Patents

Literature

79results about How to "Realize automatic shifting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

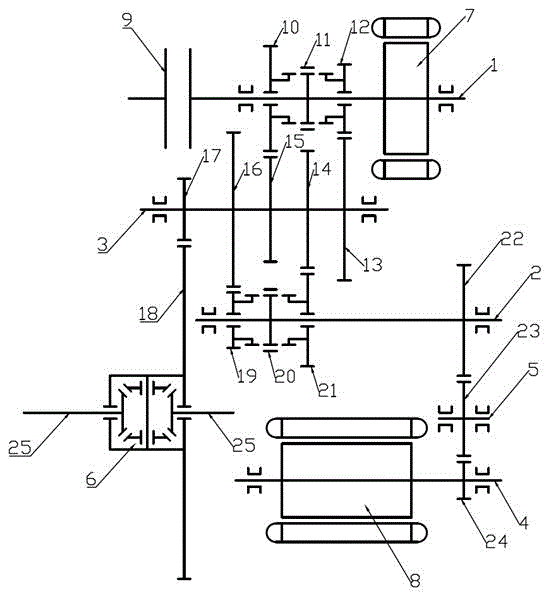

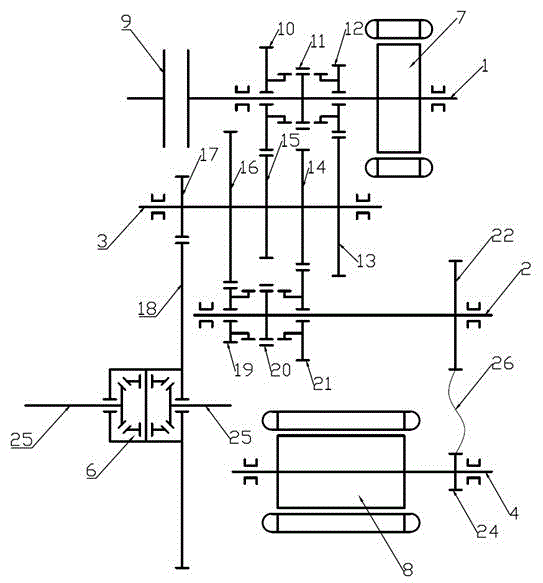

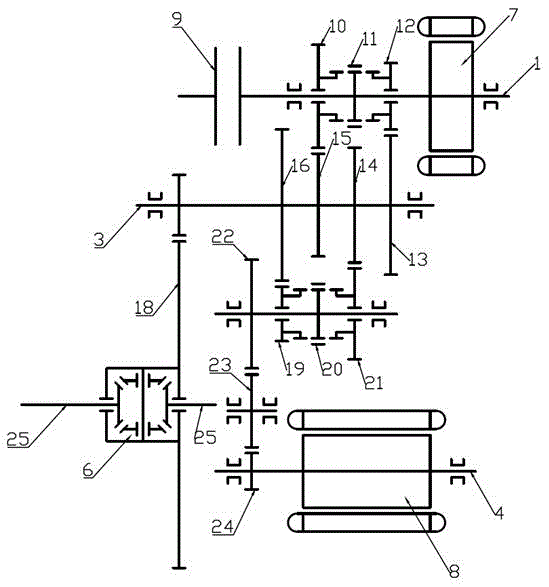

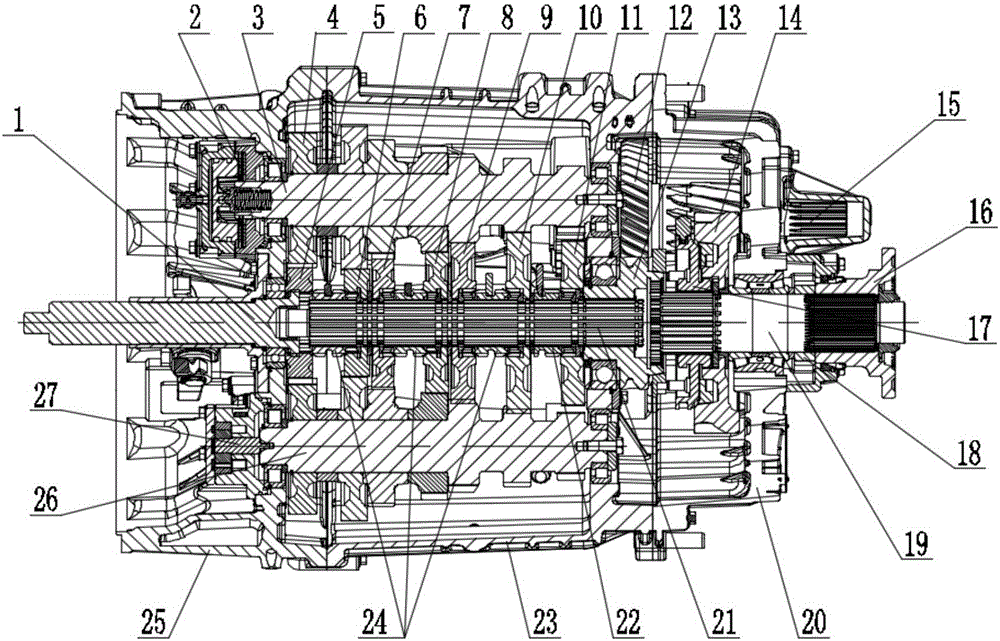

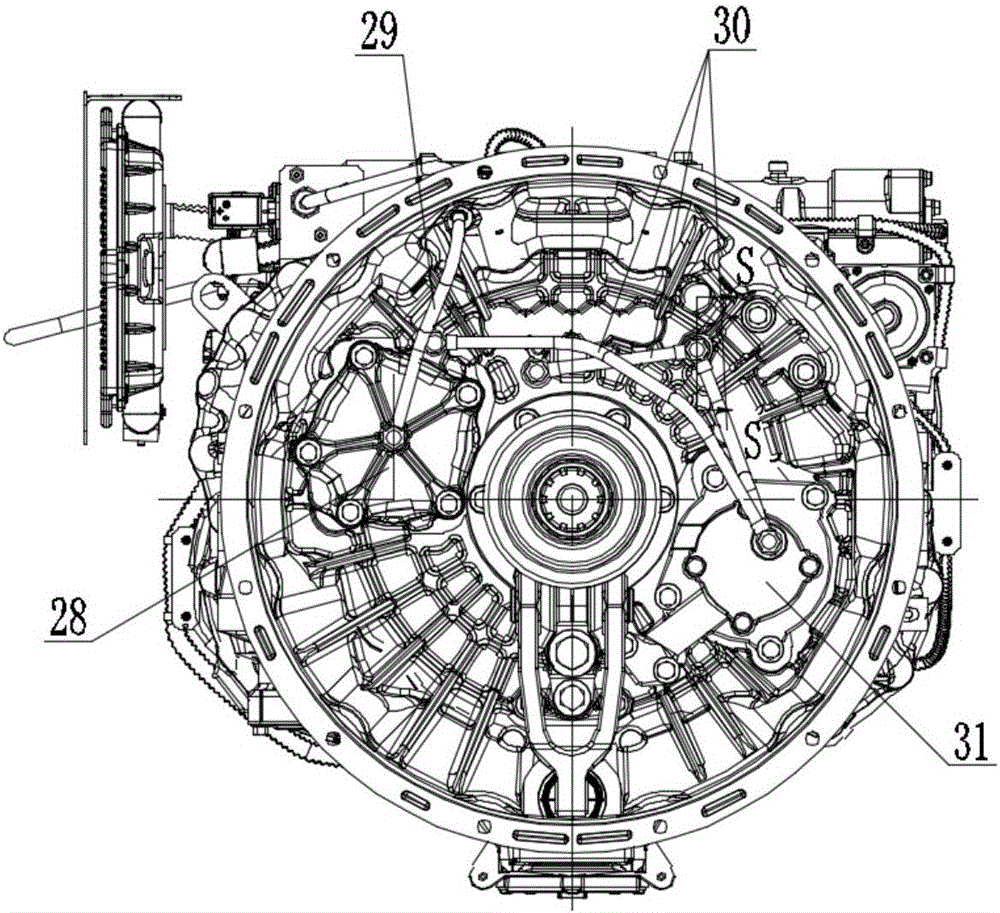

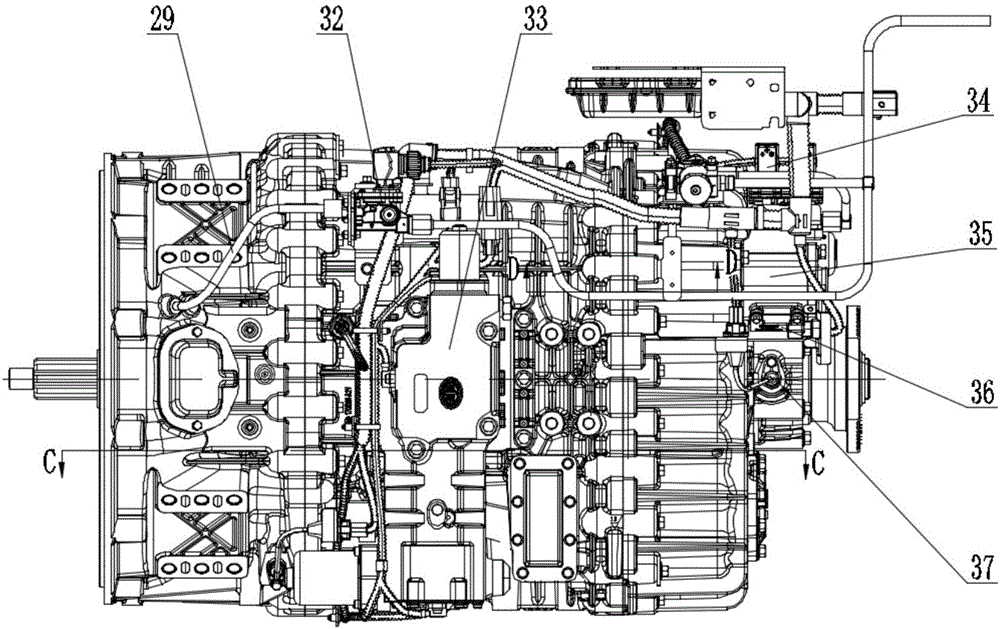

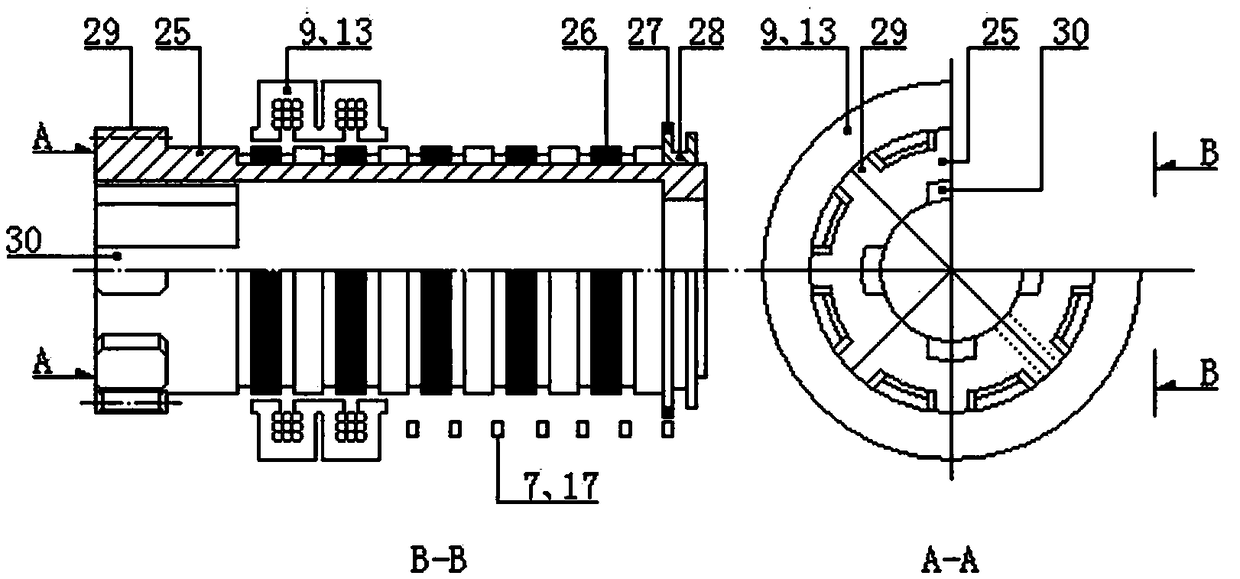

