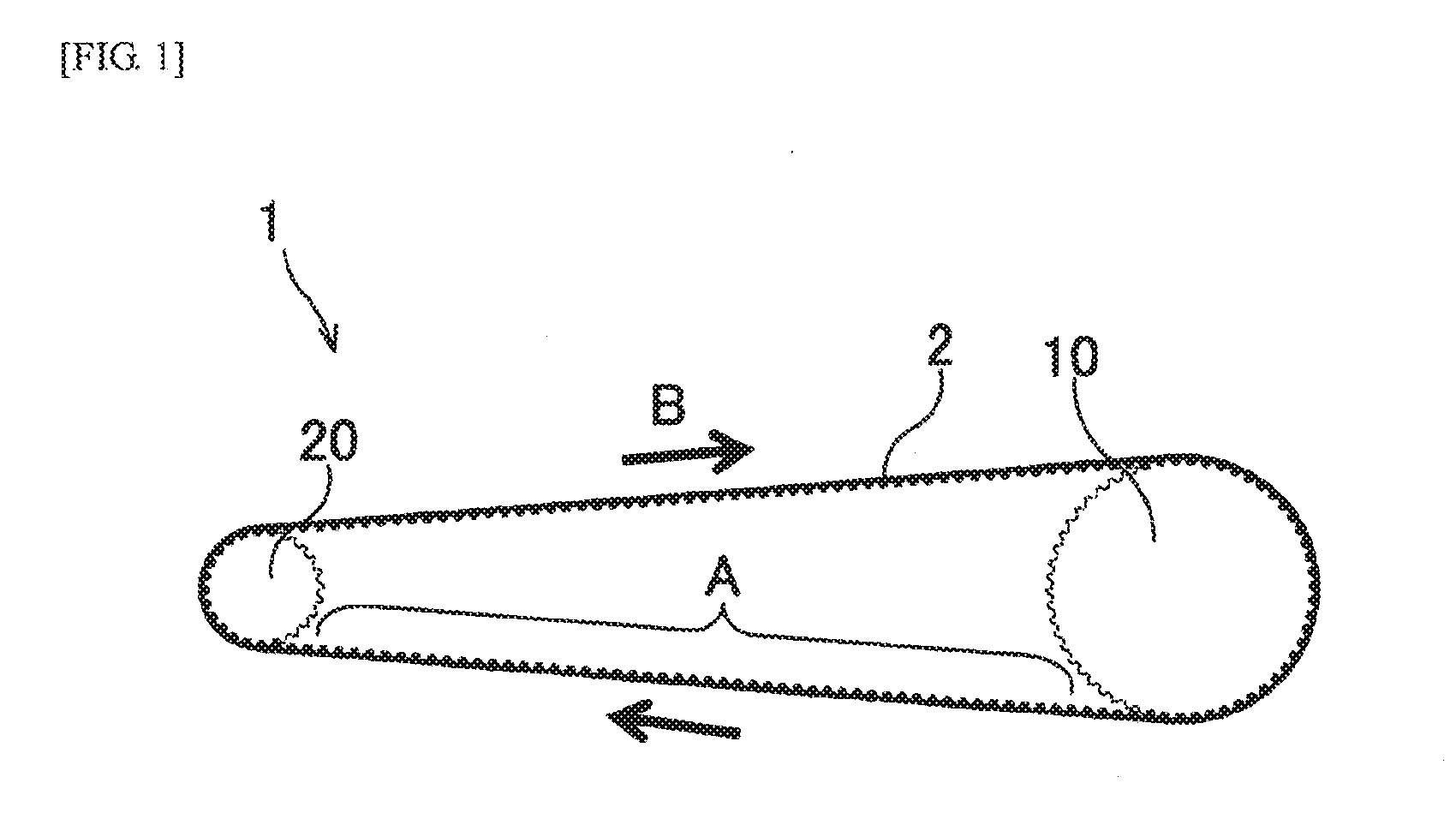

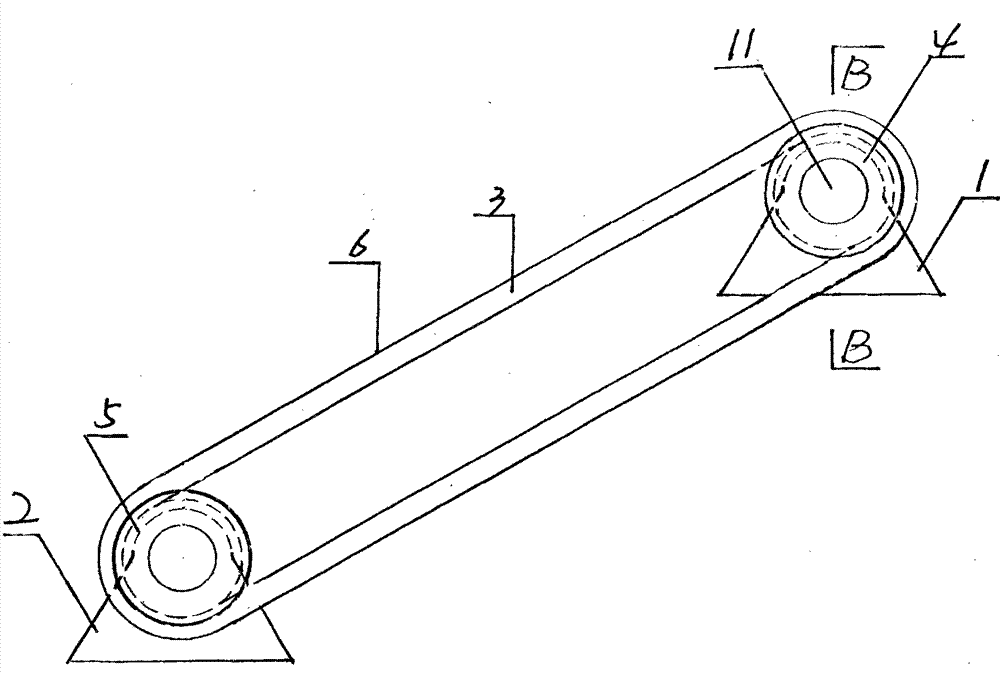

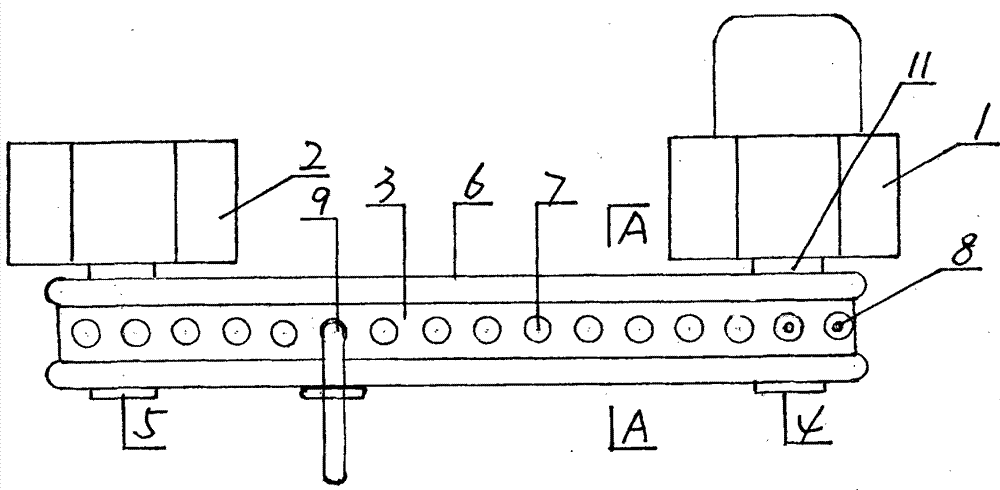

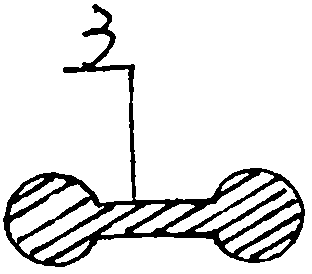

Steel belt type mining inclined roadway travel aid

ActiveCN102515005AReduce your weightImprove power transmission performanceMine liftsEngineeringSteel belt

A steel belt type mining inclined roadway travel aid structurally comprises a head, a tail and a stepless steel belt. A steel belt pulley is arranged on the head, a driven pulley is disposed on the tail, and the stepless steel belt is connected between the driven pulley and the steel belt pulley, so that the driven pulley, the steel belt pulley and the stepless steel belt form the integral steel belt type mining inclined roadway travel aid. A rope clamping bar is arranged on the steel belt, the end of the rope clamping bar is inserted into a hole of the steel belt, and accordingly the steel rope bar is connected with the steel belt in a clamped manner.

Owner:JIANGSU LIWEI SHEARING & BENDING MACHINE

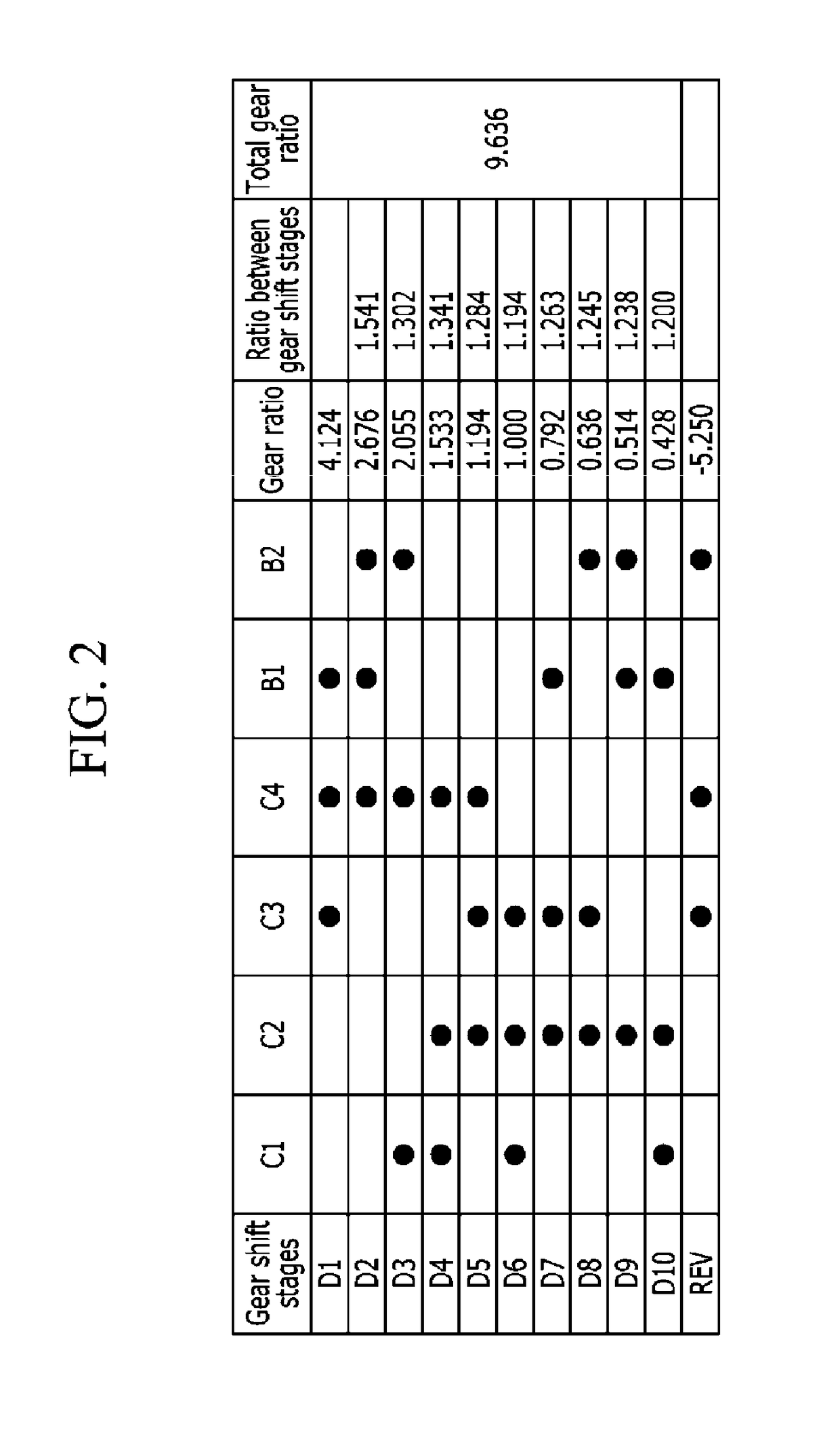

Planetary gear train of automatic transmission for vehicle

ActiveUS20160333977A1Improve fuel efficiencyImprove performance efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear train

A planetary gear train of an automatic transmission for a vehicle may include an input shaft receiving power from an engine, an output shaft outputting power changed in speed, a first planetary gear set including first, second, and third rotating elements, a second planetary gear set including fourth, fifth, and sixth rotating elements, a third planetary gear set including seventh, eighth, and ninth rotating elements, a fourth planetary gear set including tenth, eleventh, and twelfth rotating elements, and six control elements disposed between the rotating elements, and disposed at positions where the rotating elements are selectively connected with a transmission housing.

