Patents

Literature

54results about How to "Many gears" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

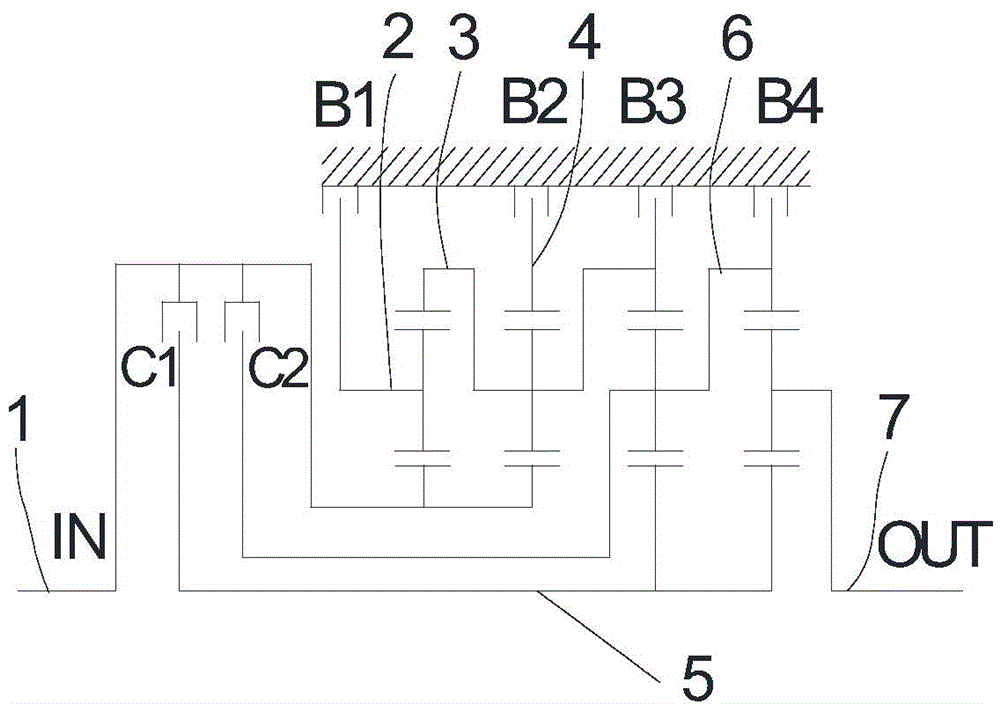

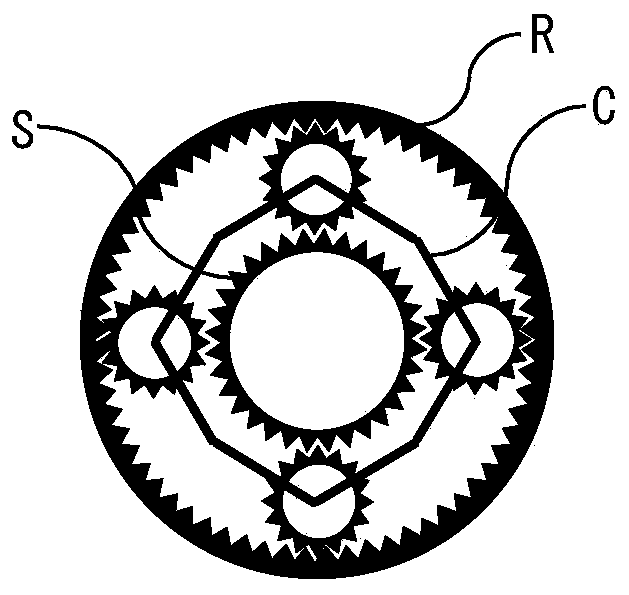

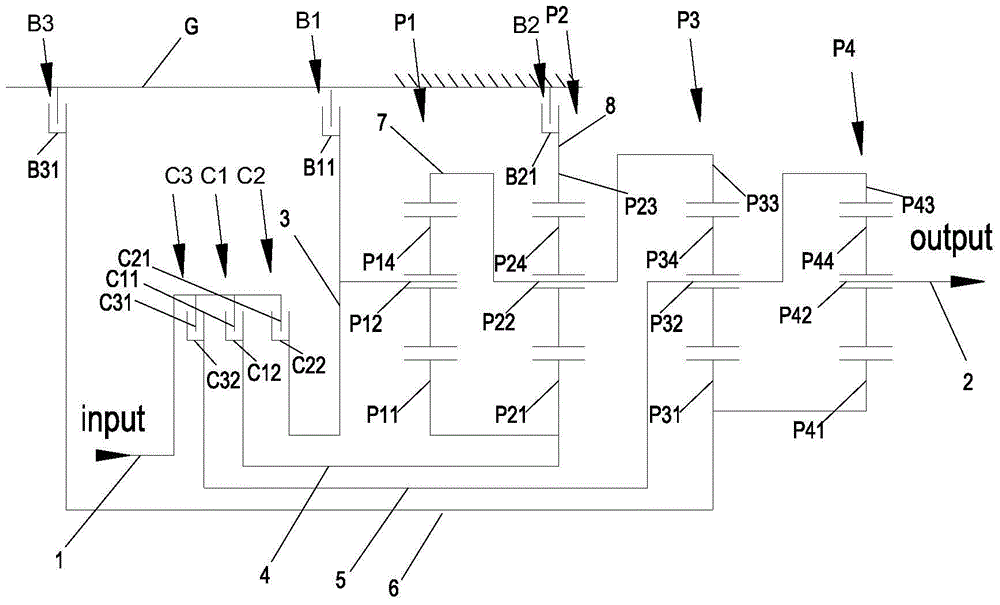

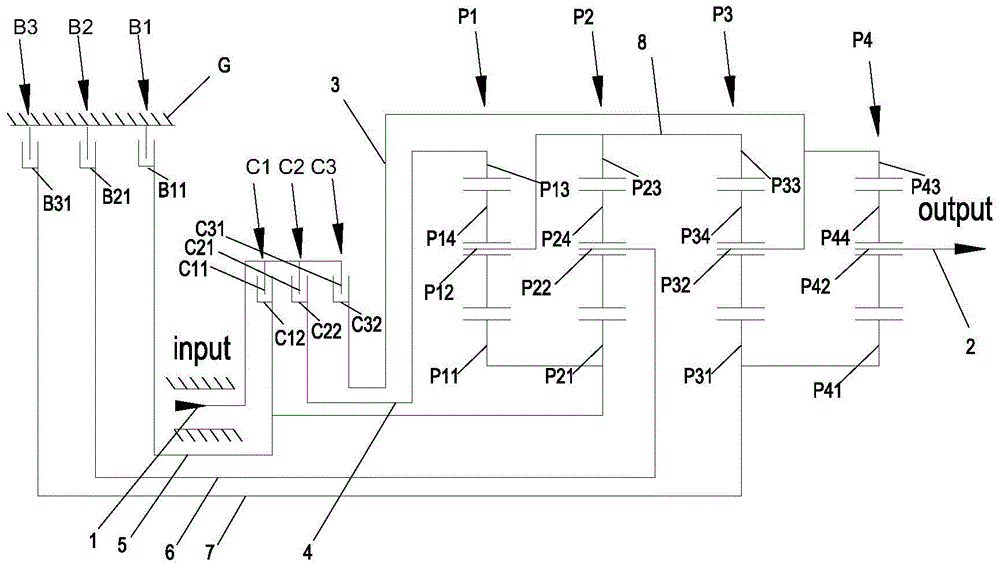

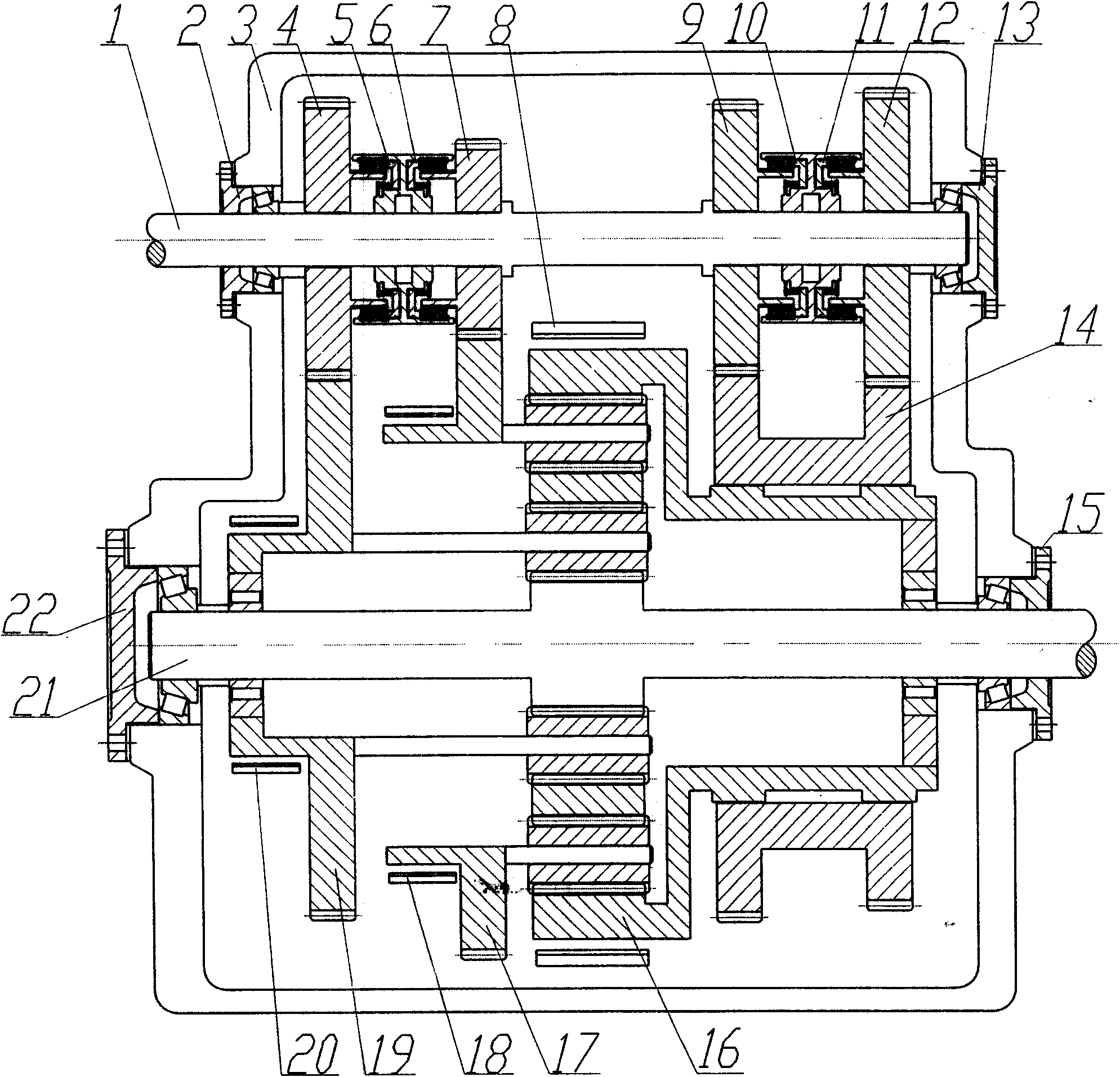

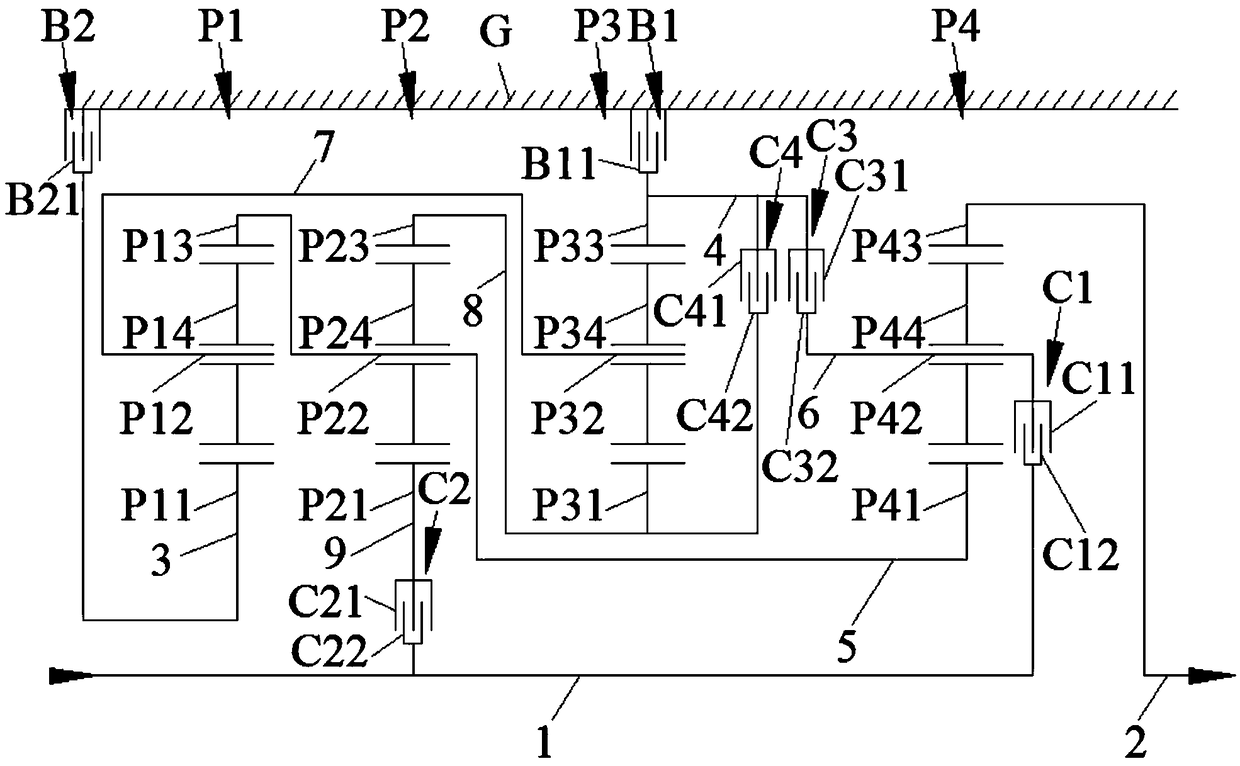

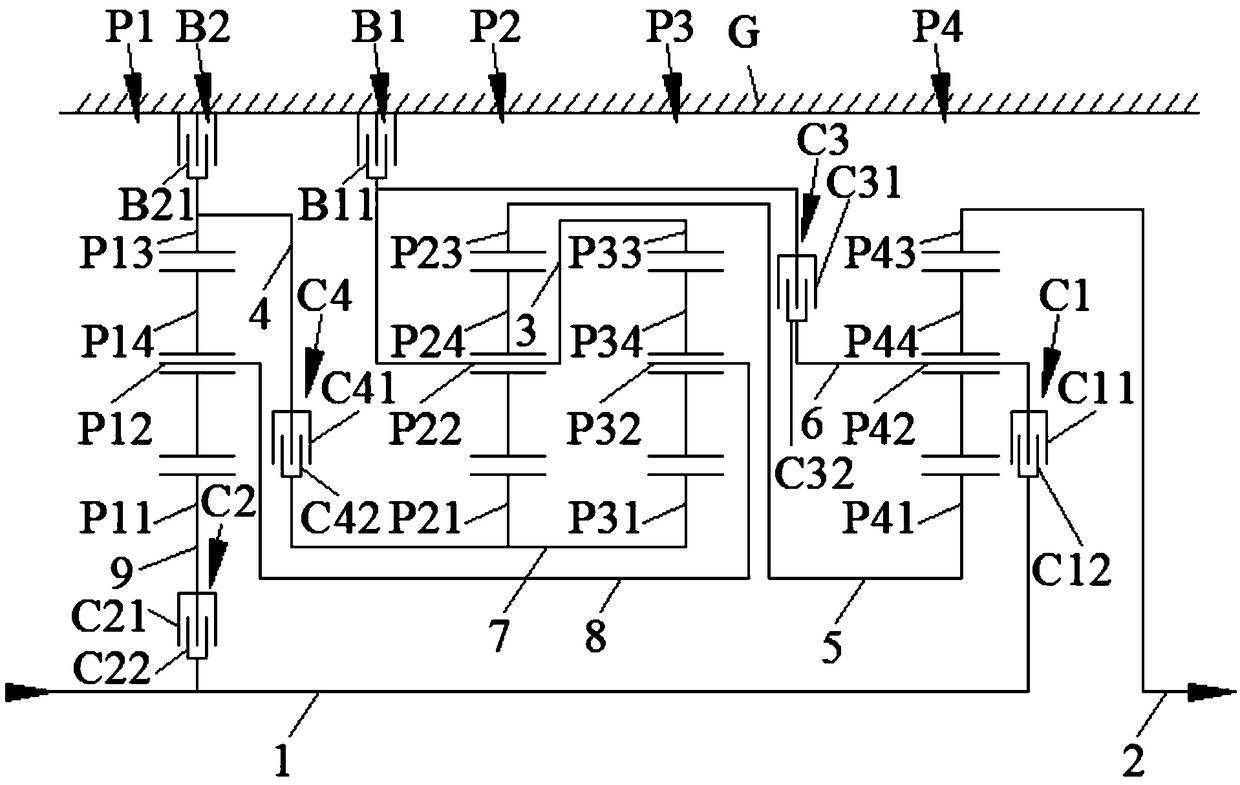

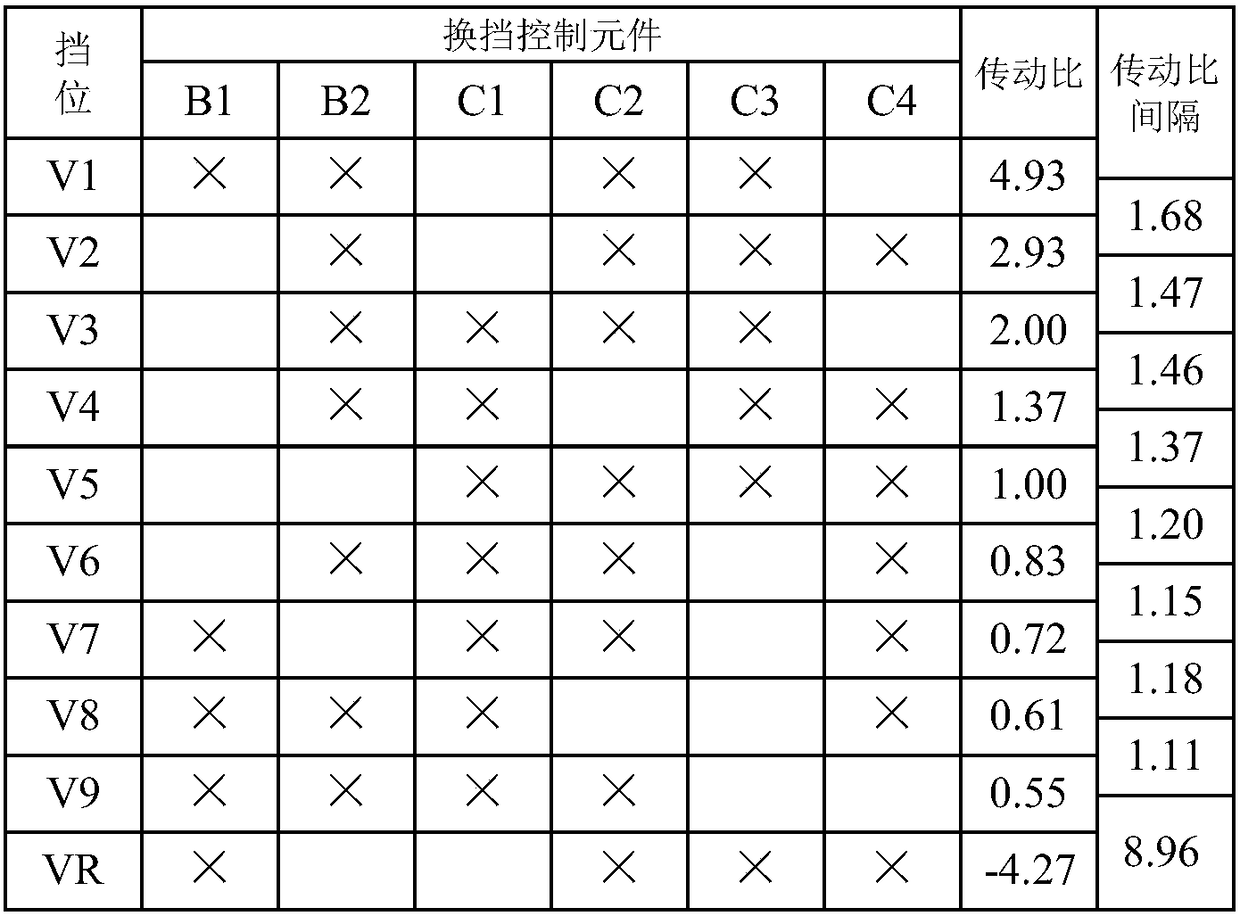

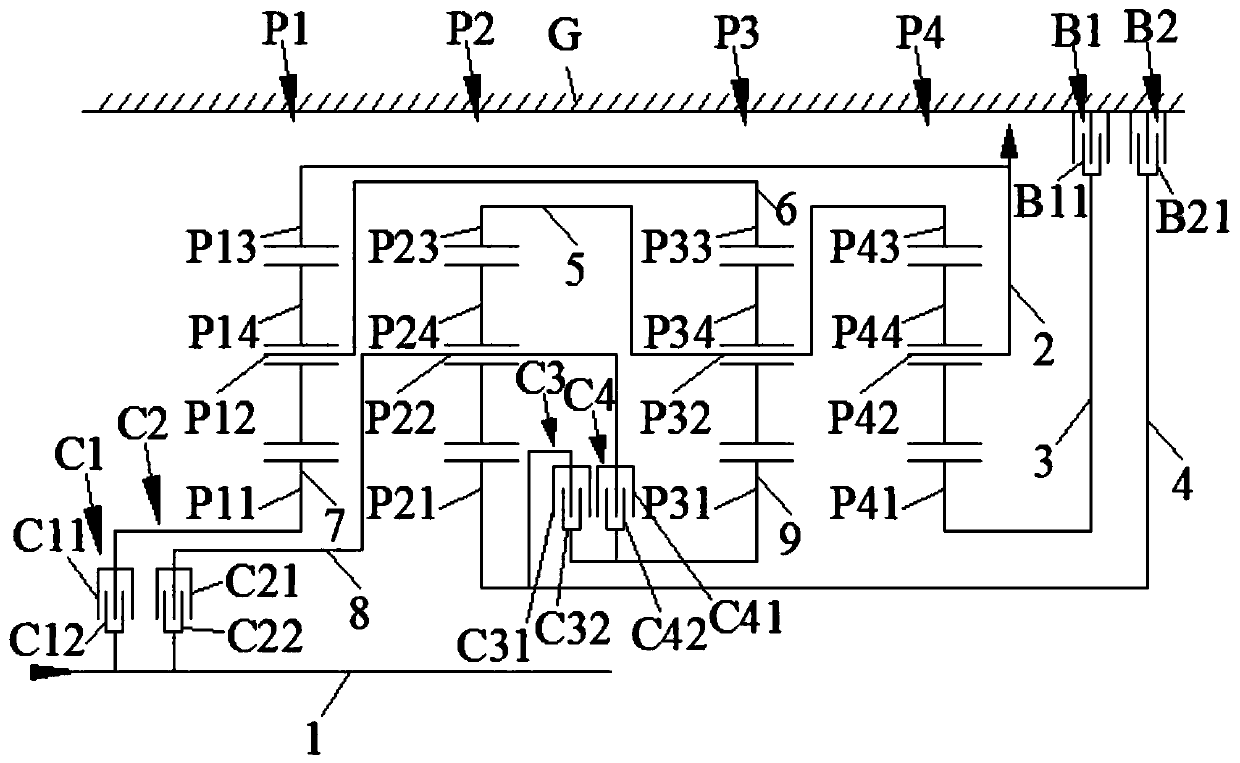

Multi-gear transmission and planetary gear train thereof

ActiveCN104896038AShorten the lengthMeet the durabilityToothed gearingsTransmission elementsAutomatic transmissionGear wheel