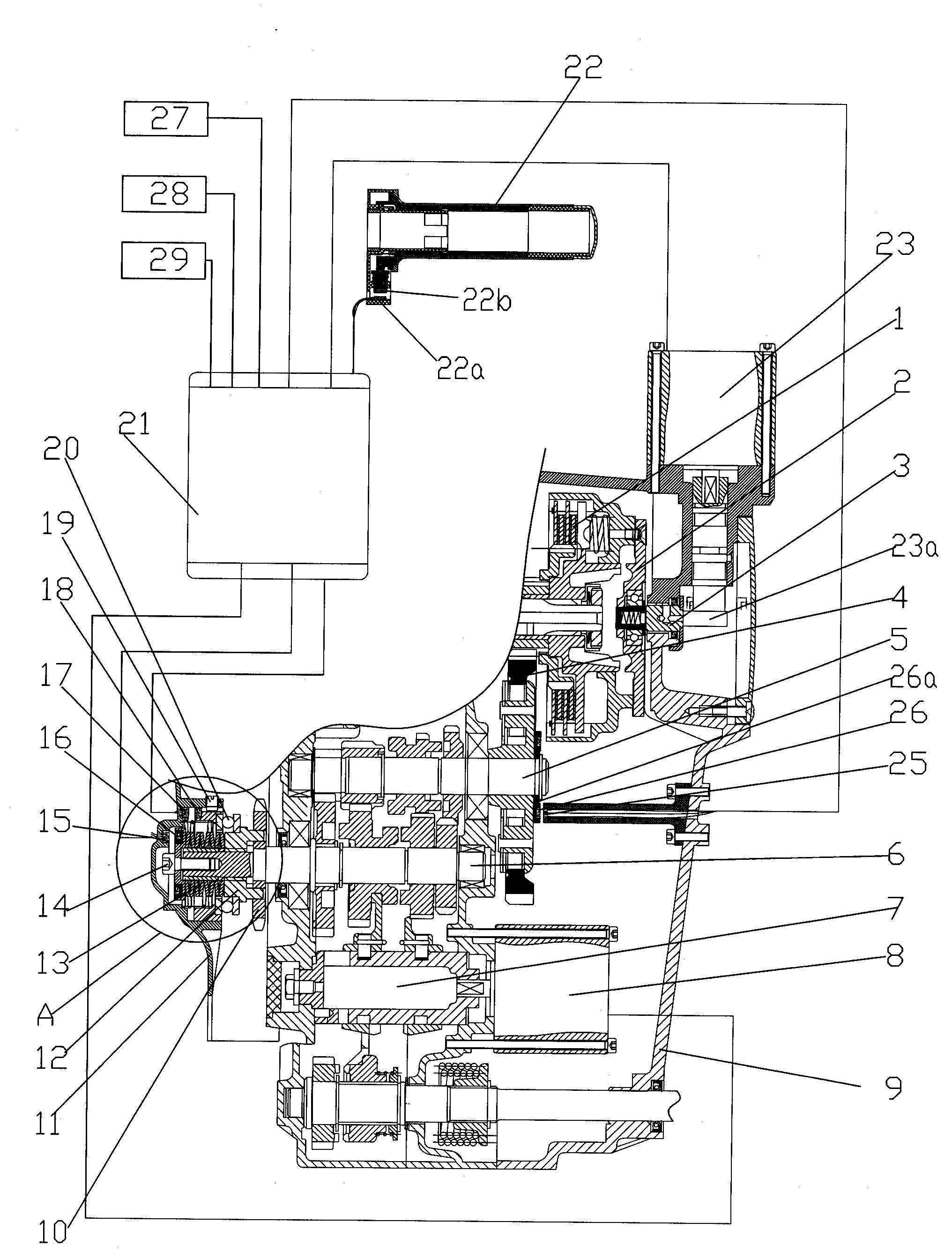

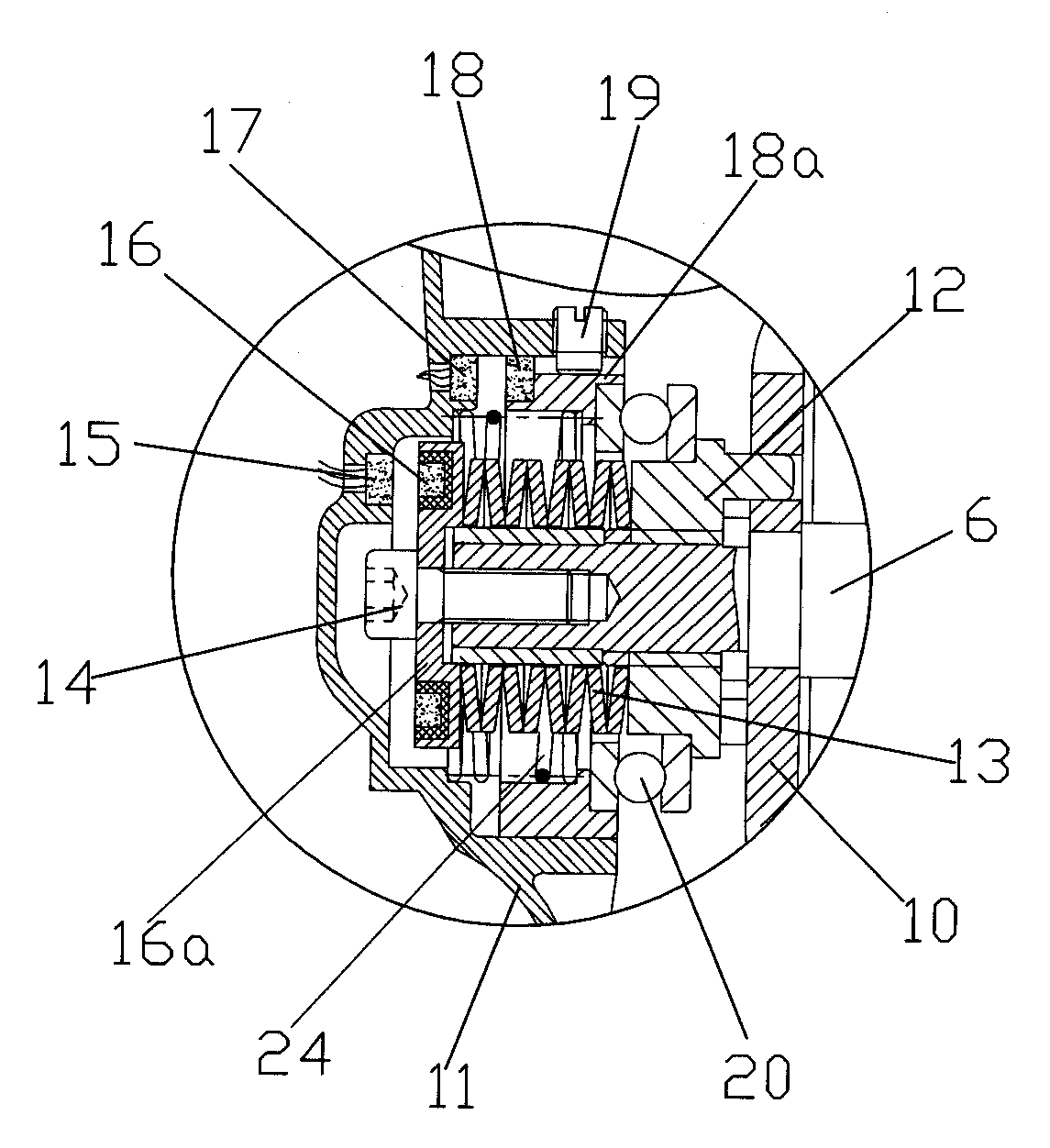

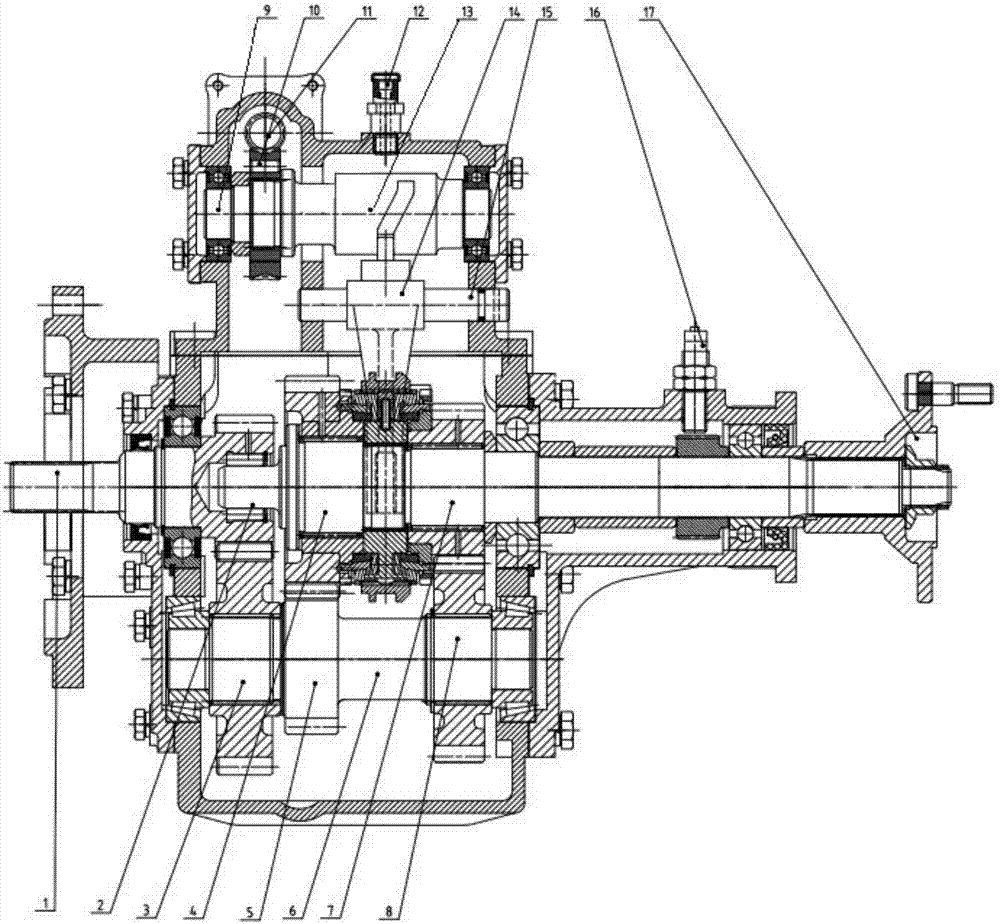

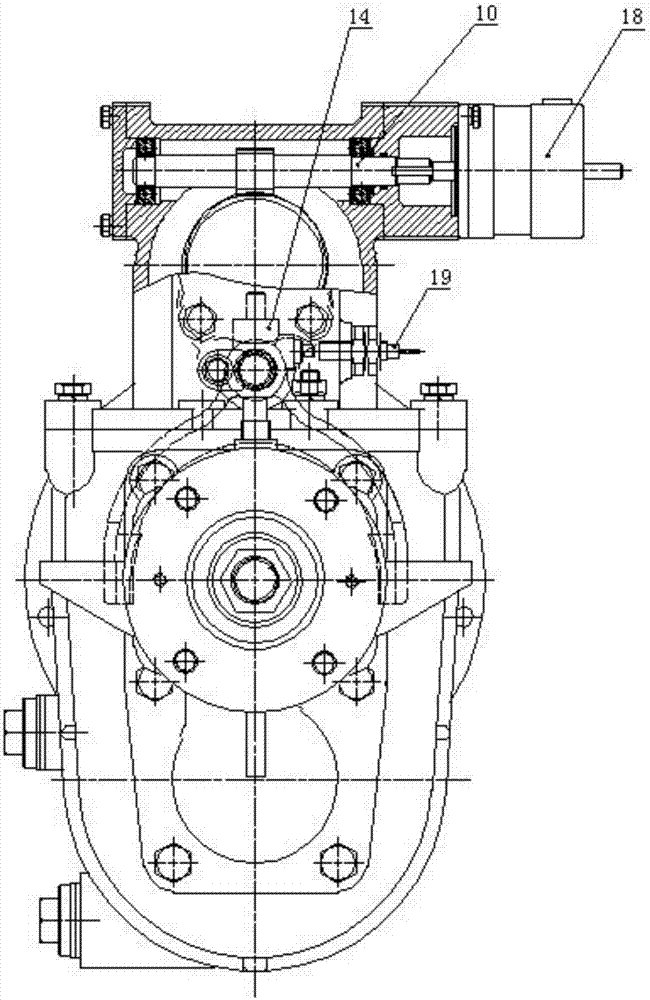

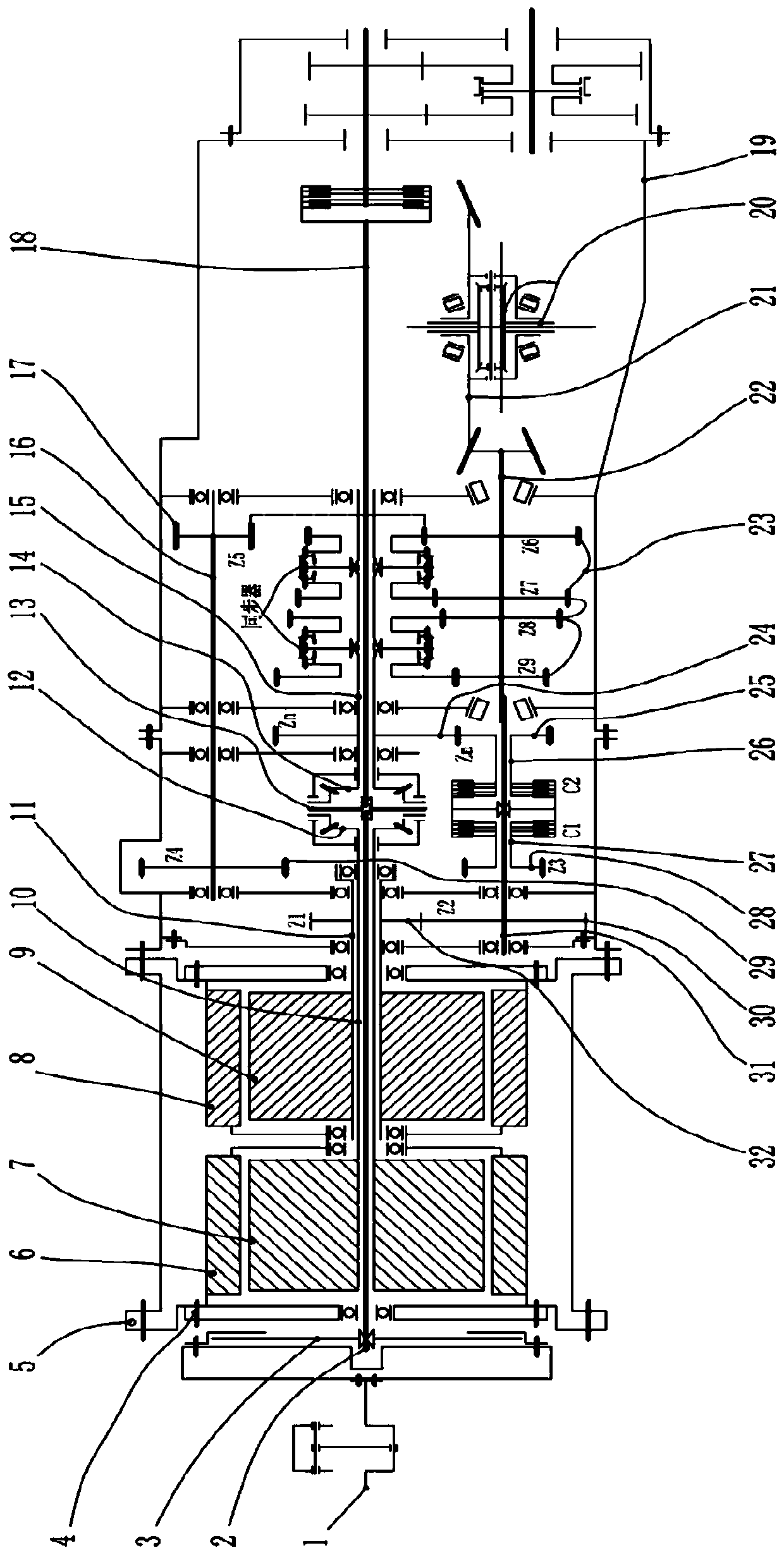

Dual-motor hybrid power automatic transmission

ActiveCN104972890ARealize automatic shiftingMeet driving comfortHybrid vehiclesGas pressure propulsion mountingAutomatic transmissionElectric machine