Owner:HYUNDAI MOTOR CO LTD

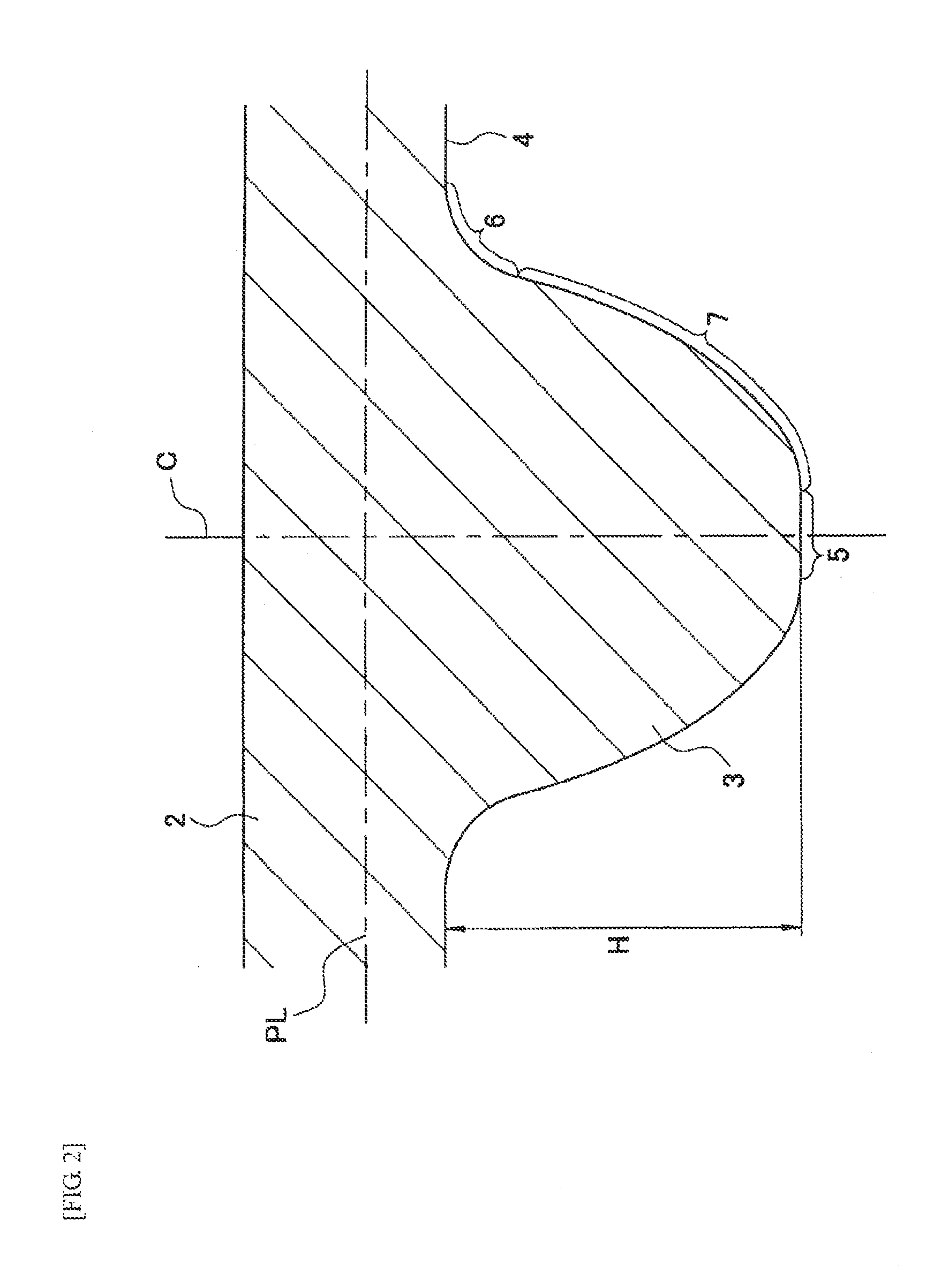

Toothed Belt Driving Device for Bicycle

ActiveUS20160221637A1InhibitionPrevent jumpingChain/belt transmissionGearingShortest distanceEngineering

The present invention relates to a toothed belt driving device for bicycle, in which, in drive state, the pulley groove portion of a driven pulley is in surface contact with a portion of a surface of the belt tooth portion, this portion in surface contact is present in a range positioned closer to a tooth root portion than a reference circle, the maximum value of the shortest distance between the pulley groove portion of the driven pulley and the surface of the belt tooth portion opposite to the traveling direction of the belt is 10% or more and 18% or less of the tooth pitch, a groove depth of the driven pulley is greater than the tooth height of the belt tooth portion, and the difference therebetween is 5% or more of the tooth height.

Owner:MITSUBOSHI BELTING LTD

Planetary gear train of automatic transmission for vehicle

ActiveUS20160363193A1Improve fuel efficiencyImprove performance efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for a vehicle may include an input shaft receiving power from an engine, an output shaft outputting power changed in speed, a first planetary gear set which has first, second, and third rotating elements, a second planetary gear set which has fourth, fifth, and sixth rotating elements, a third planetary gear set which has seventh, eighth, and ninth rotating elements, a fourth planetary gear set which has tenth, eleventh, and twelfth rotating elements, and six control elements disposed between the rotating elements, and disposed at positions where the rotating elements are selectively connected to a transmission housing.

Owner:HYUNDAI MOTOR CO LTD

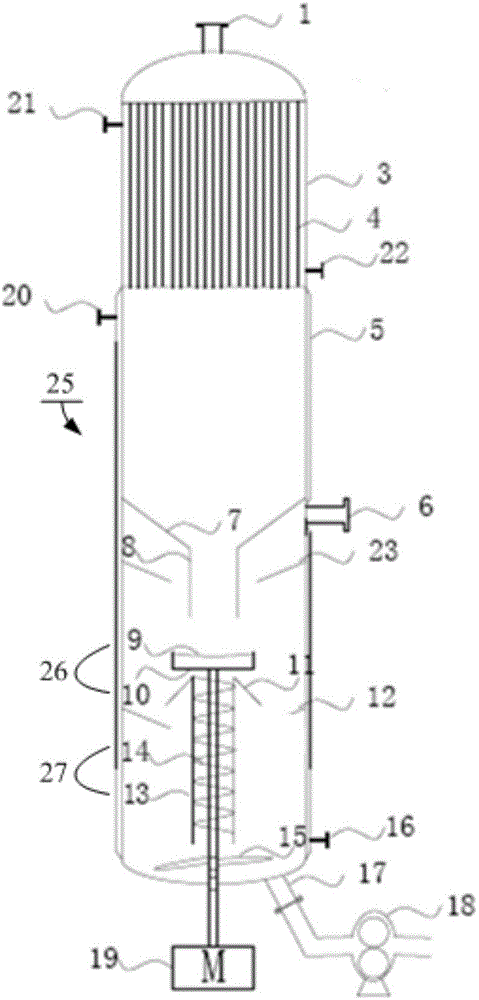

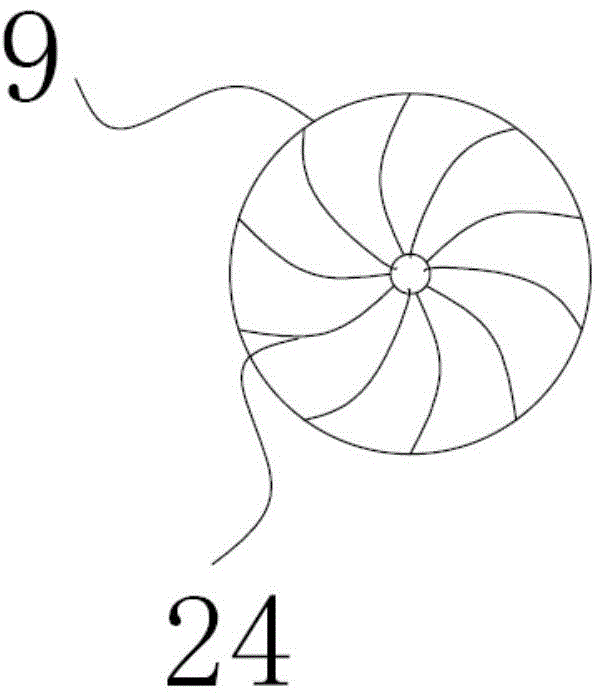

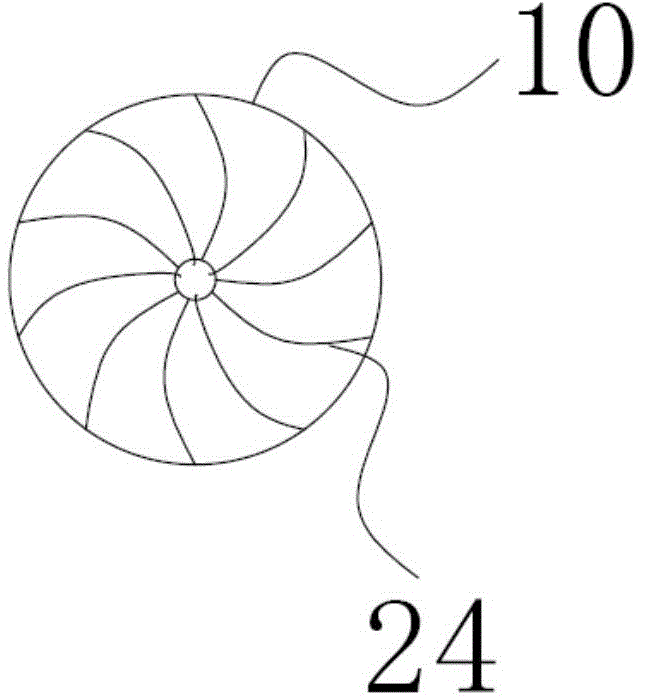

Polymer degassing apparatus

ActiveCN106031832ALong downsideImprove power transmission performanceLiquid degasificationPetrochemicalEngineering

The embodiments of the invention provide a polymer degassing apparatus, and belong to the degassing field in the petrochemical industry technology, wherein the mass transfer and heat transfer effect of the high-viscosity polymer during the degassing process can be increased with the polymer degassing apparatus so as to increase the degassing effect of the polymer. The polymer degassing apparatus comprises a heat exchange device and a degassing tank arranged below the heat exchange device, wherein the degassing tank is sequentially provided with a flow collection member and a rotation member from top to bottom, the side wall between the flow collection member and the rotation member is provided with a flash evaporation steam outlet, the flow collection member is used for collecting the polymer from the heat exchange device onto the rotation member, and the rotation member is used for carrying out rotary dispersion on the polymer so as to remove the gas bubbles from the polymer. The polymer degassing apparatus of the present invention can be used for the high-viscosity polymer degassing process.

Owner:山东省滕州瑞达化工有限公司

Axle protection structure

InactiveCN107662452APrevent penetrationImprove securityShaftsAxle unitsInterference fitWear resistant

The invention discloses an axle protection structure, which comprises an axle, a fixed ring, a protective tube, a filling layer and a connecting flange; One side of the shaft extends axially outward to form a plurality of fixed rods; the fixed rods on the two fixed rings are located on the sides of the two fixed rings away from each other; the connecting flange is sleeved on the axle, and a through hole is opened on the connecting flange , the fixed rod goes through the through hole; the connecting flange is fixed on the fixed ring through the nut threaded with the fixed rod; the protective tube is set on the axle, and the two ends of the protective tube are respectively fixedly connected with the two connecting flanges; Between the outer surface of the axle and the inner surface of the protection cylinder, the filling layer is wear-resistant rubber. The invention can slow down the loss of driving force of the vehicle after the axle breaks, and prevent the fragments produced by the breakage of the axle from penetrating the fuel tank.