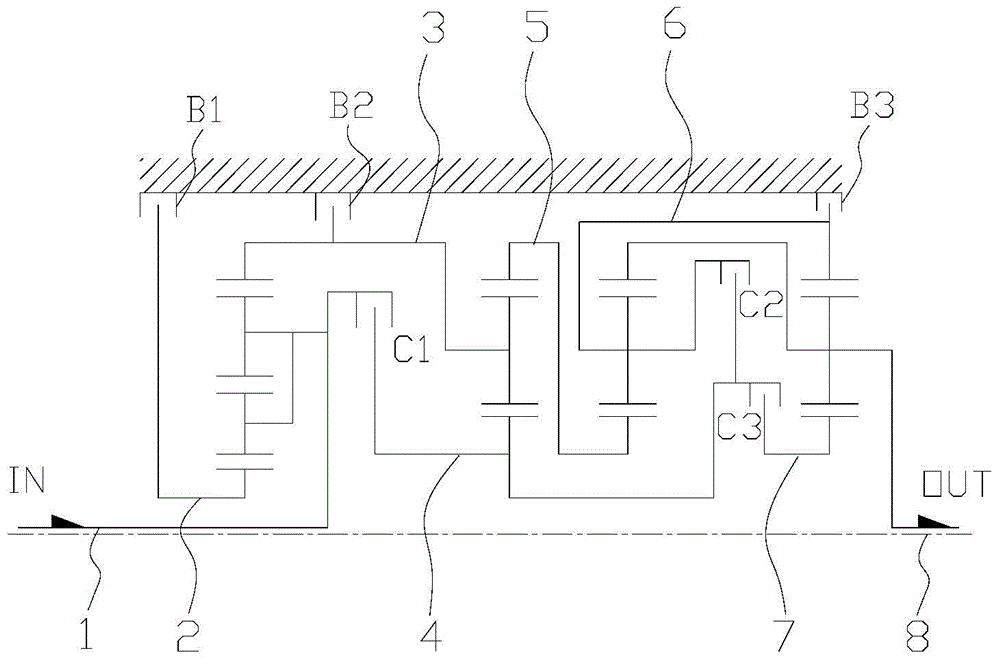

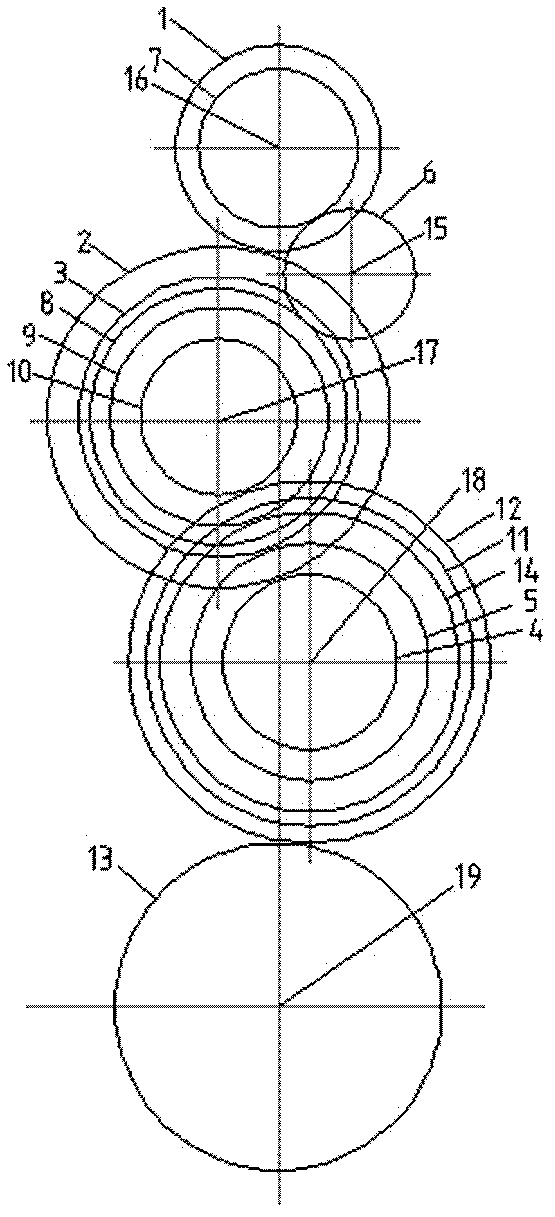

The invention discloses a planetary gear train to be used for a multi-gear transmission. At least nine available forward gears and at least one available reverse gear can be obtained. The planetary gear train comprises a first planet row, a second planet row, a third planet row and a fourth planet row. Each planet row comprises a sun gear, a planet carrier and a gear ring. Components and connection members of the planet rows can form seven rotation elements. A gear shifting component comprises two clutches and four brakes. The clutches are arranged among the selected rotation elements of the rotation elements, and the brakes are arranged between the selected rotation elements of the rotation elements and fixing parts. The planetary gear train has more gears and optimal speed ratio, the power transmission performance and the fuel economy of the cars can be improved apparently, and the planetary gear train is short, compact in overall design, capable of meeting requirements of cars for transmission durability, power transmission efficiency, size, costs and the like well. The invention further discloses an automatic transmission with the planetary gear train.

Owner:SHAANXI FAST GEAR CO

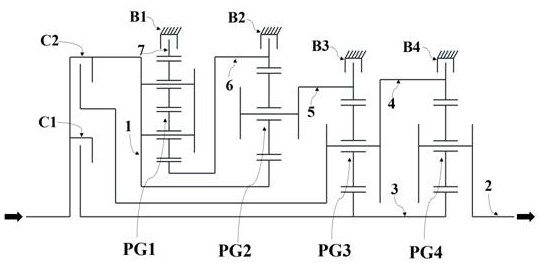

Multi-gear transmission achieved in mode of planetary gear structure

InactiveCN105114560AReduce loadMany gearsToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention discloses a multi-gear transmission achieved in the mode of a planetary gear structure and belongs to the technical field of automatic transmissions. The problems that in the prior art, the automatic transmissions are large in number of components and complex in structure, and particularly slightly-progressive and well-graded transmission ratio series and good meshing efficiency are hard to provide are solved. The multi-gear transmission comprises four planetary gear sets which are arranged one after another along a main rotating shaft and six gear shifting switching elements, and the gear shifting switching elements are allowed to be selectively manipulated so that nine forwarding gears and one reversing gear can be formed between an input shaft and an output shaft of the transmission. The input shaft is connected with a fourth shaft connected to a first sun gear through a first clutch in a disengaging mode and connected with an eighth shaft through a second clutch in a disengaging mode, and the eighth shaft is connected with a first planet carrier and a second gear ring and connected to a shell through a first brake. A fifth shaft is connected with a second sun gear and connected to the shell through a second brake. The output shaft is connected with a fourth planet carrier.

Owner:ZHAOQING UNIV

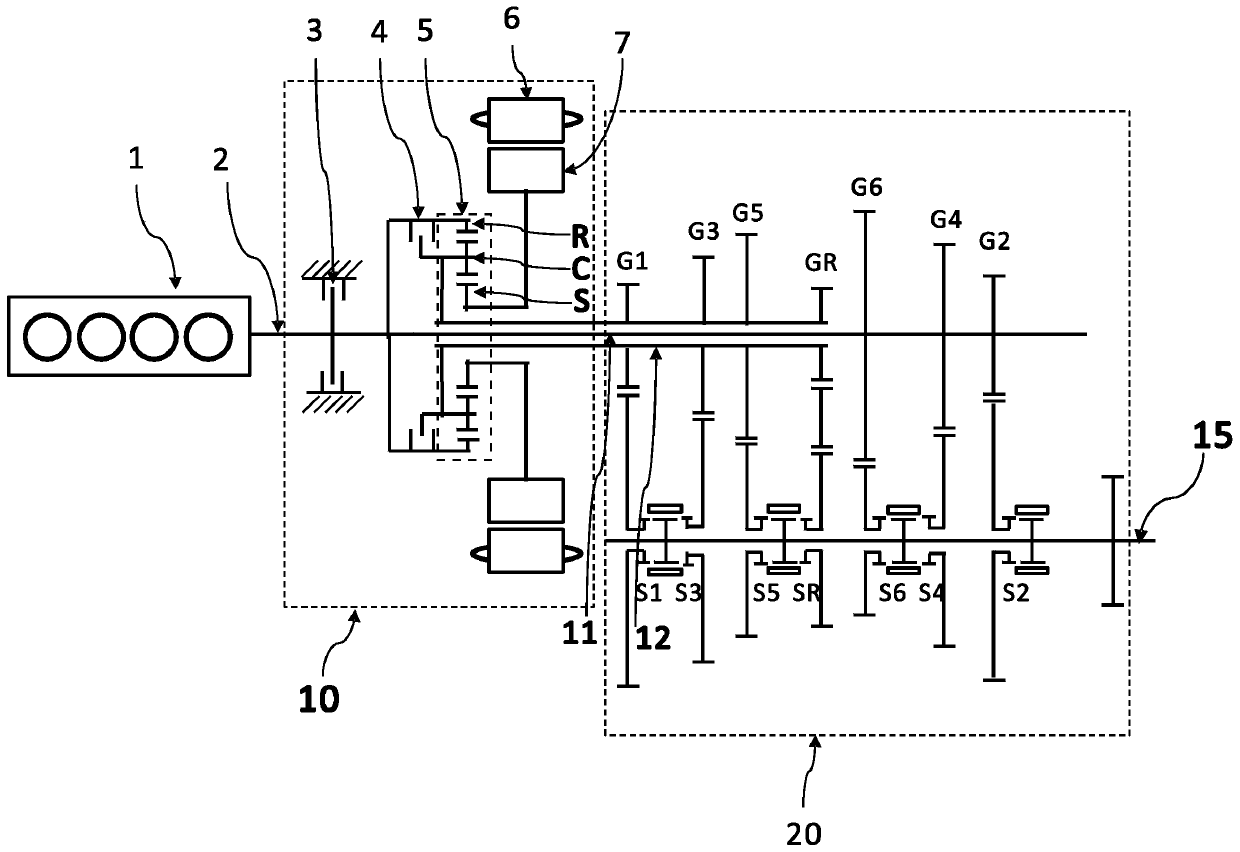

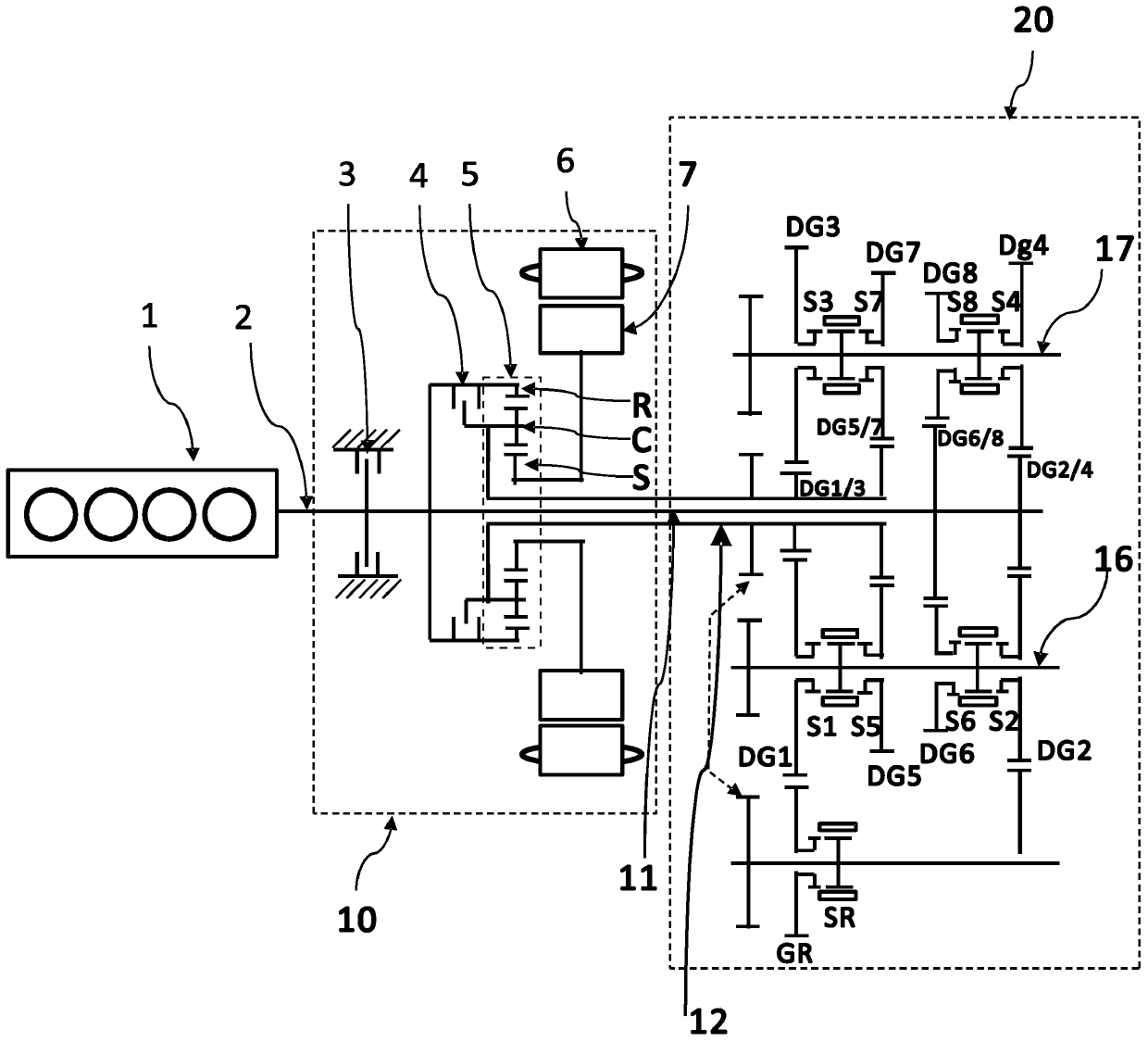

Vehicle hybrid power system and control method thereof

ActiveCN110525191AAdjust torqueTorque balanceHybrid vehiclesGas pressure propulsion mountingElectric machineGear wheel

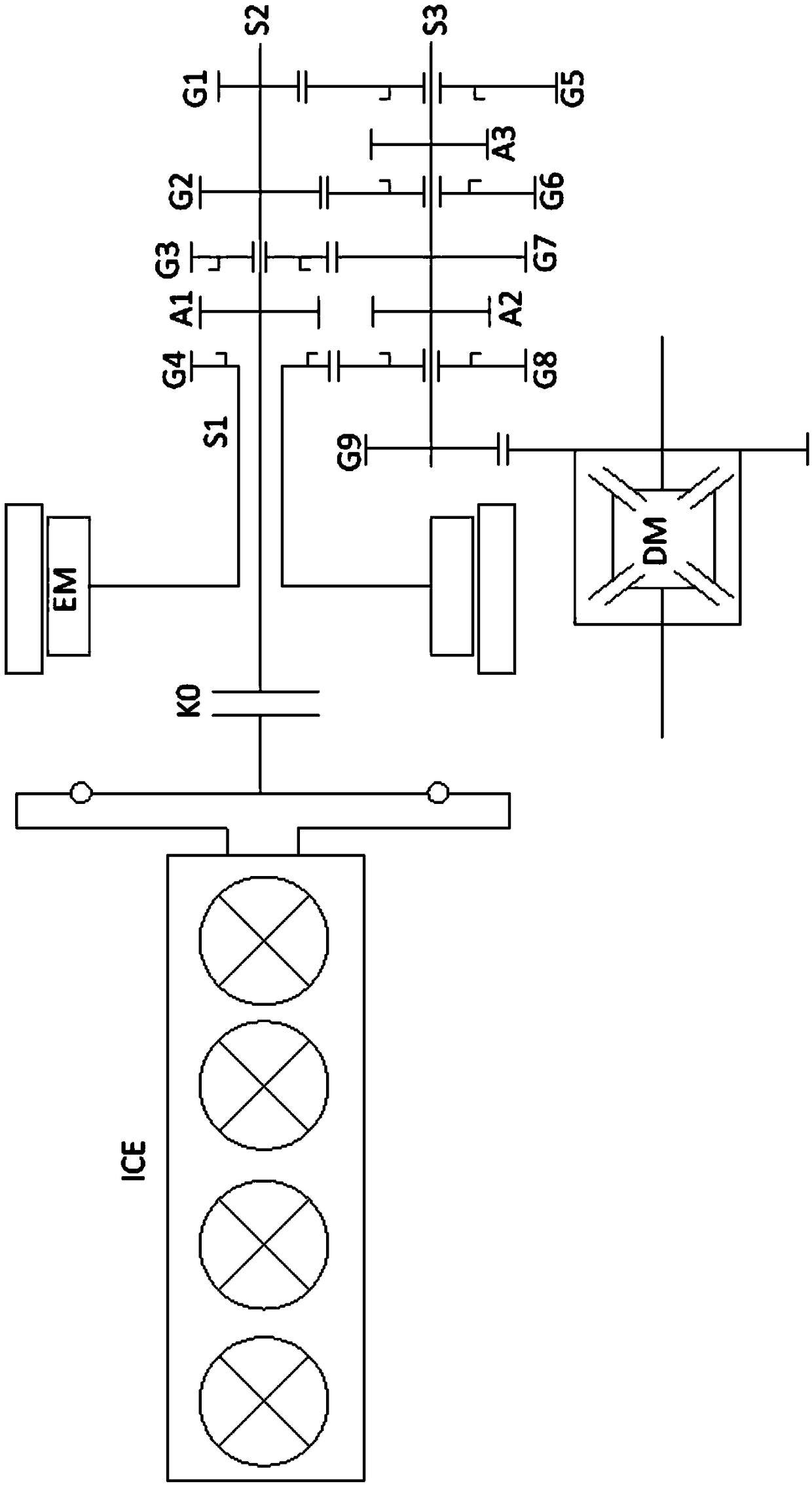

The invention discloses a vehicle hybrid power system and a control method thereof. The system involves an engine, a hybrid power module and a double-input-shaft speed change mechanism, wherein the hybrid power module is composed of a motor, a planetary gear train and a first clutch, the planetary gear train is provided with at least three rotating shafts, the three rotating shafts comprise a rotating shaft X1, a rotating shaft X2 and a rotating shaft X3, axes of the three rotating shafts are on one straight line, the rotating speed of the rotating shaft X2 is between the rotating speed of therotating shaft X1 and the rotating speed of the rotating shaft X3, a first clutch is arranged between any two of the three rotating shafts, a power output shaft of the engine is connected with the rotating shaft X3 or the rotating shaft X1 of the planetary gear train and a second input shaft of the double-input-shaft speed change mechanism, a rotor of the motor is connected with the rotating shaft X1 or the rotating shaft X3, and the rotating shaft X2 is connected with a first input shaft of a double-input-shaft gearbox. According to the system and the method, the transmission efficiency is high, multiple gears are provided, the three-axis double-freedom-degree planetary gear train is introduced, a vehicle is driven to start by the differential between the engine and the motor, starting of the vehicle is stable, the smoothness of gear shifting is good, and the impact of gear shifting is small.