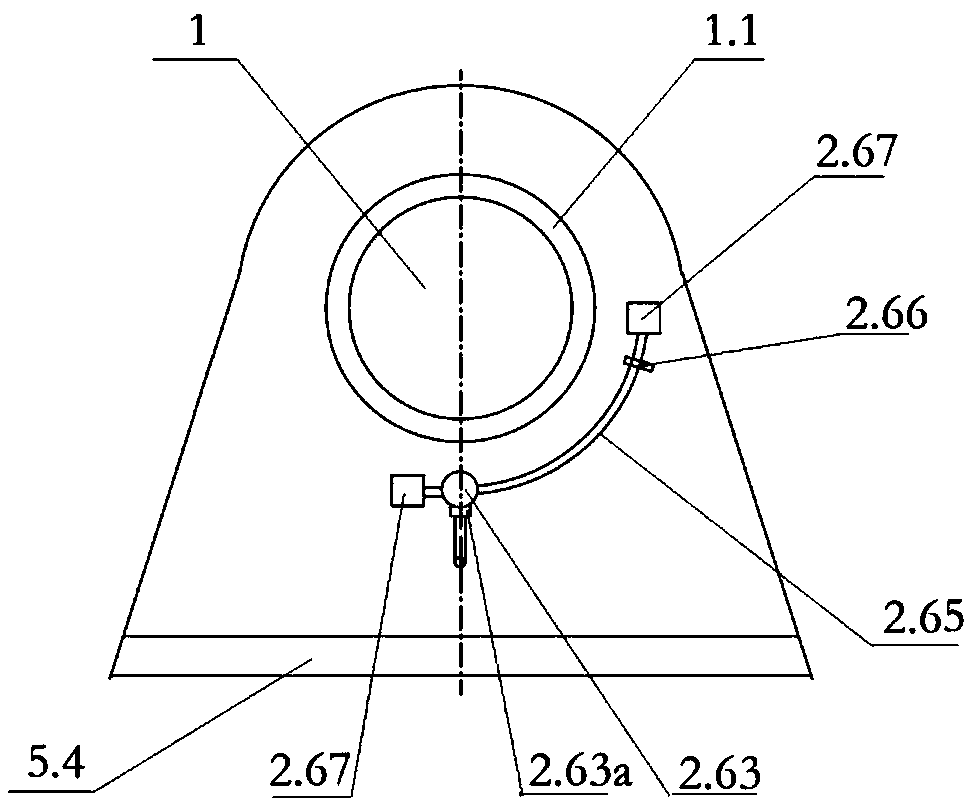

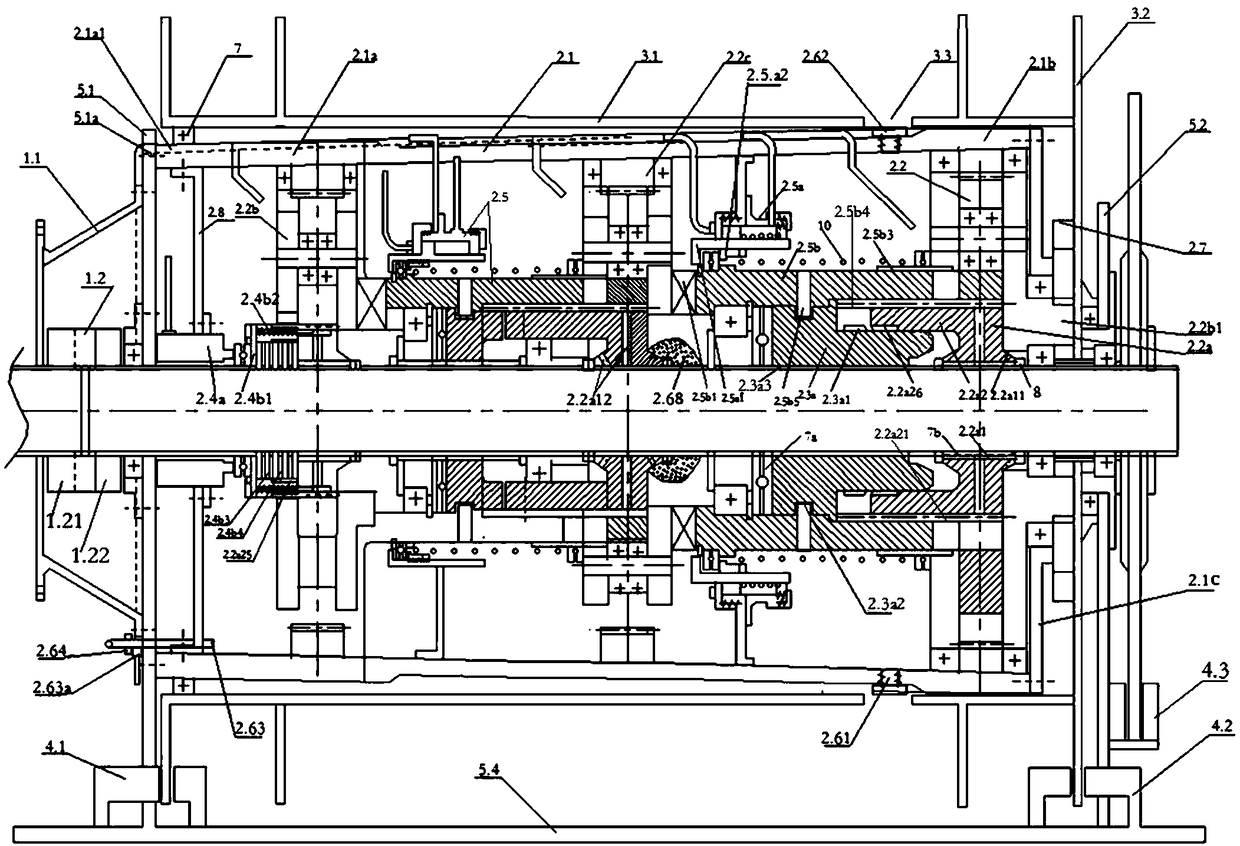

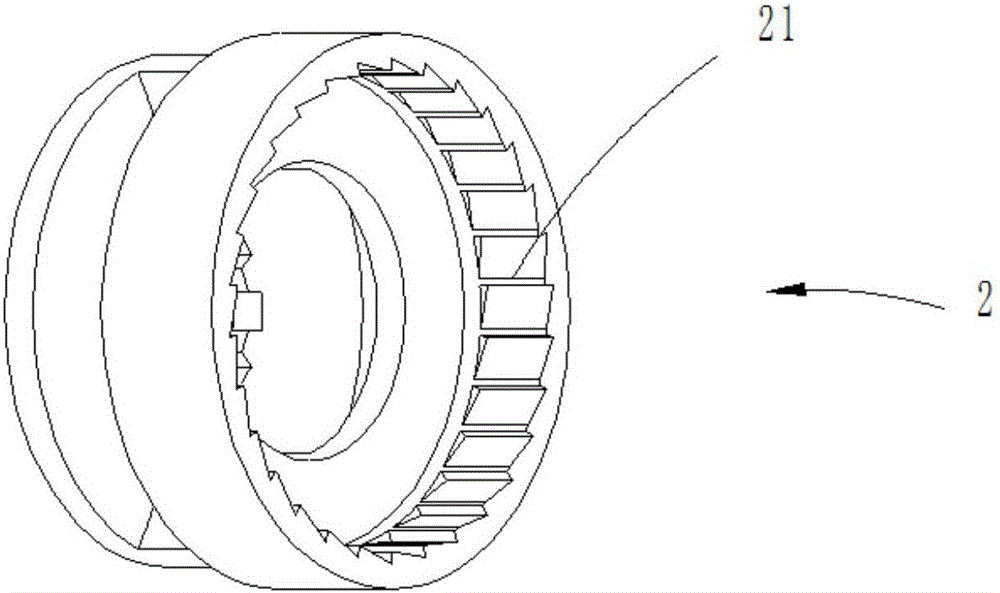

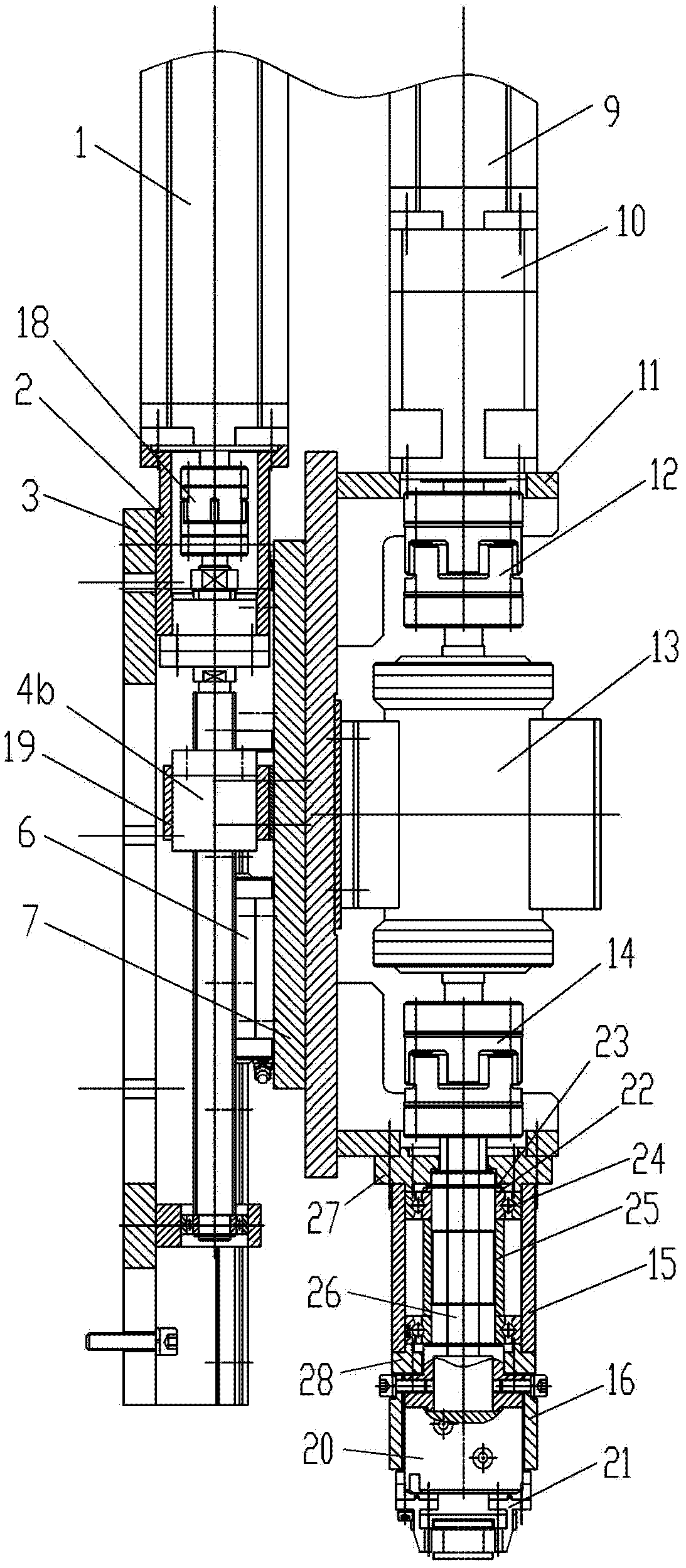

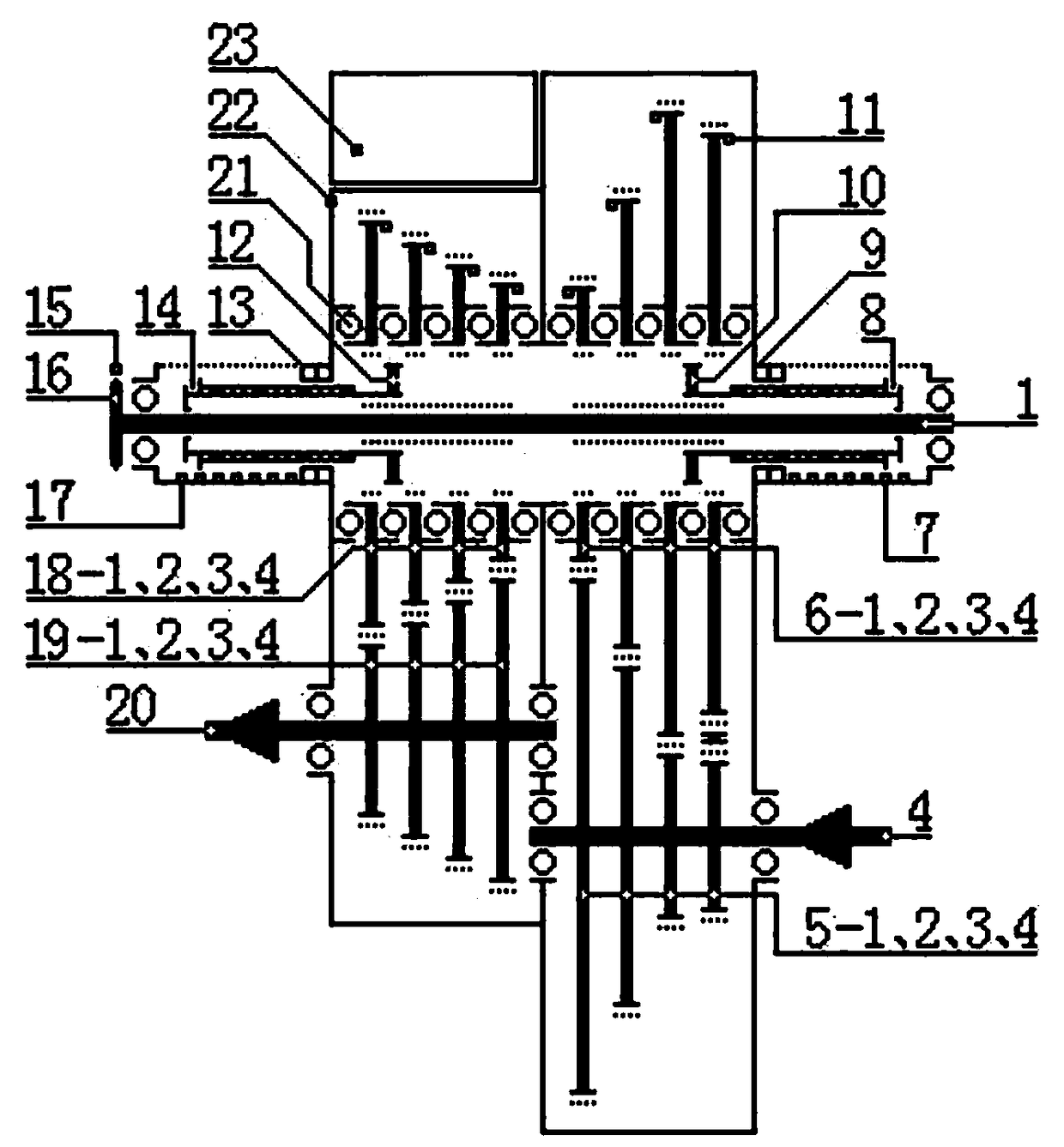

The invention relates to new energy automobile parts, in particular to a dual-motor hybrid power automatic transmission. According to the dual-motor hybrid power automatic transmission, a dual-input-shaft structure is adopted, the two dual input shafts are parallel to an output shaft, and the first input shaft can transmit the power of a first motor as well as the power of an engine by being connected with the engine through a clutch; the second input shaft can transmit the power of a second motor; meanwhile, the power of the engine can also be separated from the first input shaft through the clutch, the power of the first motor can also be separated from the first input shaft through a second gear and fourth gear synchronizer, and the power of the second motor can also be separated from the second input shaft through a first and third synchronizer. By the adoption of the dual-motor hybrid power automatic transmission, all driving states of starting and stopping of the engine, the pure electric mode, the series mode, the parallel mode and the parallel-serial mode can be realized, unpowered interruption type automatic gear shafting of each power source can also be achieved, and therefore driving comfort is guaranteed.