Owner:CHONGQING ZHANRUI AUTOMOBILE FITTING FACTORY

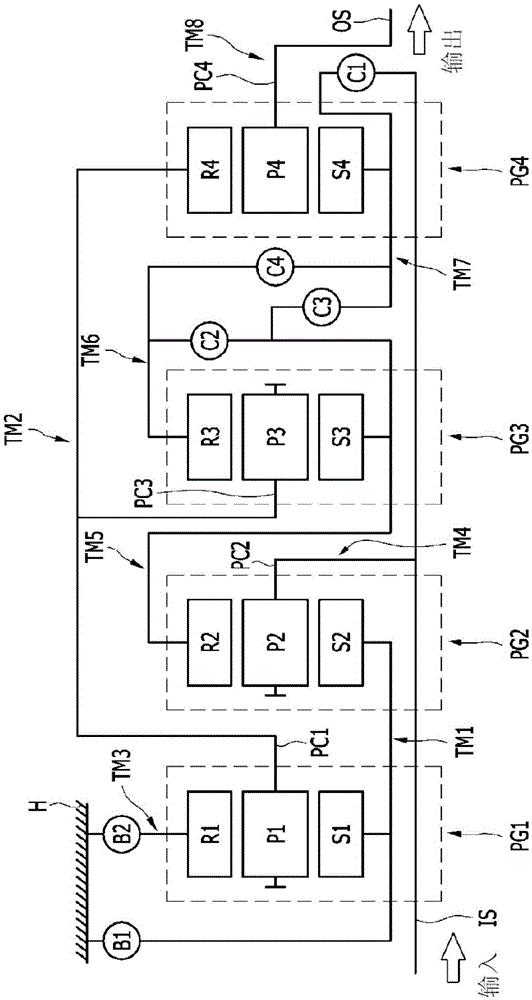

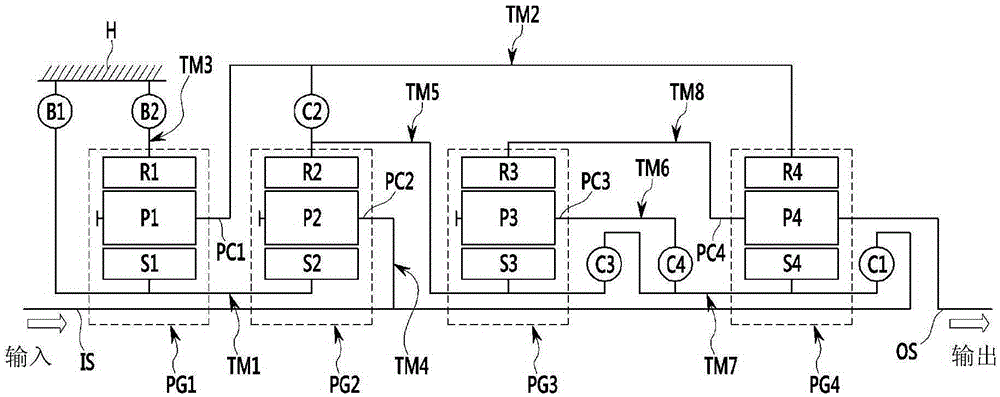

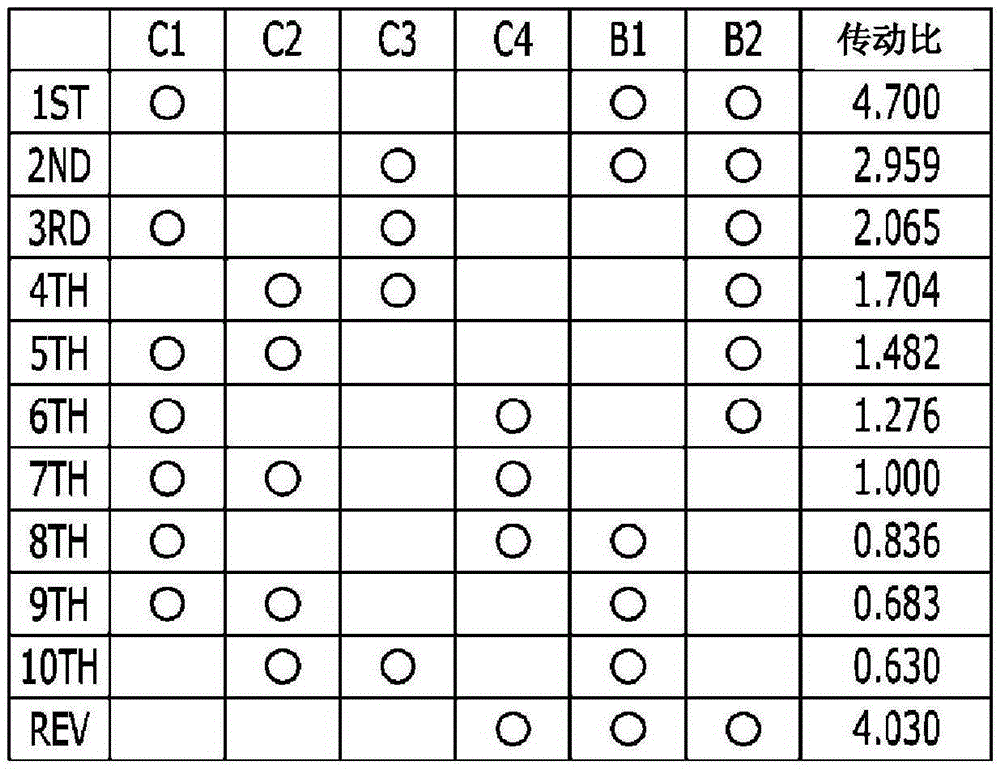

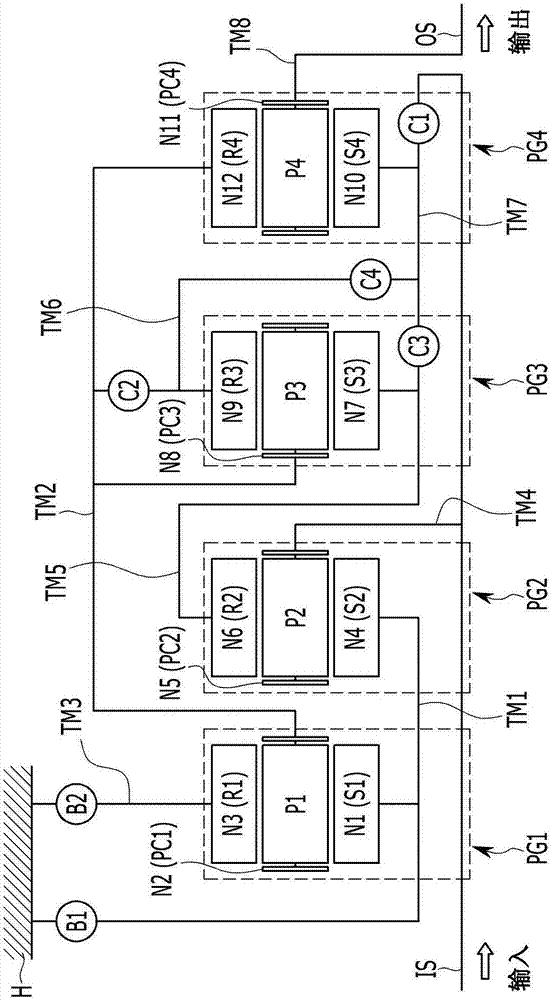

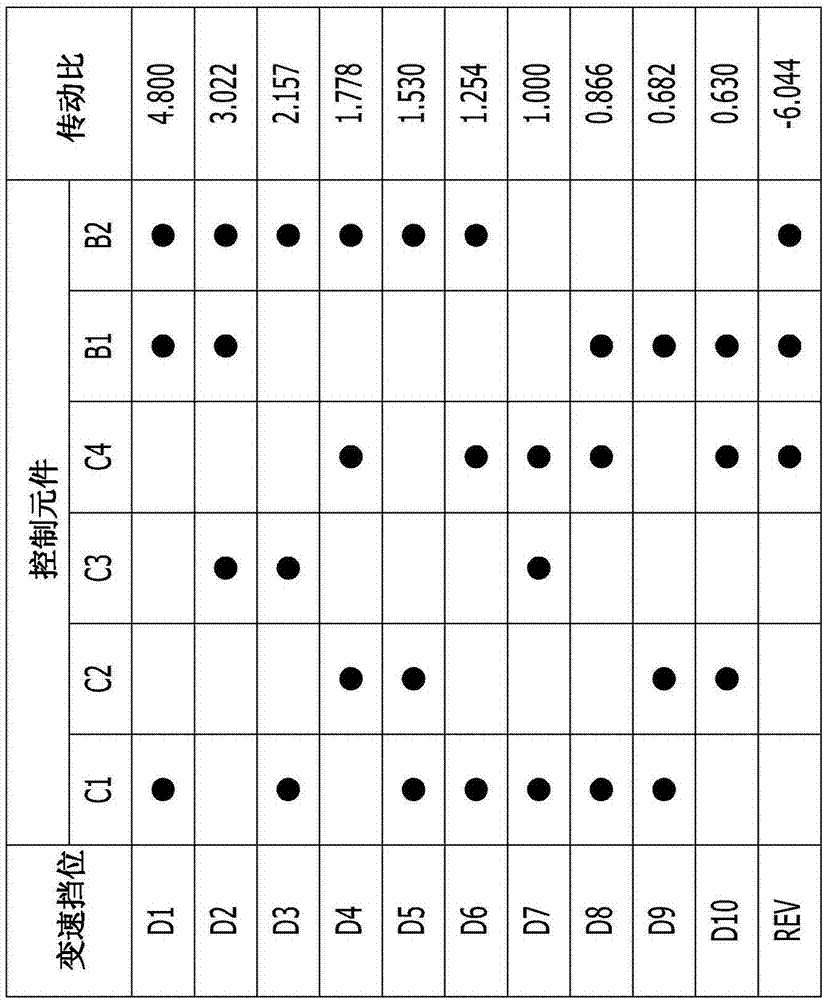

Planetary gear train of an automatic transmission for a vehicle

ActiveCN107939921AImprove driving stabilityImprove driving efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

Ten forward speeds and one or more reverse speed are achieved by a planetary gear train of an automatic transmission for a vehicle including an input shaft, an output shaft, four planetary gear sets respectively having three rotational elements, and six control elements for selectively interconnecting the rotational elements and a transmission housing.