Owner:段志辉

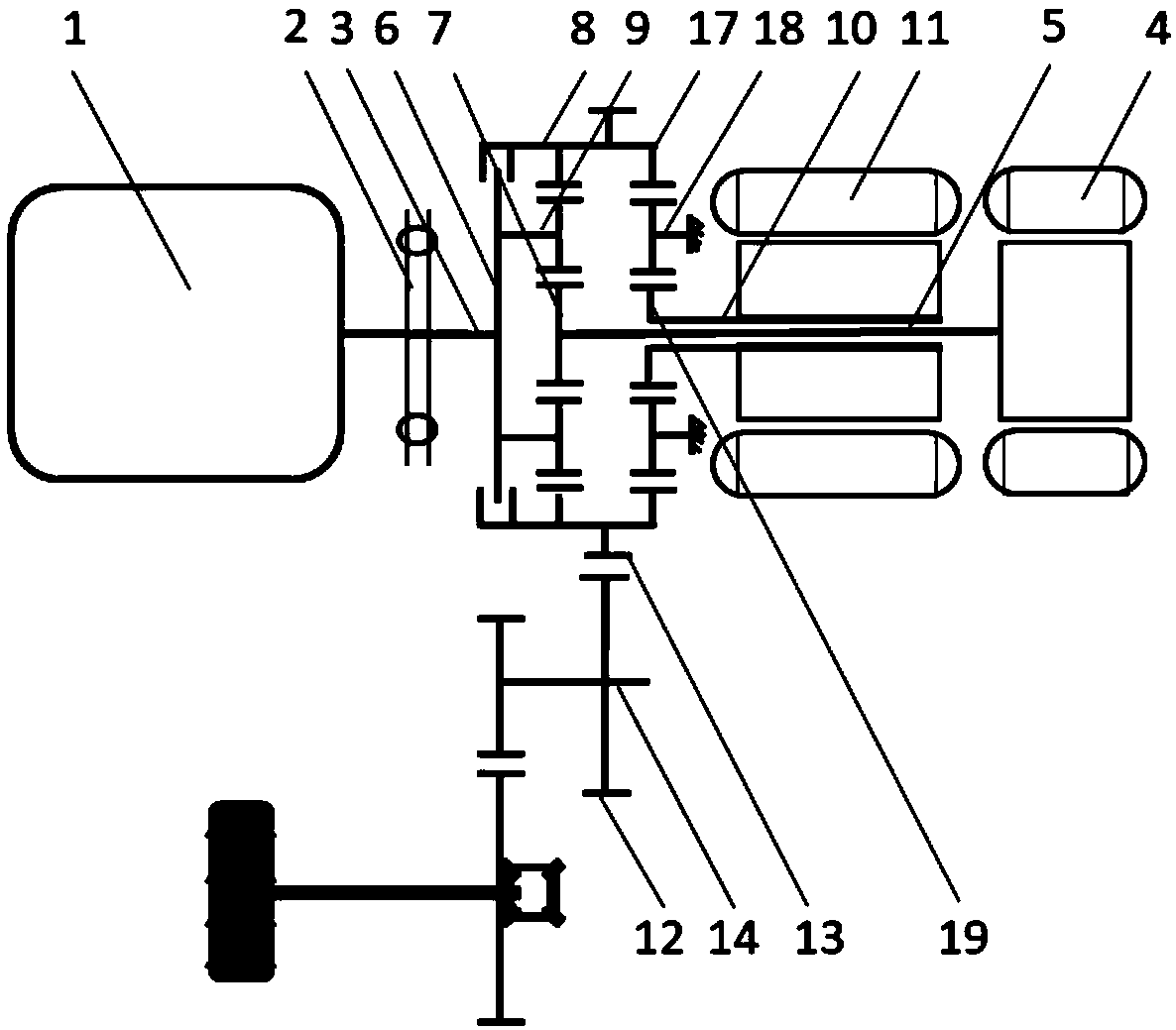

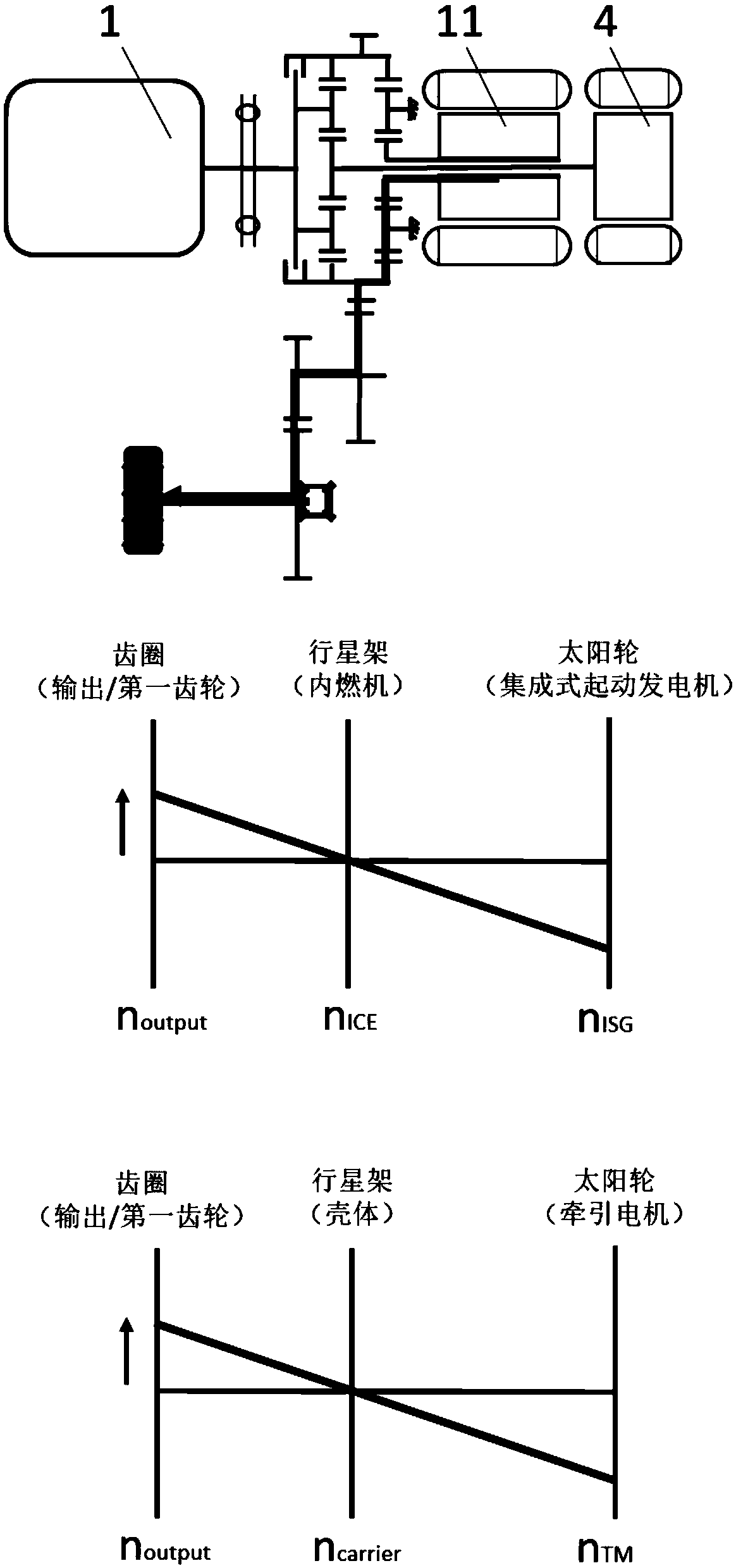

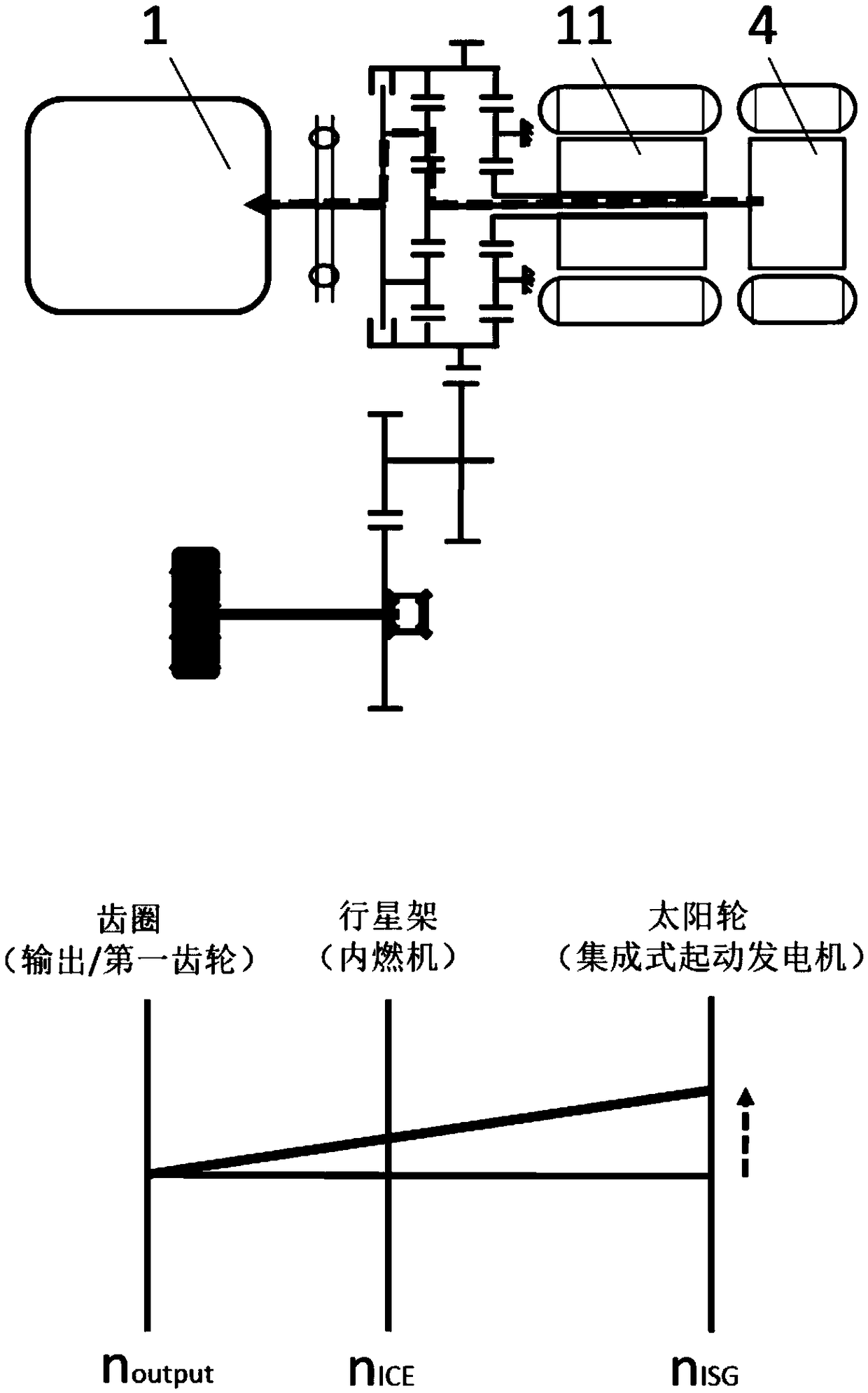

Hybrid power module and vehicle

InactiveCN108944411AAchieve primary transmissionEasy to manufactureHybrid vehiclesGas pressure propulsion mountingTransmitted powerComputer module

The invention relates to a hybrid power module and a vehicle. The hybrid power module comprises a hybrid power speed changer, a first motor and a second motor, wherein the hybrid power speed changer comprises an input shaft connected with an internal combustion engine, a first planetary gear mechanism, a clutch device and an output shaft. The input shaft is connected with a planet carrier in a torsion resistance mode, and a first motor shaft of the first motor is connected with a sun wheel in a torsion resistance mode. A gear ring can transmit power to the output shaft, and the second motor can output the power to the output shaft through a second motor shaft, wherein the first end and the second end of the clutch device are correspondingly connected with the planet carrier and the gear ring in a torsion resistance mode, the first planetary gear mechanism, the first motor and the second motor are arranged coaxially, and the first motor and the second motor are located on the side, faraway from the internal combustion engine, of the first planetary gear mechanism. The second motor shaft is a hollow shaft, and the first motor shaft penetrates through the second motor shaft coaxially. The vehicle is provided with the hybrid power module.

Owner:SCHAEFFLER TECH AG & CO KG

Multi-gear automatic transmission

InactiveCN105114558AMany gearsEfficient gradingToothed gearingsTransmission elementsAutomatic transmissionEngineering

The invention discloses a multi-gear automatic transmission, and belongs to the technical field of automatic transmissions. The problems that in an existing automatic transmission technology, the number of members is large, the structure is complex, and particularly it is difficult to provide a transmission ratio series which is slightly progressive and well graded and good in meshing efficiency are solved. The multi-gear automatic transmission comprises a first planet wheel set, a second planet wheel set, a third planet wheel set and a fourth planet wheel set and six gear shift switching elements, wherein the first planet wheel set, the second planet wheel set, the third planet wheel set and the fourth planet wheel set are sequentially arranged along a main rotating shaft front and back, and the gear shift switching elements are allowed to be selectively operated to form nine forward gears and one reverse gear between an input shaft and an output shaft of the transmission; the input shaft and a fourth shaft are connected through a first clutch in the mode of being capable of loosening, the fourth shaft is connected with a first sun wheel and a second sun wheel, the fourth shaft and a third shaft are connected through a second clutch in the mode of being capable of loosening, the third shaft is connected with a first planet rack and connected to a shell through a first brake, and the input shaft and a fifth shaft are connected through a third clutch in the mode of being capable of loosening.

Owner:ZHAOQING UNIV

Multi-gear transmission with planet gear structure mode

InactiveCN105114562AReduce loadMany gearsToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention discloses a multi-gear transmission with a planet gear structure mode, and belongs to the technical field of automatic transmissions. The multi-gear transmission solves the problems that in the prior art of the automatic transmissions, more elements and a complex structure exist, and especially, a slightly progressive well graded transmission ratio series and the good meshing efficiency are difficult to supply. The multi-gear transmission comprises a first planet gear set, a second planet gear set, a third planet gear set and a fourth planet gear set which are sequentially arranged front and back along a main rotation shaft and six gear shifting elements, and the gear shifting elements are allowed to be selectively controlled, so that nine forward gears and one reverse gear are formed between an input shaft and an output shaft of the transmission; the input shaft is separably connected with a fifth shaft through a first clutch, and the fifth shaft is connected with a first sun gear and a second sun gear and connected to a shell through a first brake; the input shaft is separably connected with a fourth shaft connected to a first gear ring through a second clutch and connected with a third shaft through a third clutch; the output shaft is connected with a fourth planet carrier.