Owner:武汉瑞长捷机电有限公司

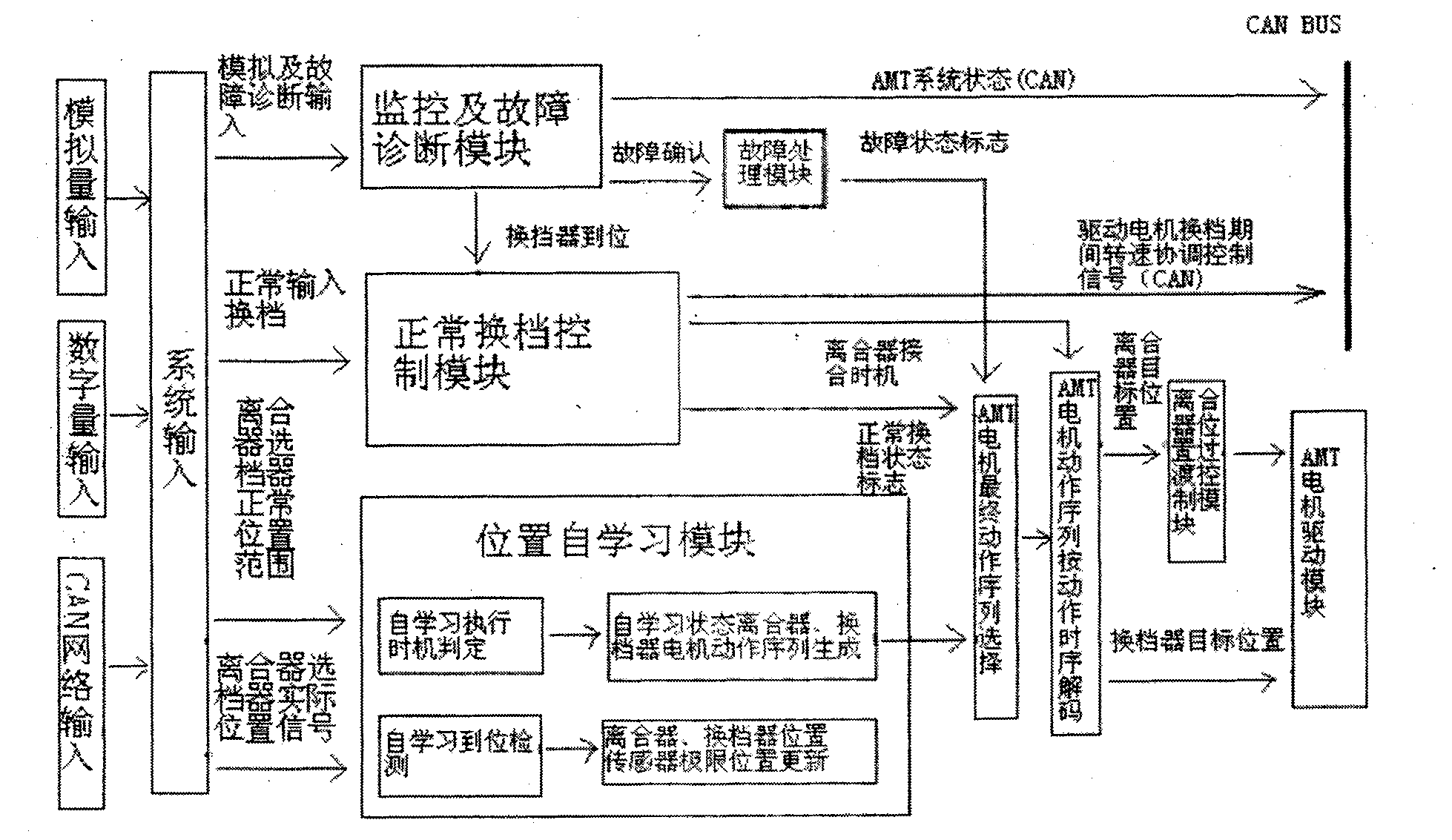

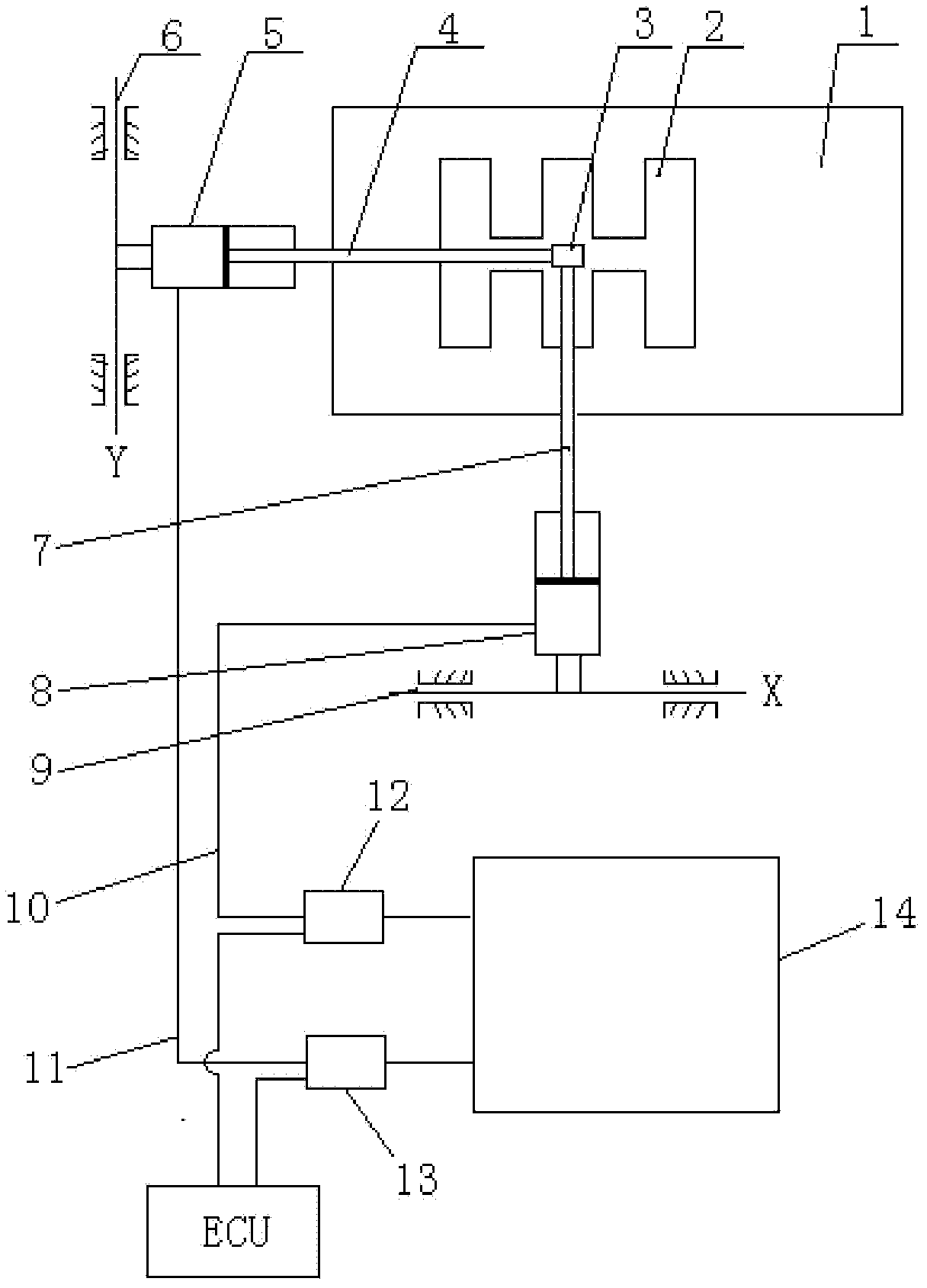

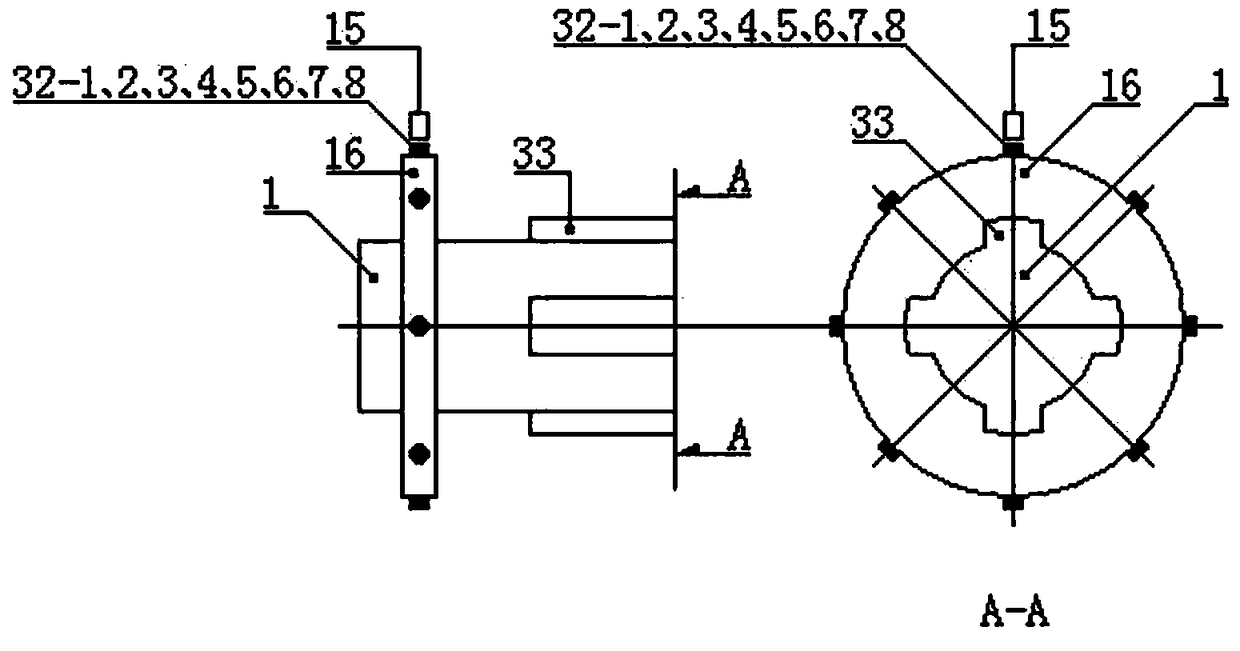

Gearshift mechanism extreme position self-learning control method for AMT system

InactiveCN102182821AMinor changesRealize automatic shiftingGearing controlMotor driveControl engineering

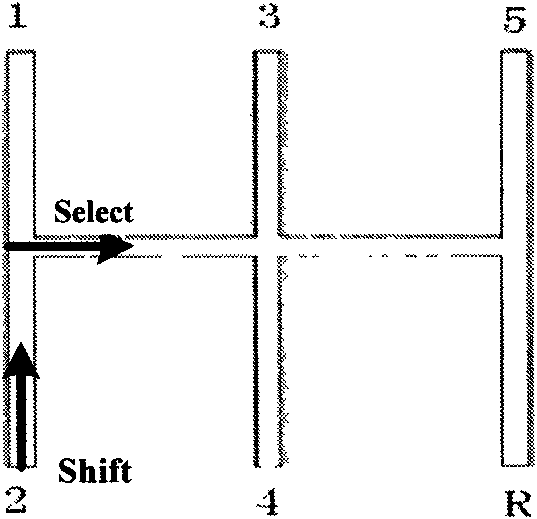

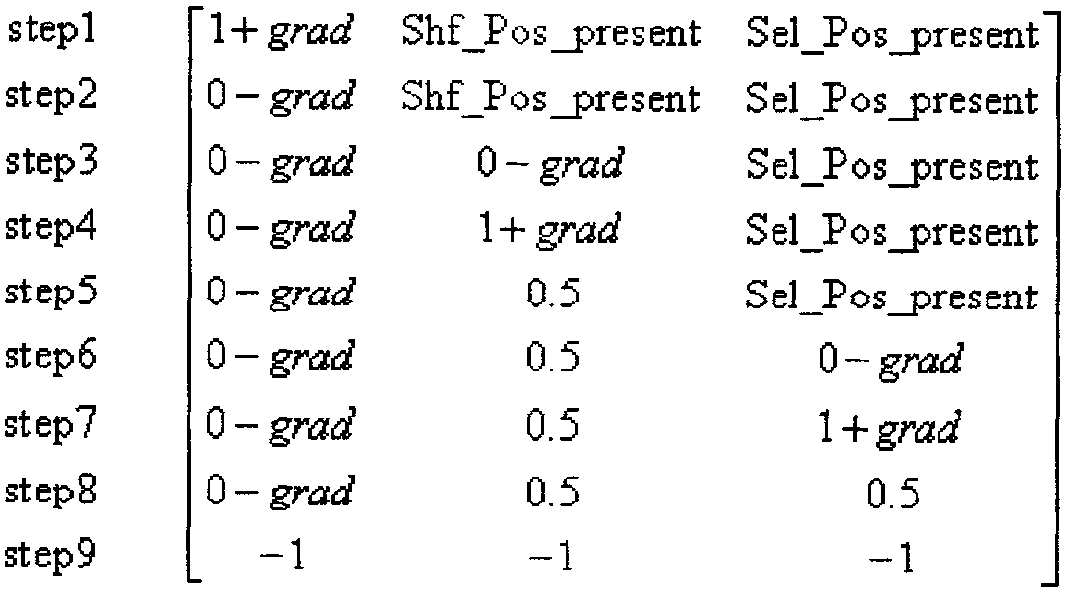

A gearshift mechanism extreme position self-learning control method for an AMT system is adopted for controlling the working sequence of the AMT system, and comprises the steps that firstly, an input signal of a self-learning module is acquired and input by a TCU (the control unit) and a self-learning bit zone is output to other subsequent modules of the AMT system; then an ATM action sequence module selects an action sequence matrix according the bit zone, and decoding is conducted according to action time sequence, so that the target position of each gearshift mechanism is obtained; and finally, the gearshift mechanism is driven to act by a motor driving module. The self-learning module conducts the in-place detection according to the actual position of the gearshift mechanism, and if the self learning process is completed, the extreme position parameter of a mechanical mechanism is updated and stored automatically. Therefore, when temperature is changed greatly or traveled distance is accumulated to a certain degree, the precision and the speed of motor driving can be guaranteed.

Owner:海博瑞德(北京)汽车技术有限公司

Hydraulic pliers

InactiveCN101429856AImplement auto-scalingReduce labor intensityDrilling rodsDrilling casingsLow speedEngineering

The invention relates to an oil field well workover treatment tool, in particular to hydraulic tongs capable of realizing the automatic loading / unloading of an oil pipe and a sucker rod. The hydraulic tongs comprise main tongs, back tongs, a high-low-speed gear shift mechanism and a connecting support. The back tongs are arranged on the connecting support; the main tongs are positioned above the back tongs and are connected with the back tongs through a guide bar; and the main tongs can reciprocate up and down along the guide bar. The high-low-speed gear shift mechanism is arranged on the main tongs; the output end of the high-low-speed gear shift mechanism is connected with a gear shift device inside the main tongs; and the high-low-speed gear shift mechanism is also connected with a hydraulic control module. The hydraulic tongs are connected with a hydraulic tongs telescopic bracket of the machine body of the well workover machine through the connecting support. The hydraulic tongs are driven by the telescopic bracket to realize automatic telescoping, thereby freeing operators from a dangerous operating environment. Automatic operation is realized for the loading / unloading of the hydraulic tongs, thereby not only reducing the labor intensity of workers, but also avoiding possible accidental injury of workers during the operation.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU +1

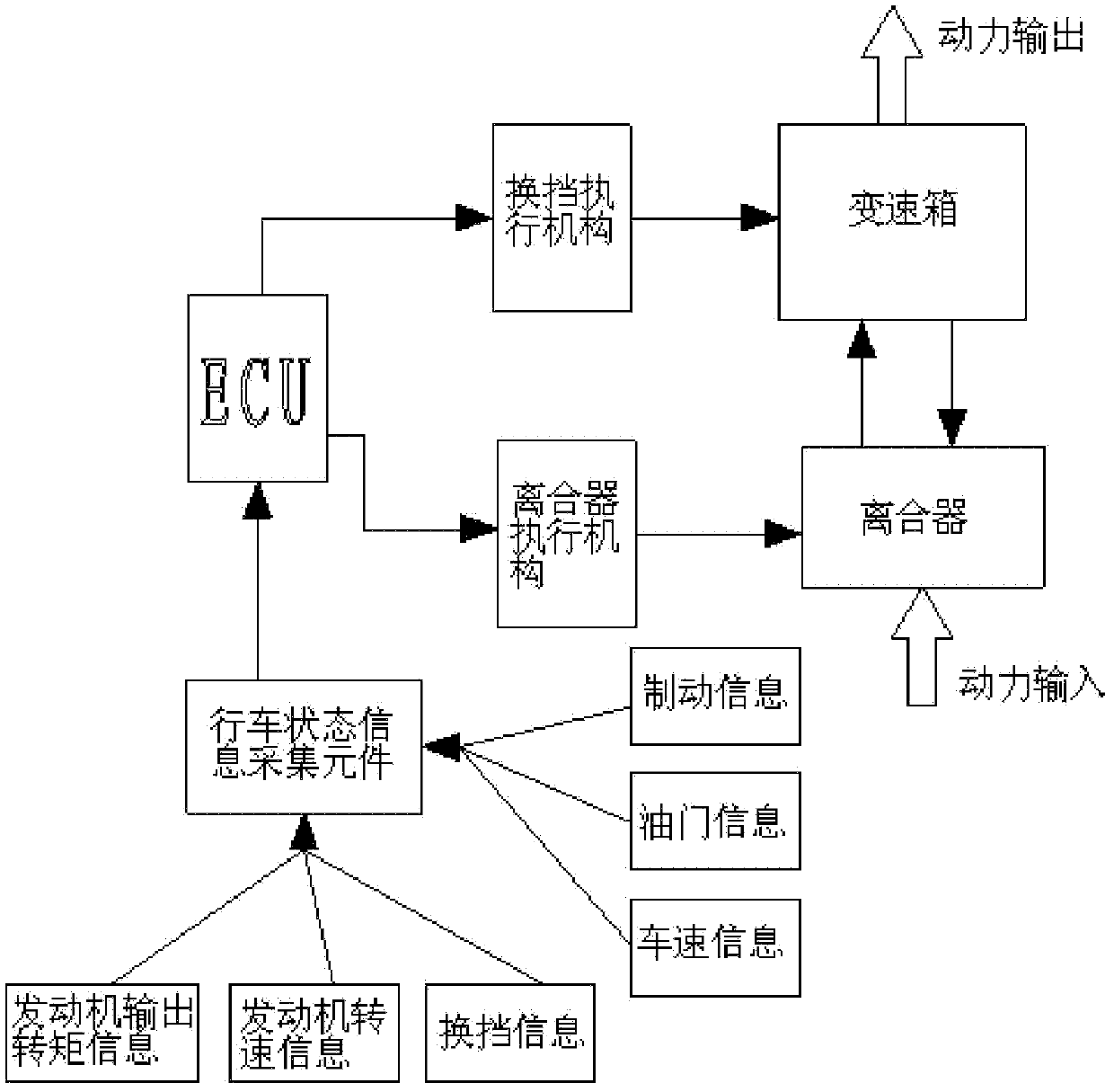

Automatic speed changing method based on manual gearbox and system

InactiveCN102606722ARealize automatic shiftingLow costControlled membersGearing controlAutomatic controlEngineering

The invention discloses an automatic speed changing method based on a manual gearbox and a system. The automatic speed changing method includes controlling linkage of a clutch actuating mechanism and a clutch to realize engaging and disengaging and controlling linkage of a gear shifting actuating mechanism and the gearbox to change a gear position by a central processing unit according to obtained vehicle driving state information. The automatic speed changing method and the system have the advantages that 1, a working mode is an automatic step speed change mode, the characteristic of high-torque output of a manual speed changing mode is inherited, automatic gear shifting can be realized, and the automatic speed changing method and the system can be applied to heavy-duty goods vehicles and public transport vehicles; 2, speed-changing gear shifting is completed hydraulically or by the aid of a motor controlled by an ECU (electronic control unit) on the basis of manual speed changing, and manufacturing cost is low; and 3, shortcomings of a hydraulic torque converter are overcome due to an automatic control effect of the ECU, and power loss of an engine is greatly reduced.

Owner:HUNAN UNIV

Novel automatic transmission without clutch and synchronizer and speed change method thereof

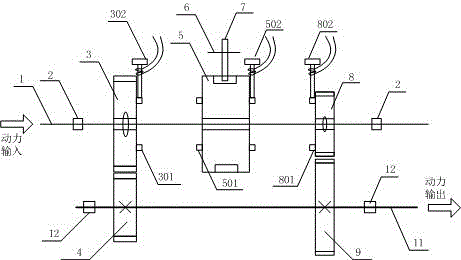

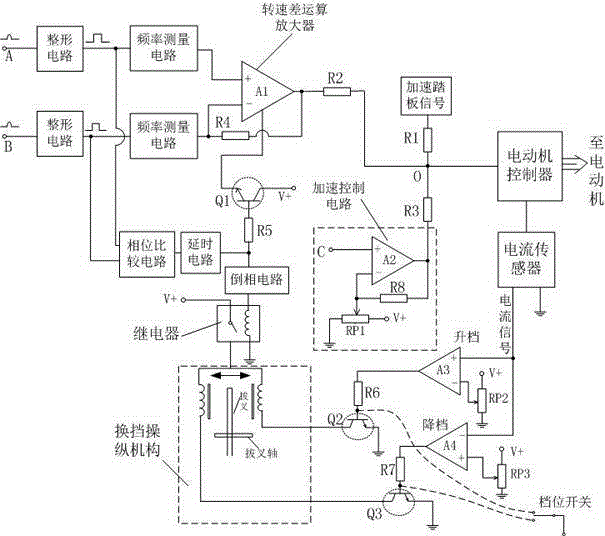

The invention proposes a novel automatic transmission without a clutch and a synchronizer and a speed change method thereof. The automatic transmission comprises a first-gear driving gear, a second-gear driving gear, a combination gear arranged between the first-gear driving gear and the second-gear driving gear, a first-gear driven gear engaged with the first-gear driving gear, a second-gear driven gear engaged with the second-gear driving gear, a gear shifting control circuit, and a motor controller; rotating speed sensors are respectively arranged on the first-gear driving gear, the second-gear driving gear and the combination gear, and are used for measuring the rotating speeds and phases of the corresponding gears and sending to the gear shifting control circuit; the gear shifting control circuit adjusts the rotating speed of the combination gear through comparing the rotating speed difference between the combination gear and the driving gear to be combined with the combination gear in gear shifting until the rotating speed difference is in a set range; and when the combination gear and the driving gear to be combined with the combination gear in gear shifting are matched in phase, a shifting fork is driven to control the gear combination.

