Coupler strong in stability

A high-stability coupling technology, applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve problems such as friction loss of coupling equipment, insufficient structural strength of couplings, low power transmission efficiency, etc. , to achieve the effects of reducing equipment wear and loss, improving power transmission capacity and stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

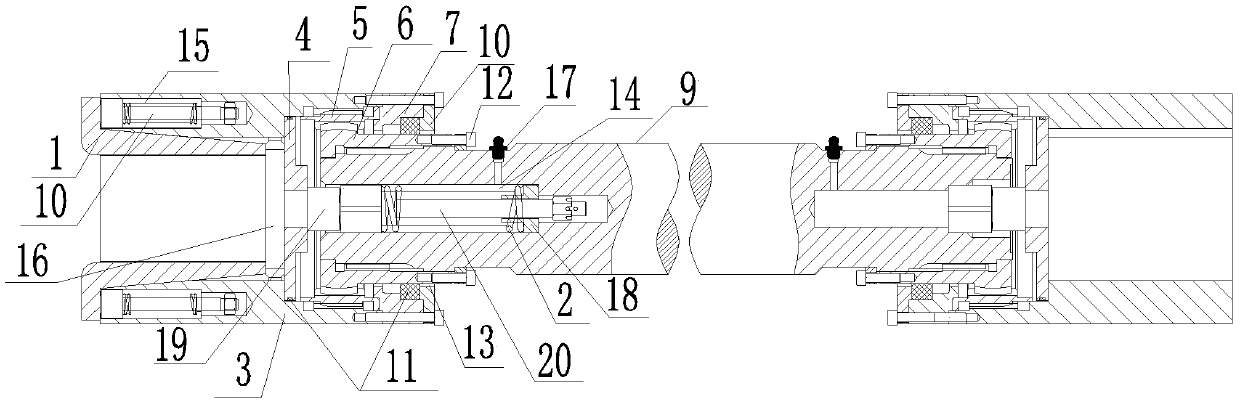

[0018] Such as figure 1 The high stability coupling includes copper brake iron 1, buffer spring 2, connecting flange 3, backing plate 4, transition gear sleeve 5, drum gear sleeve 6, positioning sleeve 7, end cover 8 , the intermediate shaft 9, the spring ejector rod 10 and the seal ring 11, there are two connecting flanges 3, and the two connecting flanges 3 are coaxially distributed, and the connecting flange 3 is an "I"-shaped cavity structure, and the connection method A connecting cavity 31 is set on the front end of the blue 3, and a positioning cavity 32 is set on the rear end. The connecting cavity 31 and the positioning cavity 32 are coaxially distributed and communicated with each other, and the inner diameter of the connecting cavity 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com