Owner:HYUNDAI MOTOR CO LTD

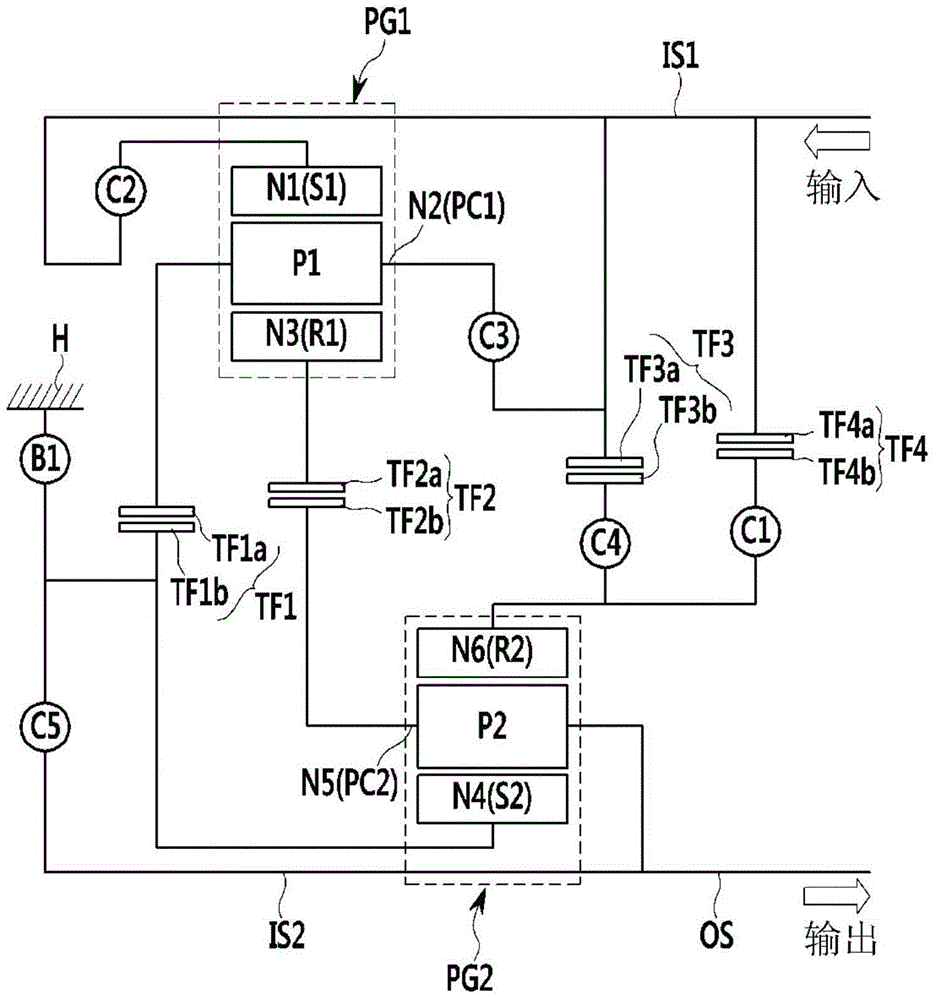

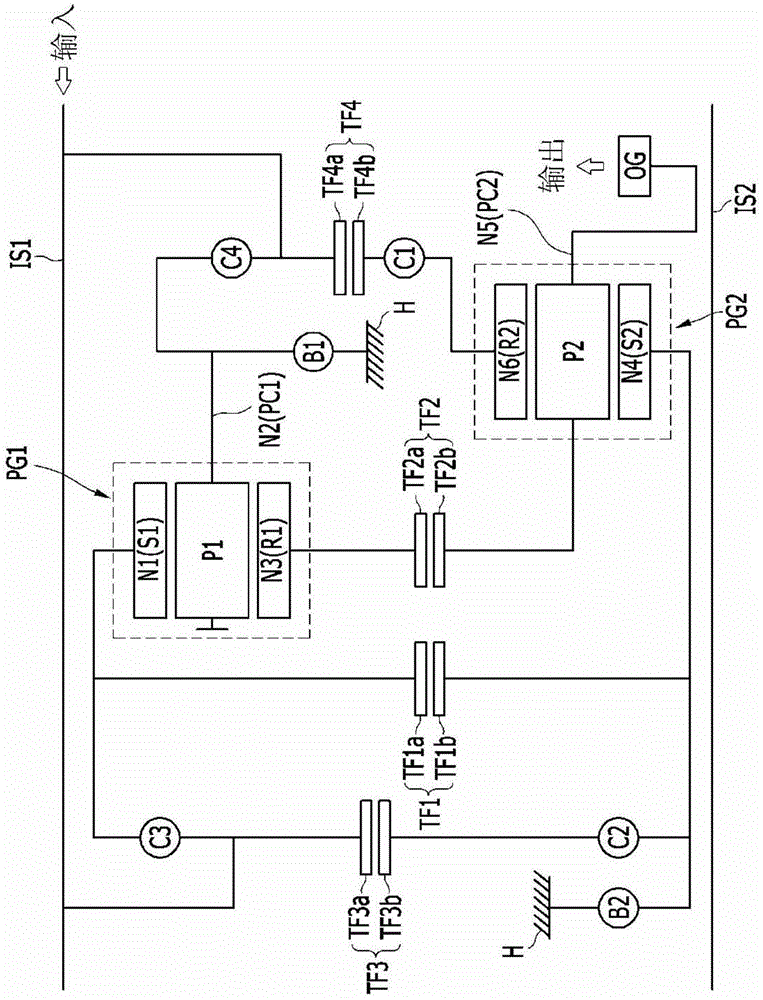

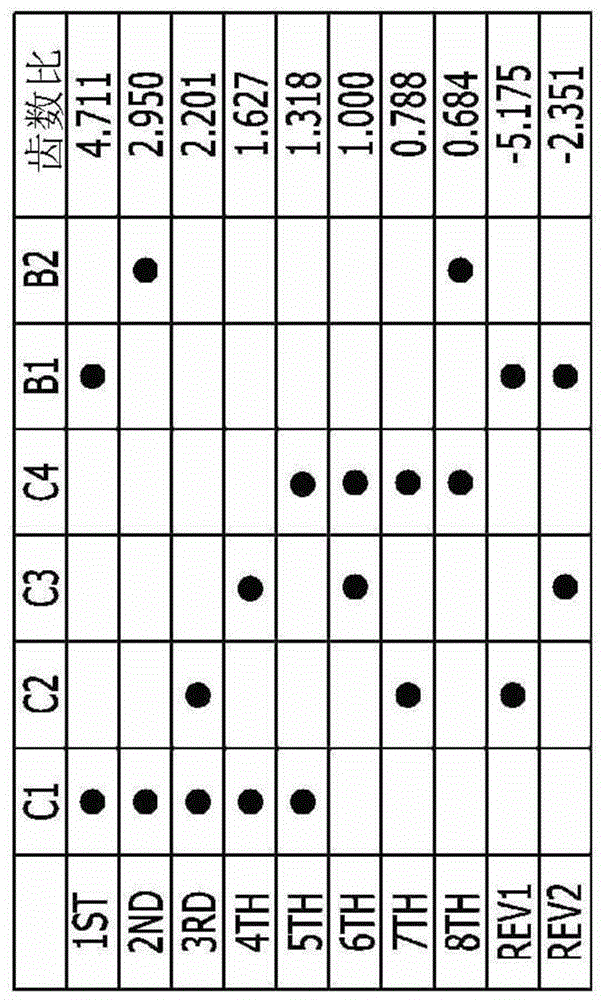

Planetary Gear Train Of Vehicular Automatic Transmission

InactiveCN105782370AShorten the lengthImprove installabilityToothed gearingsTransmission elementsAutomatic transmissionEngineering

A planetary gear train of an automatic transmission for a vehicle including a first shaft receiving torque of an engine, a second shaft disposed in parallel with the first shaft at a predetermined distance, a first planetary gear set disposed on the first shaft, and including a first rotation element, a second rotation element, and a third rotation element, a second planetary gear set disposed on the second shaft, and including a fourth rotation element connected to the second rotation element through an externally-meshed gear, a fifth rotation element connected to the third rotation element through an externally-meshed gear, and a sixth rotation element selectively connected to the first shaft through two paths including respectively externally-meshed gears, four transfer gears forming the externally-meshed gears, and frictional elements including clutches and a brake.

Owner:HYUNDAI MOTOR CO LTD

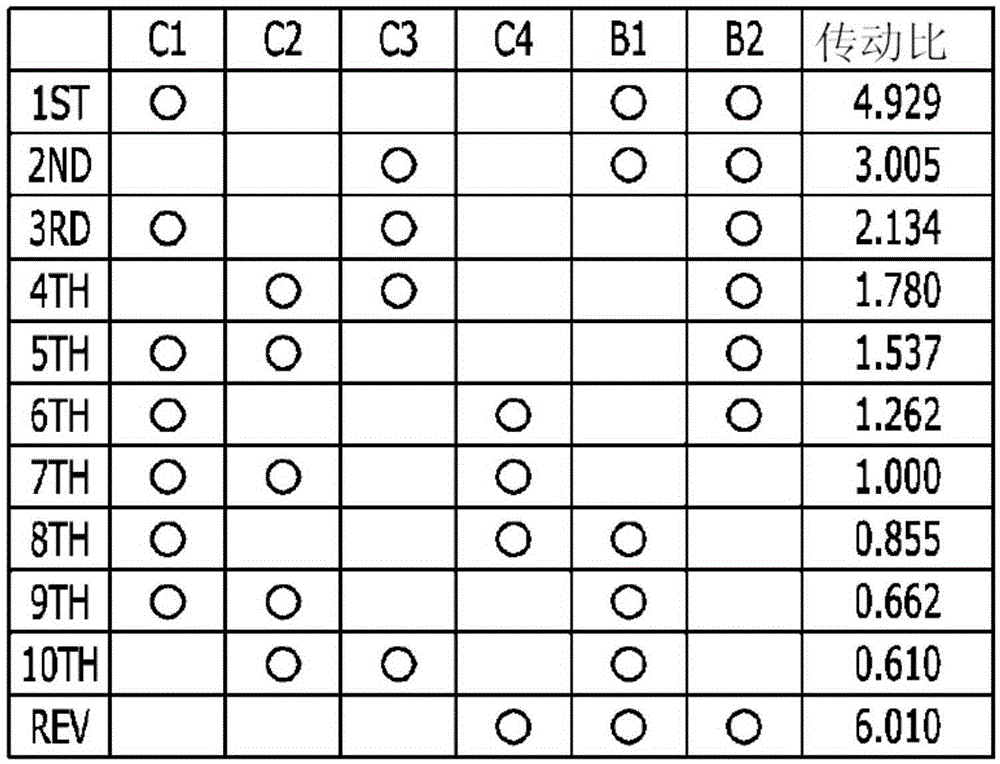

Planetary gear train of automatic transmission for a vehicle

InactiveCN105697688AImprove economyImprove power transmission performanceToothed gearingsTransmission elementsAutomatic transmissionEngineering

A planetary gear train of an automatic transmission for a vehicle may include an input shaft receiving torque of an engine, an output shaft outputting changed torque, a first planetary gear set, a second planetary gear set, a third planetary gear set, a fourth planetary gear set, a first rotation shaft selectively connected to a transmission housing, a second rotation shaft, a third rotation shaft selectively connected to the transmission housing, a fourth rotation shaft directly connected to the input shaft, a fifth rotation shaft selectively connected to the second rotation shaft, a sixth rotation shaft, a seventh rotation shaft selectively connected to the input shaft, and selectively connected to the fifth rotation shaft or the sixth rotation shaft, and an eighth rotation shaft directly connected to the output shaft.

Owner:HYUNDAI MOTOR CO LTD

Planetary gear train of automatic transmission for vehicles

ActiveCN107202105AImprove driving stabilityImprove driving efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear train

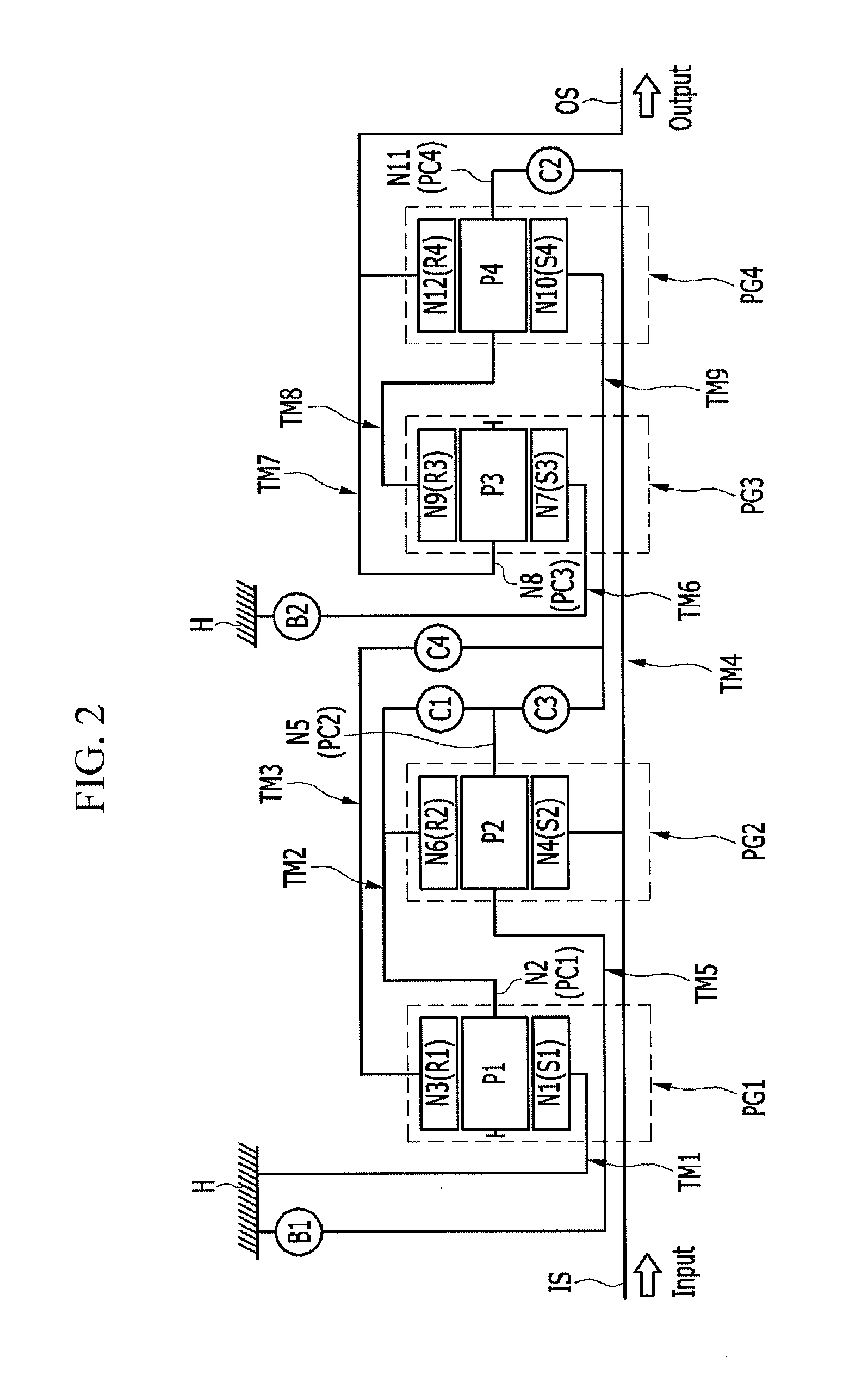

The invention provides a planetary gear train of claim of an automatic transmission for a vehicle, which comprises an input shaft configured to receive an engine torque; an output shaft configured to output a shifted torque; a first planetary gear set having first, second, and third rotational elements; a second planetary gear set having fourth, fifth, and sixth rotational elements; a third planetary gear set having seventh, eighth, and ninth rotational elements; a fourth planetary gear set having tenth, eleventh, and twelfth rotational elements; a first shaft connected with the first rotational element; a second shaft interconnecting the second rotational element, the fourth rotational element, and seventh rotational element, and directly connected with the input shaft; a third shaft interconnecting the third rotational element and the eleventh rotational element; a fourth shaft interconnecting the fifth rotational element and the ninth rotational element, and selectively connected with the third shaft; a fifth shaft connected with the sixth rotational element; a sixth shaft connected with the eighth rotational element; a seventh shaft connected with the tenth rotational element, and selectively connected with the fourth shaft and the fifth shaft respectively; and an eighth shaft connected with the twelfth rotational element, selectively connected with the sixth shaft, and directly connected with the output shaft.