Owner:闫永革

Winch with planetary gear transmission having function of automatic gear shifting

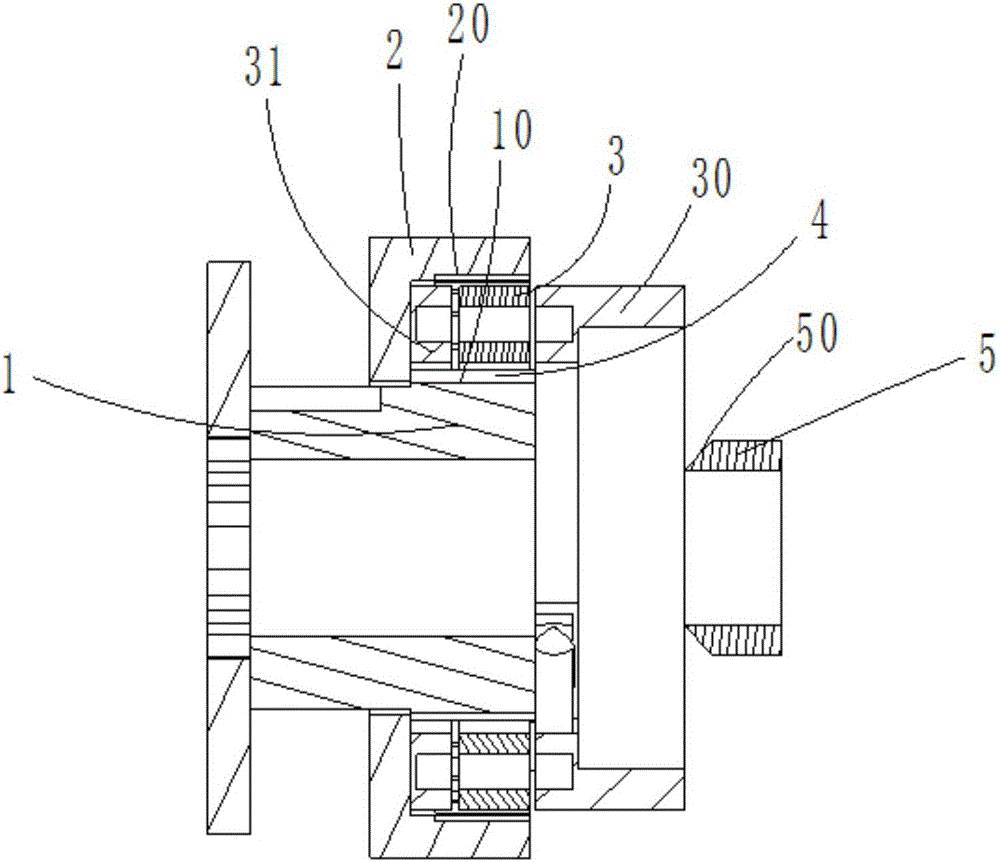

ActiveCN109368525AEliminate the trolley phenomenonLow costGearboxesToothed gearingsGear wheelElectric vehicle

The invention relates to a winch with a planetary gear transmission having a function of automatic gear shifting, and belongs to the technical field of planetary gear transmissions and winches. The winch comprises a power mechanism, an electric motor or a hydraulic motor, a transmission arranged in a drum, the drum, a brake, a machine frame and a sensor, wherein the housing of which the inner diameter is tapered, of the transmission is fixed on the left machine frame; a driving shaft penetrates through a center hole of a sun wheel at the center of each level planetary gear; clutch shifters arerespectively arranged between each level planetary gear and the last level planetary gear and the drum; when the winch is at neutral gear, the clutch shifters are connected with a planetary gear carrier on the power input side and center sun wheels on the power output side; a driving unit is used for driving an executing unit tubular piece to move rightwards; the connection between a clutch and left planetary gears is separated and cut off, and right driving shaft power output gears are connected with the center sun wheel, so that gear shifting is completed; and an empty hood or light load power mechanism is used for directly driving the drum to rotate through the driving shaft. The winch disclosed by the invention with the synchronizer can be used for electric vehicles and the like.

Owner:姜启胜

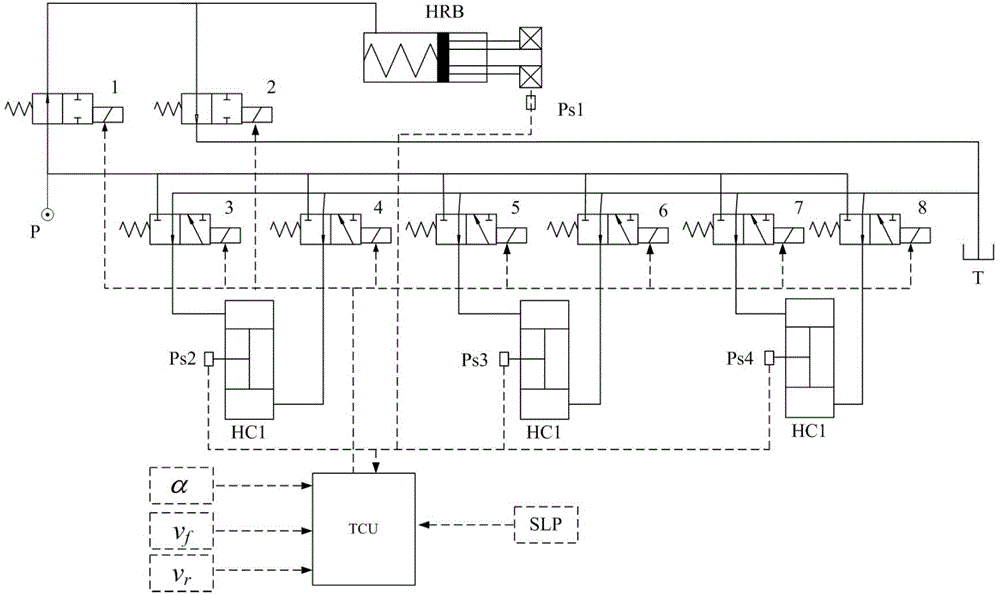

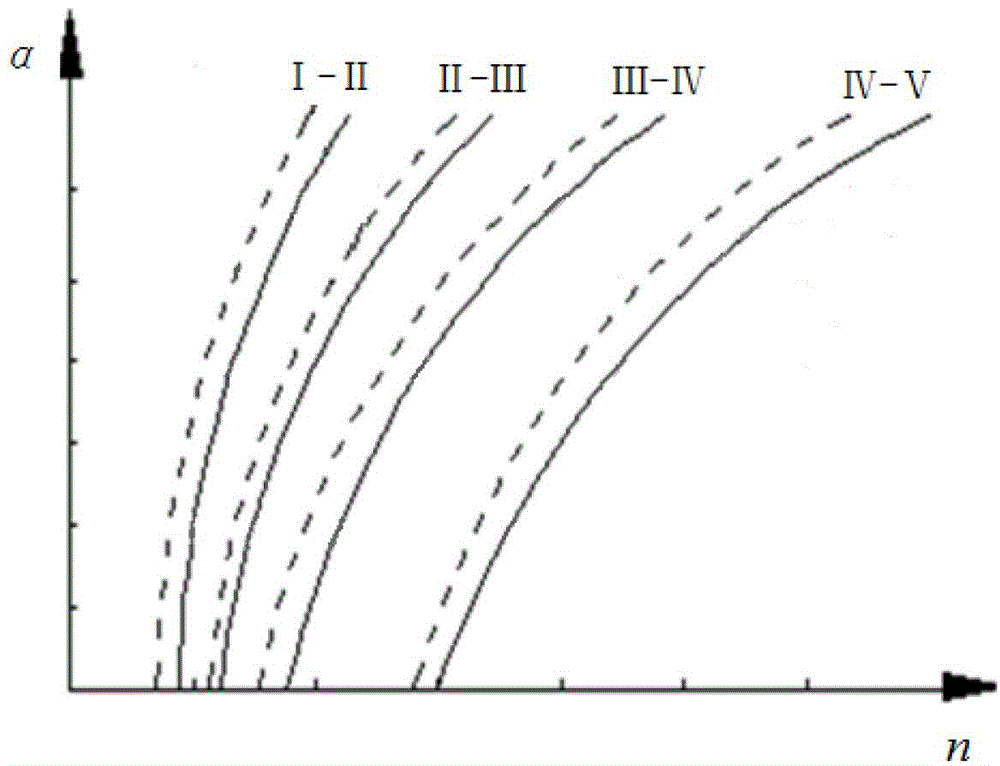

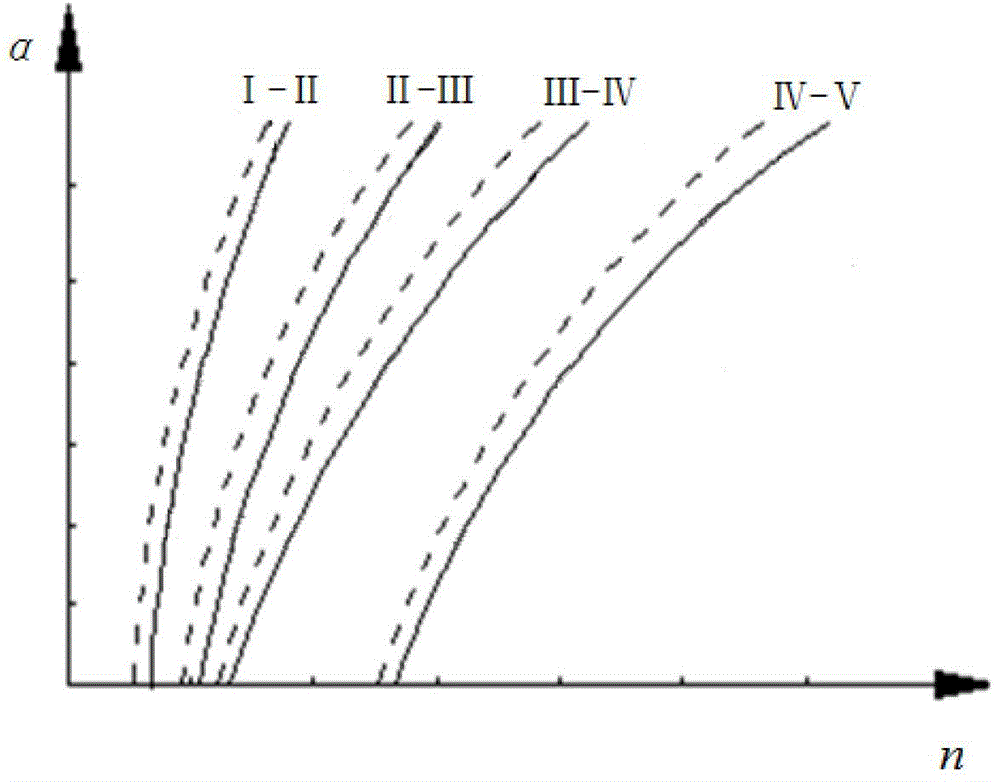

Gear-shifting schedule curve measuring method and corresponding gear-shifting control method for off-road vehicles

The invention relates to a gear-shifting schedule curve measuring method and a corresponding gear-shifting control method for off-road vehicles, and belongs to the technical field of automatic variable speed control of the off-road vehicles. According to the methods, a gear-shifting schedule curve equation of an AMT (automated mechanical transmission) of an off-road vehicle is calculated firstly; a corresponding gear-shifting schedule curve is drawn; the current practical vehicle speed, the slip ratio and the throttle opening degree are collected, and corresponding target gears are determined; control signals for electromagnetic valves of actuating mechanisms are output through an logical operation; therefore, the electromagnetic valves of the actuating mechanisms are enabled to perform corresponding actions, and the automatic gear shifting is achieved. The gear-shifting schedule curve measuring method and the corresponding gear-shifting control method can guarantee the tractive efficiency and the fuel oil economic efficiency of the AMT of the off-road vehicles, reduces the work intensity of a driver, and enables the vehicles to travel more smoothly; meanwhile the gear-shifting actuating mechanisms are improved, a gear selecting process is omitted, the gear-shifting time is reduced and the gear-shifting efficiency is improved due to the direct gear shifting; and the methods can be used for AMT of off-road engineering vehicles, agricultural vehicles and military motor vehicles.

