Dynamic power shifting transmission

A power shift and transmission technology, applied in the field of power shift transmission, can solve the problems of high precision requirements, inconvenient operation, easy failure, etc., and achieve the effects of small size, convenient operation and short transmission route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

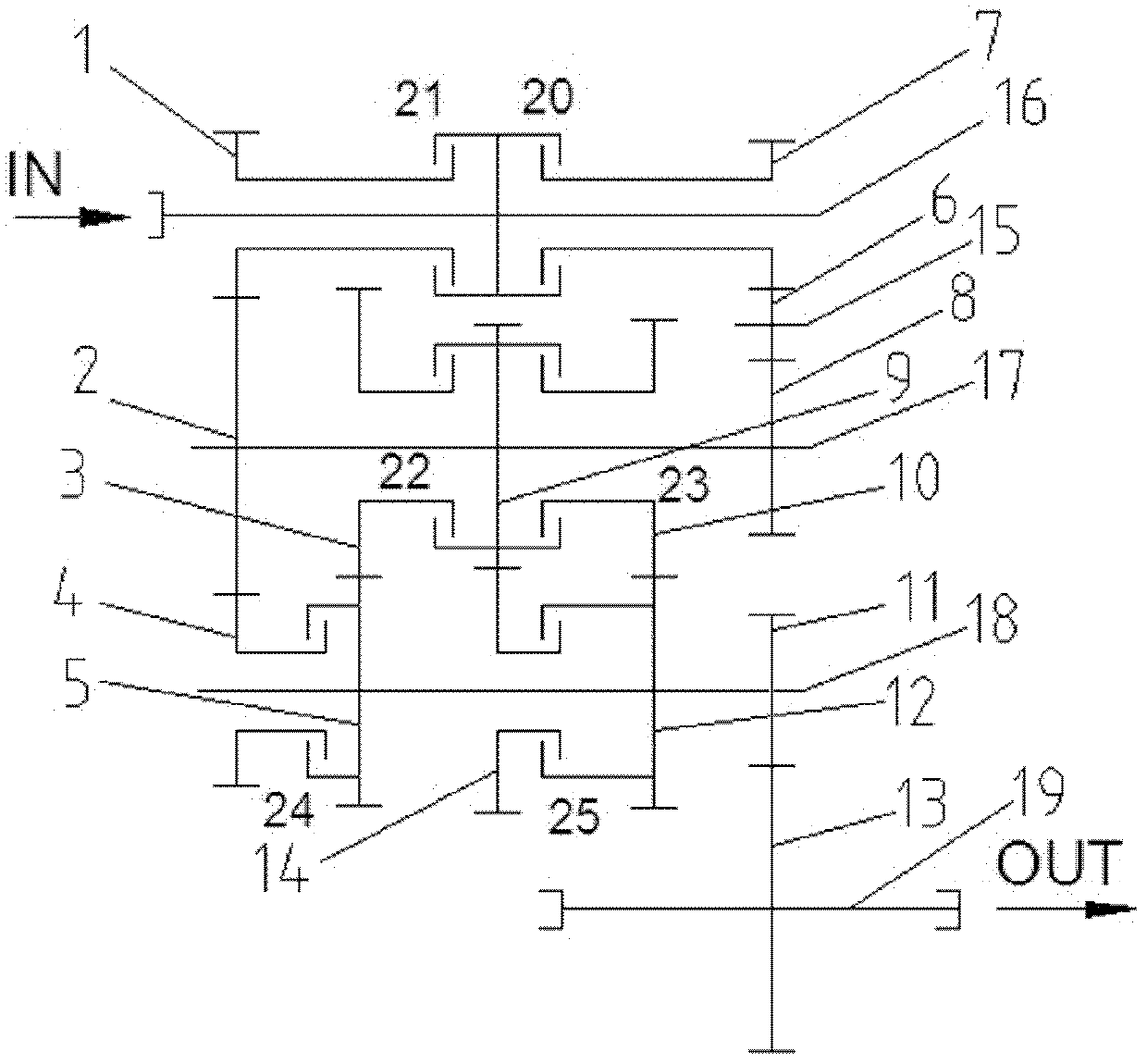

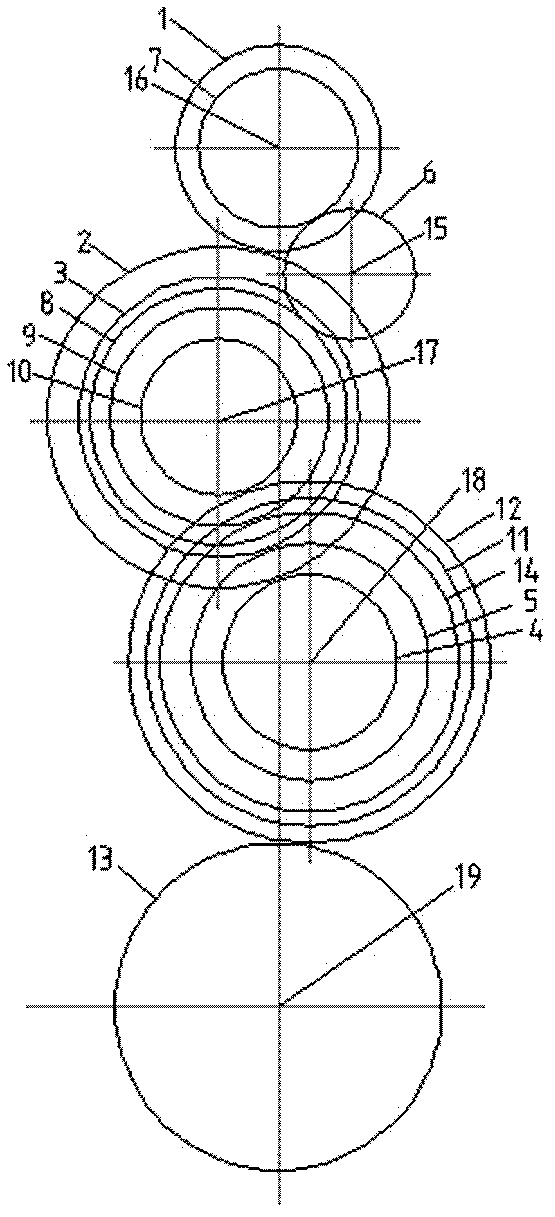

[0020] Please check figure 1 and figure 2 , A power shift transmission, such as a power shift transmission suitable for a wheel loader, which includes an input shaft 16, an output shaft 19, two intermediate shafts 17, 18 and an idler shaft 15. The input shaft 16, the idler shaft 15, the first intermediate shaft 17, the second intermediate shaft 18 and the output shaft 19 are arranged in parallel in sequence, and the axial end faces of the input shaft 16, the idler shaft 15 and the first intermediate shaft 17 Triangular arrangement in projection.

[0021] The input shaft 16 is provided with two movable gears 1, 7 and two clutches 21, 20, and the two clutches 21, 20 respectively control the two movable gears 1, 7 to control the movable gear and the input shaft to be in a synchronous rotational connection relationship.

[0022] The output shaft 19 is provided with a fixed gear 13 .

[0023] Described first intermediate shaft 17, it establishes three fixed gears 2,8,9, two mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com