Owner:ZHAOQING UNIV

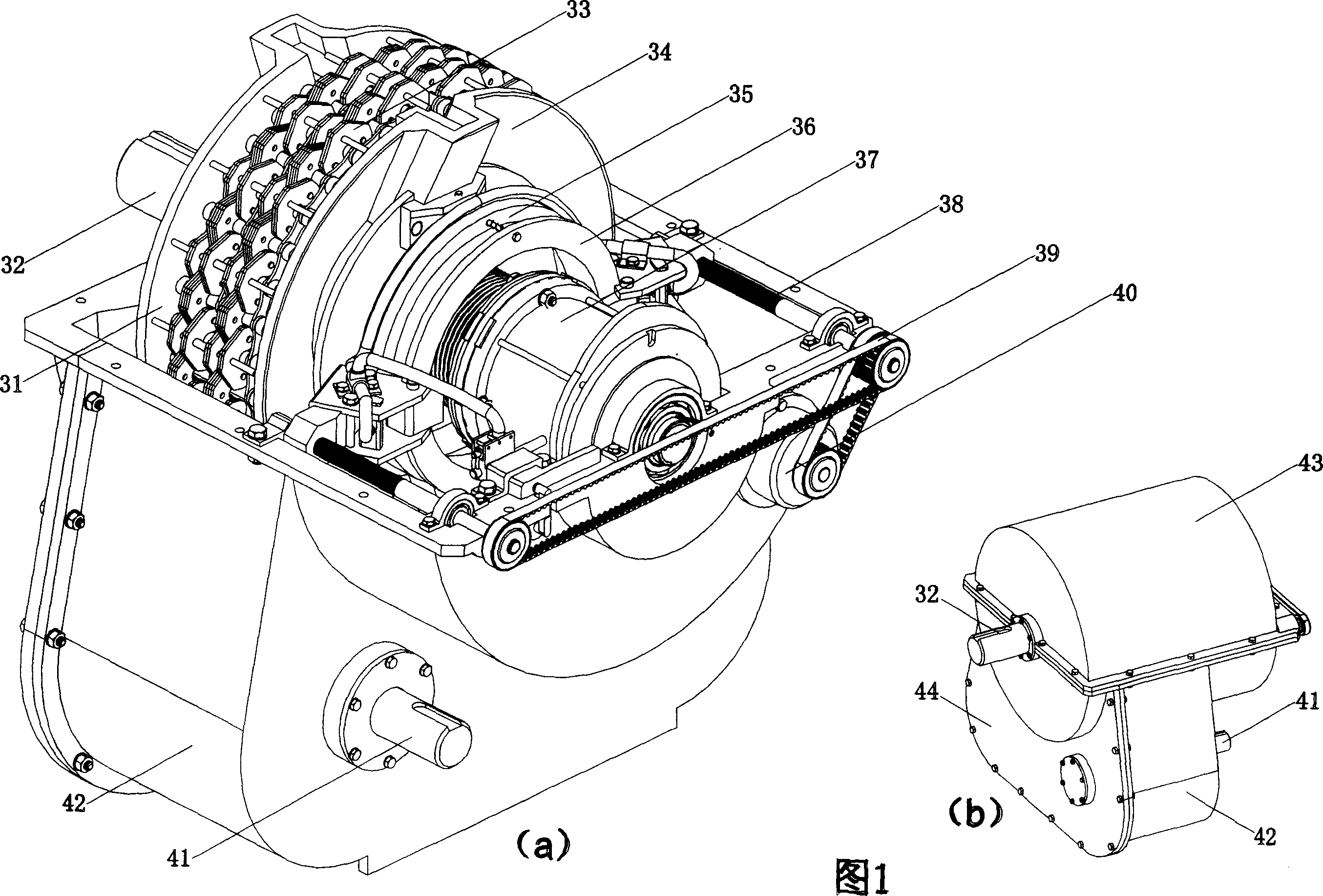

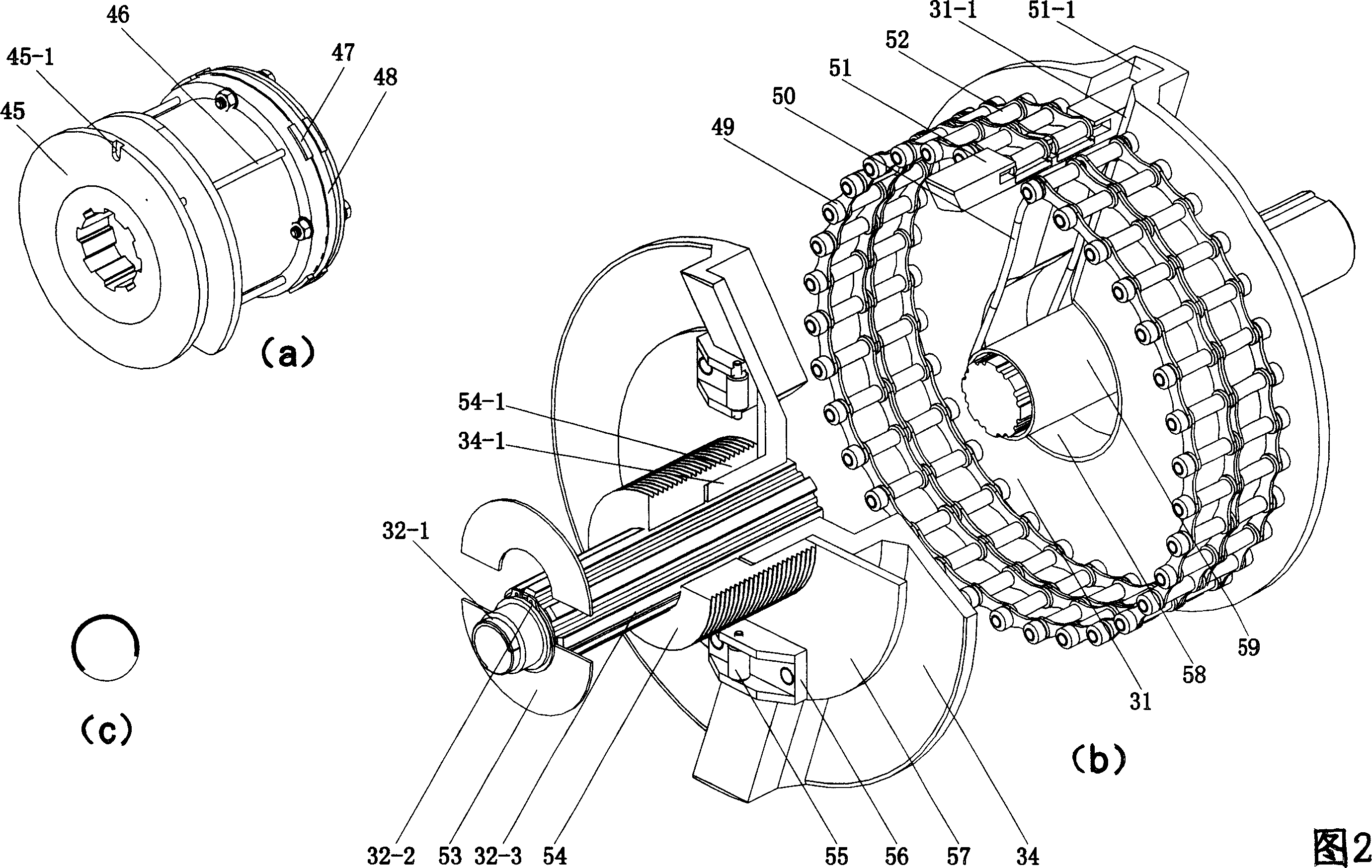

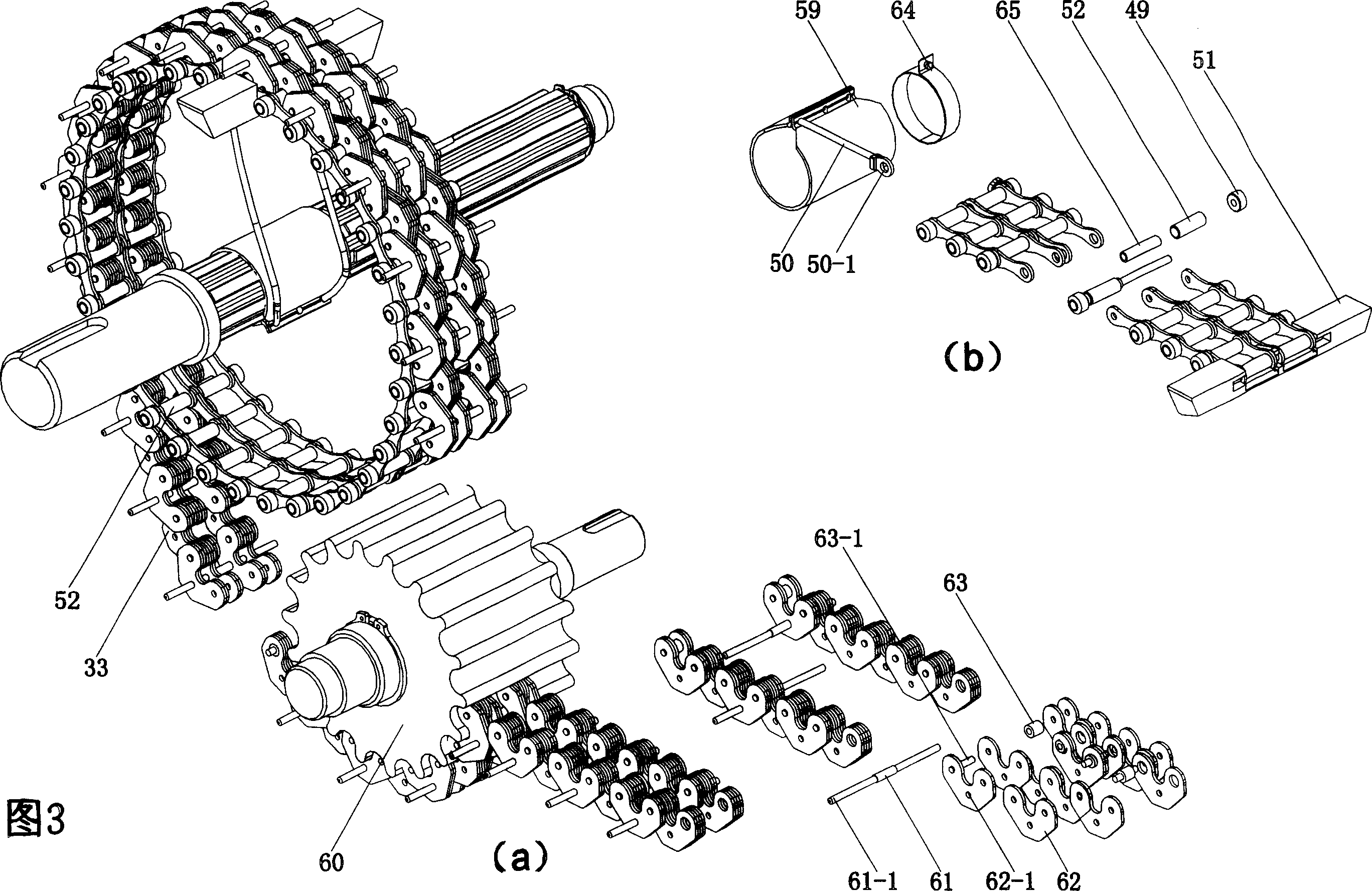

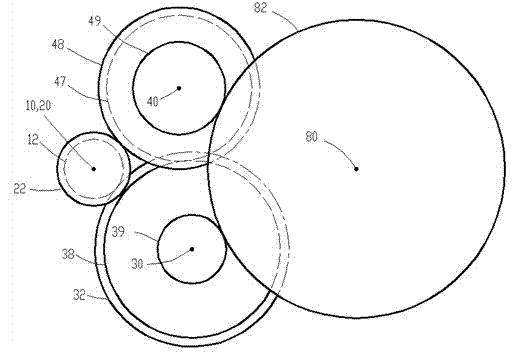

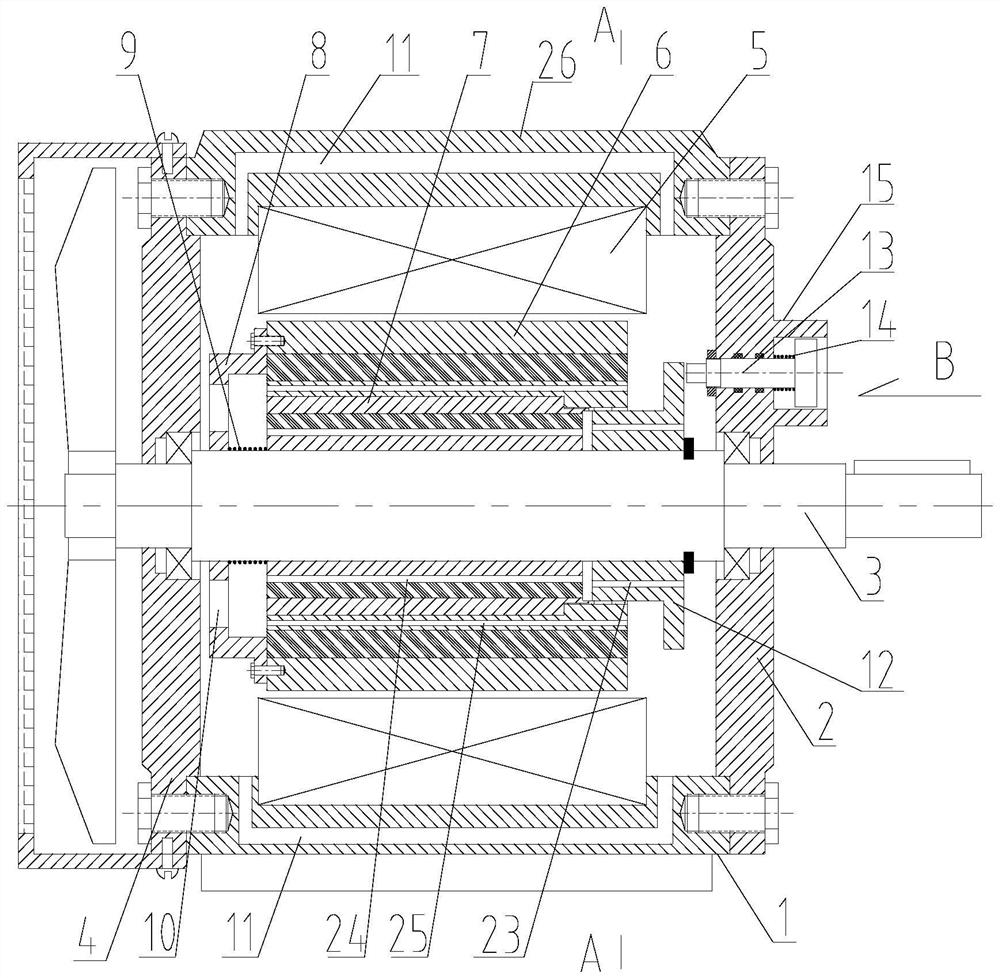

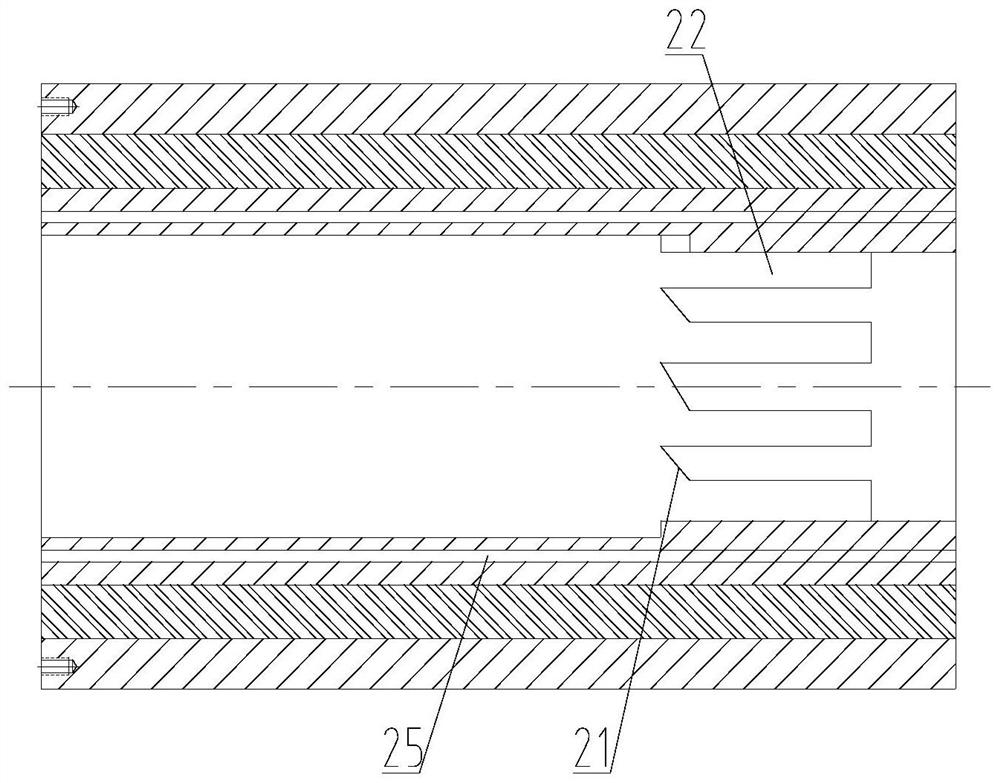

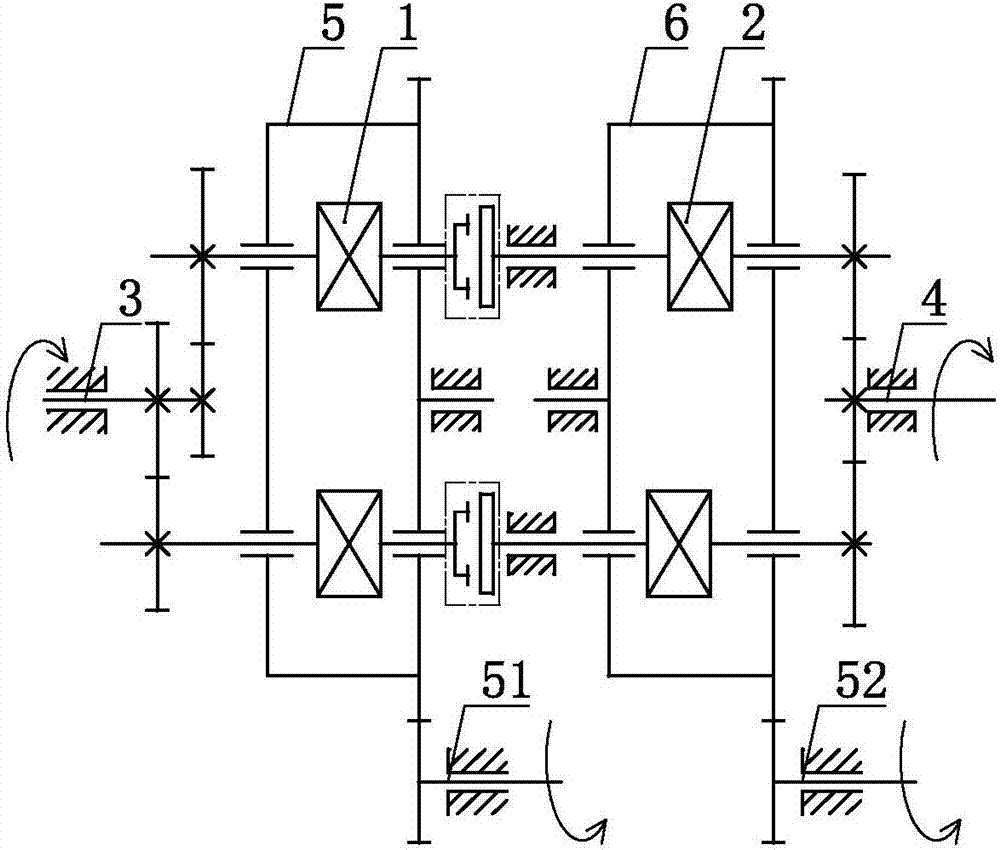

Double-layer planet gear train speed changer

The invention relates to a double-layer planet gear train speed changer. The speed changer utilizes the motion combination of a hydraulic or electronic-controlled wet type multi-gear clutch and a bandbrake to synthesize the motive power and rotation speed of an input shaft through a double-layer planet gear train and then output the synthesized motive power and rotation speed from an output shaftso as to make the speed changer have 10 forward gears and one reverse gear. The speed changer is easy to automatically control, can achieve the effect of stepless speed change, and improves economy and dynamic properties of vehicles.

Owner:熊涔博

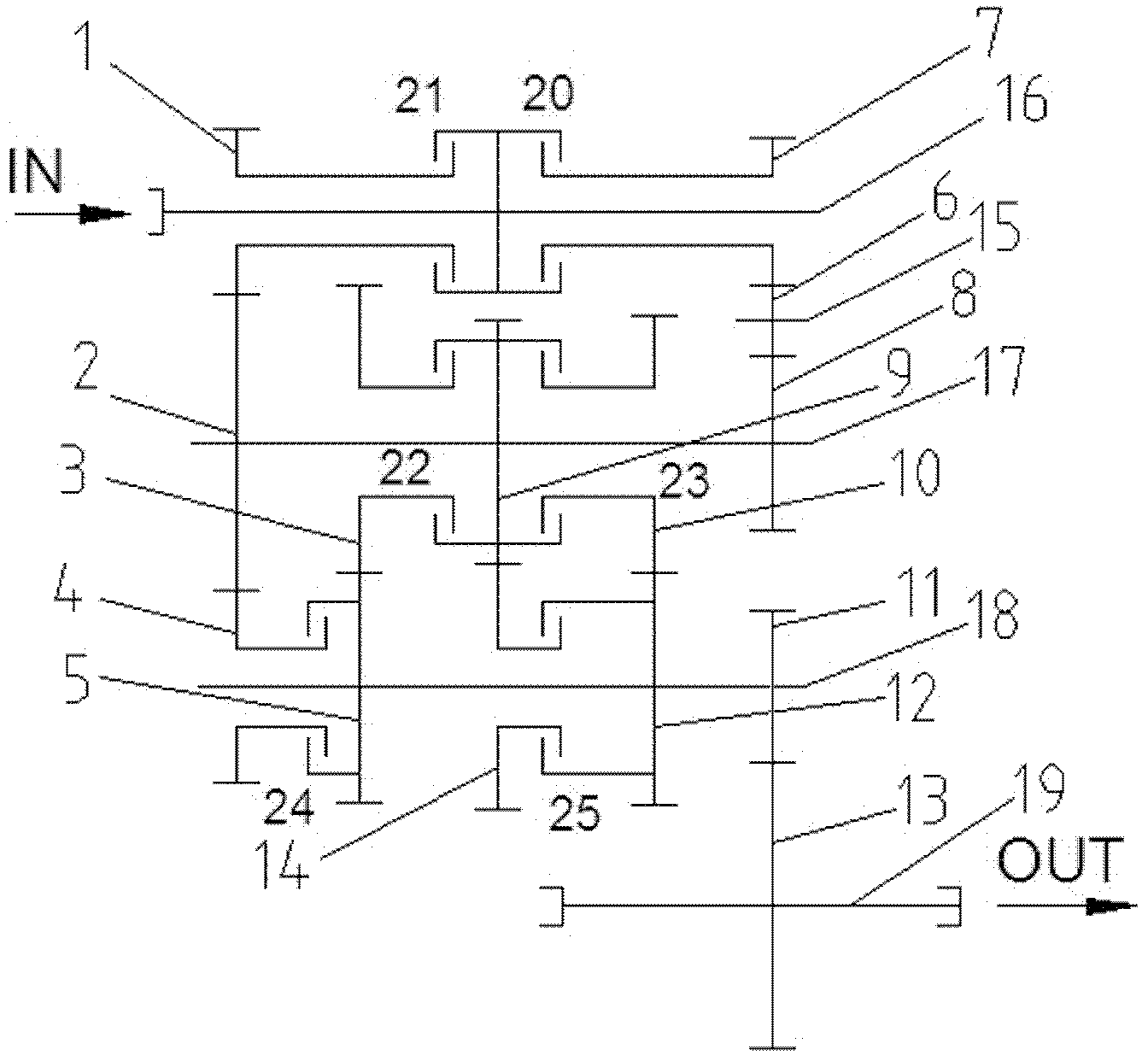

Automatic gear transmission

InactiveCN109372956AReduce volumeSimple structureToothed gearingsTransmission elementsAutomatic transmissionMultiple sensor

The invention discloses an automatic gear transmission for a motor vehicle. A linear stepping motor, spline synchronizers and multiple sensors are used in the automatic gear transmission for the firsttime. The automatic gear transmission can achieve the aim of precise synchronization in the gear shift process. The automatic gear transmission has the advantages that the automatic synchronization process is fast and free of friction; the number of spline teeth of the spline synchronizers is low, operation is simple and reliable, and machining and assembling are easy; and the number of the adopted spline synchronizers is low. If two-stage speed changing is adopted in the transmission, only two spline synchronizers are adopted, and the total number of transmission gears can be dozens. The number of gears of the gear transmission can be increased or decreased by increasing or decreasing the number of pairs of gears. The effect of stepless speed changing can be obtained as long as the number of the gears is large enough.

Owner:夏元峰

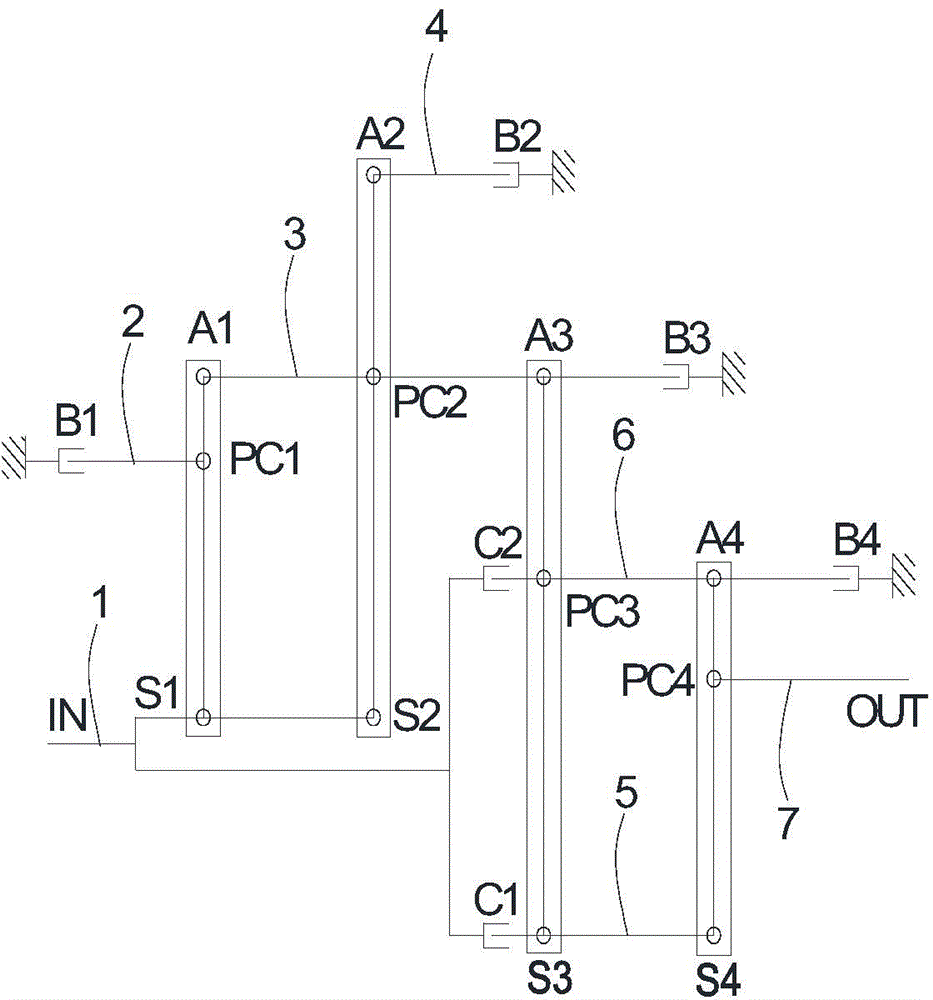

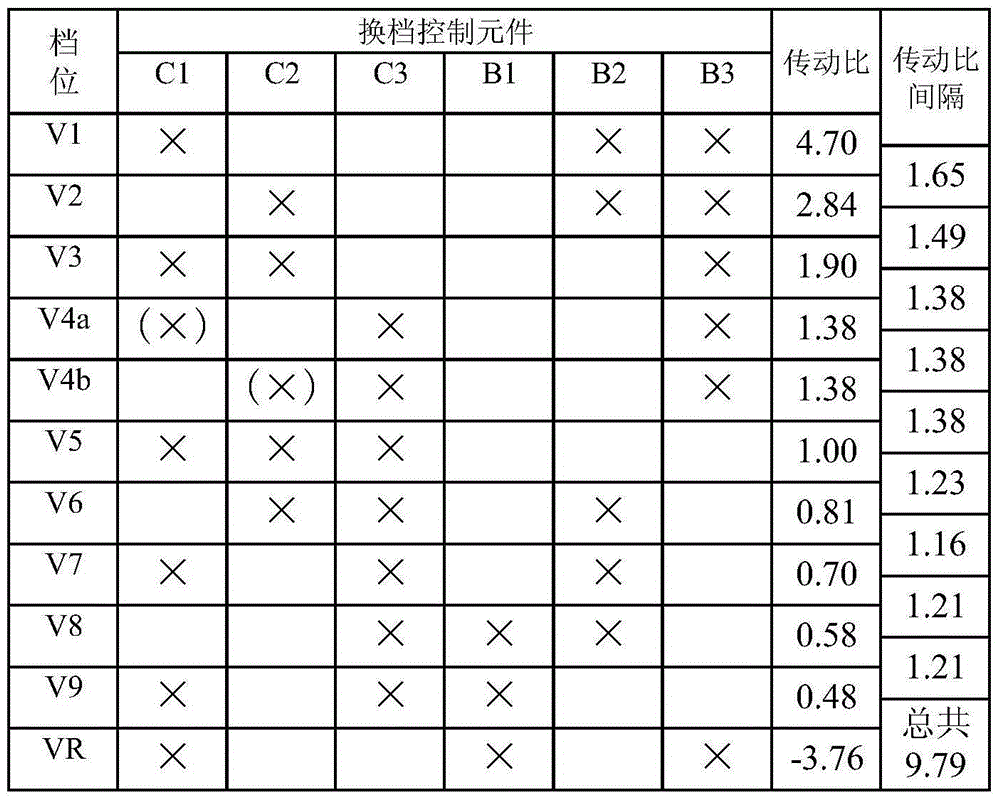

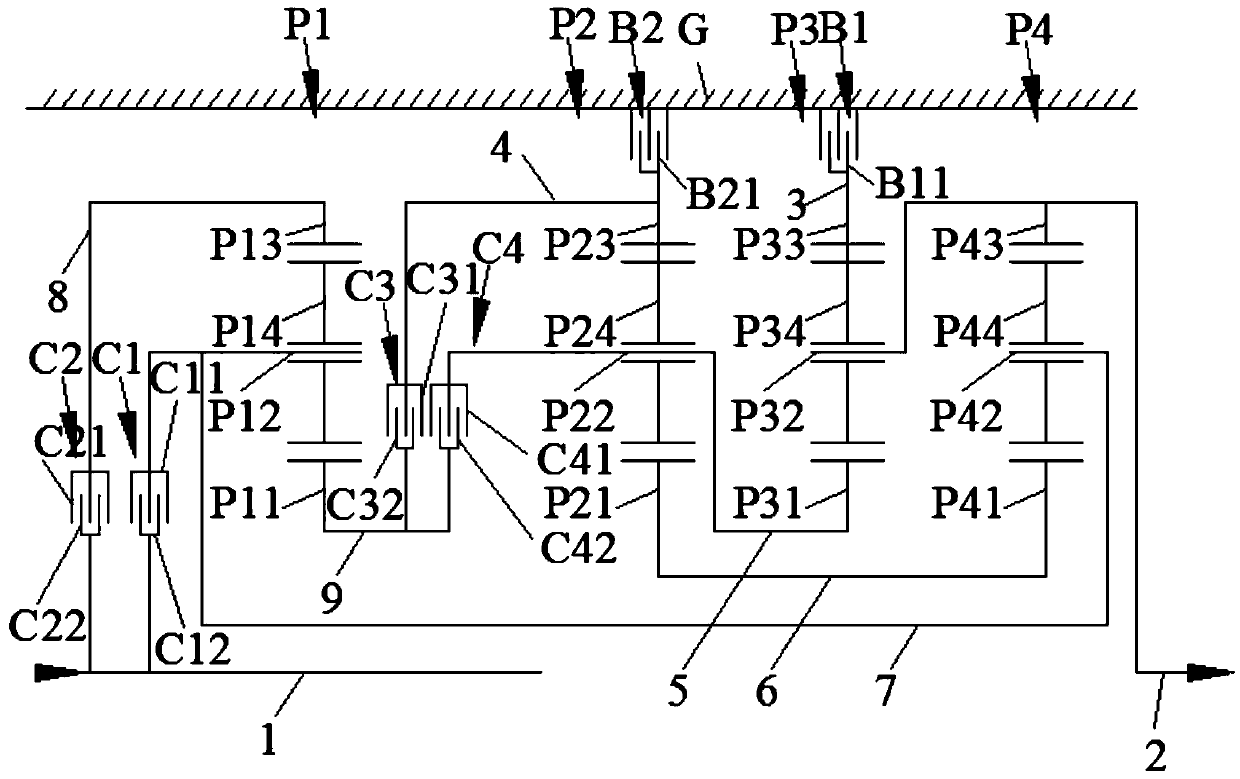

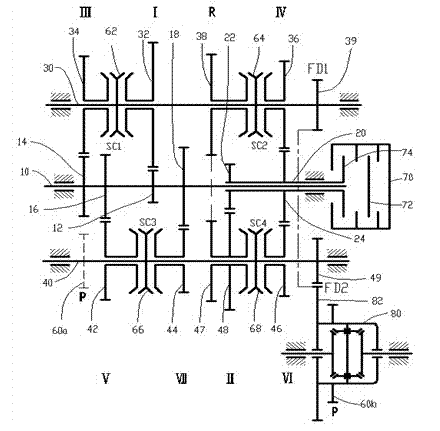

Automatic transmission and planetary gear train thereof

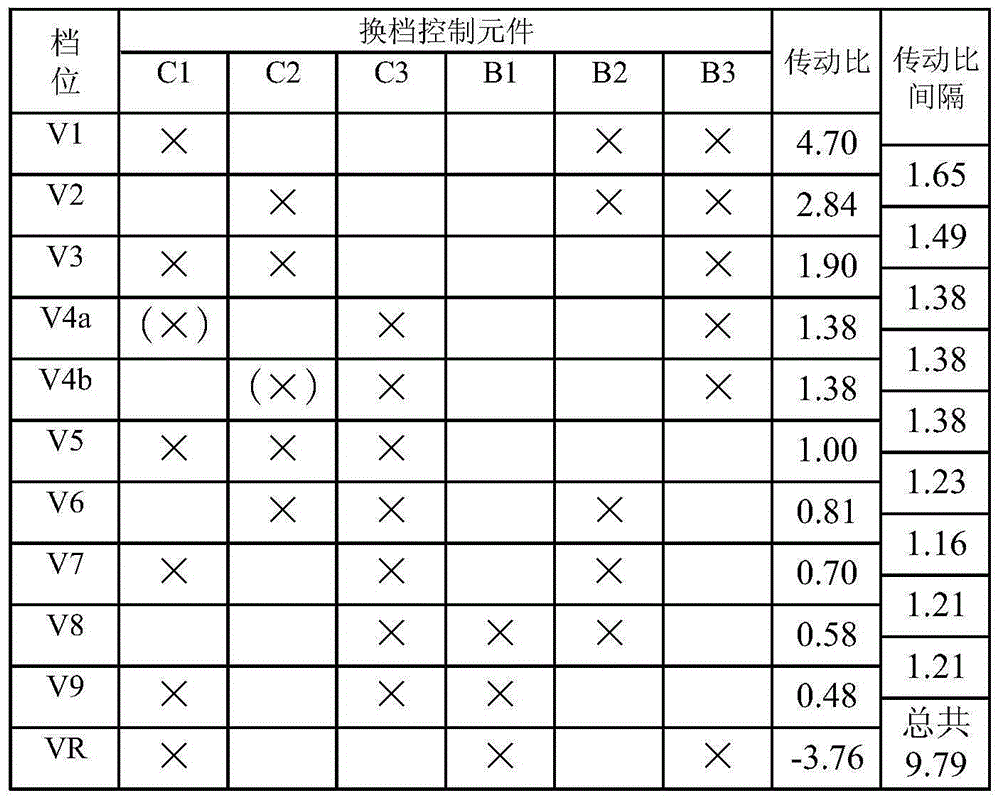

ActiveCN105485271AImprove power transmission performanceImprove fuel economyToothed gearingsGearing detailsAutomatic transmissionGear wheel