Owner:HYUNDAI MOTOR CO LTD

Planetary gear train of automatic transmission for vehicle

InactiveCN103851137AImprove economyImprove power transmission performanceToothed gearingsTransmission elementsAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for a vehicle may include: a first shaft; a second parallel shaft; a first planetary gear set on the first shaft including a first element selectively connected to the first shaft, a second element selectively connected to the first shaft or a transmission housing, and a third output element; a second planetary gear set on the second shaft, and including a fourth element selectively connected to the first shaft, connected to the first element, and selectively connected to the transmission housing, a fifth element connected to the third element and directly connected to an output gear, and a sixth element selectively connected to the first shaft; four transfer gears; and frictional elements including clutches selectively connecting the first, second, fourth, and sixth elements with the first shaft and brakes selectively connecting the second and fourth elements with the transmission housing.

Owner:HYUNDAI MOTOR CO LTD

Planetary gear train of automatic transmission for vehicles

ActiveUS20170074361A1Improve fuel efficiencyImprove performance efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

An automatic transmission for a vehicle may include an input shaft; an output shaft; first to fourth planetary gear sets and six control elements which are disposed between the rotating elements, and disposed at portions where the rotating elements are selectively connected to a transmission housing, in which the input shaft is directly connected with the second rotating element, the output shaft is directly connected with the eleventh rotating element, the first rotating element is directly connected with the seventh rotating element, the sixth rotating element is directly connected with the transmission housing, the fourth rotating element is directly connected with the ninth rotating element, the eighth rotating element is directly connected with the tenth rotating element, and at least ten forward speeds and one reverse speed are implemented by operations of three control elements among the six control elements.

Owner:HYUNDAI MOTOR CO LTD

Planetary gear train of automatic transmission for vehicles

InactiveCN105697672AImprove economyImprove power transmission performanceToothed gearingsAutomatic transmissionGear train

A planetary gear train of an automatic transmission for vehicles may include an input shaft receiving torque of an engine, an output shaft outputting changed torque, a first planetary gear set, a second planetary gear set, a third planetary gear set, a fourth planetary gear set, a first rotational shaft selectively connected to a transmission housing, a second rotational shaft directly connected to the input shaft, a third rotational shaft, a fourth rotational shaft, a fifth rotational shaft selectively connected to the first rotational shaft or the second rotational shaft, a sixth rotational shaft directly connected to the output shaft, a seventh rotational shaft selectively connected to the transmission housing, an eighth rotational shaft selectively connected to the fourth rotational shaft or the fifth rotational shaft, and six friction elements interposed between the rotational shafts, or between at least one rotational shaft and the transmission housing to connect selectively.

Owner:HYUNDAI MOTOR CO LTD

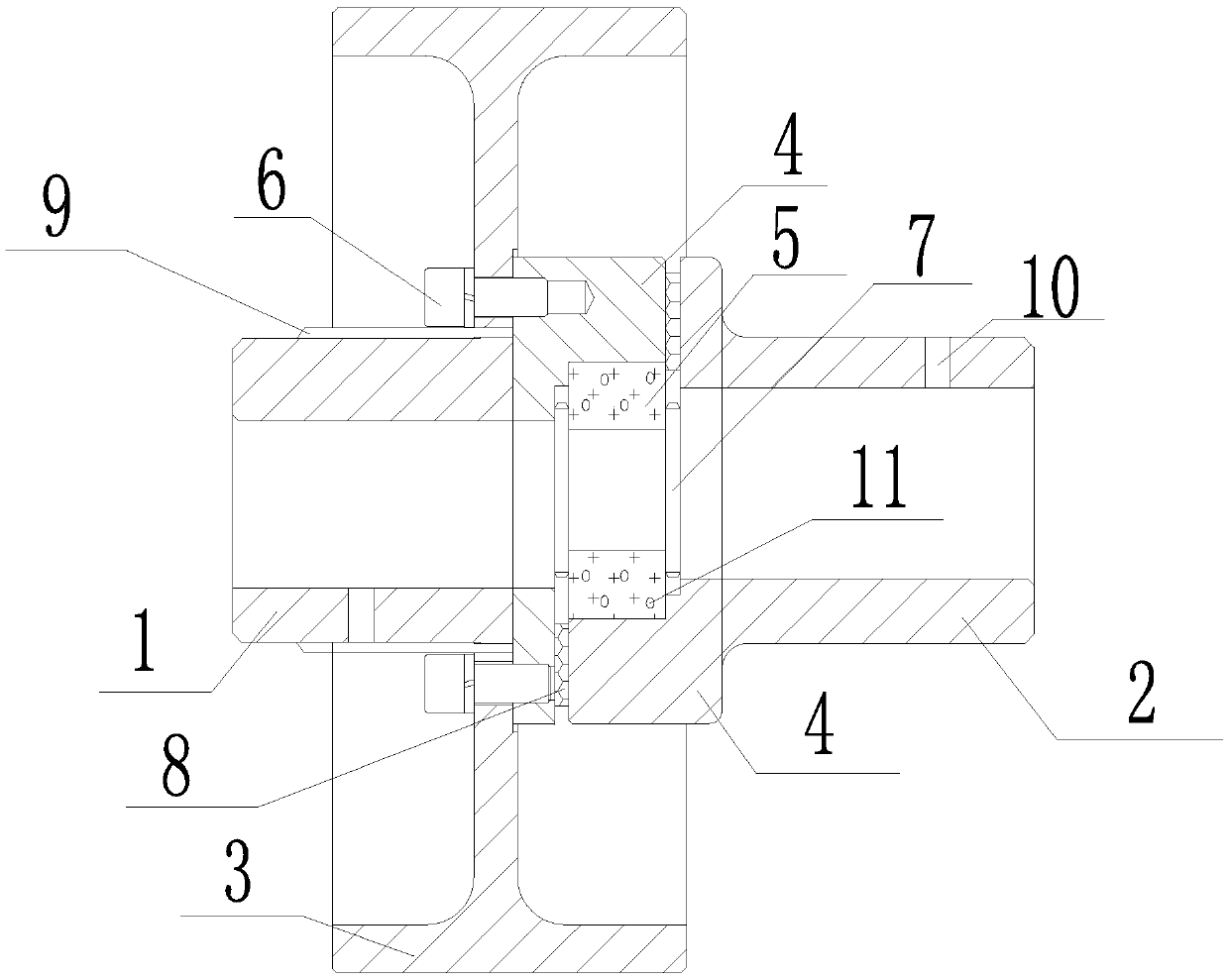

Positioning coupler

The invention relates to a positioning coupler. The positioning coupler comprises a left flange, a right flange, a brake wheel, a connecting clamping jaw and an elastic base body, wherein the left flange and the right flange are coaxially distributed, the left flange is connected with the right flange through the connecting clamping jaw, the outer side surface of the elastic base body abuts against the inner side surface of the connecting clamping jaw, and the left end surface and the right end surface of the connecting clamping jaw are connected with the left flange and the right flange to abut against the bottom of the clamping jaw, the brake wheel wraps outside the left flange, and the rear end surface of the connecting clamping jaw connected with the left flange is connected with the rear end surface of the brake wheel through a positioning bolt. According to the positioning coupler, on one hand, the structure strength and bearing capability can be effectively improved, and the power transmission capacity and stability are greatly improved; and on the other hand, the purpose of synchronous braking and speed regulation operation of the coupler and a shaft rod workpiece can be achieved, and the damage condition of the coupler structure caused by inertia during the running process of the coupler and the shaft rod workpiece can be effectively eliminated.

Owner:江苏泰克曼传动设备有限公司

Nanometer magnetic product for minitype electromechanical machine

InactiveCN101710522AImprove magnetic permeabilityReduce volumeInorganic material magnetismAdditivesMagnetorheological fluidStearate

The invention discloses a nanometer magnetic product for a minitype electromechanical machine; the magnetic product is prepared by adopting the mixture of nanometer magnetic powder, synthesized hydroxy metallic stearates, synthesized mineral oil and nanometer crystal whisker, caking and rusting of the magnetic powder, and sedimentation, clustering and leakage of magnetorheological fluid are avoided, therefore, the nanometer magnetic product can be widely applied and can replace the existing magnetic powder and the magnetorheological fluid; the nanometer magnetic product has the advantages of the existing magnetic product and can be widely applied to minitype electromechanical devices. The frictional wear of the device to the working surface is reduced, the magnetic-conductance performance of the magnetic product is increased, the power transmission property is improved and the volume of the device is reduced; under the action of the magnetic filed, the stress on the surface of a transmission part is uniform, the part deformation caused by extrusion of large-particle magnetic powder is avoided, therefore, the nanometer magnetic product has good compactness, heat stability and abrasion resistance, the using performance of a magnetic transmission system is improved, and the service life of the magnetic product body and the transmission system is prolonged.

