Multi-gear automatic transmission

An automatic transmission and brake technology, which is applied to vehicle gearboxes, multi-gear ratio transmissions, transmission elements, etc., can solve problems such as difficulty in providing meshing efficiency and complex structure of components, and achieve sufficient transmission range, high transmission efficiency, and gears. A large number of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The present invention is described in detail below in conjunction with accompanying drawing:

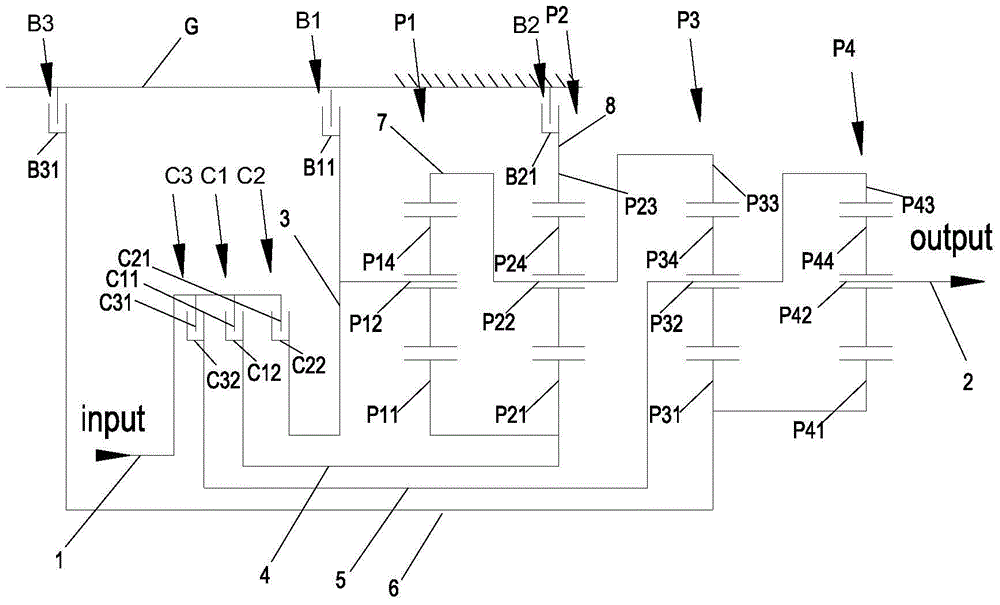

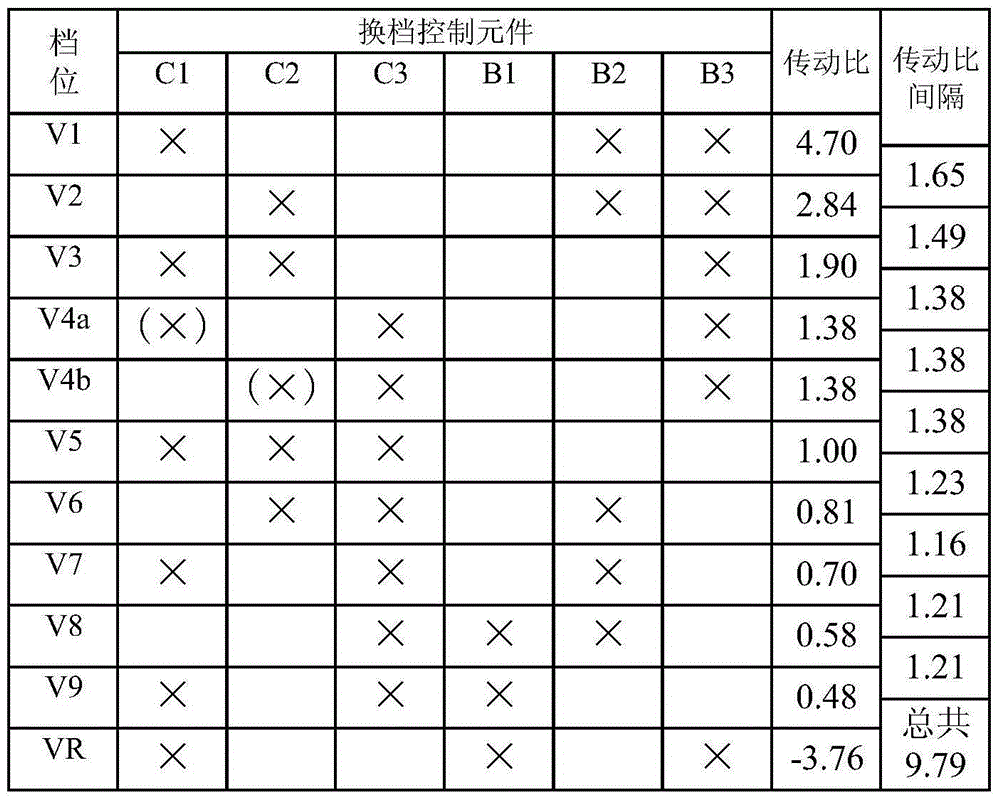

[0094] figure 1 An exemplary embodiment of an automatic transmission unit, which is designed as a motor vehicle automatic transmission unit, is shown. The automatic transmission unit has four planetary gear sets P1, P2, P3, P4. The first planetary gear set P1, the second planetary gear set P2, the third planetary gear set P3 and the fourth planetary gear set P4 are successively arranged along the main rotation axis. All planetary gear sets P1, P2, P3, P4 of the automatic transmission unit have single-stage planetary gear sets. The transmission unit has six shifting elements C1 , C2 , C3 , B1 , B2 , B3 . The shifting elements are provided for shifting exactly nine forward automatic transmission gears V1, V2, V3, V4, V5, V6, V7, V8, V9 and one reverse gear VR. However, the automatic transmission unit can also be operated with only eight forward transmission gears, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com