The invention discloses a planetary gear train used for an automatic transmission. At least eight forwarding gears and at least two reversing gears can be obtained, and the planetary gear train comprises a first planet row, a second planet row, a third planet row and a fourth planet row. Each planet row is provided with a sun gear, a planetary frame and a gear ring; eight rotating bodies can be jointly formed by assemblies of the planet rows and connecting components; a gear shifting assembly comprises three clutches and three brakes, and the clutches are arranged between selected rotating bodies in the rotating bodies; and the brakes are arranged between the selected rotating bodies in the rotating bodies and fixing parts. The planetary gear train can have more gears and the more optimized speed ratio; the power transmission performance and the fuel economy of a vehicle can be obviously improved, the length is shorter, the whole design is more compact, and the requirements of the vehicle for durability, the power transmission rate, the size, the cost and the like of the transmission can be met well. The invention further discloses the automatic transmission provided with the planetary gear train.

Owner:西安双特智能传动有限公司

Multi-gear planetary gear transmission

ActiveCN111536211AWide transmission ratio rangeWide range of speed ratioToothed gearingsTransmission elementsClutchGear transmission

The invention discloses a multi-gear planetary gear transmission, which comprises eight rotating shafts, five brakes, two clutches and five planetary lines, wherein five simple minus planetary lies and seven gear shifting elements (including five brakes and two clutches) are adopted; the two clutches are arranged at the front end of the transmission rather than the middle part of the transmission,and the oil supply is very convenient; the five brakes are included, a large number of brakes are arranged and can be embedded with the planetary lines, the pressure oil can be directly fed into thebrakes from a box body, and the structure layout is more compact; the two gear shifting elements are closed at each gear, twelve forward gears and one reverse gear can be achieved, more gears are provided, and the range of transmission ratio is wider.

Owner:BEIHANG UNIV

Diameter-variable driving wheel and full-automatic micro-shift transmission

InactiveCN1880804ADensely distributedEvenly distributedGearingPortable liftingTransmission beltEngineering

The invention relates to a reducing transmission wheel and full-automatic micro-shift speed changer, wherein said transmission device is formed by a reducing transmission wheel, a middle transmission belt and relative shift device; the wheel draws coil to be working surface of reducing transmission wheel, while the part not in transmission is coiled at the wheel center; the wheel draw belt and the transmission belt form the meshed transmission couple; the transmission wheel, via the drawing support that moving inside the radial slide groove of taper transmission disc, transmit torque; the position of drawing support decides the size of node circle radius of transmission wheel; the reducing wheel via the expanding device and the reducing device realizes the change of node circle of transmission wheel; said transmission device utilizes the change of node circle to realize speed-variable transmission. The invention can be used in the working mechanism with frequent transmission ratio change.

Owner:张惠东

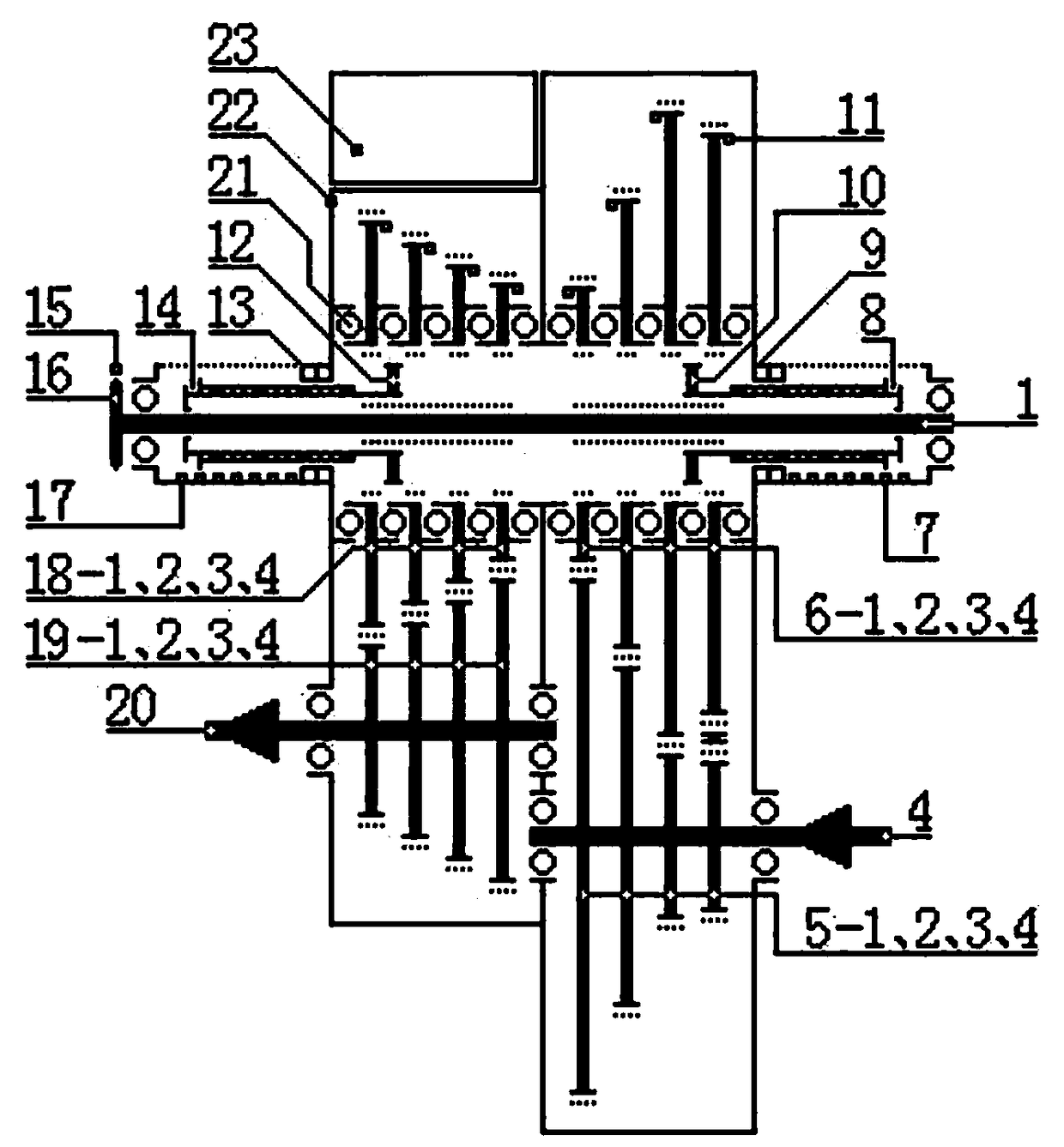

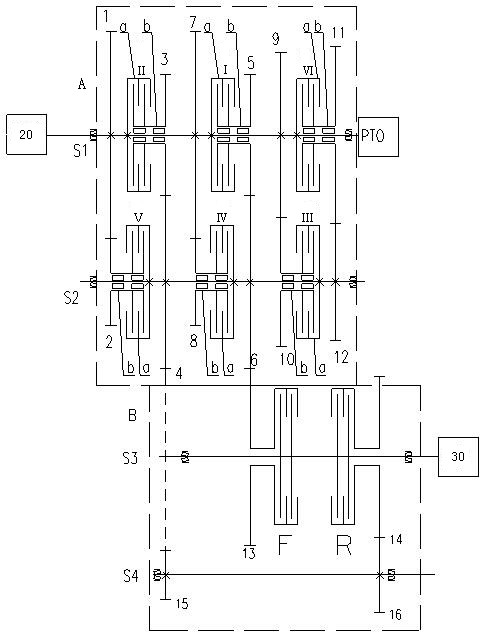

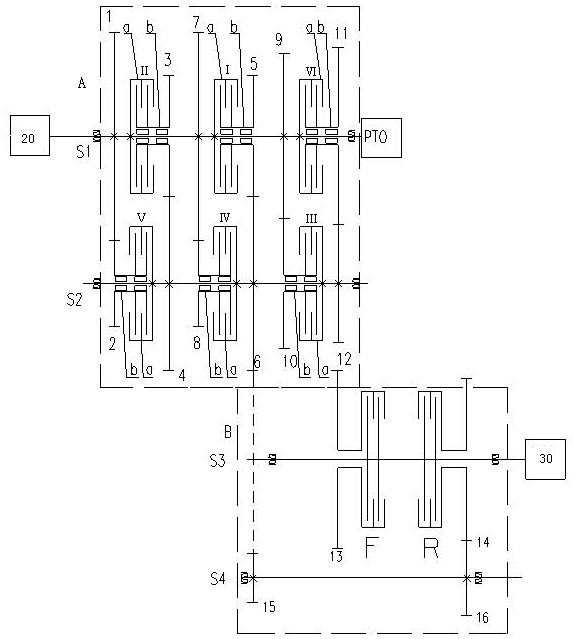

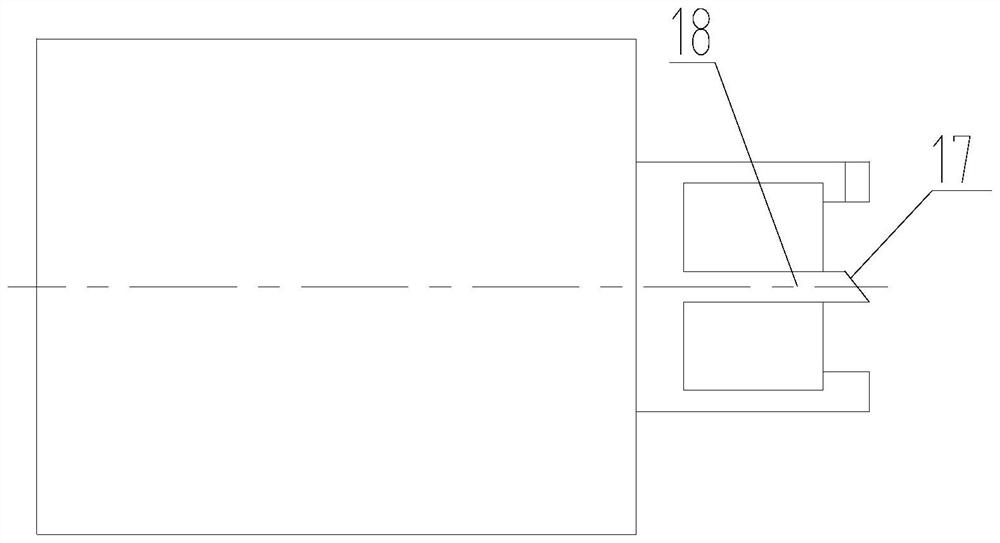

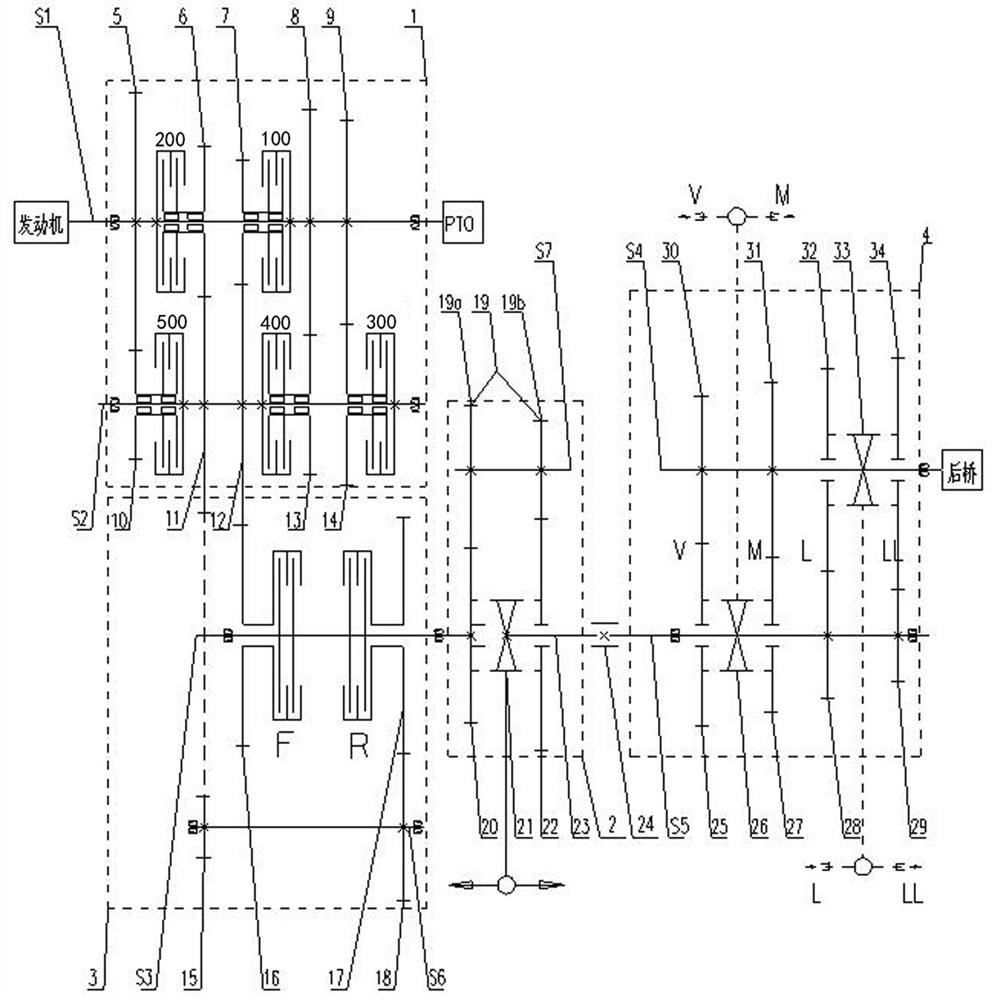

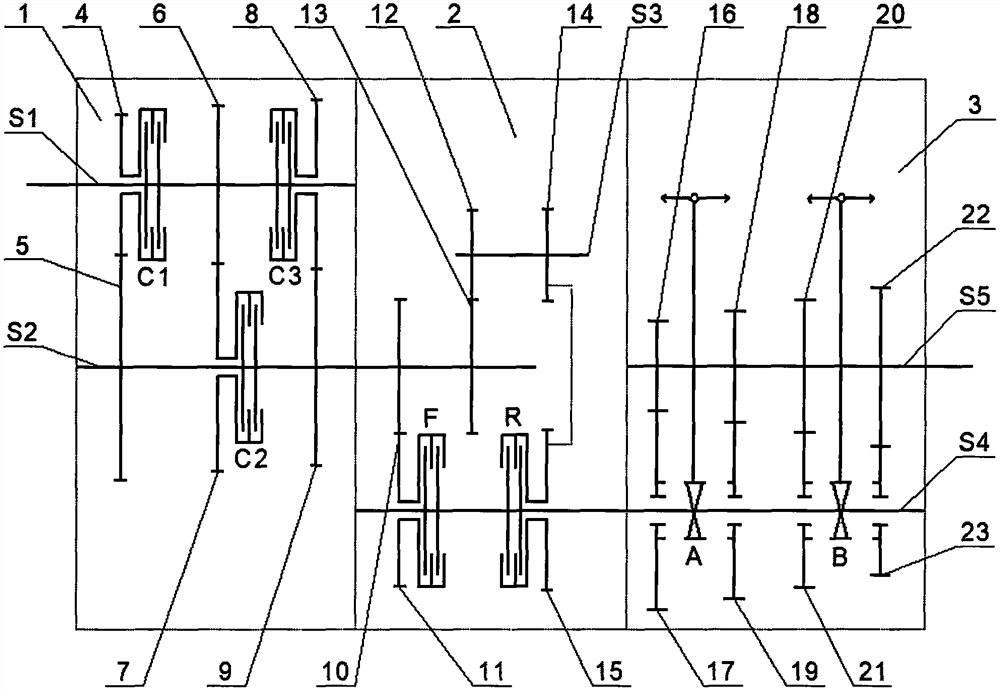

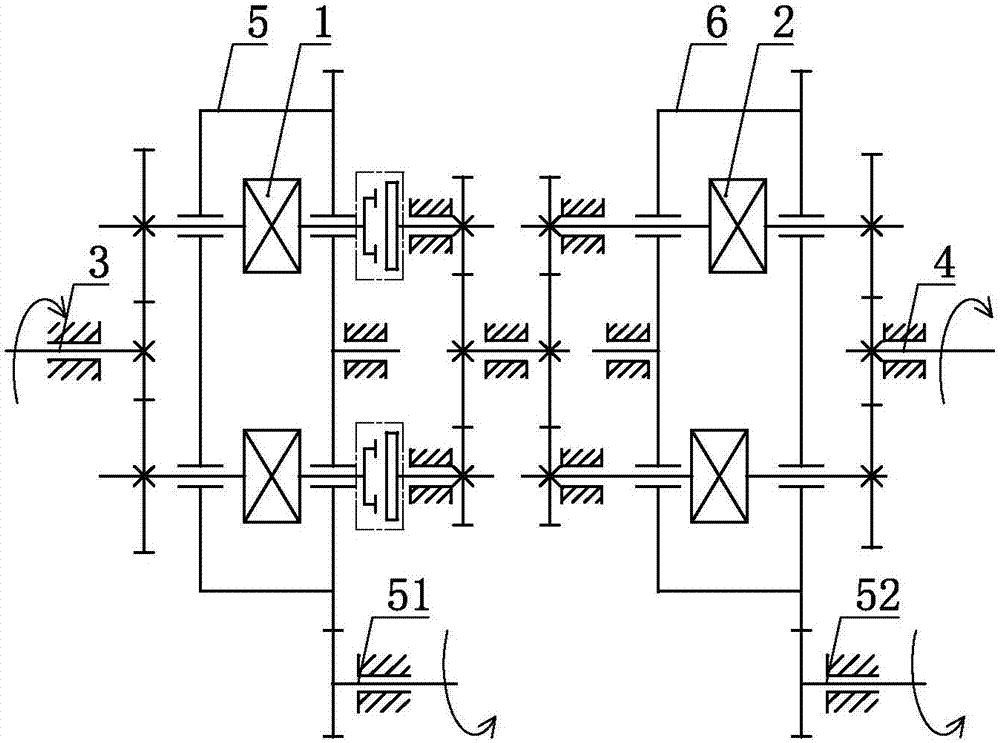

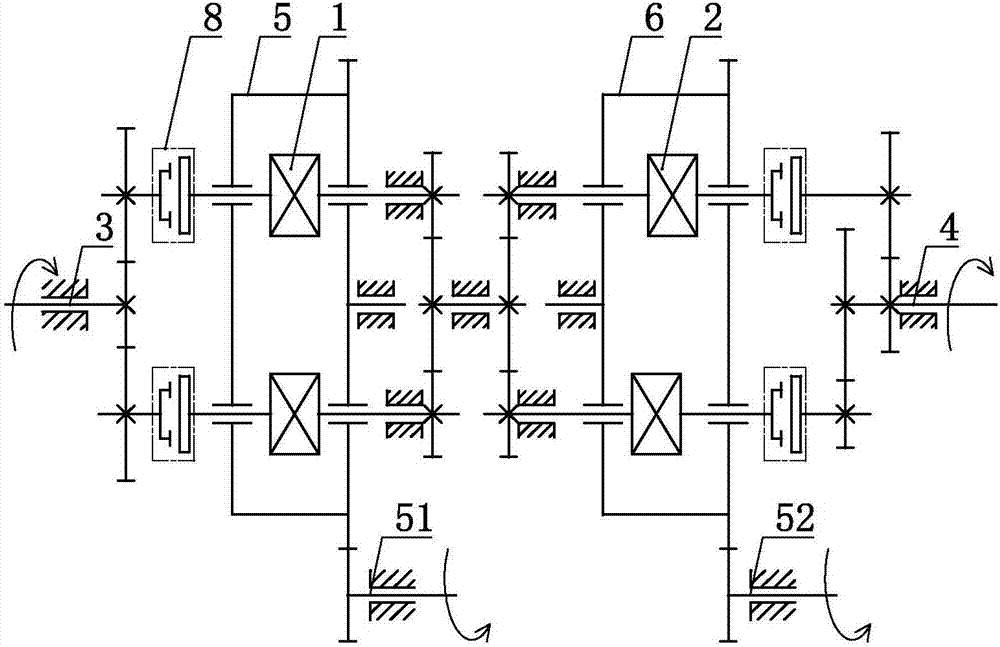

Tractor power gear shifting and power reversing transmission device

PendingCN112664623AImprove transmission efficiencySimple logic controlGearboxesToothed gearingsGear wheelControl theory

A tractor power gear shifting and power reversing transmission device comprises a power gear shifting module and a power reversing module, wherein the power gear shifting module comprises an input shaft and an output shaft; a plurality of clutches are mounted on the input shaft and the output shaft according to the number of gears; a plurality of meshed gears I are also arranged on the input shaft and the output shaft; the front end of the input shaft is in transmission connection with an engine; the rear end of the input shaft is connected with a tractor PTO device; the power reversing module comprises a reversing shaft and an idler shaft; the reversing shaft is provided with a forward clutch, a backward clutch and a gear II; the gear II is connected with both the forward clutch and the backward clutch; the rear end of the reversing shaft is connected with an auxiliary variable-speed driving shaft of a rear box body of a gearbox; two gears III are fixedly arranged on the idler shaft to form two-stage transmission; the power gear shifting module and the power reversing module are in gear-meshing transmission with each other; and the input shaft, the output shaft, the reversing shaft and the idler shaft are arranged by the adoption of parallel space. The tractor power gear shifting and power reversing transmission device has the advantages that the gear shifting time is short; the number of the gears is large; and the repairing and the maintenance are convenient.