Owner:HENAN UNIV OF SCI & TECH

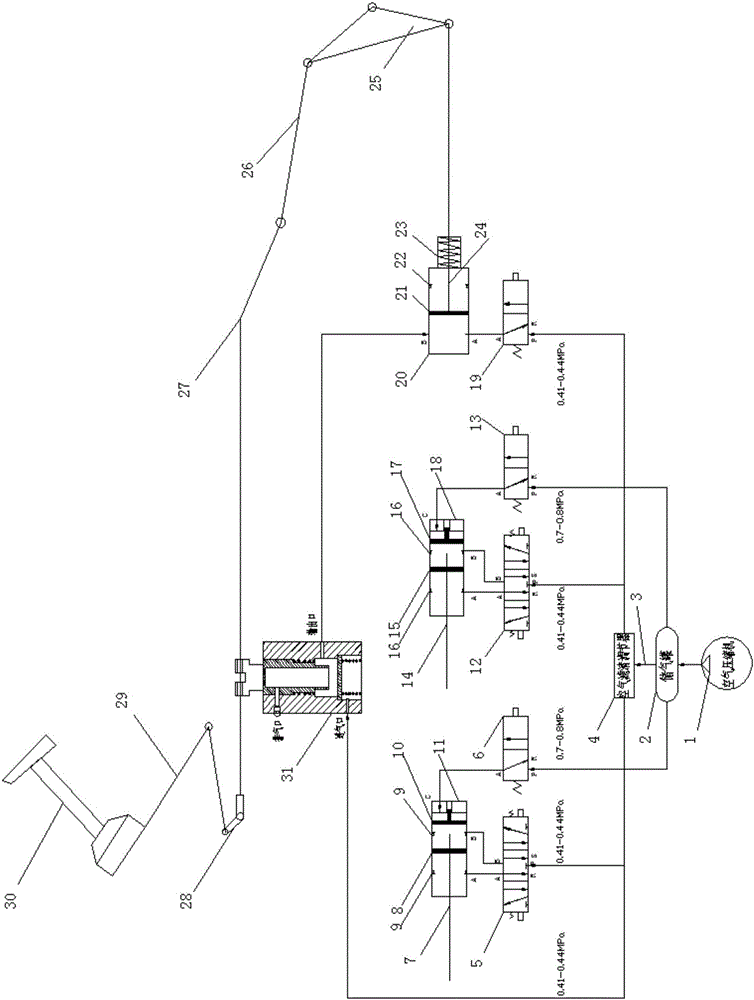

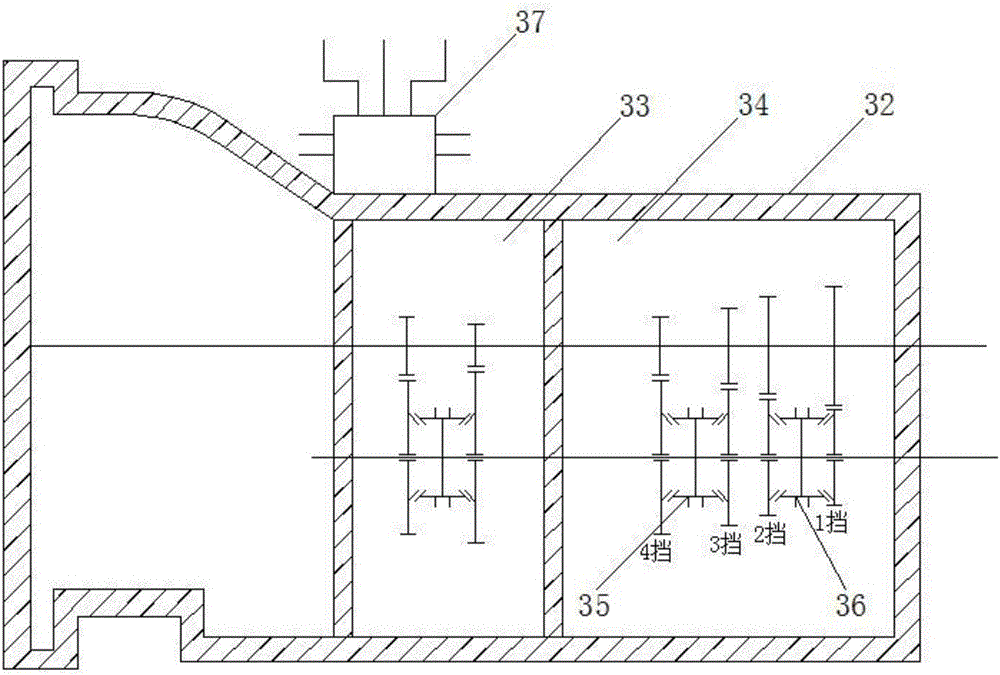

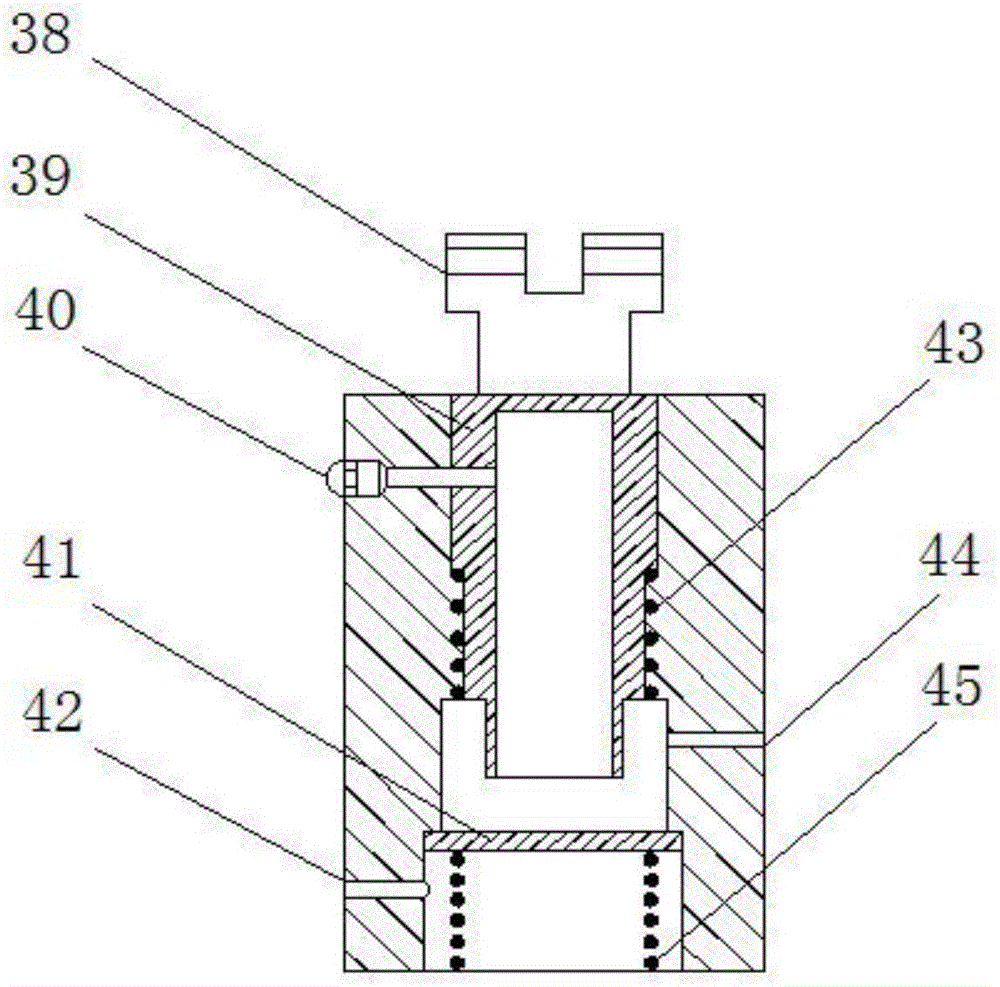

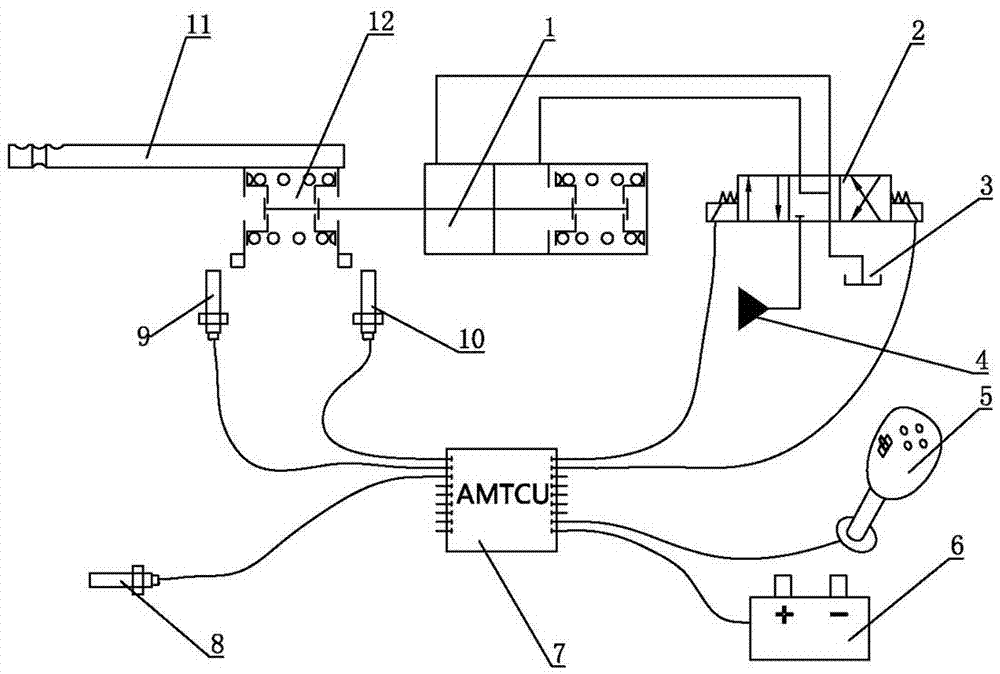

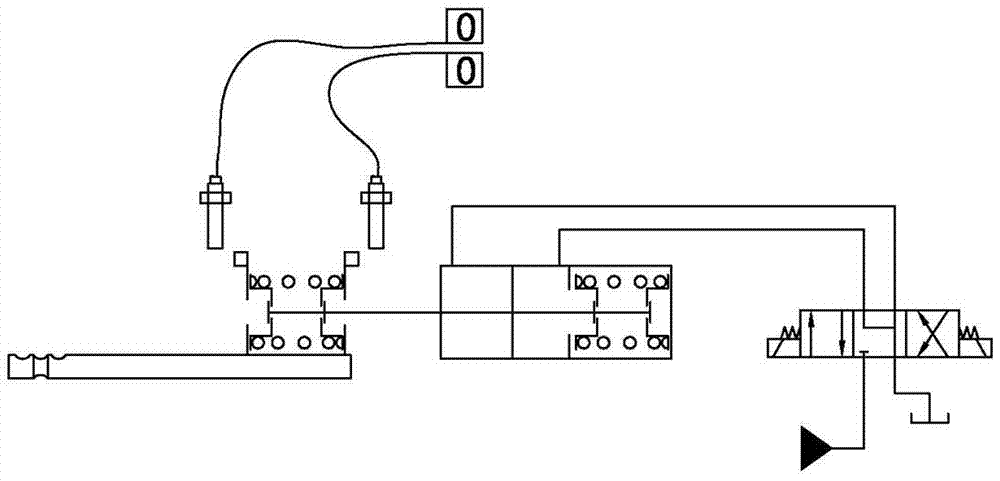

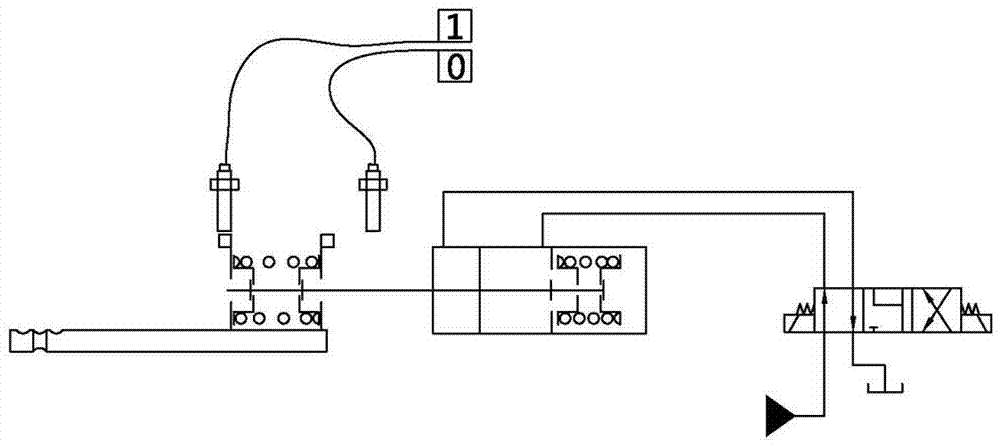

Electronic control pneumatic gear shifting device of tractor transmission

An electronic control pneumatic gear shifting device of a tractor transmission comprises a whole vehicle air source, a gear shifting execution mechanism, a clutch operation mechanism and a controller. The whole vehicle air source comprises an air compressor, an air storage tank and an air filtration regulator. The gear shifting execution mechanism comprises a first three-position five-way pneumatic electromagnetic valve, a first two-position three-way pneumatic electromagnetic valve, a second three-position five-way pneumatic electromagnetic valve, a second two-position three-way pneumatic electromagnetic valve, a first gear shifting cylinder and a second gear shifting cylinder. The clutch operation mechanism comprises a third two-position three-way pneumatic electromagnetic valve, an assistance cylinder, a control valve and a pedal mechanical transmission device. The air compressor is connected with the pneumatic electromagnetic valves through an air conveying pipeline by means of the air storage tank and the air filtration regulator. All the pneumatic electromagnetic valves are connected with the controller. An air inlet of a control valve is connected with the whole vehicle air source through the air conveying pipeline. Electronic control pneumatic gear shifting and pneumatic assistance are adopted for the electronic control pneumatic gear shifting device, and therefore the operation comfort and the work efficiency of the transmission are improved, the fatigue strength is lowered, and the automation degree of a tractor is improved.

Owner:WUHAN UNIV OF TECH

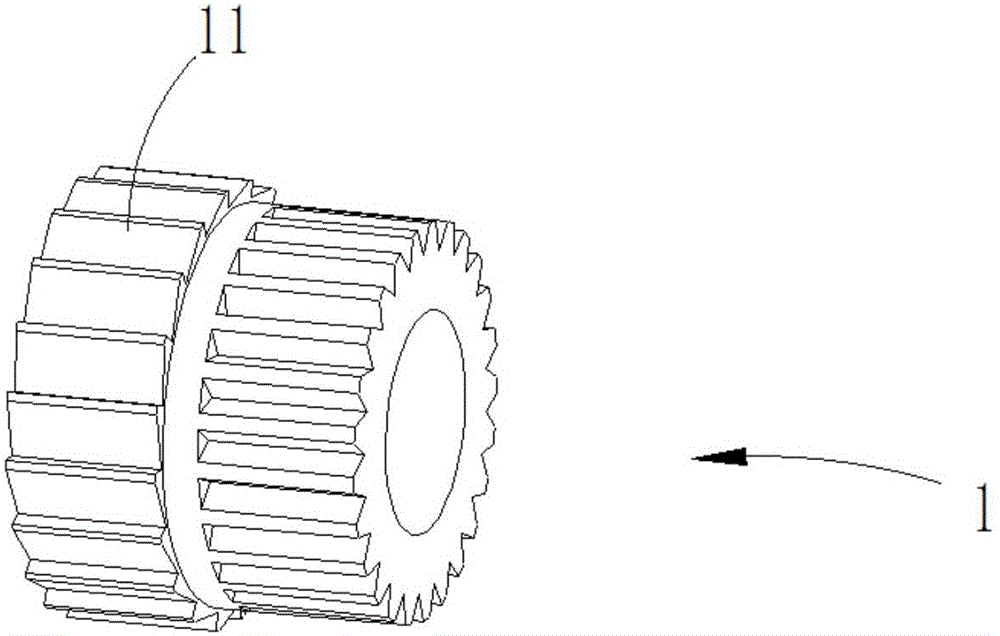

Centrifugal gear shifting device

The invention relates to a centrifugal gear shifting device, which comprises a first transmission element, a second transmission element and a gear shifting mechanism, wherein an accommodating cavity is formed between the second transmission element and the first transmission element; the second transmission element is provided with an inner wall positioned in the accommodating cavity; the first transmission element is provided with an outer wall positioned in the accommodating cavity; a first ratchet wheel is arranged in the outer wall position of the first transmission element; a second ratchet wheel is arranged in the inner wall position of the second transmission element; the gear shifting mechanism comprises a gear shifting element frame and a gear shifting element device; the gear shifting element device comprises a plurality of gear shifting elements; the gear shifting elements are connected through balancing elements; each gear shifting element comprises an installing part and a weight balancing block; the installing part comprises an inner surface and an outer surface; the first pallet is arranged on the inner surface of the installing part; the second pallet is arranged on the outer surface of the installing part; an elastic element used for controlling the initial position of the first pallet and the second pallet is arranged on the gear shifting element frame. The centrifugal gear shifting device can realize the automatic gear shifting in the running process.

