Automatic gear transmission

A gear transmission and automatic transmission technology, which is applied in vehicle gearboxes, gear transmissions, belts/chains/gears, etc., to achieve the effect of simple structure, many gears, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

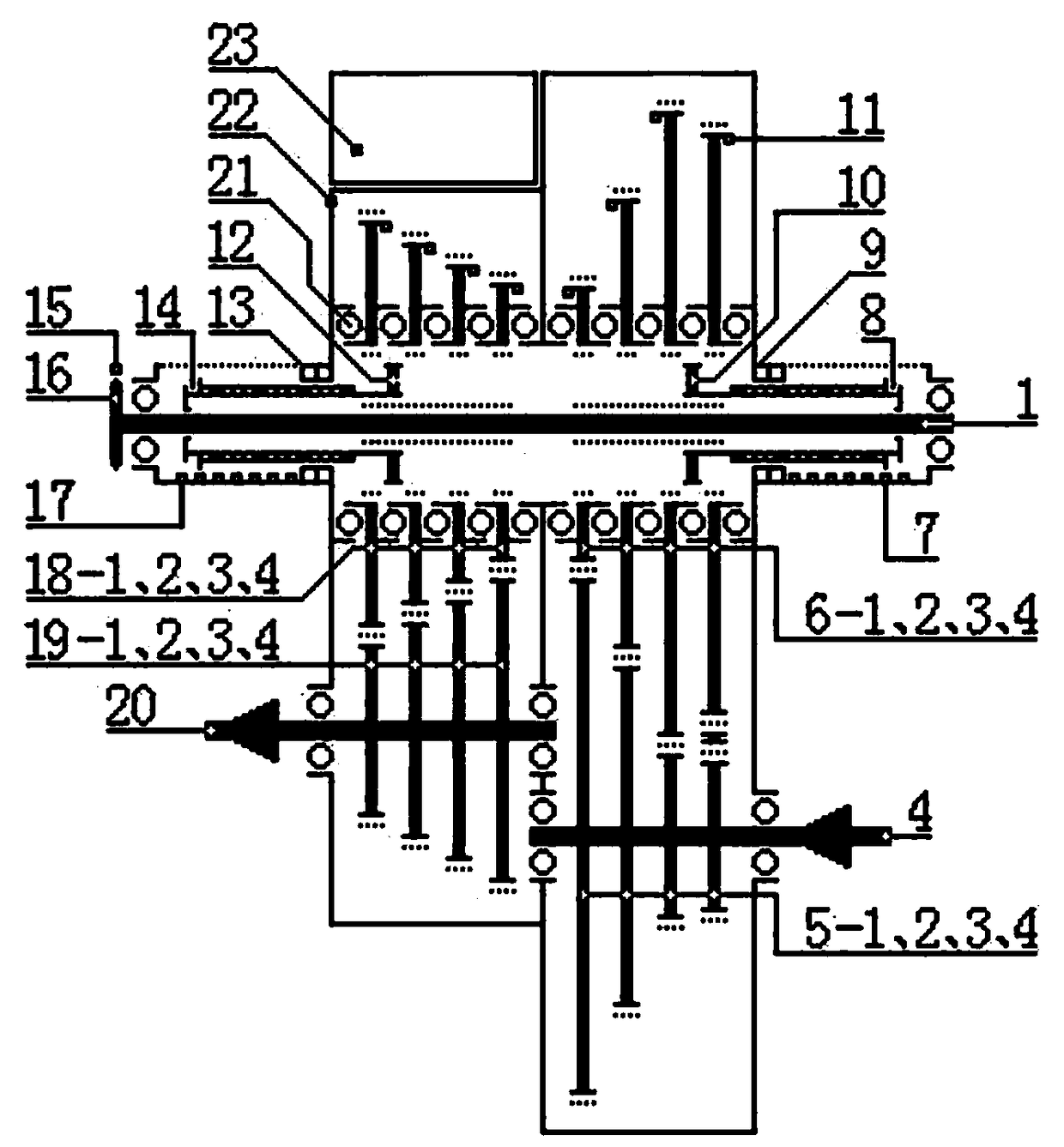

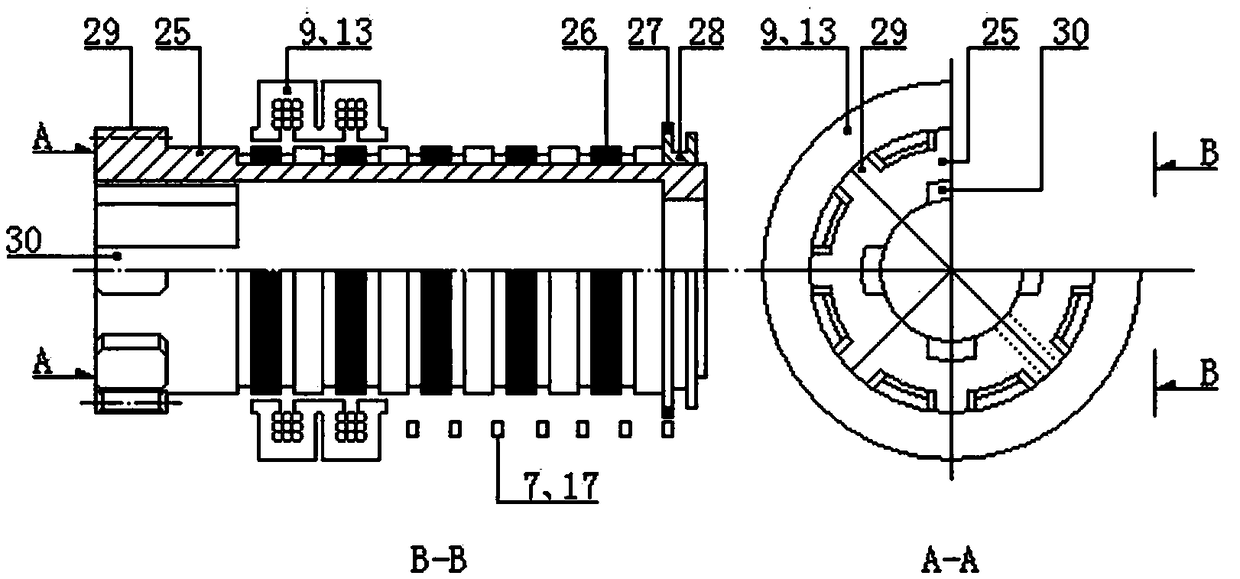

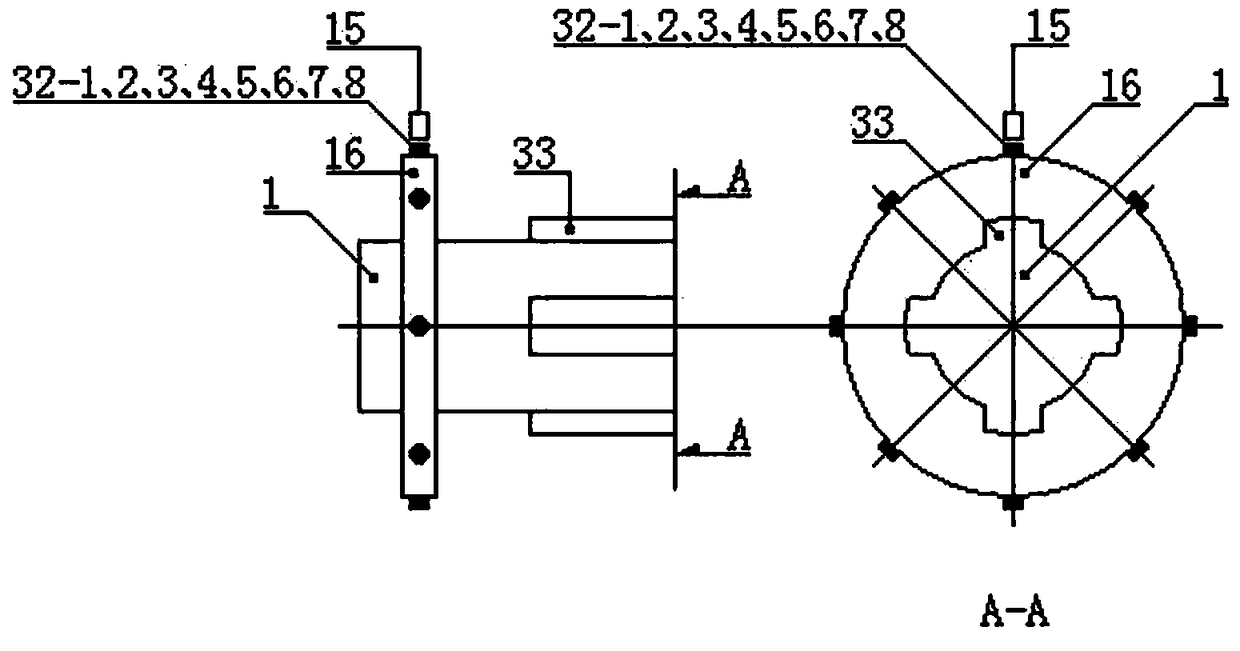

[0017] The present invention is achieved like this: see attached figure 1 : The main components of the automatic gear transmission include center shaft 1, input shaft 4, primary gear set (5-1, 2, 3, 4), primary synchronous gear set (6-1, 2, 3, 4), First-level linear displacement sensor group 7, first-level spline synchronizer shift fork 8, first-level cylindrical linear stepper motor stator 9, first-level spline synchronizer 10, synchronous gear speed and angular displacement sensor group 11, Secondary spline synchronizer 12, secondary cylindrical linear stepping motor stator 13, secondary spline synchronizer shift fork 14, synchronizer speed and angular displacement sensor 15, support ring 16, secondary linear disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com