Owner:CHONGQING UNIV

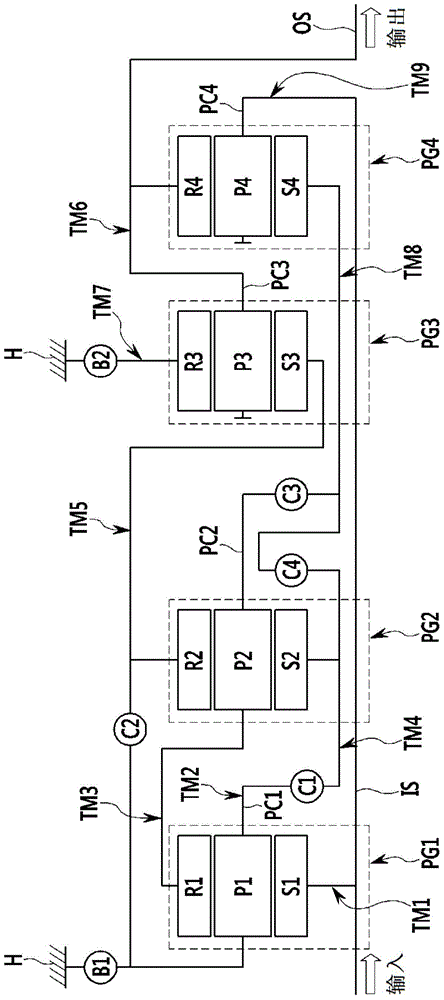

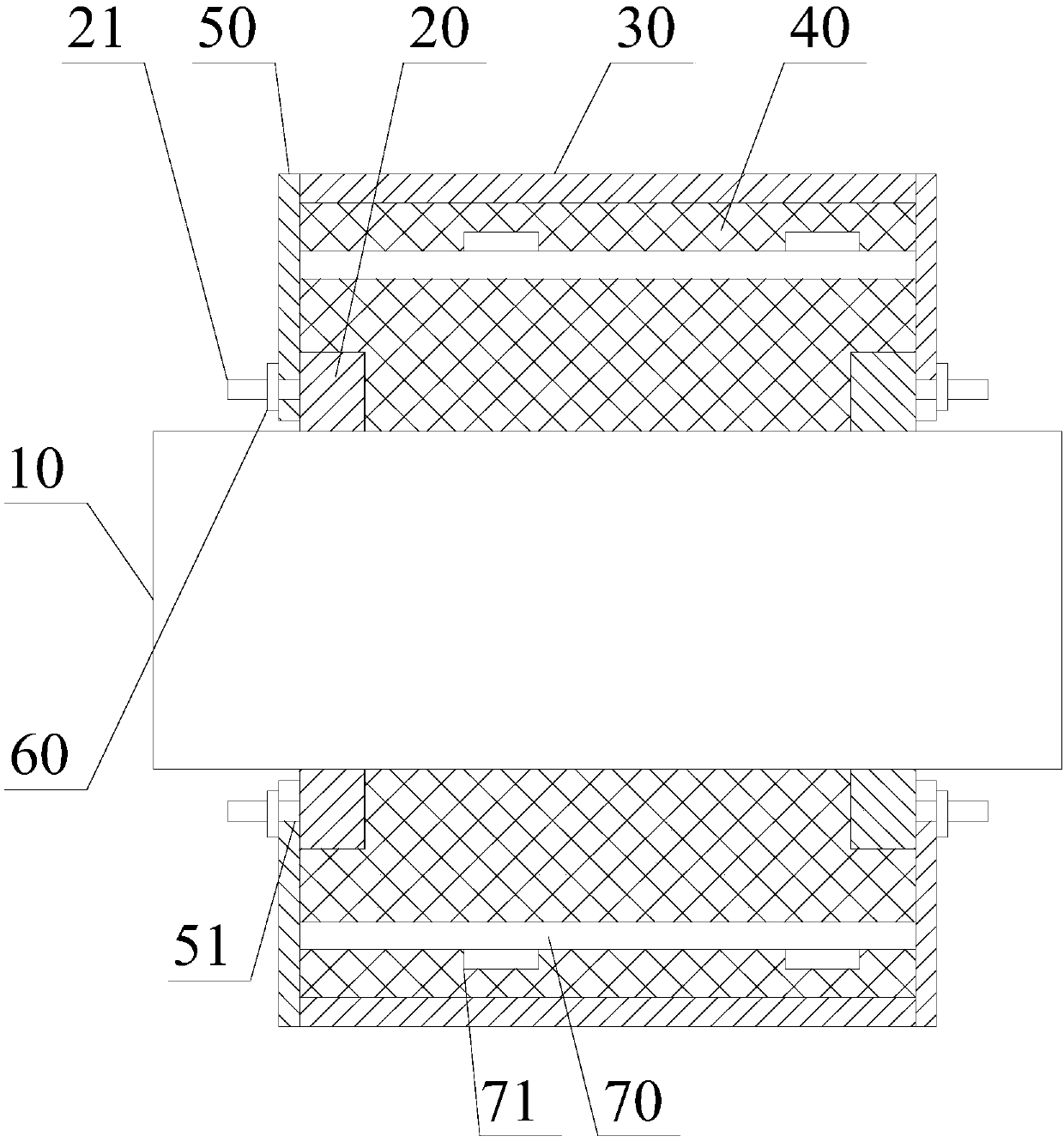

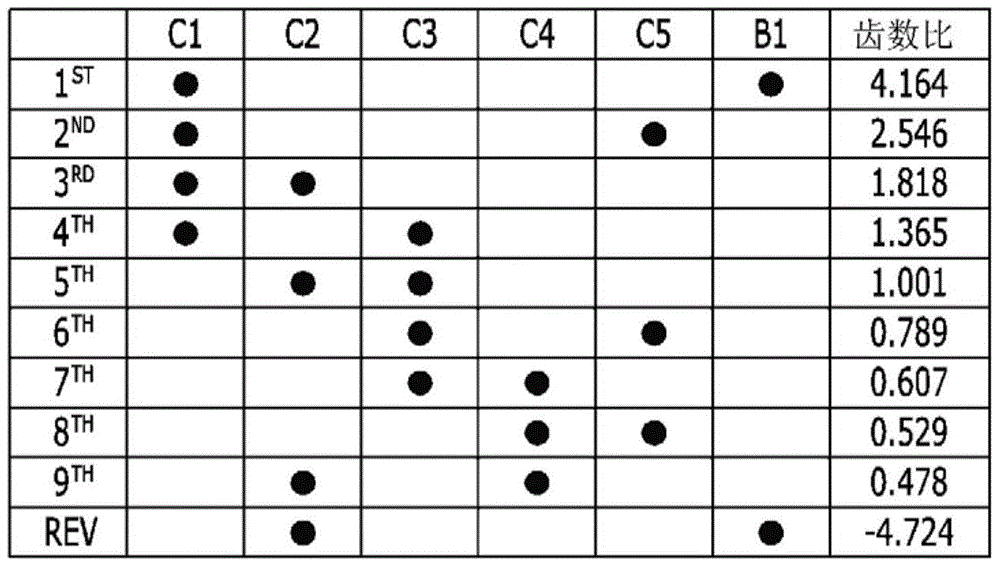

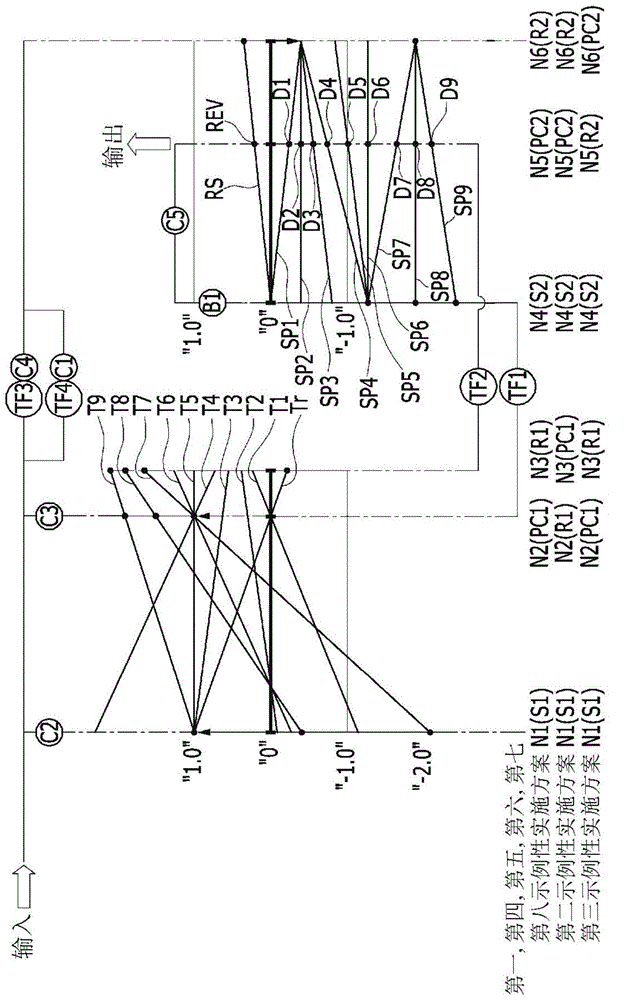

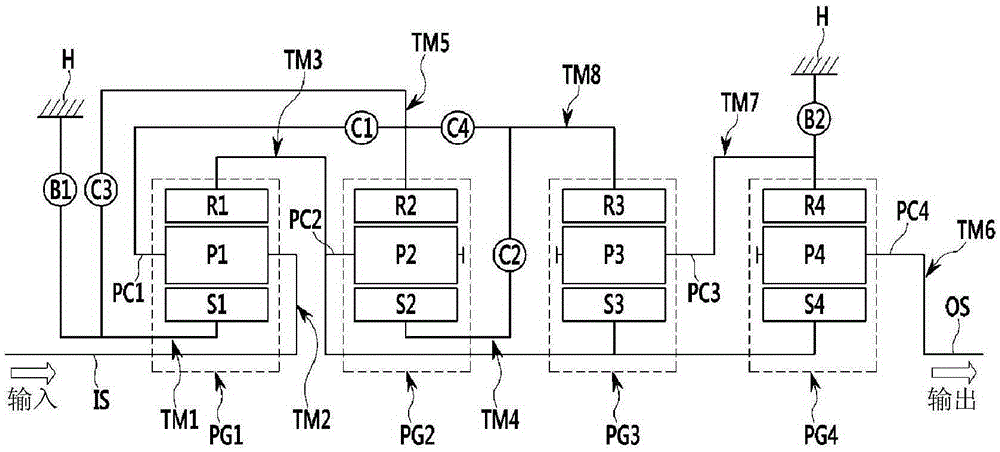

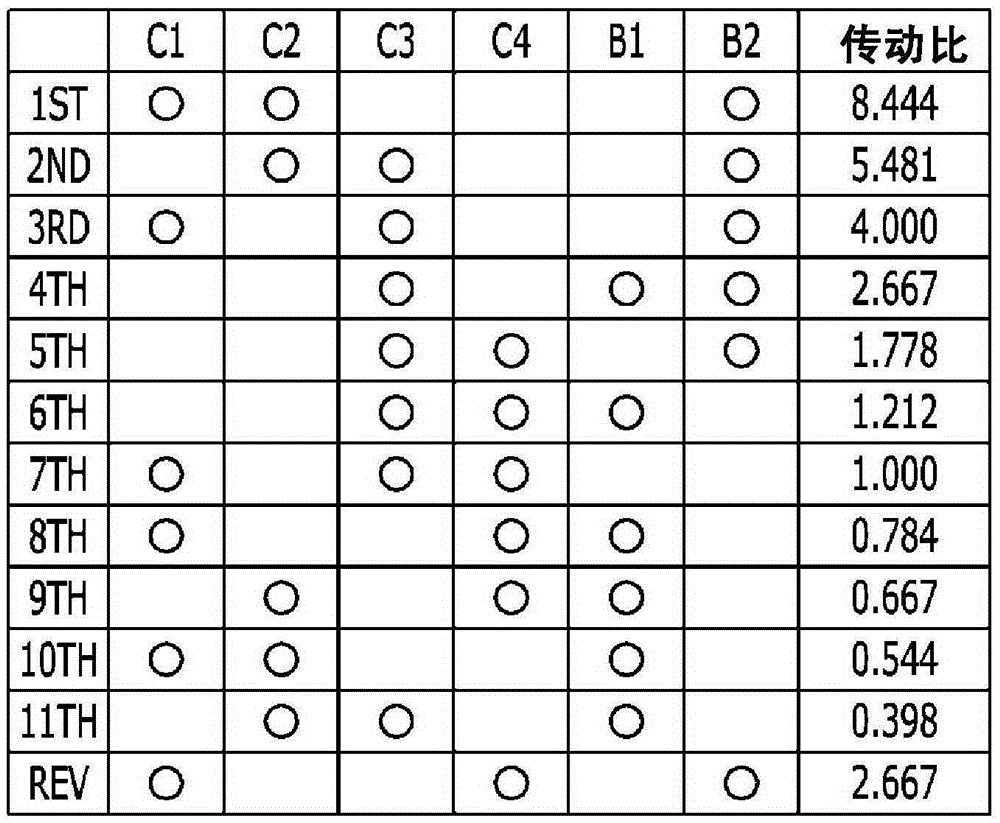

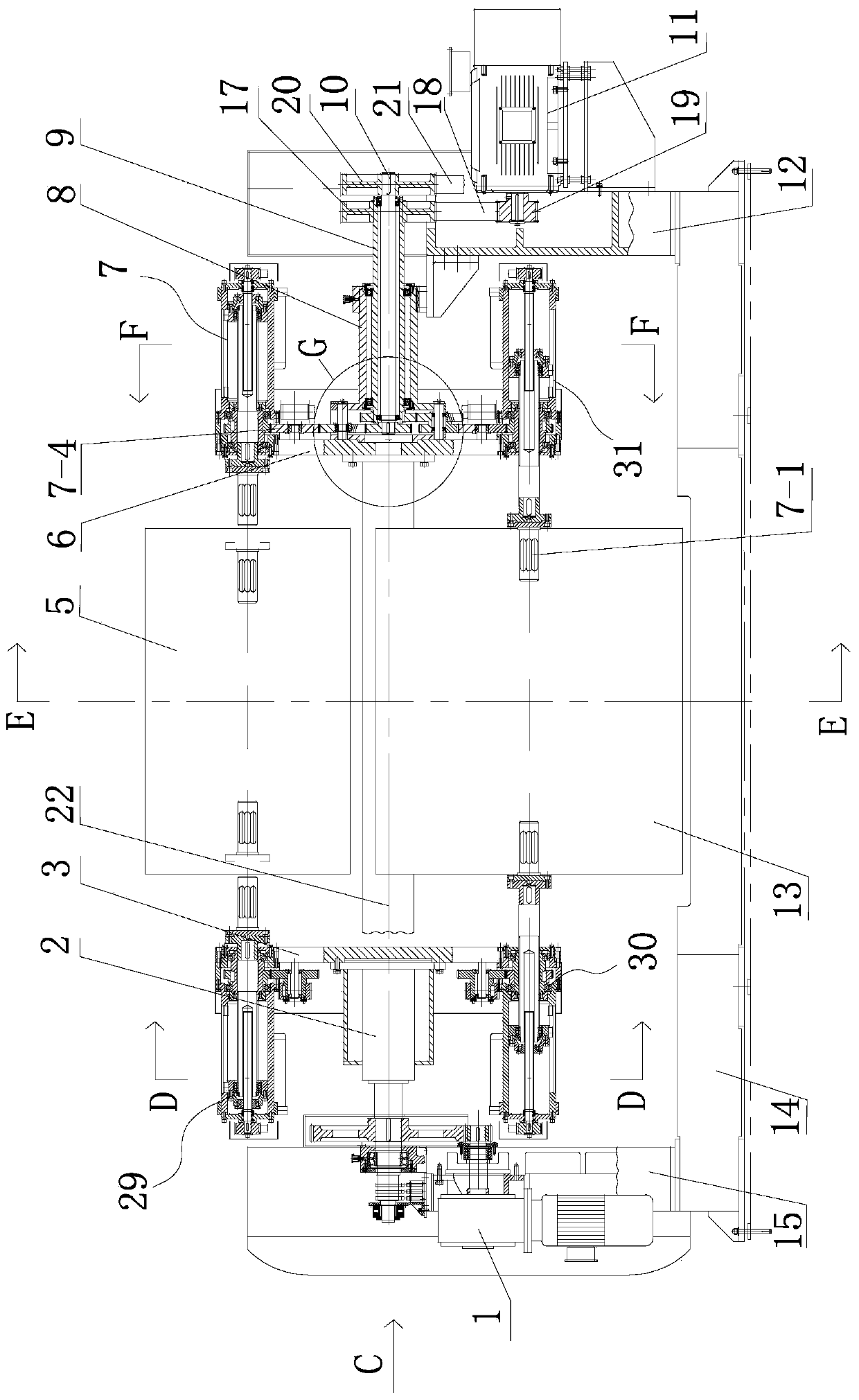

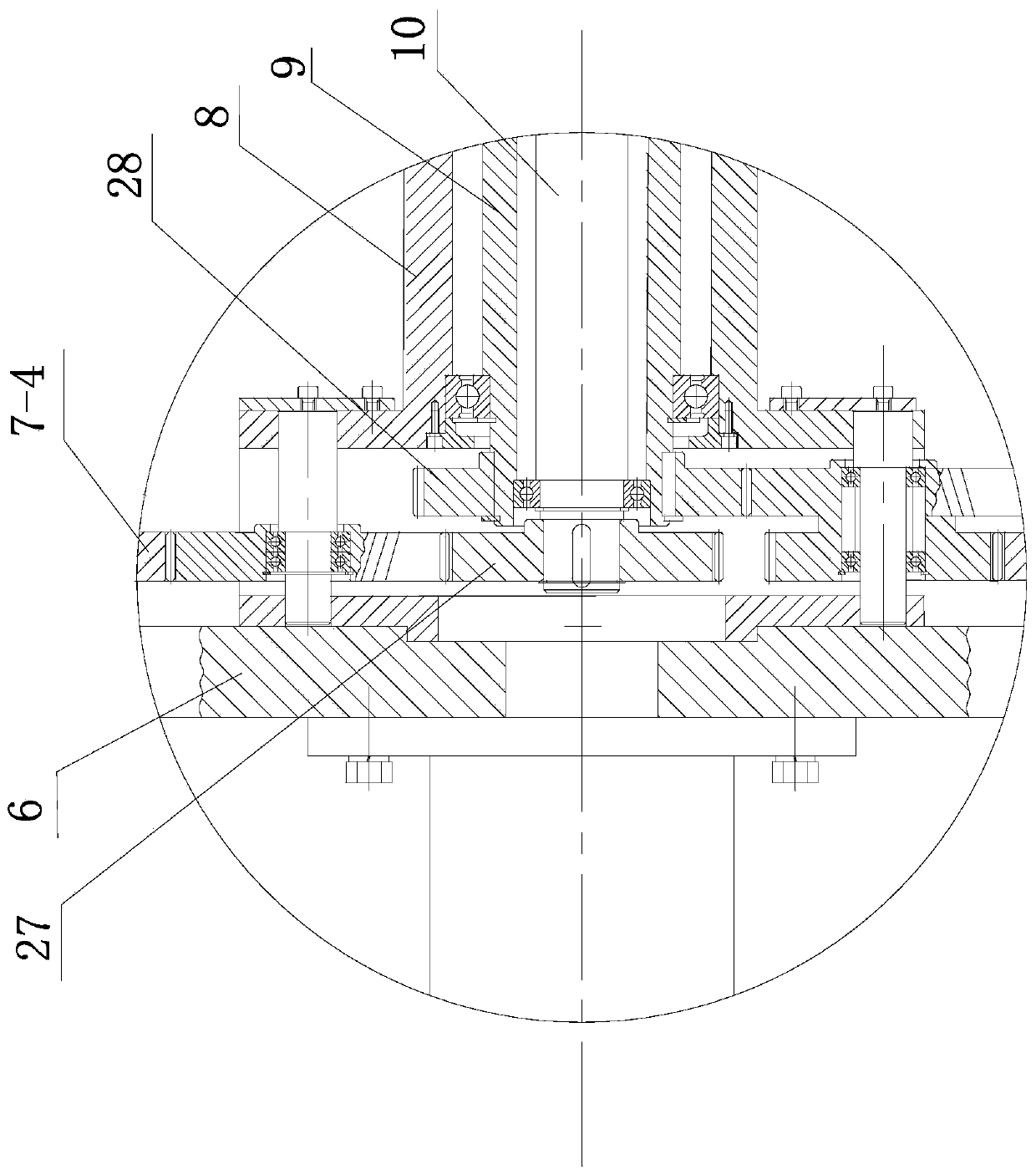

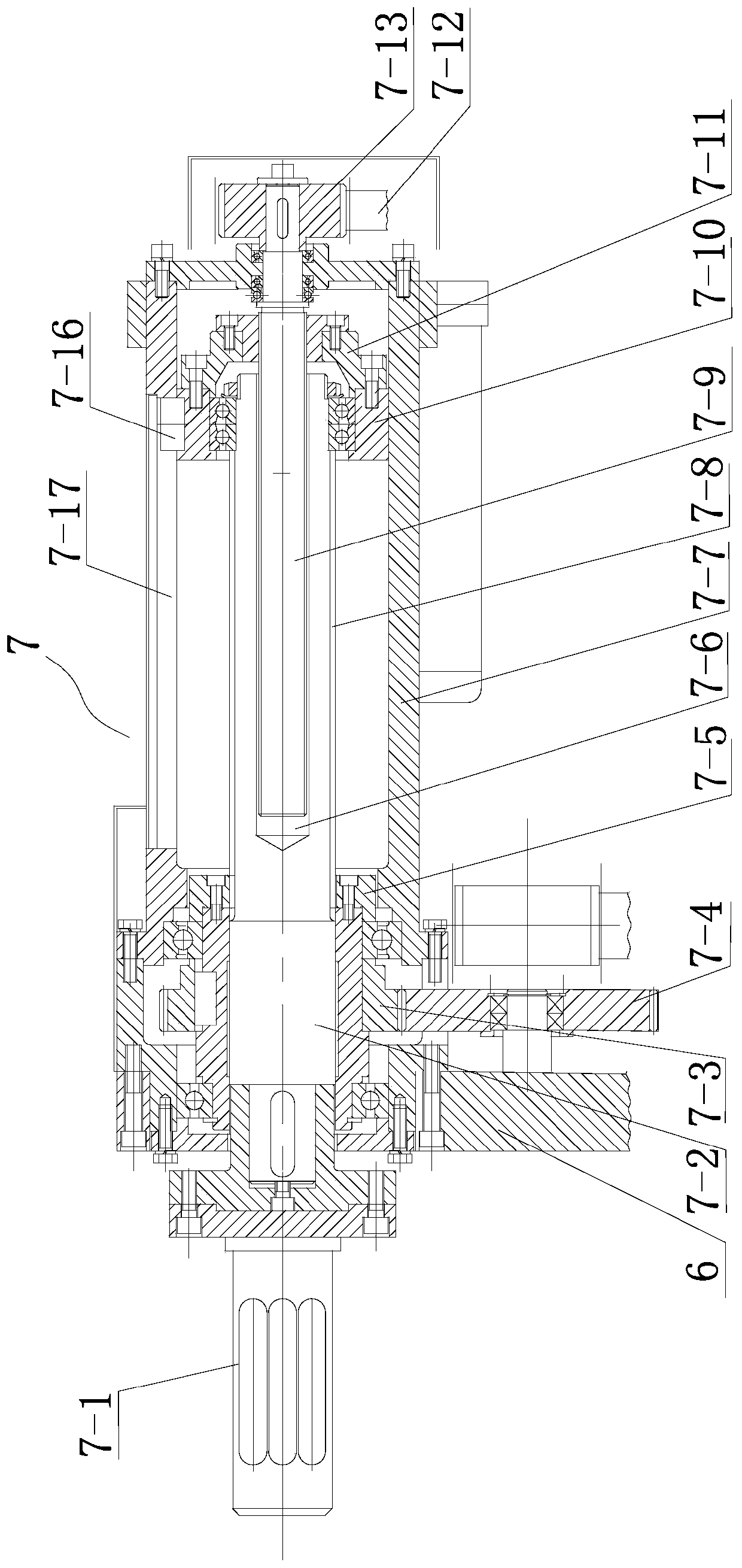

Eleven-gear transmission based on planetary gear train

ActiveCN112081884AExtended service lifeMany gearsToothed gearingsTransmission elementsClutchGear transmission

The invention relates to a transmission, and particularly relates to an eleven-gear transmission based on a planetary gear train. The eleven-gear transmission based on the planetary gear train solvesthe technical problem that an existing four-speed transmission and an existing six-speed transmission have limitations in the aspects of fuel economy, response power performance, stability and the like. The eleven-gear transmission based on the planetary gear train comprises a transmission shell and the planetary gear train. The planetary gear train comprises four planetary rows and seven gear shifting assemblies, wherein the four planetary rows and the seven gear shifting assemblies are arranged on the same shaft system; eight rotating bodies are formed among the four planetary row assembliesthrough connecting components such as rotating shafts; the gear shifting assemblies change the degree of freedom of the planetary gear train through clutches and brake; and different speed ratio transmission between an input shaft and an output shaft can be achieved through combination and separation of the different assemblies, and finally the gear shifting speed of at least eleven forward gearsand at least two reverse gears can be obtained. The eleven-gear transmission based on the planetary gear train has a more optimized speed ratio, and the power transmission performance and fuel economy of a vehicle are remarkably improved.