Owner:ZHANGJIAGANG CHUANJUN VEHICLE IND CO LTD

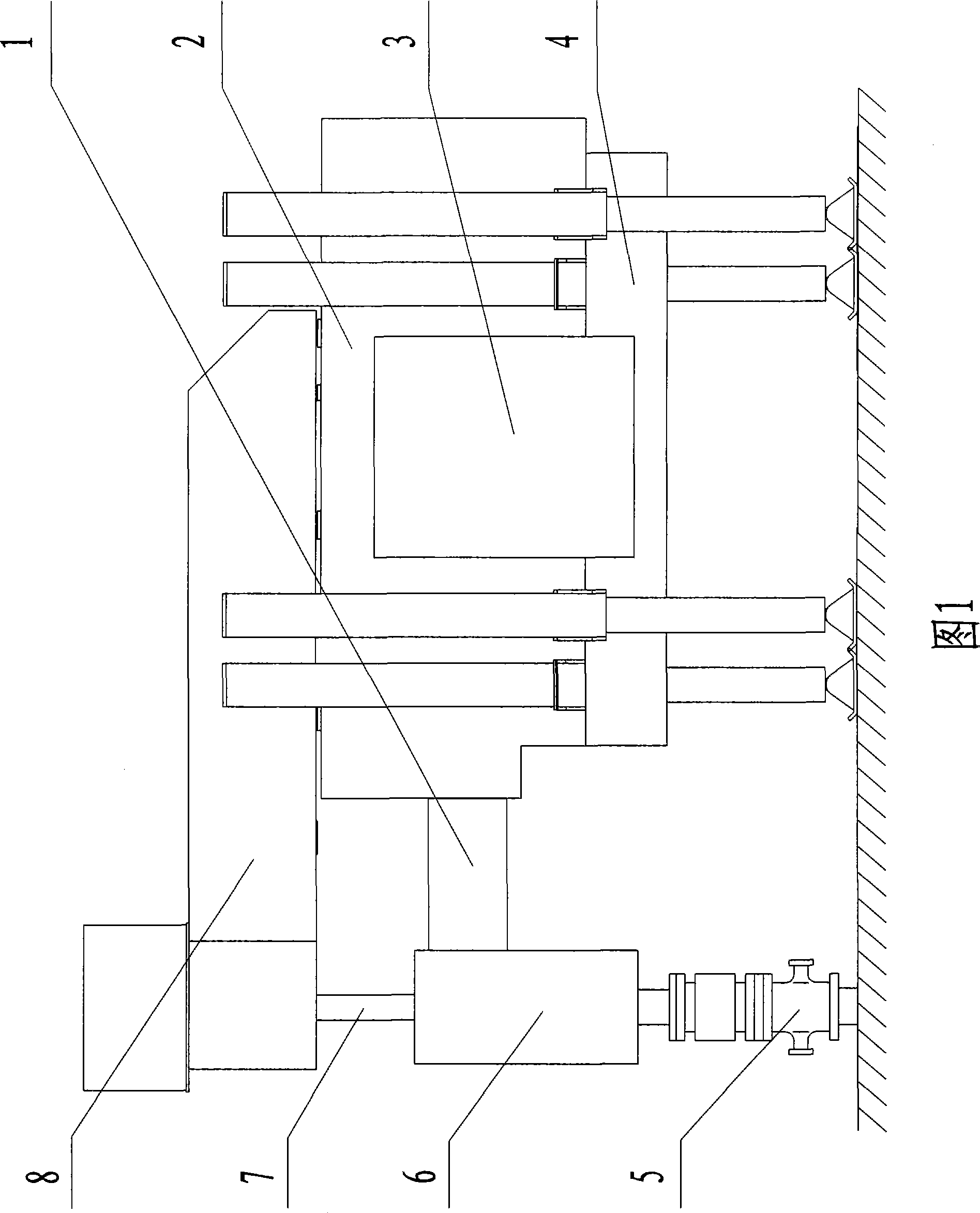

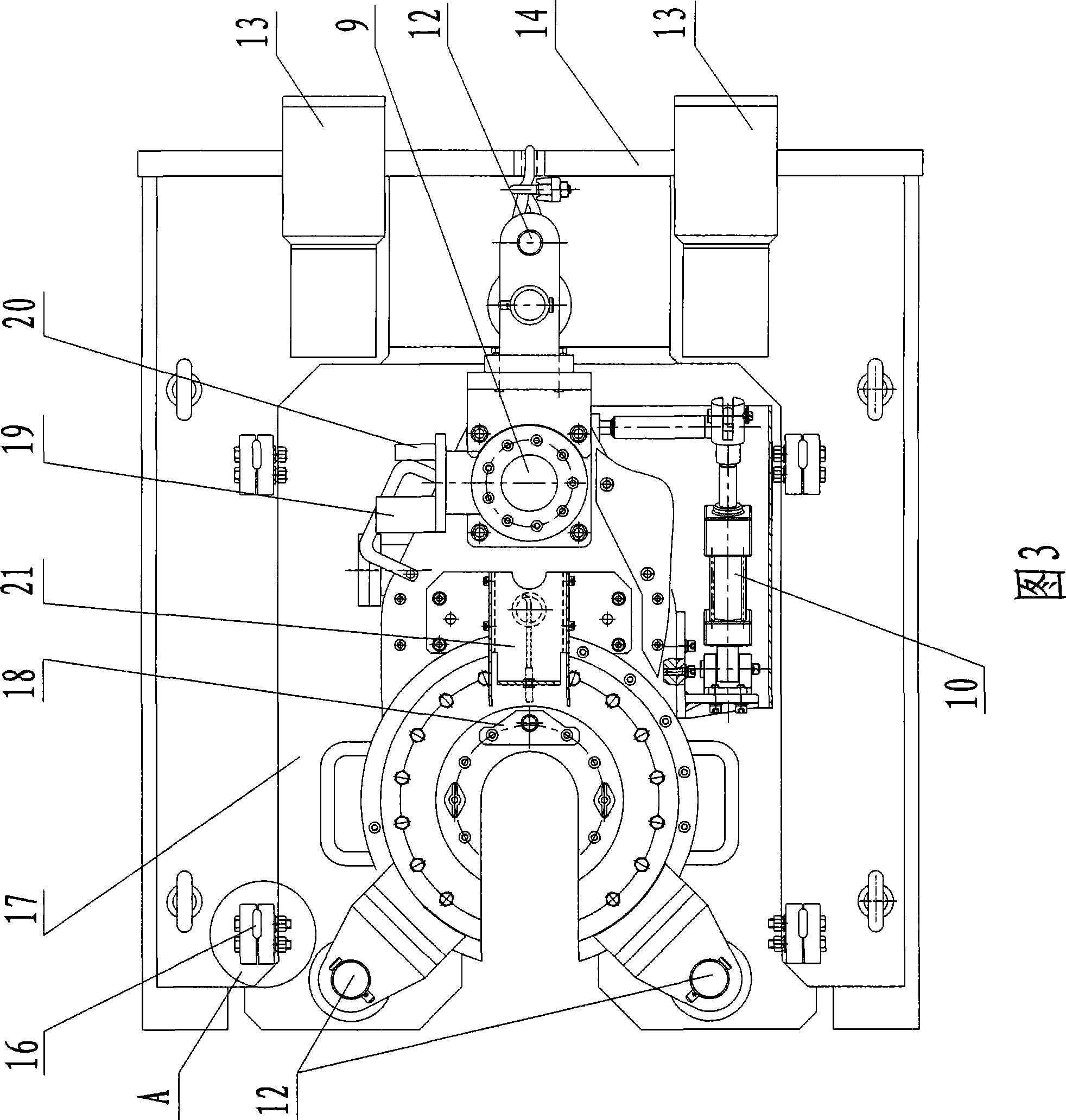

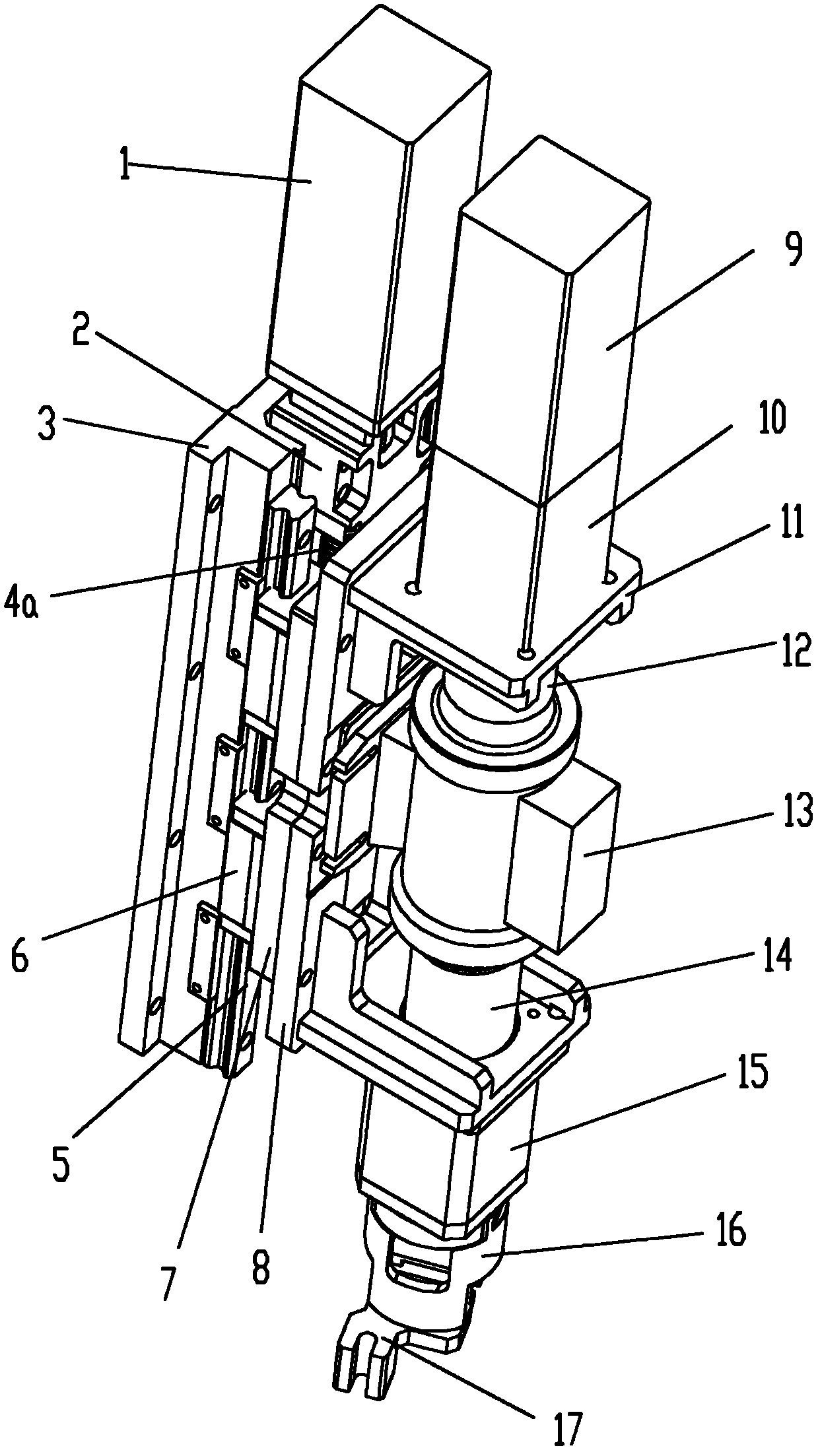

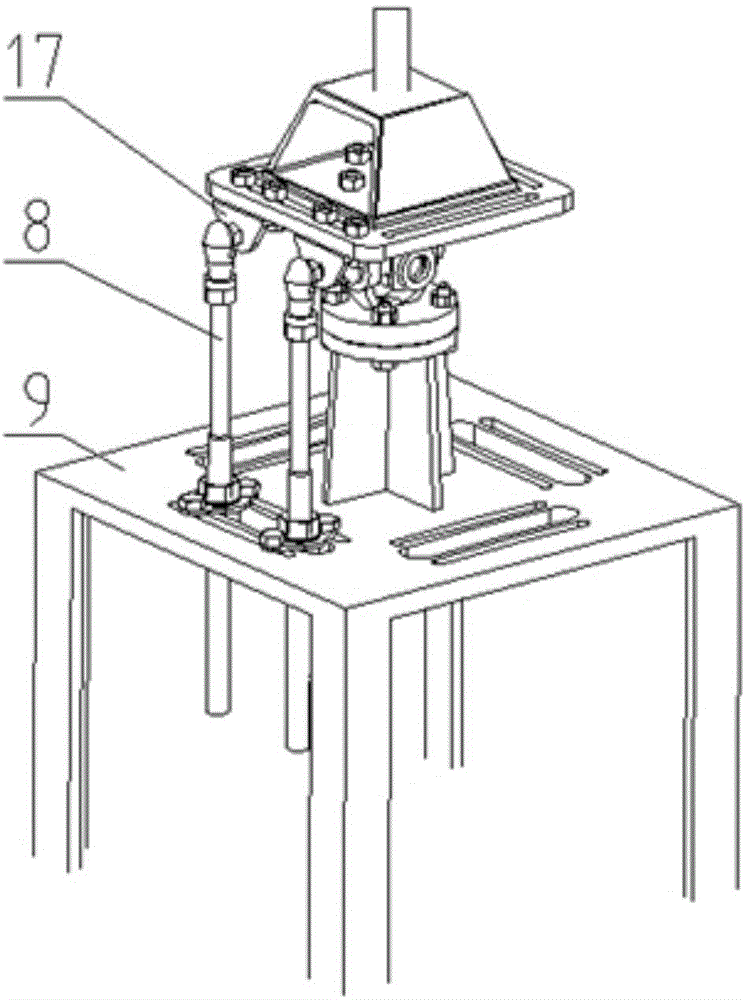

On-line loading test stand shift mechanism of manual transmission

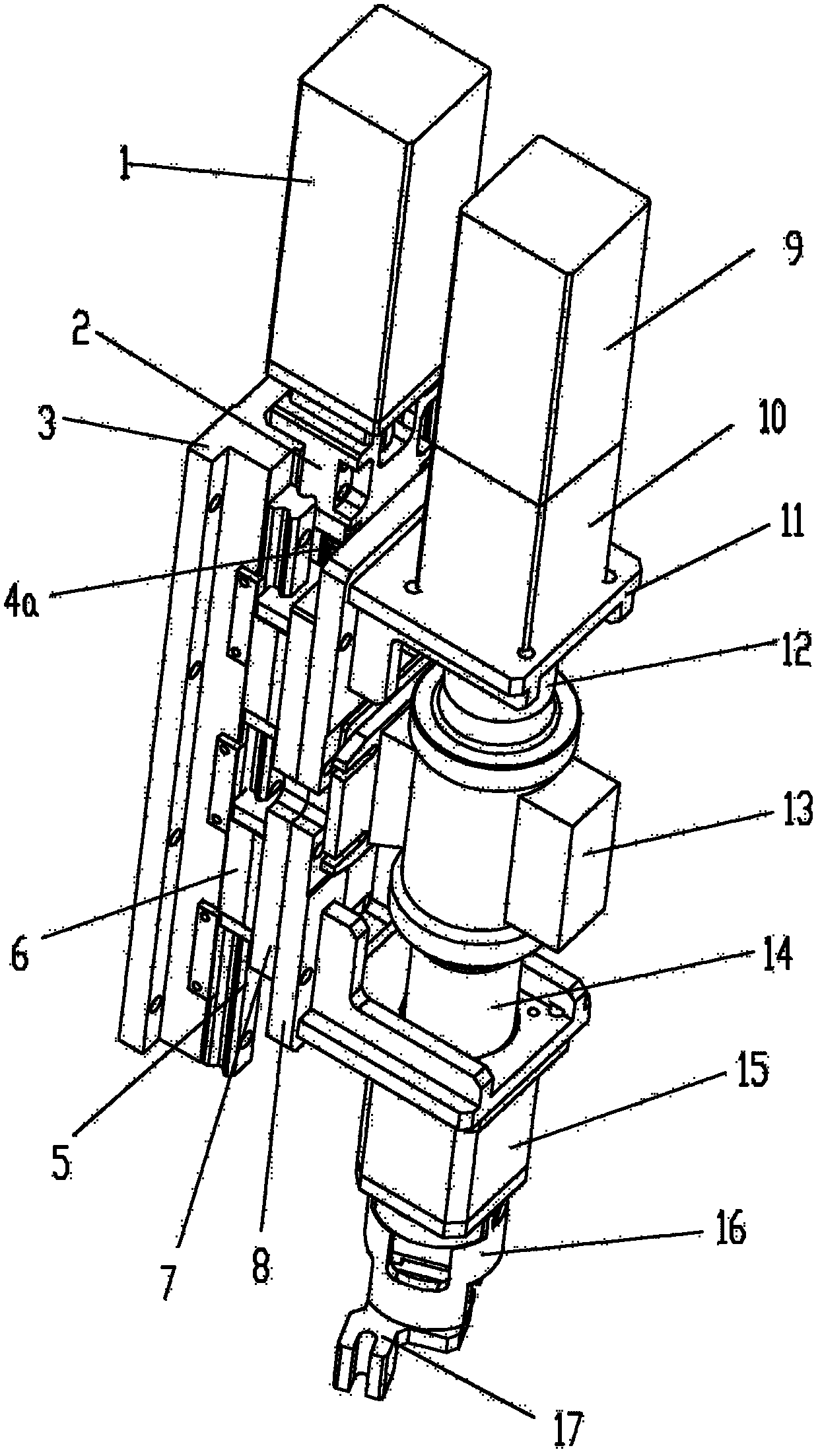

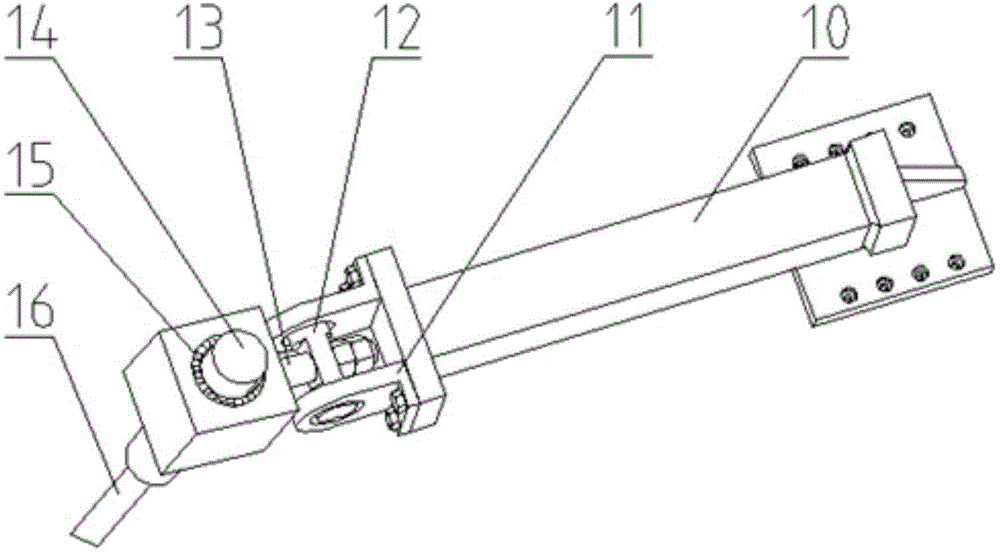

ActiveCN102384845ARealize automatic shiftingSimple structureMachine gearing/transmission testingMotor driveDrive shaft

The invention discloses an on-line loading test stand shift mechanism of a manual transmission.The on-line loading test stand shift mechanism is characterized in that a gear selection unit is arranged and has a working principle that a gear selection servo motor drives a screw sliding table to slide along the axial direction of a ball screw; a gear shift unit has a working principle that a gear shift servo motor drives a gear shift shifting head through a transmission shaft to rotate for a set angle; the transmission shaft in the gear shift unit and the ball screw in the gear selection unit are in the same axial direction; the gear shift unit is supported by a gear shift unit support plate; the gear shift unit support plate is fixedly connected with the screw sliding table; and the screw sliding table drives the gear shift unit to slide along the axial direction of the ball screw. The on-line loading test stand shift mechanism has the advantages of simple structure and high control precision and can act accurately and reliably, and the manual transmission can automatically shift gears.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

