Graphene composite optical cable

A composite optical and graphene technology, applied in the direction of insulated cables, communication cables, cables, etc., can solve problems affecting performance, affecting the transmission capacity of composite optical cables, limited electrical conductivity and thermal conductivity of copper or aluminum conductors, etc. To achieve the effect of increasing carrying capacity, good marketing value, saving construction and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

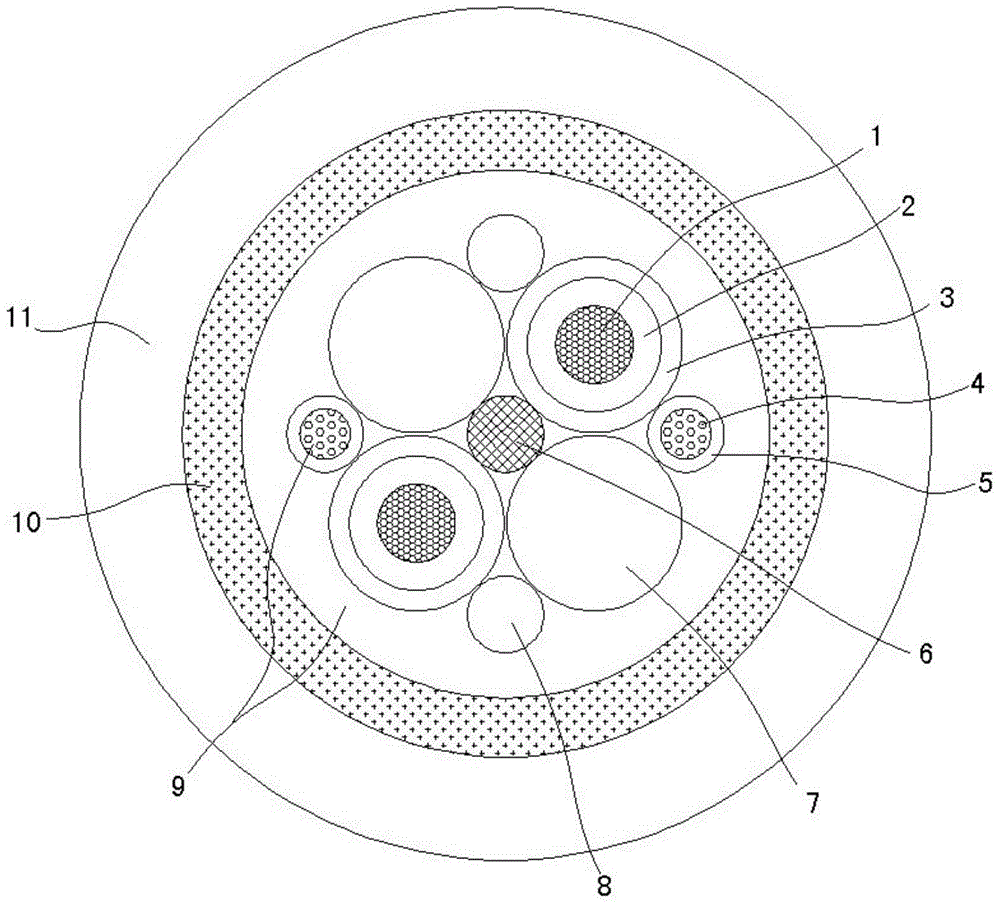

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0023] refer to figure 1 As shown, the present invention is a graphene composite optical cable, comprising a stranded core, a metal protection layer 10 coated on the outside of the stranded core, and an outer sheath 11 coated on the outside of the metal protection layer 10, the outer sheath 11 is made of polyethylene material, the stranded core includes a central reinforcement 6 that sets the central position of the stranded core, and cable cores and large-diameter filling ropes 7 that are uniformly staggered on the peripheral surface of the central reinforcement 6, and the central reinforcement 6 It is made of phosphating steel wire, which improves the mechanical strength of the graphene composite optical cable.

[0024] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com