Owner:FIRST TRACTOR

Nine-gear automatic transmission

ActiveCN109372959AReduce loadMany gearsToothed gearingsTransmission elementsAutomatic transmissionElectrical and Electronics engineering

The invention discloses a nine-gear automatic transmission, belongs to the technical field of automatic transmissions, solves the problems that in the existing automatic transmission technology, morecomponents and a complicated structure are provided, particularly a transmission ratio series which is slightly progressive and is excellent in grading is difficult to be provided and the transmissionratio range is large. The nine-gear automatic transmission comprises four planet wheel sets sequentially arranged front and back along a main rotary shaft, nine rotatable shafts, two brakes and fourclutches, and six gearshift switching elements are provided in total; the gearshift switching elements allow to be selectively controlled, so that nine forward gears and one reverse gear are formed between the input shaft and the output shaft of the transmission; the input shaft is detachably connected with a sixth shaft connected with a fourth planet carrier via the first clutch and is detachablyconnected with a ninth shaft connected with a second sun wheel via the second clutch; a third shaft connected with a first sun wheel is detachably connected via the first brake; and the output shaftis connected with a fourth gear ring.

Owner:ZHAOQING UNIV

Nine-speed automatic transmission of automobiles

The invention discloses a nine-speed automatic transmission of automobiles, and belongs to the technical field of automatic transmissions. The problems that the complicated structure in the existing automatic transmission technology is difficult to provide slightly gradual, well-graded transmission ratio series and a large transmission ratio range particularly are overcome. The nine-speed automatic transmission of the automobiles includes four planet gear sets arranged front and back along a main rotating shaft in sequence, nine rotatable shafts, two brakes and four clutches; the six shiftingswitching elements allow selectively to be manipulated, so that nine forward gears and one reverse gear are formed between an input shaft and an output shaft the transmission; the input shaft is connected with a seventh shaft in a loosened mode through a first clutch, and the seventh shaft is connected with a first planet carrier and a fourth planet carrier; the input shaft is connected with an eighth shaft in a loosened mode through a second clutch, and the eighth shaft is connected with a first gear ring; and a third shaft is connected with a third gear ring and connected with a shell through a first brake, and a fourth shaft is connected with a second gear ring and connected with the shell through a second brake; and the output shaft is connected with a third planet carrier and a fourthgear ring.

Owner:彭建新

Dynamic power shifting transmission

InactiveCN102537228AReasonable speed ratioSimple and efficient operationToothed gearingsClutchVariator

Owner:XIAMEN UNIV

Double-clutch automatic gearbox transmission device

InactiveCN103711877AControl Axial DimensionsIncrease freedomToothed gearingsTransmission elementsAutomatic transmissionGear drive

The invention relates to a double-clutch automatic gearbox transmission device for vehicles. The double-clutch automatic gearbox transmission device structurally comprises an inner input shaft, an outer input shaft, two auxiliary shafts, two clutches, a differential assembly, a plurality sets of normally engaged gears and a synchronizer, wherein the inner input shaft is coaxial with the outer input shaft, and the two auxiliary shafts are parallel with the two input shafts. A first-gear driven gear and a reverse-gear driven gear are disposed on the same auxiliary shaft, the main reducing drive gear on the auxiliary shaft is the one, with low tooth number, of the two main reducing drive gears, and accordingly a double-clutch automatic gearbox is allowed to have large reverse gear transmission ratio, and high reverse gear safety is achieved. The fourth gear and the sixth gear share a drive gear. The second-gear driven gear directly drives the reverse-gear driven gear. The first-gear gear set and the second-gear gear set which serve as low-speed gears are disposed at the position, away from the shaft end, of the shafting of the gearbox. The pinion process size is used to the maximum extent, the double-clutch automatic gearbox is allowed to be small in axial size. The transmission device is simple and compact in structure, small in axial size, large in gear transmission ration freedom degree, and the like.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Vehicle automatic transmission of planet gear structural mode

ActiveCN109340327AMany gearsEfficient gradingToothed gearingsTransmission elementsVariatorElectrical and Electronics engineering

The invention discloses a vehicle automatic transmission of a planet gear structural mode, and belongs to the technical field of automatic transmissions. The problems that existing automatic transmission technologies have a large number of components and a complex structure, especially, a slightly gradual and well-graded transmission ratio series is difficult to provide, and the transmission ratiorange is large are solved. The vehicle automatic transmission comprises four planet gear sets which are successively arranged front and back along a main rotary shaft, nine rotating shafts, two brakes and four clutches; the total six gear shifting switch components are included and are allowed to be selectively operated so that nine forward gears and one reverse gear can be formed between an input shaft and an output shaft of the transmission; an input shaft is connected with a sixth shaft connected with a fourth planet carrier through the first clutch in a releasable mode and is connected with a ninth shaft connected with a fist sun wheel through the second clutch in a releasable mode; a seventh shaft is connected with a second sun wheel and a third sun wheel and is connected to a shellthrough the second brake; and the output shaft is connected with a fourth gear ring.

Owner:ZHAOQING UNIV

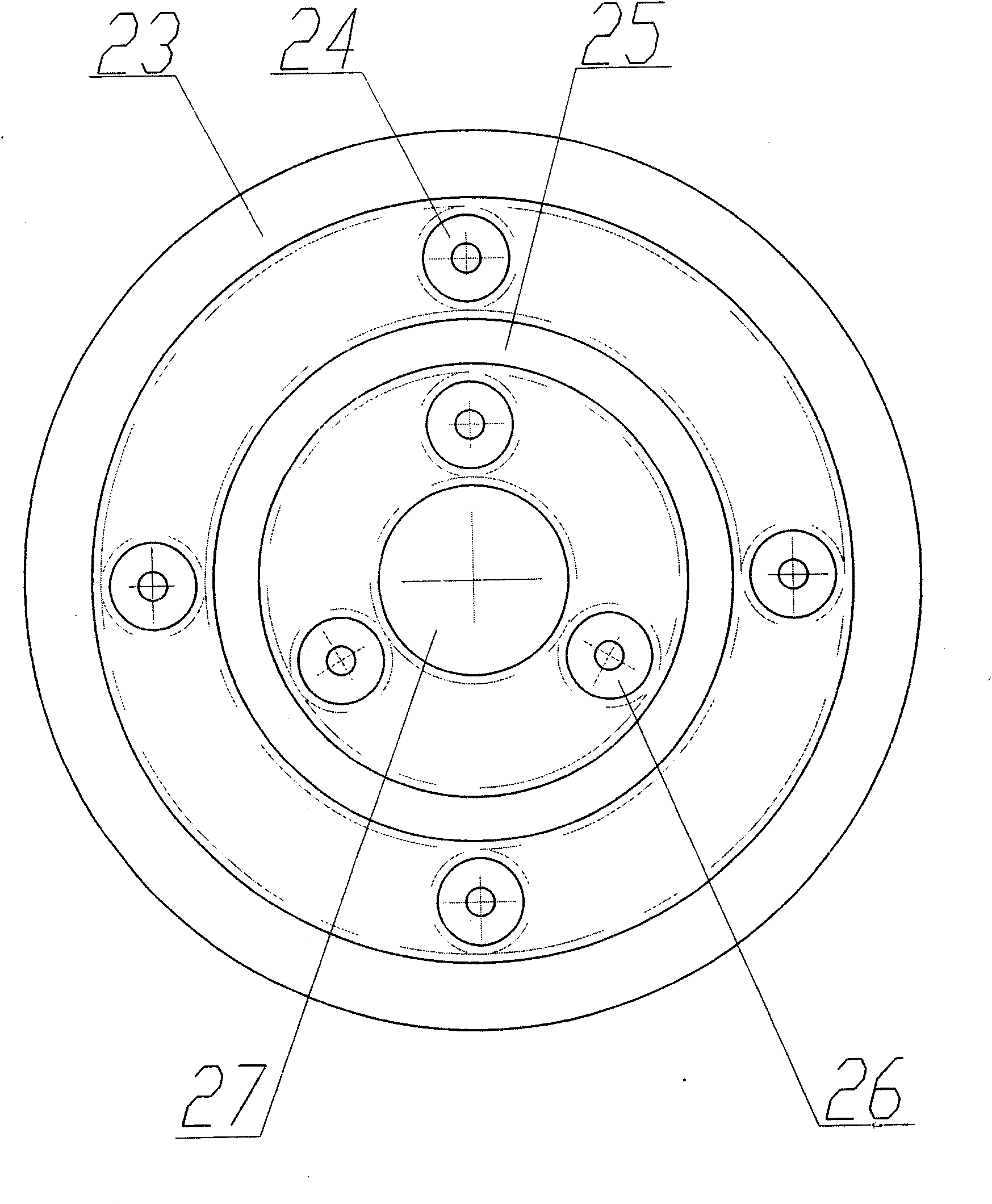

Permanent magnet energy-saving motor for mechanical equipment

InactiveCN114400852AImprove heat transfer efficiencyExtended service lifeMagnetic circuit rotating partsMechanical energy handlingSpiral bladeElectric machinery

The invention provides a permanent magnet energy-saving motor for mechanical equipment. Relates to the technical field of oilfield downhole tools. The rotor is composed of an outer rotor and an inner rotor, an inner hole of the outer rotor is in clearance fit connection with the outer circle of the inner rotor, the outer rotor and the inner rotor are provided with uniformly distributed permanent magnets in the circumferential direction, the outer rotor is fixedly connected with a positioning sleeve, and the positioning sleeve is fixedly connected with the motor shaft. Compared with the prior art, the motor has the following beneficial effects that the inner rotor rotates once relative to the outer rotor every time the push rod is pressed through a pressing rotating mechanism composed of the sliding claws of the inner rotor, the indexing grooves of the outer rotor and the guide strips and the guide teeth of the push rod, multi-stage speed regulation can be achieved, speed regulation can be achieved without disassembling the motor, and the motor is simple and convenient to use and has multiple speed regulation gears; air flow in the motor is generated when the spiral blade rotates along with the rotor, forced air internal circulation is formed through the flow passing channel and the vent holes I, II and III, heat of the rotor is brought to the machine shell for heat dissipation, and the heat exchange efficiency of the motor is improved.

Owner:DAQING RUISID PETROLEUM MASCH MFG CO LTD

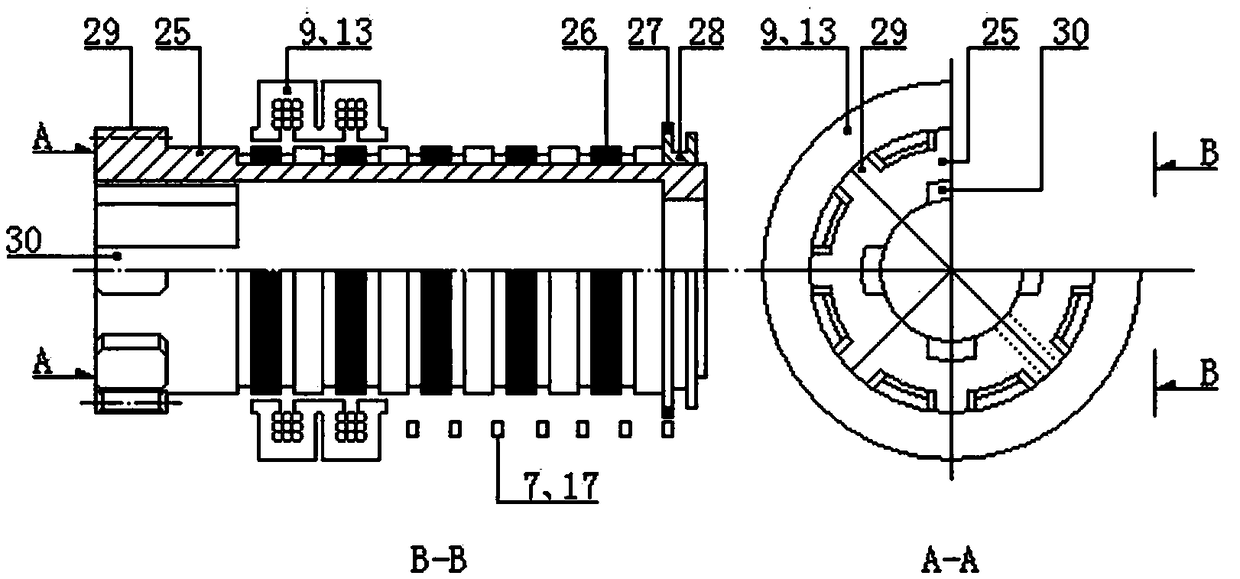

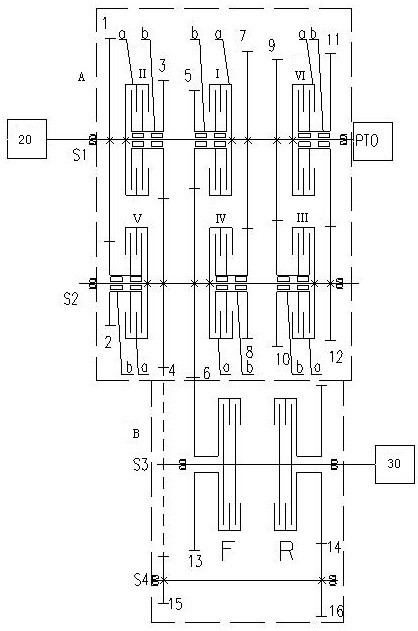

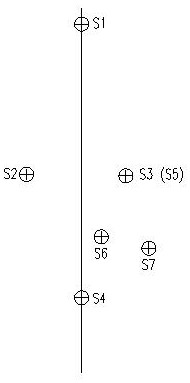

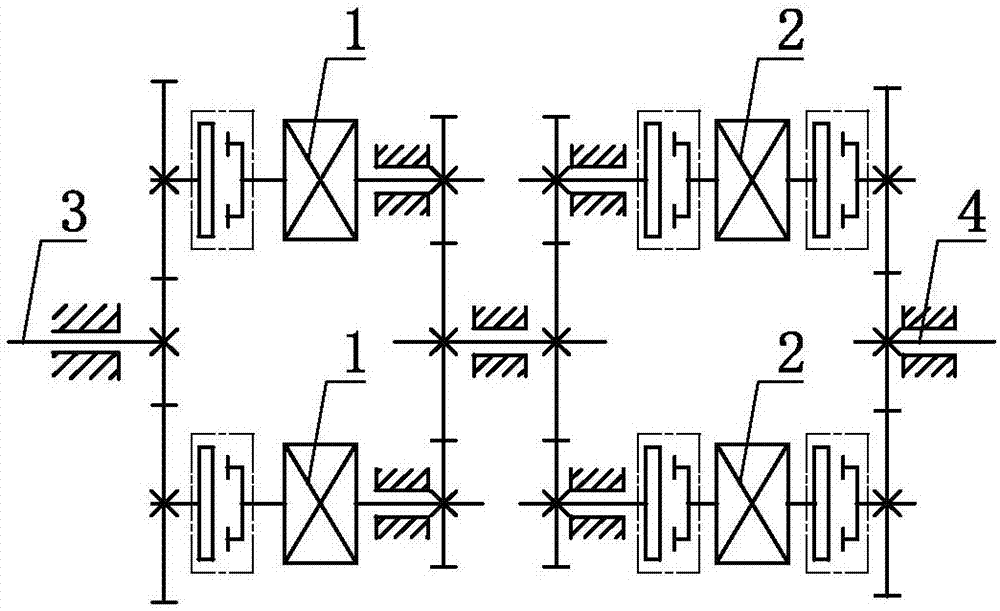

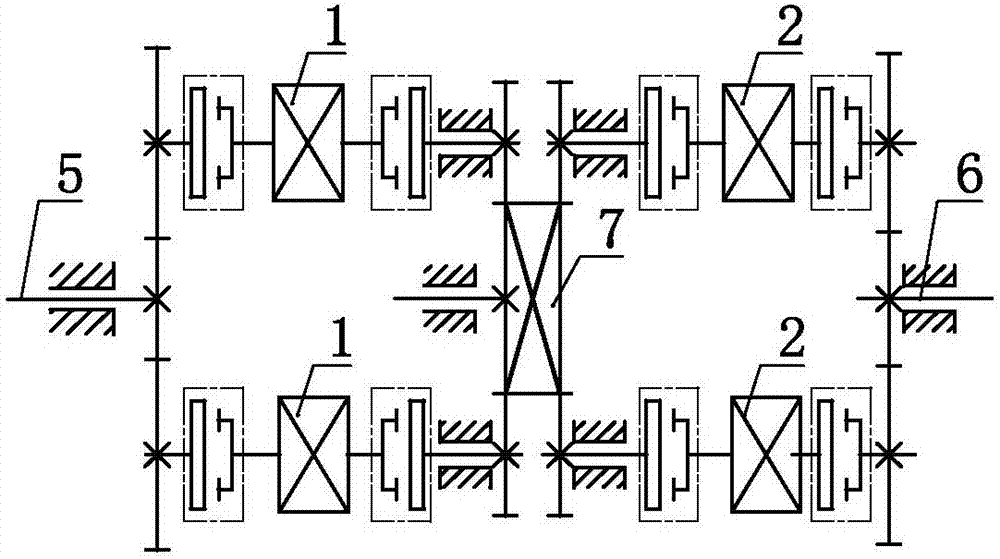

40F and 40R power gear shifting tractor gearbox

A 40F and 40R power gear shifting tractor gearbox comprises a power gear shifting transmission device, a creeper gear transmission device, a power reversing transmission device and a section gear shifting transmission device, wherein a first shaft and a second shaft are arranged in the power gear shifting transmission device; one end of the first shaft is connected with a tractor engine; the other end of the first shaft is connected with a tractor PTO; clutches and matched gears are mounted on the first shaft and the second shaft; the clutches are used for the achievement of different gears; a third shaft and a sixth shaft are arranged in the power reversing transmission device; a forward clutch and a backward clutch are arranged on the third shaft; a two-stage external meshing mechanism is arranged in the creeper gear transmission device; the input end of the creeper gear transmission device is connected with the third shaft; the output end of the creeper gear transmission device is connected with the input end of the section gear shifting transmission device; the output end of the section gear shifting transmission device is connected with a rear axle; the first shaft and a fourth shaft are distributed in the longitudinal center plane of a tractor; the second shaft and the third shaft are correspondingly positioned on two sides of the longitudinal center plane of the tractor; and a fifth shaft and the third shaft are arranged on one and the same straight line. The 40F and 40R power gear shifting tractor gearbox has the characteristics of being simple in structure, complete in function and high in transmission efficiency.