Owner:SHAANXI FAST GEAR CO

Winding drum material unwinding and winding printing tandem axle-free fixing unit

ActiveCN111285156ARealize rotation unwindingGuaranteed to workWebs handlingElectric machineEngineering

The invention relates to the field of reel material printing and coating production. According to the technical scheme, the winding drum material unwinding and winding printing tandem axle-free fixingunit comprises a base, a left wall plate, a right wall plate, a material rotating disc, a transposition power motor, a first left clamping machine head, a first right clamping machine head, a secondleft clamping machine head, a second right clamping machine head, a first gap bridge transmission mechanism and a second gap bridge transmission mechanism, wherein the left wall plate and the right wall plate are vertically fixed to the left side and the right side of the base, the two ends of the material rotating disc are rotationally positioned on the left wall plate and the right wall plate correspondingly, the transposition power motor drives the material rotating disc to rotate, the first left clamping machine head and the first right clamping machine head are coaxially installed on thematerial rotating disc at an interval so as to clamp an A-axis winding drum material, and the second left clamping machine head and the second right clamping machine head are coaxially installed on the material rotating disc at an interval so as to clamp a B-axis winding drum material. The unit can adapt to winding drum materials with different widths, manual shaft stringing is not needed, the labor intensity of workers is greatly relieved, the winding drum materials are driven to rotate through bilateral transmission, and the unit has the advantages of being reasonable in structure, reliablein work, convenient to operate, suitable for automatic application and high in production efficiency.

Owner:ZHEJIANG MEIGE MACHINERY

Coupler strong in stability

InactiveCN110107608AImprove convenienceImprove efficiencyYielding couplingCouplingUltimate tensile strength

The invention relates to a coupler strong in stability. The coupler strong in stability comprises a copper brake, a buffer spring, connection flanges, a cushion plate, a transition gear sleeve, crowngear sleeves, a positioning sleeve, end caps, a middle shaft, a spring ejection rod and a seal ring, wherein the number of the connection flanges is two, the two connection flanges are coaxially distributed, a connection cavity is formed in the front end face of each connection flange, a positioning cavity is formed in the rear end face of each connection flange, the cushion plate abuts against the bottoms of the connection cavities, the transition gear sleeve and the positioning sleeve are each of a closed ring structure distributed coaxial with the connection cavities, each end cap is embedded in the front end face of each connection cavity and connected with the front end face of each corresponding connection flange through a positioning bolt, and two ends of the middle shaft are respectively connected with the connection flanges. The coupler strong in stability can effectively improve structure strength and bearing cavity and effectively improve convenience and efficiency of connection operation on the one hand, and has good structure toughness and can effectively reduce acting force of axial endplay and radial runout, generated during the power transmission process, on the other hand.

Owner:江苏泰克曼传动设备有限公司

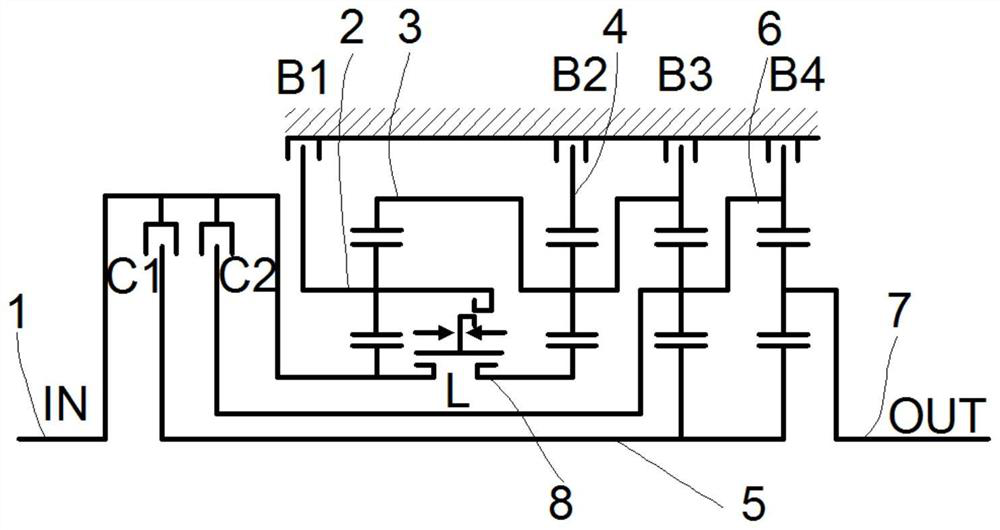

Planetary gear train for an automatic transmission of a vehicle

ActiveCN107202115BImprove driving performanceMaximize driving efficiencyToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The present invention provides a planetary gear train of an automatic transmission for a vehicle, including: an input shaft configured to receive engine torque; an output shaft configured to output shifted torque; a first planetary gear set having a second 1. Second and third rotation elements; second planetary gear set with fourth, fifth and sixth rotation elements; third planetary gear set with seventh, eighth and ninth rotation elements; fourth planetary gear group, with the tenth, eleventh and twelfth rotation elements; the first shaft, connected with the first rotation element, and directly connected with the transmission case; the second shaft, which makes the second rotation element, the sixth rotation element and The seventh rotating element is interconnected and selectively connected to the transmission housing; the third shaft is connected to the third rotating element; the fourth shaft is connected to the fourth rotating element and is directly connected to the input shaft and selectively connected to the third shaft sexual connection; the fifth axis; the sixth axis; the seventh axis; and the eighth axis.

Owner:HYUNDAI MOTOR CO LTD

Steel belt type mining inclined roadway travel aid

ActiveCN102515005BReduce your weightImprove power transmission performanceMine liftsEngineeringSteel belt

A steel belt type mining inclined roadway travel aid structurally comprises a head, a tail and a stepless steel belt. A steel belt pulley is arranged on the head, a driven pulley is disposed on the tail, and the stepless steel belt is connected between the driven pulley and the steel belt pulley, so that the driven pulley, the steel belt pulley and the stepless steel belt form the integral steel belt type mining inclined roadway travel aid. A rope clamping bar is arranged on the steel belt, the end of the rope clamping bar is inserted into a hole of the steel belt, and accordingly the steel rope bar is connected with the steel belt in a clamped manner.

Owner:JIANGSU LIWEI SHEARING & BENDING MACHINE

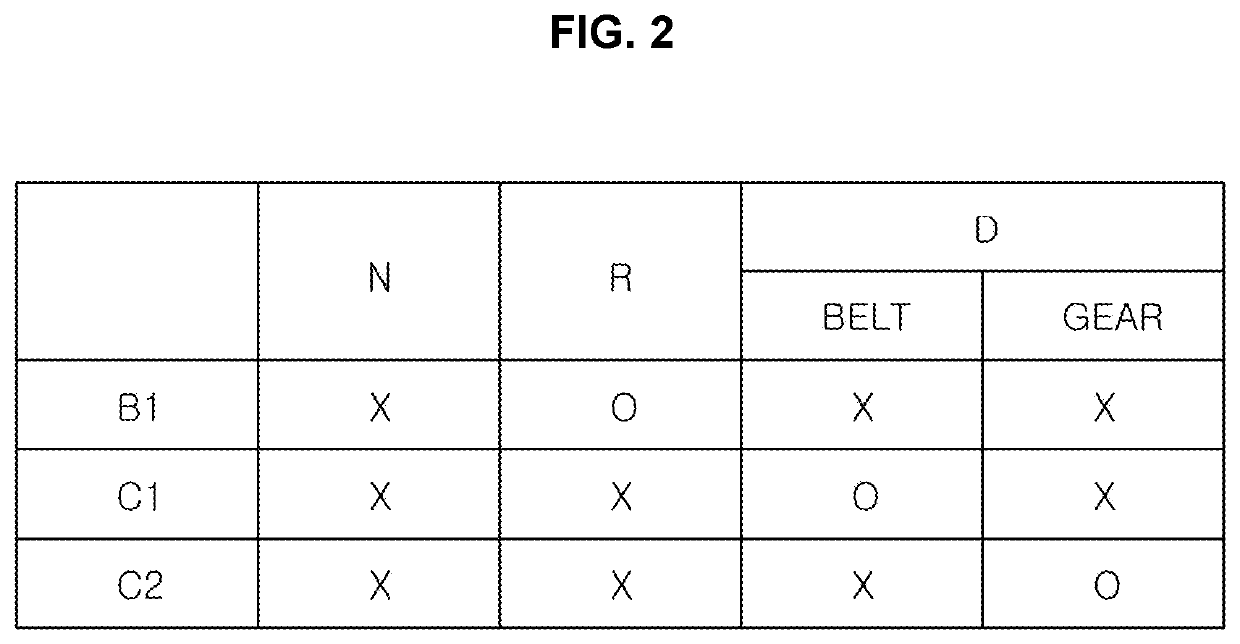

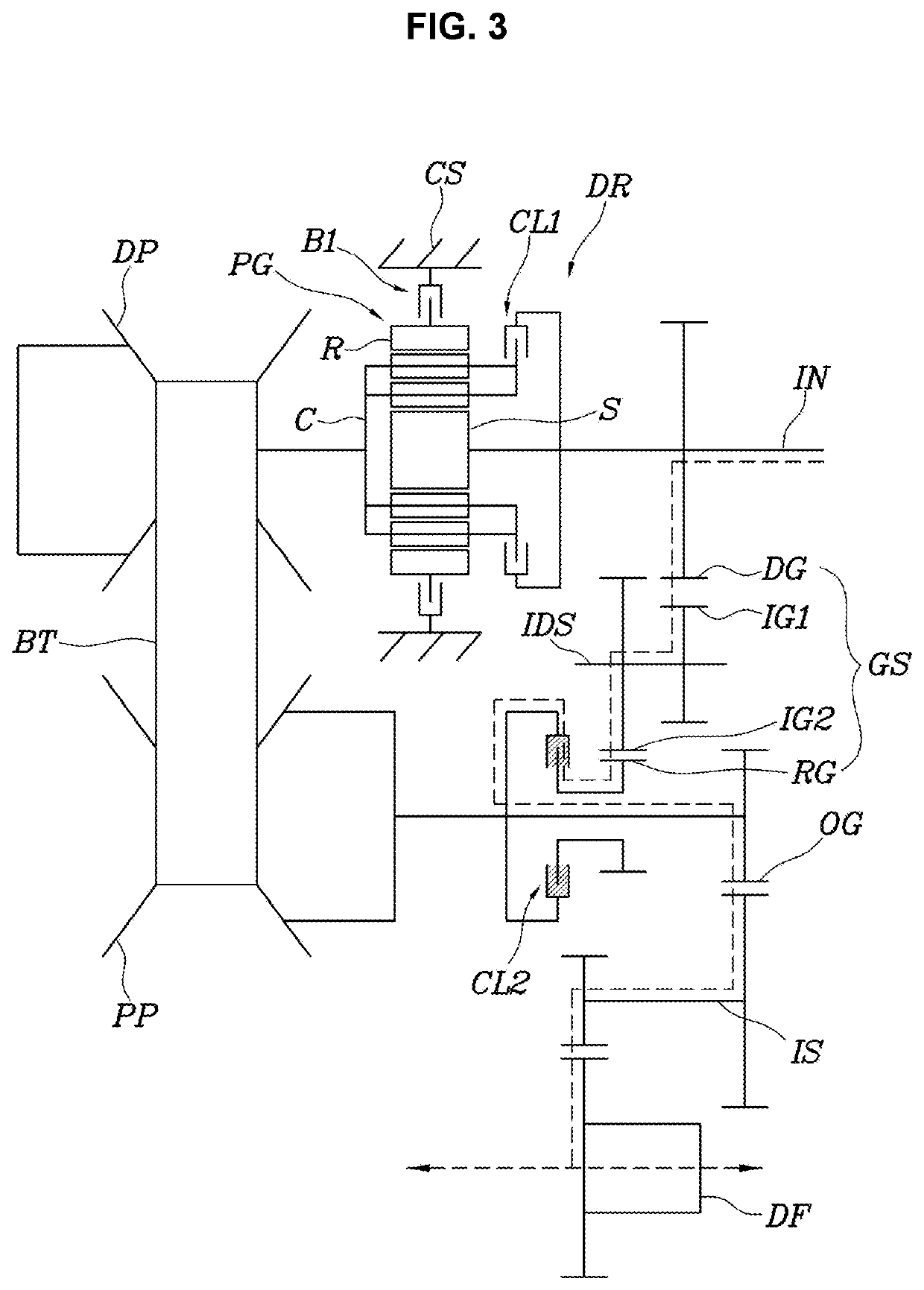

Continuously variable powertrain for vehicle

ActiveUS20200263771A1Improve power transmission performanceImprove fuel efficiencyToothed gearingsRotational axisGear wheel

A powertrain may include an input shaft; a drive pulley and a driven pulley engaged to each other by a belt; a forward / backward switching mechanism provided to selectively switch a direction of power from the input shaft to the drive pulley by a plurality of friction members and transmit the power; a gear train provided to transmit the power of the input shaft to a rotation shaft of the driven pulley without passing through the drive pulley; and another friction member provided to interrupt a power transmission path of the gear train.

Owner:HYUNDAI MOTOR CO LTD +1

Planetary gear train of automatic transmission for vehicle

ActiveCN107202103AImprove transmission efficiencyReduce consumptionToothed gearingsGearing controlAutomatic transmissionGear wheel

A planetary gear train of an automatic transmission for a vehicle is provided. Ten or more forward speeds and one or more reverse speed are achieved by a planetary gear train of an automatic transmission for a vehicle. The vehicle includes an input shaft, an output shaft, four planetary gear sets respectively having three rotational elements, and six control elements to selectively connect the rotational elements and a transmission housing.

Owner:HYUNDAI MOTOR CO LTD

A kind of wind power generator transmission structure

InactiveCN103835892BLow failure rateImprove reliabilityToothed gearingsMachines/enginesFailure rateWind driven

The invention relates to a transmission structure for a wind driven generator. The transmission structure is composed of a spiral bevel gear mechanism arranged in a generator cabin and a planetary gear gearbox arranged in a tower cylinder. An impeller of the wind driven generator is connected with an input shaft of the spiral bevel gear mechanism, an output shaft of the spiral bevel gear mechanism is connected with an input shaft of the a planetary gear gearbox, and an output shaft of the a planetary gear gearbox is connected with a rotary shaft of a generator set. The output shaft of the spiral bevel gear mechanism and the input shaft of the planetary gear gearbox are arranged coaxially and are identical to the axis direction of the tower cylinder. The transmission structure is low in failure rate, high in reliability and convenient to dismount and maintain, and accordingly, the maintenance cost of the transmission structure is reduced.

Owner:BEIJING BUFFALO TRANSMISSION TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com