Owner:FIRST TRACTOR

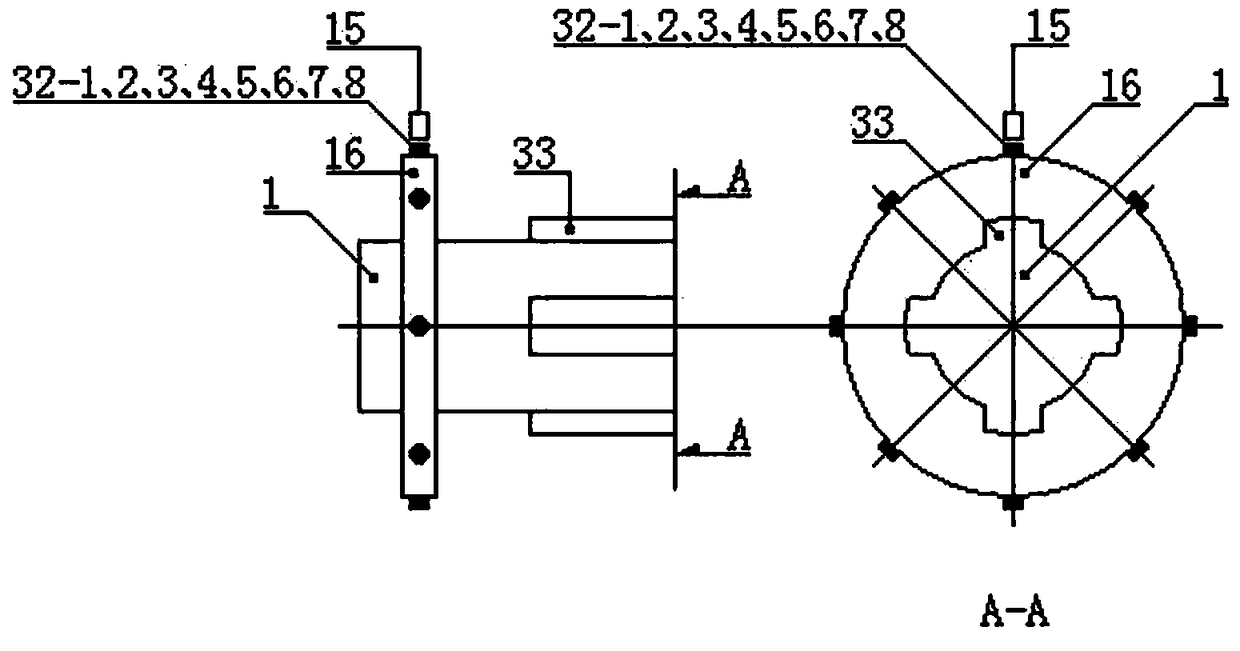

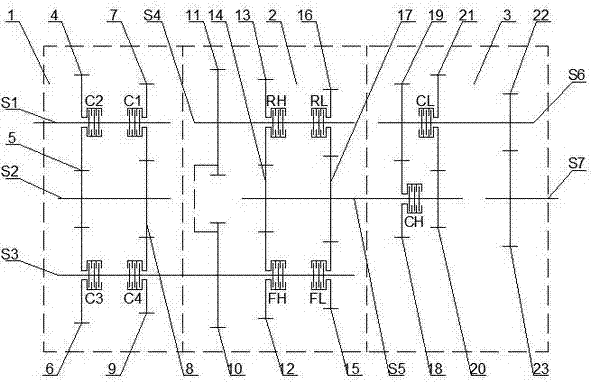

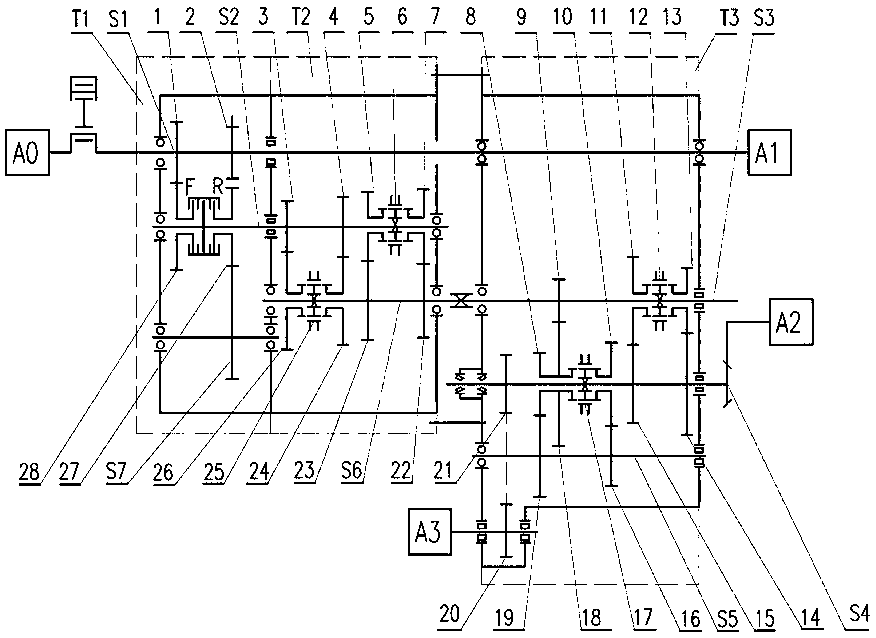

Novel 16+16 full-power gear-shifting and reversing gearbox

ActiveCN107035853AImprove work efficiencyReduce fatigue strengthGearing controlTransmission elementsDriver/operatorEngineering

The invention discloses a novel 16+16 full-power gear-shifting and reversing gearbox. The gearbox is composed of a full-power gear shifting main transmission device, a full-power reversing transmission device and a full-power gear-shifting auxiliary transmission device; the full-power gear-shifting main transmission device is connected to the output end of an engine; the full-power gear-shifting auxiliary transmission device is connected to a central transmission device; the gearbox can form 16 forward gears and 16 backward gears, totally, 32 gears; and gear shifting of all the gears is full-power gear shifting. According to the novel 16+16 full-power gear-shifting and reversing gearbox, the structure is simple and compact, the arrangement is convenient, the space is saved, the transmission path is clear, more gears are realized, a full-power gear-shifting and reversing technology is adopted so that the gear shifting and reversing operation can be completed under the condition that power is not cut off, and therefore the operation efficiency of a tractor can be greatly improved, and the fatigue strength of a driver can be reduced.

Owner:JILIN UNIV

12-speed power high-low gear and power reversing gearbox

PendingCN113108029AReduce work intensitySimple, clear and compact structureGearboxesToothed gearingsGear transmissionTractor

The invention discloses a 12-speed power high-low gear and power reversing gearbox. The gearbox comprises a power high-low gear transmission device, a power reversing transmission device and a manual gear shifting transmission device, the power high-low gear transmission device is connected with the output end of a tractor engine, the manual gear shifting transmission device is connected with a central transmission mechanism, three power high-low gears can be achieved in the power high-low gear transmission device, one forward gear and one backward gear can be achieved in the power reversing transmission device, four manual gear shifting gears can be achieved in the manual gear shifting transmission device, the gearbox can achieve 24 gears in total including 12 forward gears and 12 backward gears, and partial power is shifted. According to the 12-speed power high-low gear and power reversing gearbox, the structure is simple, clear and compact, the transmission route is clear, the overall space is saved, more gears can be realized, gear shifting and reversing operations can be realized under the condition of not cutting off the power of the engine, the working efficiency is improved, and the working intensity of operators is reduced.

Owner:JILIN UNIV

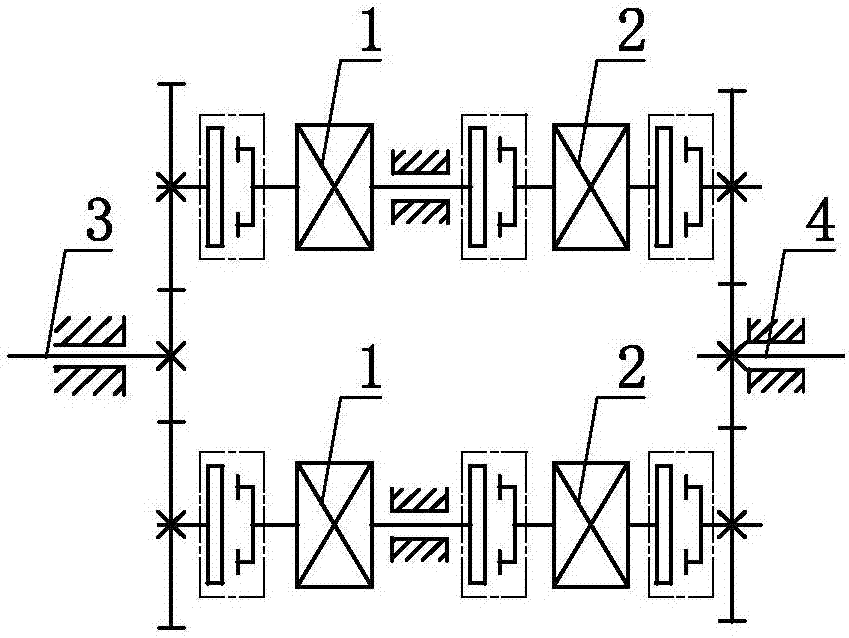

Medium/low-power tractor transmission device with power reversing and synchronous gear shifting

PendingCN109899461AAxial dimension shortCompact structureToothed gearingsGearing detailsEngineeringTractor

The invention discloses a medium / low-power tractor transmission device with power reversing and synchronous gear shifting. The device comprises a power reversing transmission device, a main speed change transmission device and a secondary speed change transmission device; the power reversing transmission device, the main speed change transmission device and the secondary speed change transmissiondevice are arranged in sequence from left to right; the front end of the power reversing transmission device is connected with an engine; the back end of the secondary speed change transmission deviceis connected with a tractor back center driver; and the power reversing transmission device and the main speed change transmission device are arranged in the same shell. Through the arrangement, thetransmission technical path is clear, the axial size is short, and the structure is compact. Through combination of the power reversing transmission device, the main speed change transmission device and the secondary speed change transmission device in sequence, 16 advancement gears and 16 retreating gears can be realized, so that the gear number is bigger, the speed distribution is reasonable, the applicable working range is wide, and the transmission efficiency is high. The transmission device can realize gear shifting without parking a vehicle, is convenient to shift gears and comfortable in operation.

Owner:FIRST TRACTOR

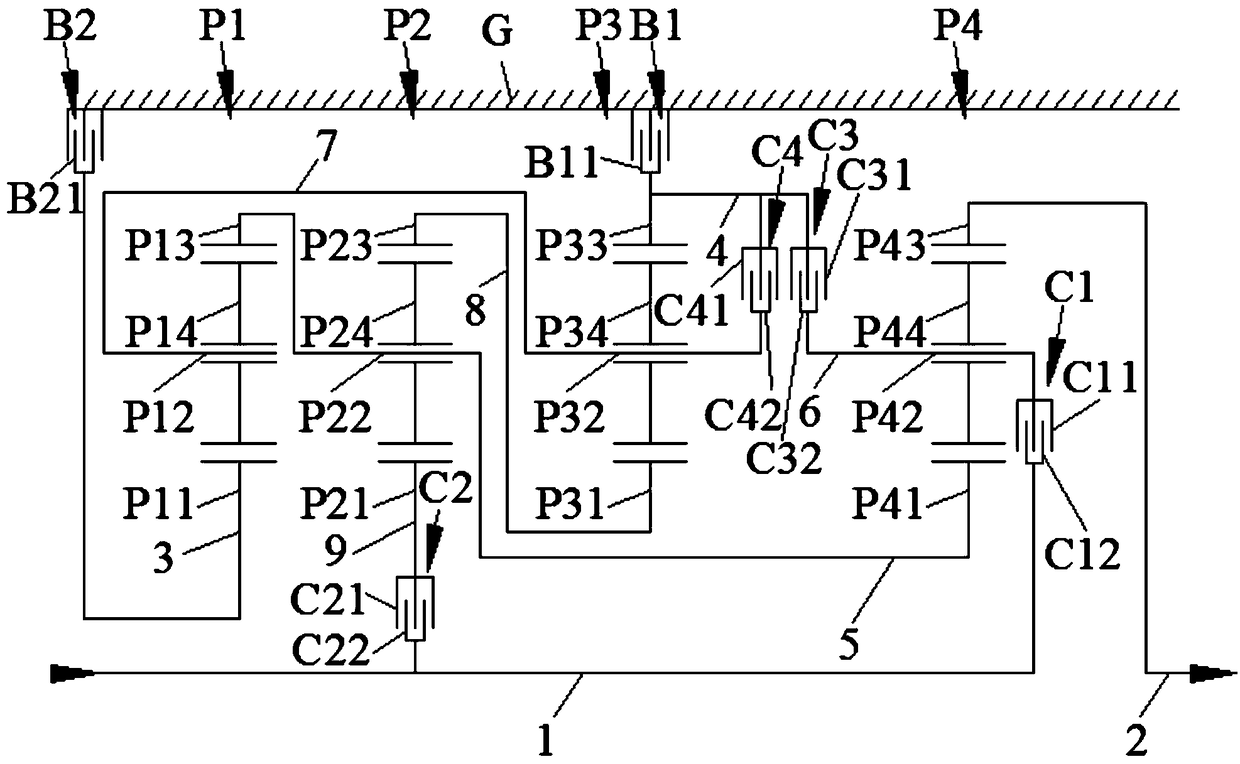

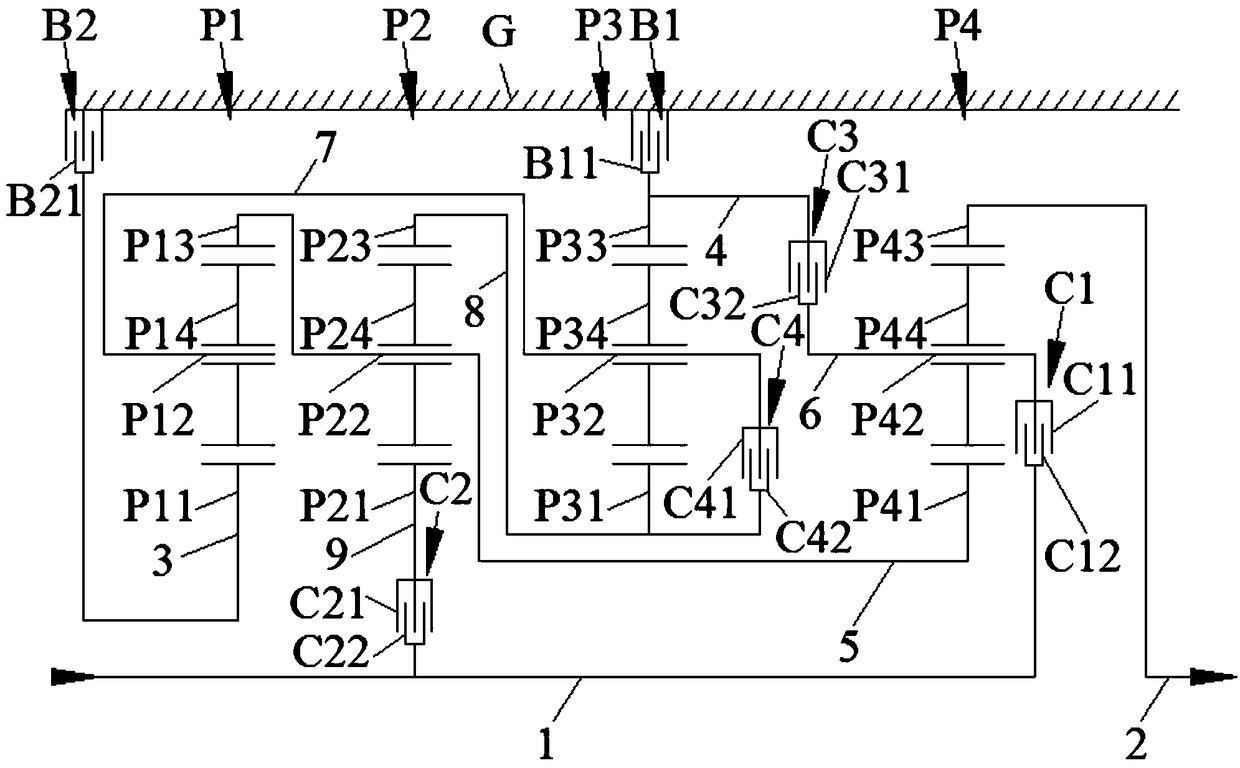

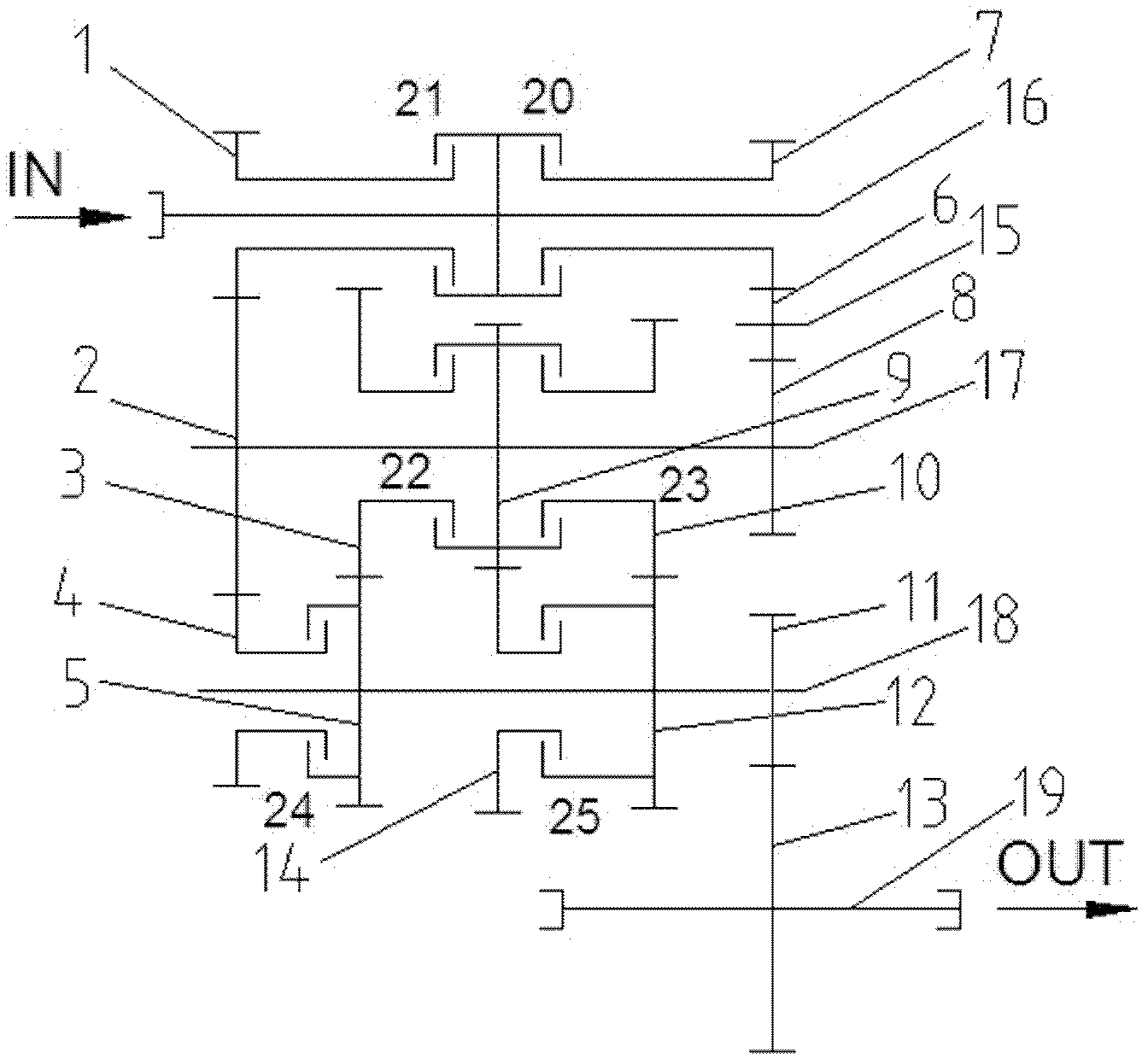

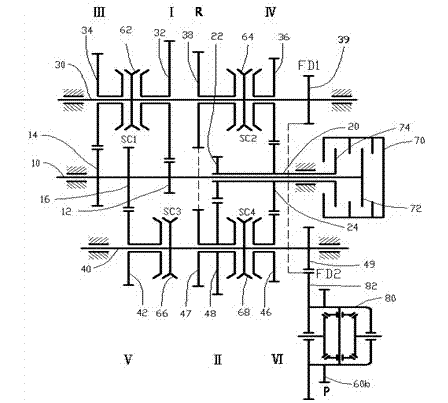

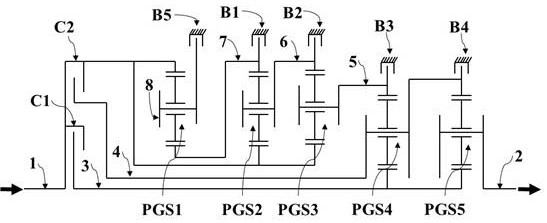

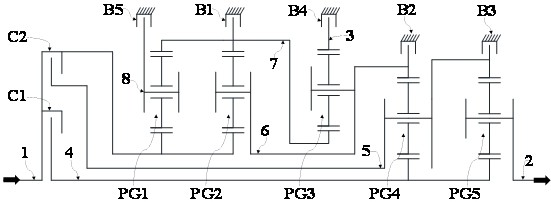

A Longitudinal Rear Drive Planetary Gear Automatic Transmission

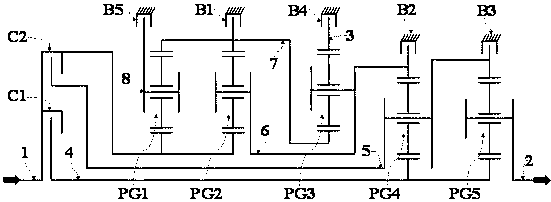

ActiveCN112984059BMany gearsEasy to controlToothed gearingsTransmission elementsAutomatic transmissionGear wheel

The invention discloses a longitudinal rear drive planetary gear automatic transmission, which adopts 5 negative sign planetary gear sets, 8 rotating shafts, 7 shift elements, including 2 clutches, 5 brakes, and 5 brakes nested Planetary gear set arrangement, 2 clutches are located at the front of the transmission, and the structural layout is more compact. In the present invention, each gear position closes 2 shifting elements, 11 forward gears and 2 reverse gears can be realized, and as the number of gears increases, a wider speed ratio range and a more uniform transmission step ratio can be obtained .

Owner:BEIHANG UNIV

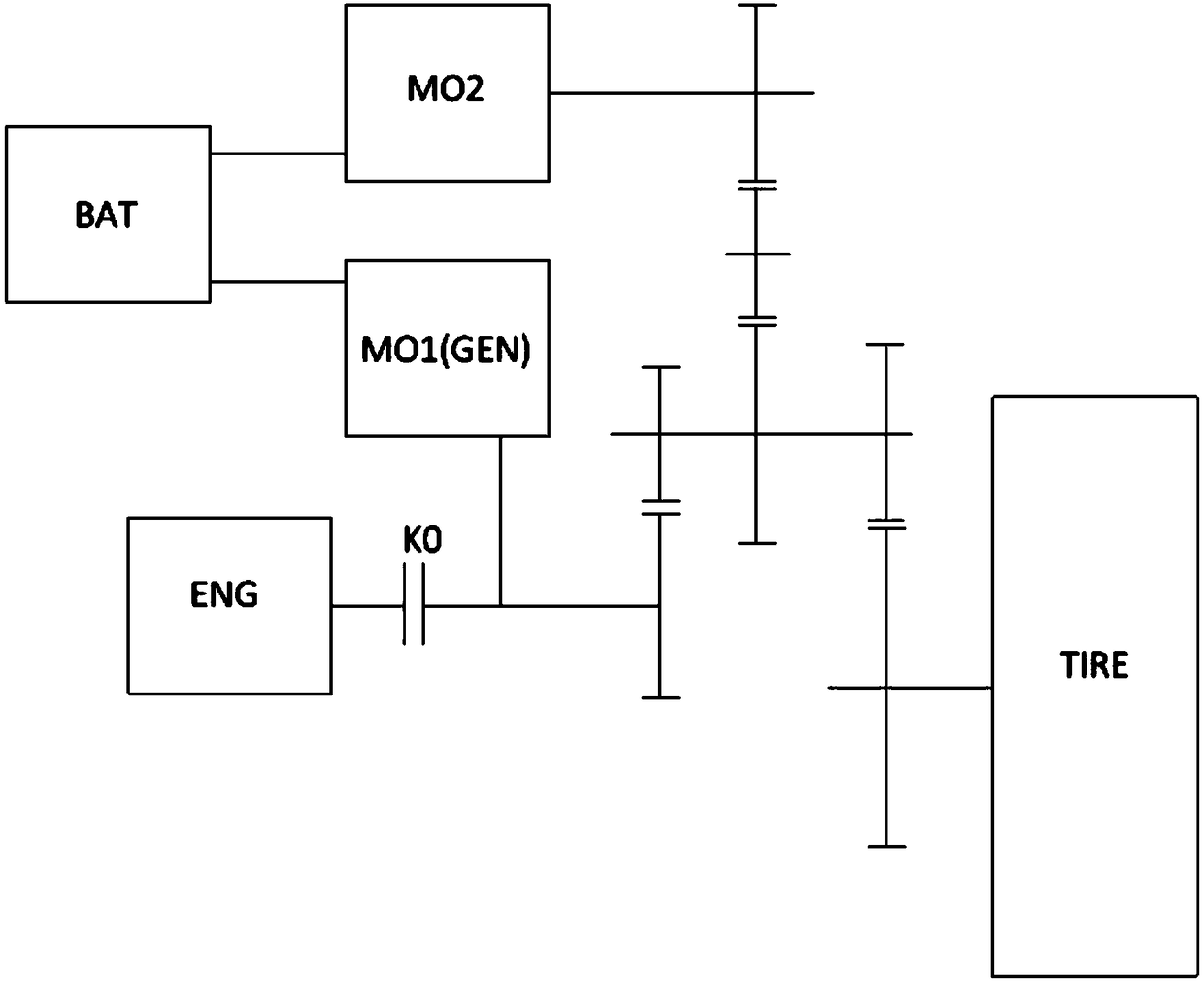

Hybrid power system and hybrid vehicle

InactiveCN108656934AMany gearsSimple structureHybrid vehiclesGas pressure propulsion mountingElectric machineTorque transmission

The invention relates to the field of hybrid vehicles, in particular to a hybrid power system and the hybrid vehicle. The hybrid power system includes a transmission, a motor, an engine and a clutch.The transmission includes a first input shaft, a second input shaft, an output shaft, synchromesh engaging mechanisms and gears. The second input shaft is sleeved with the first input shaft and the first input shaft can be selectively connected to the second input shaft and the output shaft in a transmission mode through a plurality of synchronizing engaging mechanisms and a plurality of gears. Aninput / output shaft of the motor is directly connected to the first input shaft in a coaxial mode. The engine is connected to the second input shaft in a transmission mode through the clutch. In thisway, the hybrid power system achieves the same torque transmission mode as the prior art by only one motor, and thus the structure is simpler; and moreover, the hybrid power system is provided with sufficient gears for both the motor and the engine.

Owner:SCHAEFFLER TECH AG & CO KG

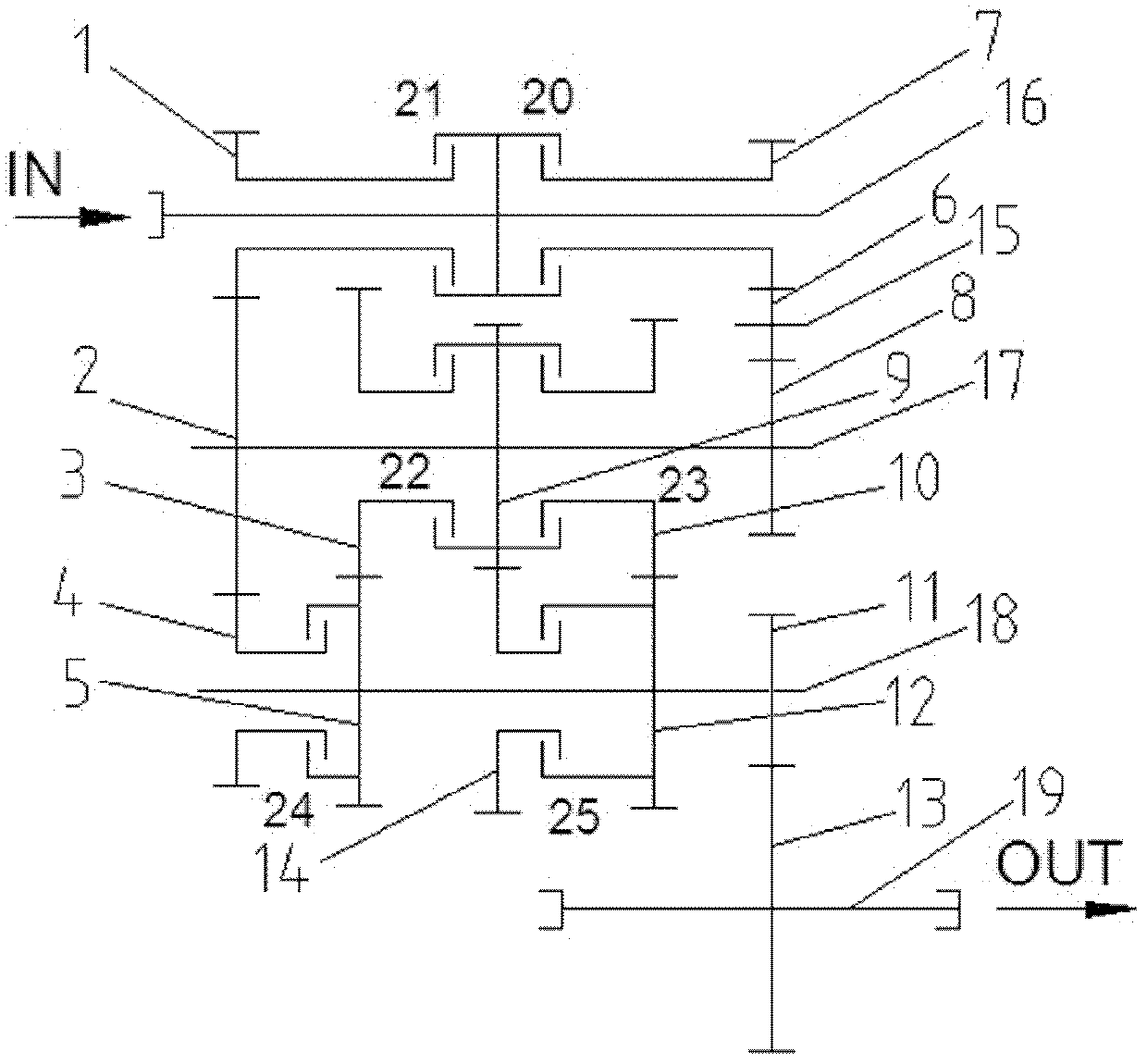

Speed change mechanism

InactiveCN107304798ASimple structureMany gearsToothed gearingsTransmission elementsEngineeringHigh transmission

The invention discloses a speed change mechanism which comprises more than two driving units A, more than two driving units B, a rotating power structure A and a rotating power structure B, wherein the driving units A are arranged in a non-coaxial form; the driving units B are arranged in a non-coaxial form; each driving unit A comprises a power end AX and a power end AY; each driving unit B comprises a power end BX and a power end BY; the rotating power structure A and the power end AX are in driving arrangement; the power end AY and the power end BX are in driving arrangement; and the power end BY and the rotating power structure B are in driving arrangement. The speed change mechanism disclosed by the invention has the advantages of simple structure, multiple gear levels, high transmission efficiency, and the like.

Owner:ENTROPY ZERO TECH LOGIC ENG GRP CO LTD

Automatic transmission unit

The invention discloses an automatic transmission unit, and belongs to the technical field of automatic transmission. The problems that the structure is complex in the existing automatic transmissiontechnology, particularly, a slightly progressive and hierarchical good transmission ratio series and a large transmission ratio range are difficult to provide are overcome. The automatic transmissionunit comprises four planetary gear sets which are sequentially arranged along the front and back of a main rotating shaft; nine rotatable shafts; two brakes and four clutches, six gear shifting switching elements, the gear shifting switching elements are allowed to be selectively actuated such that nine forward gears and one reverse gear are formed between an input shaft and an output shaft of thetransmission; the input shaft is detachably connected to a seventh shaft connected to a first sun gear via a first clutch and is detachably connected to an eighth shaft connected to a second planetary carrier via a second clutch, and a third shaft connected to a fourth sun gear is connected to a shell through a first brake; and the output shaft is connected with the first gear ring and a fourth planet carrier.

Owner:彭建新

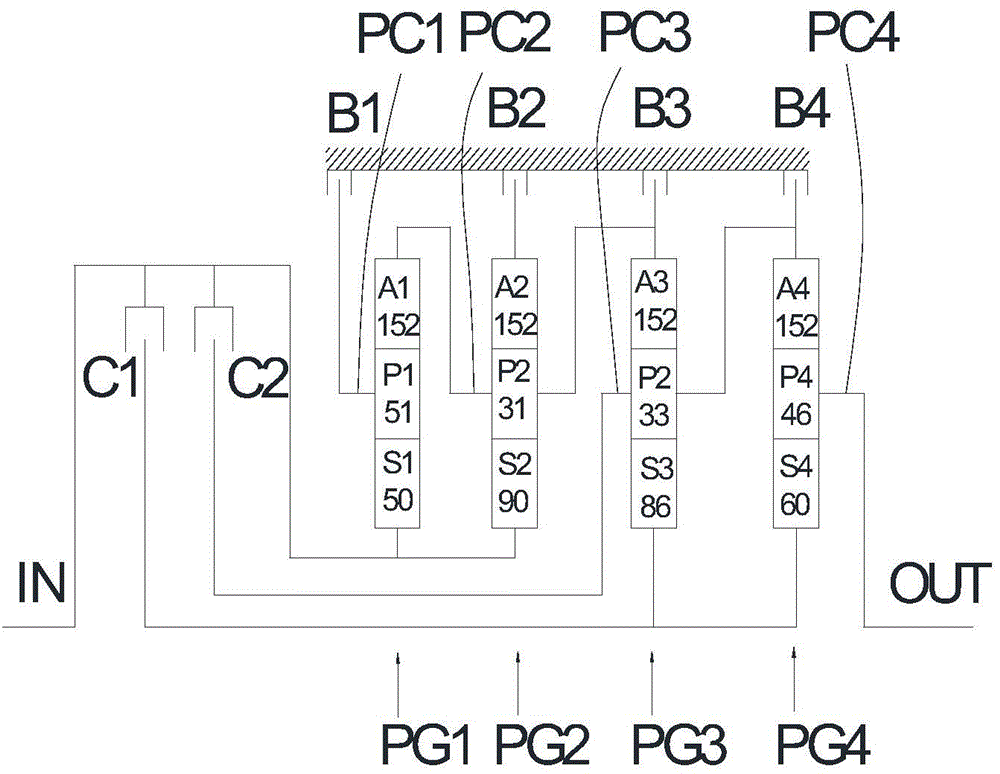

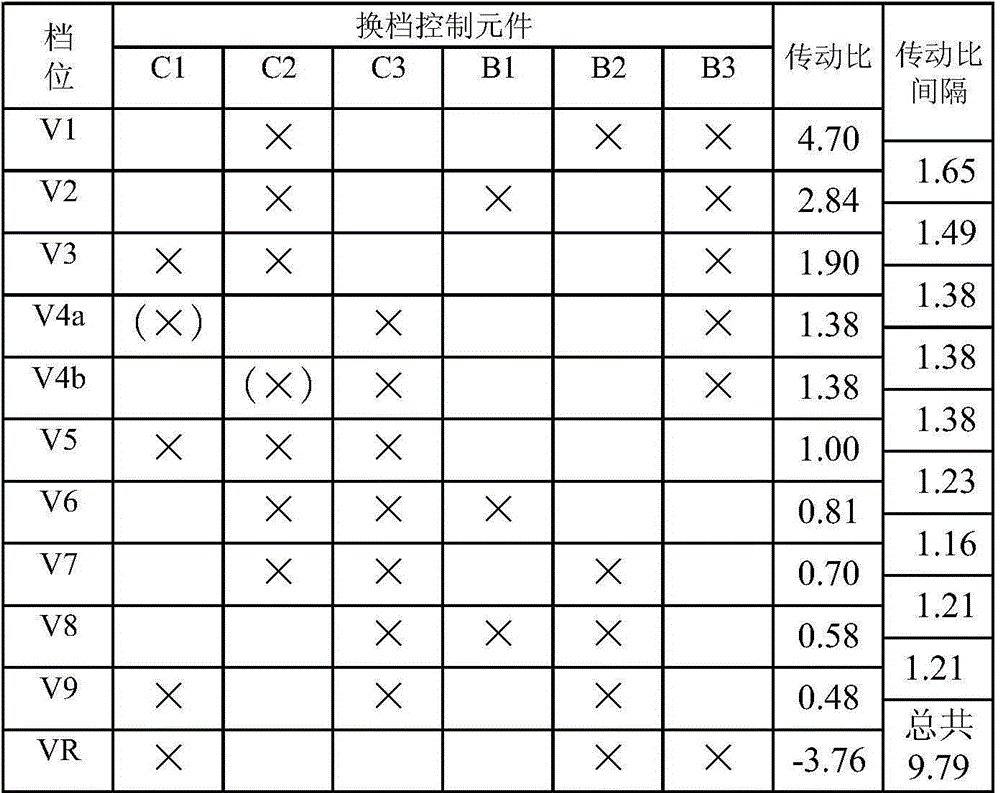

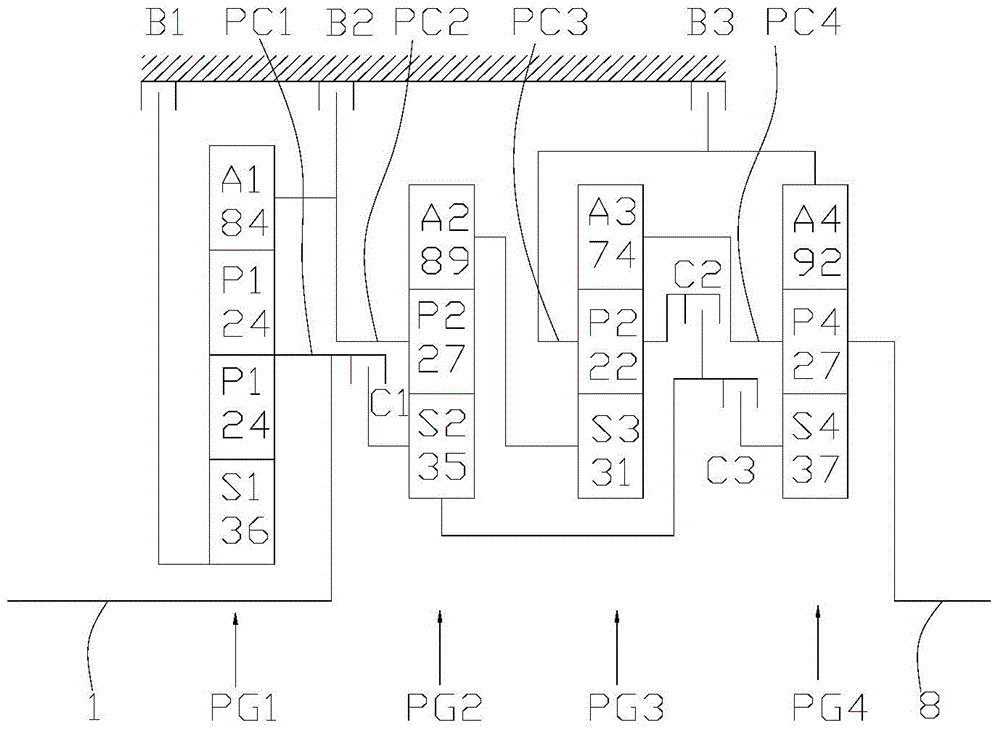

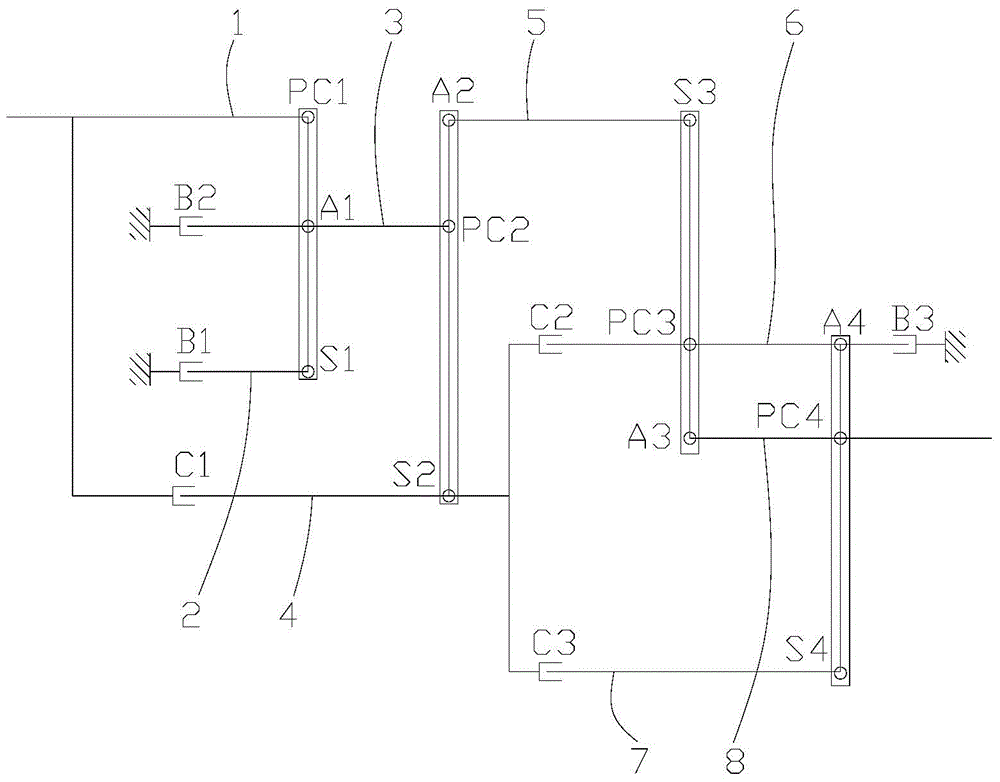

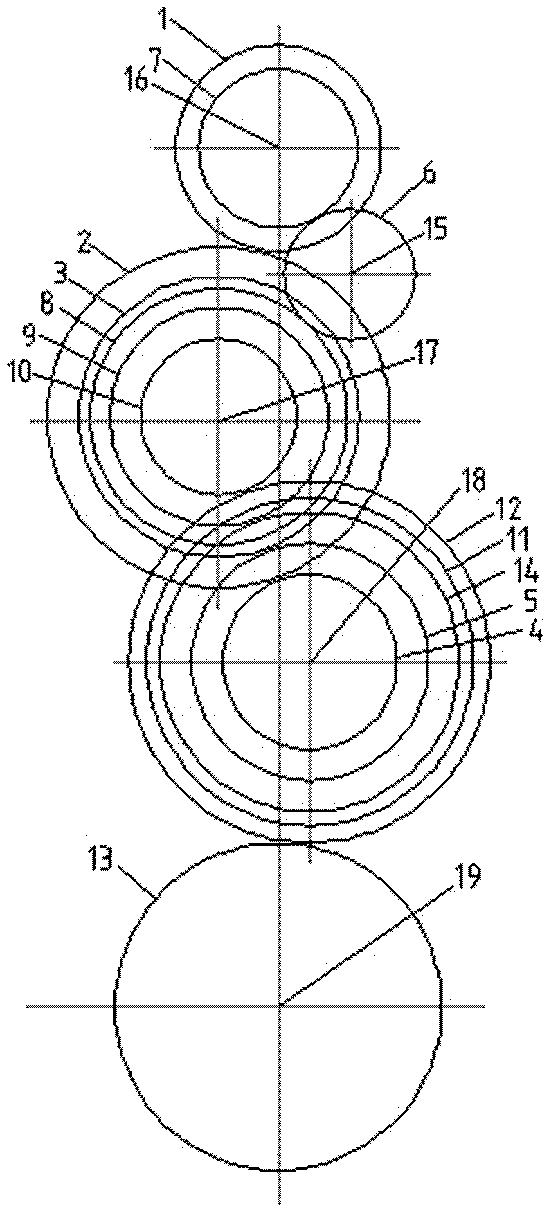

A planetary gear transmission mechanism

The invention discloses a planetary gear transmission mechanism, which adopts 4 planetary gear sets, including 1 positive sign planetary row, 3 negative sign planetary rows, 7 transmission components, 6 shifting elements, including 2 clutches, 4 There are 1 brake, 4 brakes nested planetary arrangement, 2 clutches are located at the front of the transmission, and the structure layout is more compact. In the present invention, each gear position closes two shifting elements, which can realize 9 forward gears and 1 reverse gear, and as the number of gears increases, a wider speed ratio range and a more uniform transmission step ratio can be obtained .

Owner:BEIHANG UNIV

Speed change mechanism

The invention discloses a speed change mechanism which comprises more than two driving units A, more than two driving units B, a rotating power structure A, a rotating power structure B, a rotating structure A and a rotating structure B, wherein the driving units A are arranged on the rotating structure A; the driving units B are arranged on the rotating structure B; each driving unit A comprises a power end AX and a power end AY; each driving unit B comprises a power end BX and a power end BY; the rotating power structure A and the power end AX are in driving arrangement; the power end AY and the power end BX are in clutch driving arrangement; the power end BY and the rotating power structure B are in driving arrangement; the rotating structure A is controlled by a rotating control device A; and the rotating structure B is controlled by a rotating control device B. The speed change mechanism disclosed by the invention has the advantages of simple structure, multiple gear levels, high transmission efficiency, and the like.

Owner:ENTROPY ZERO TECH LOGIC ENG GRP CO LTD

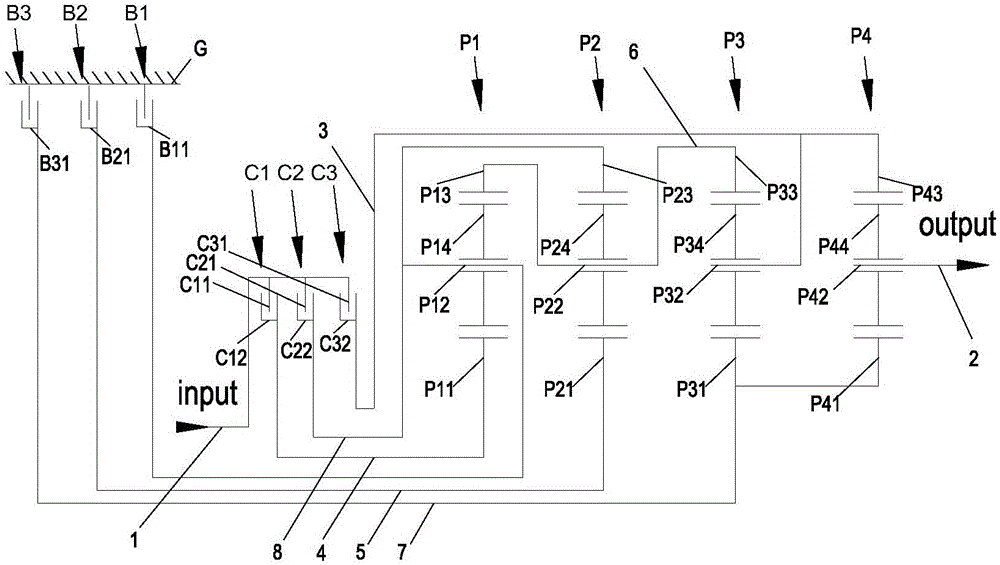

A multi-speed planetary gear transmission device

ActiveCN111536211BMany gearsWide transmission ratio rangeToothed gearingsTransmission elementsOil canGear wheel

The invention discloses a multi-gear planetary gear transmission device, which includes 8 rotating shafts, 5 brakes, 2 clutches, and 5 planetary rows. The invention uses 5 simple negative planetary rows and 7 shifting elements (including 5 brakes and 2 clutches), 2 clutches are arranged at the front end of the transmission instead of the middle of the transmission, so the oil supply is very convenient; 5 brakes are included, the number of brakes is large, and the planetary row arrangement can be embedded, and the pressure oil can be directly from the box The brake is supplied, and the structural layout is more compact; each gear position closes 2 shift elements, which can realize 12 forward gears and 1 reverse gear, with more gear numbers and a wider range of transmission ratios.

Owner:BEIHANG UNIV

Dynamic power shifting transmission

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com