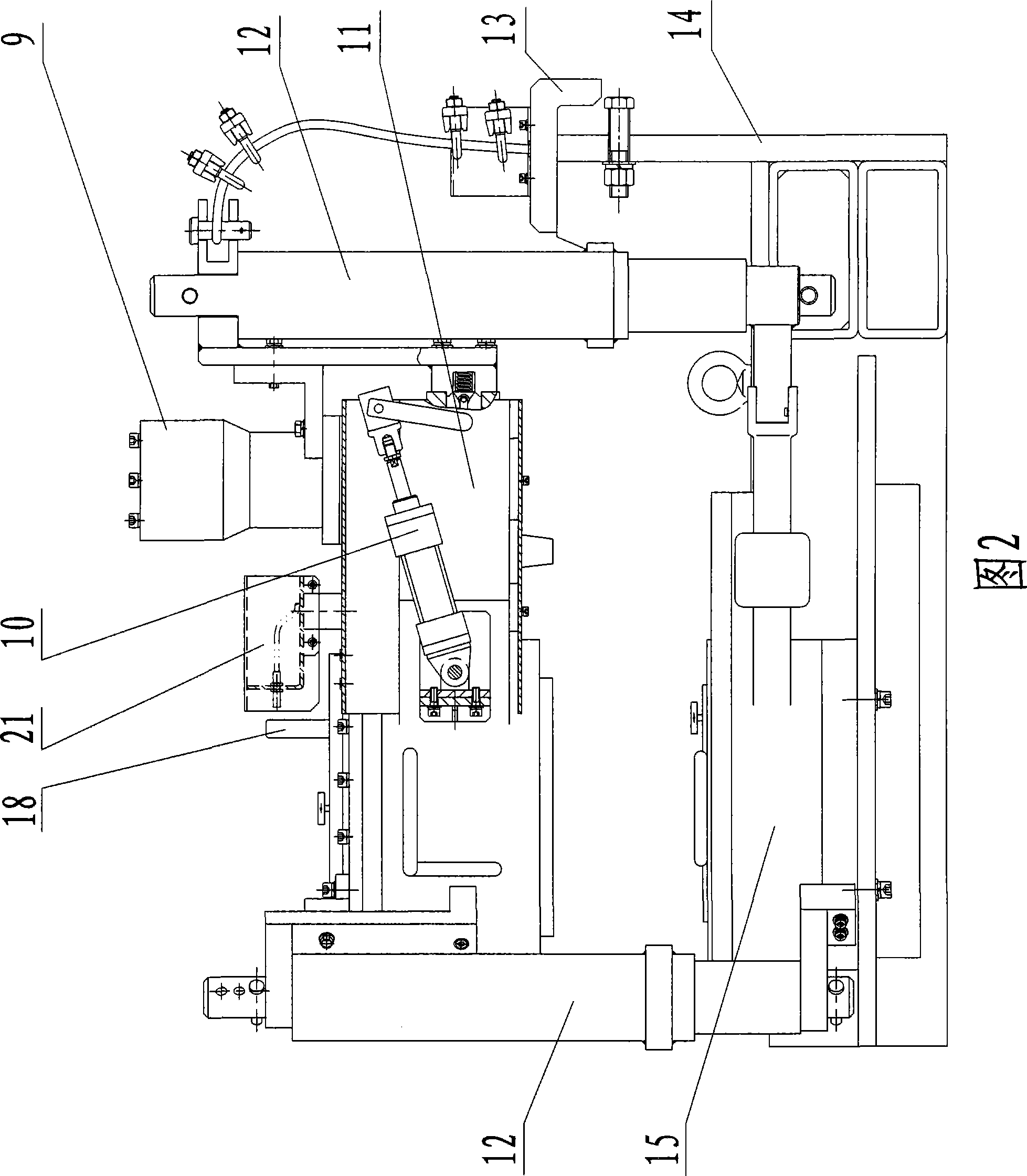

Gear-shifting device of flexible-shaft type gearbox test table

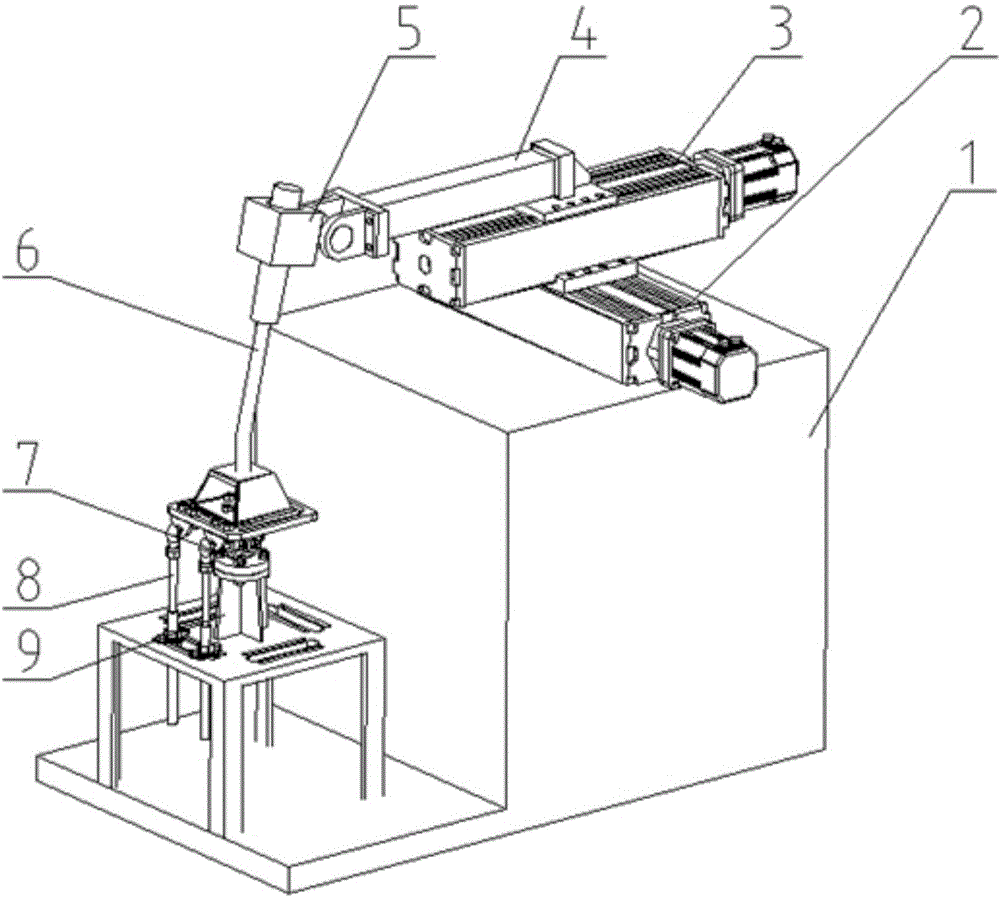

InactiveCN104897395ARealize automatic shiftingVersatileMachine gearing/transmission testingUniversal jointEngineering

The invention discloses a gear-shifting device of a flexible-shaft type gearbox test table. The gear-shifting device comprises an electrical cabinet, an electric sliding table used for gear selection, an electric sliding table used for gear shifting, a mechanical arm, a slide block, a rocker arm, a universal joint, flexible shafts and a supporting base. The electric sliding table used for gear selection and the electric sliding table used for gear shifting are vertically installed in a right-angle intersection way. The electric sliding table used for gear selection is transversely fixed at the top part of the electricalcabinet via a screw. The electric sliding table used for gear shifting is longitudinally fixed on the nut base of the electric sliding table used for gear selection via the screw. The bottom part of the mechanical arm is fixed on the nut base of the electric sliding table used for gear shifting via the screw. The side shaft of the slide block is hinged with the front end of the mechanical arm. The top part of the rocker arm is slidably connected with the slide block. The rocker arm is fixed at the top part of the universal joint via the screw. The universal joint is fixed at the top part of the supporting base via the screw. The internal core head parts of the flexible shafts are fixed on the bottom panel of the rocker arm. The pipe walls of the flexible shafts are fixed on the panel of the supporting base. The control objects of the gear-shifting device are the flexible shafts, and the structure is simple, operation is stable, installation is convenient and generality is high.

Owner:ZHEJIANG UNIV

Hydraulic gearshift of tractor

InactiveCN107023666AEasy gear shiftingMovement precisionControlled membersGearing controlHydraulic cylinderEngineering

The invention relates to technical field of manufacturing of tractors, particularly to a hydraulic gearshift of a tractor. The hydraulic gearshift comprises a gear shifting handle, a fork shifting rod and a clutch, wherein a handle position sensor connected to a gear shifting controller is mounted on the gear shifting handle; a clutch position sensor connected to the gear shifting controller is mounted on the clutch; a signal output end of the gear shifting controller is connected with a control end of a gear shifting electromagnetic valve and is used for controlling the movement of the gear shifting electromagnetic valve; the fork shifting rod is connected with a hydraulic cylinder in a transmission manner; the gear shifting electromagnetic valve is connected with an oil circuit of the hydraulic cylinder in series. According to the gearshift, the fork shifting rod is pushed to move by the hydraulic cylinder instead of manpower, so that the gear shifting operation is light and convenient, and the movement is accurate; the gear shifting controller is configured to write a corresponding gear shifting program, so that sequencing gear shifting and automatic gear shifting can be realized.

Owner:SHANDONG WEIFANG LUZHONG TRACTOR

Heavy 12-gear AMT transmission assembly

PendingCN106641195AConsistent speedImprove carrying capacityGearboxesGear lubrication/coolingControl signalControl valves

The invention discloses a heavy 12-gear AMT transmission assembly which comprises a transmission case, a main box, an auxiliary box and an automatic gear shifting control device; the automatic gear shifting control device comprises a TCU, a gear selecting and shifting actuator, a main box intermediate axle brake control valve, a main box intermediate axle brake, an auxiliary box control valve and an auxiliary box air cylinder, where in the gear selecting and shifting actuator, the main box intermediate axle brake control valve and the auxiliary box control valve are all connected with the TCU, and the main box intermediate axle brake comprises a friction plate and a piston; when the main box shifts gears, the main box intermediate axle brake control valve receives a control signal from the TCU, controls the piston to act through an air channel, the piston presses the friction plate tightly, braking on a main box intermediate axle is achieved, and then the gear selecting and shifting actuator completes a gear shifting action of the main box. Accordingly, a main-auxiliary box double-intermediate axle structure is adopted, the bearing capacity is high, the input torque reaches 2,300 Nm, the life reaches 1500,000 kilometers, the speed ratios of all the gears are reasonable, the speed ratio of the first gear is high, and the reliability is high.

Owner:CHINA FIRST AUTOMOBILE

Automatic gear transmission

InactiveCN109372956AReduce volumeSimple structureToothed gearingsTransmission elementsAutomatic transmissionMultiple sensor

The invention discloses an automatic gear transmission for a motor vehicle. A linear stepping motor, spline synchronizers and multiple sensors are used in the automatic gear transmission for the firsttime. The automatic gear transmission can achieve the aim of precise synchronization in the gear shift process. The automatic gear transmission has the advantages that the automatic synchronization process is fast and free of friction; the number of spline teeth of the spline synchronizers is low, operation is simple and reliable, and machining and assembling are easy; and the number of the adopted spline synchronizers is low. If two-stage speed changing is adopted in the transmission, only two spline synchronizers are adopted, and the total number of transmission gears can be dozens. The number of gears of the gear transmission can be increased or decreased by increasing or decreasing the number of pairs of gears. The effect of stepless speed changing can be obtained as long as the number of the gears is large enough.

Owner:夏元峰

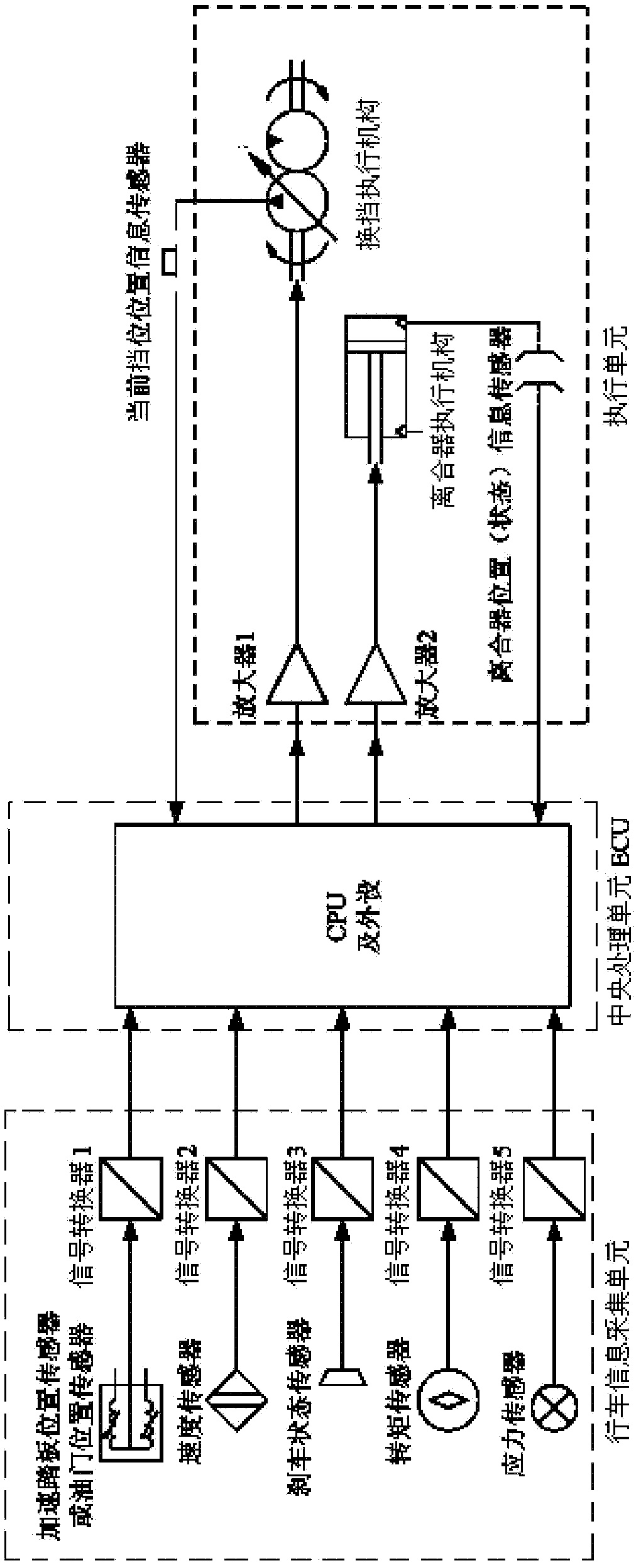

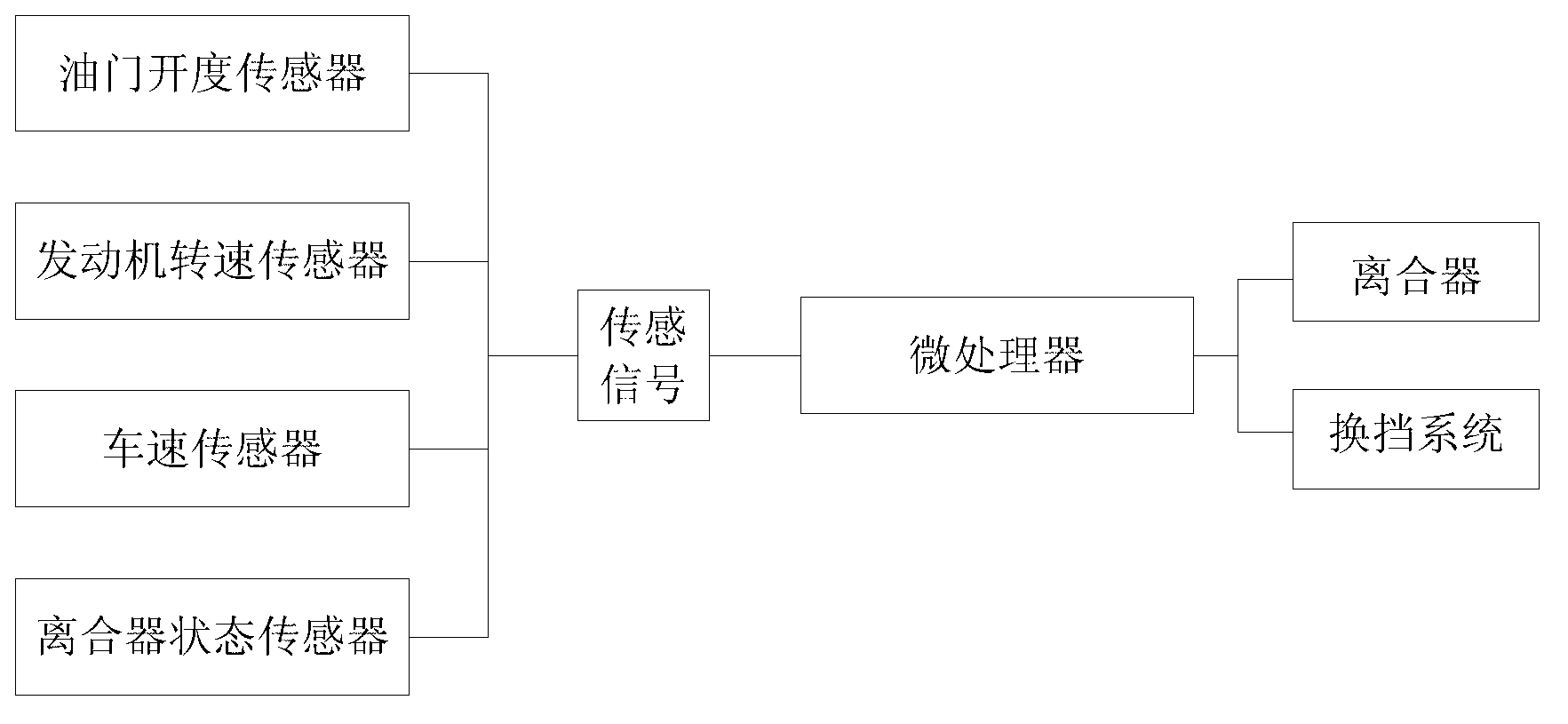

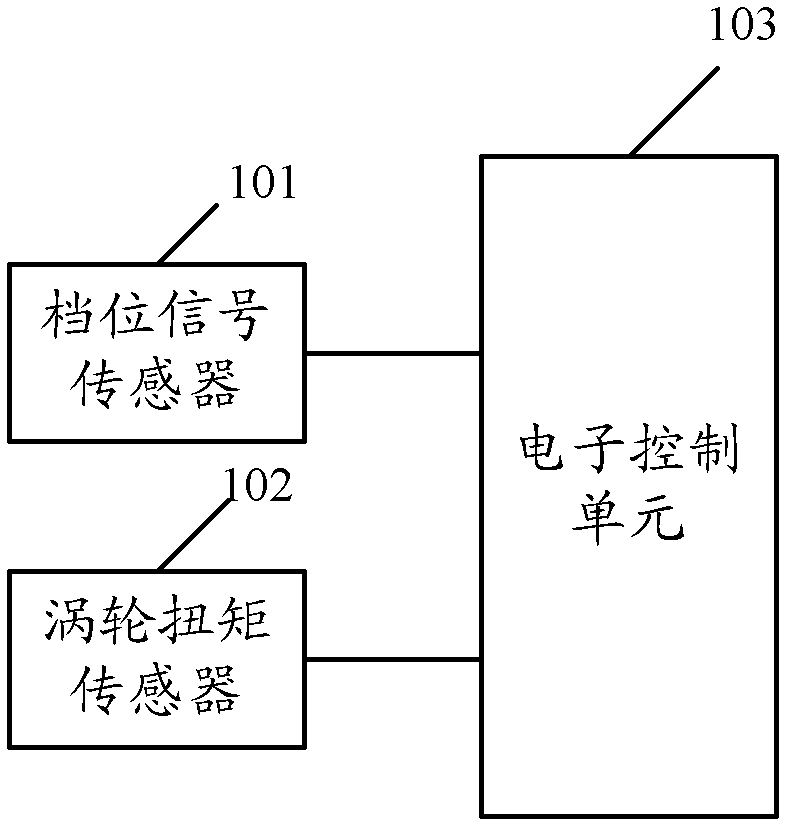

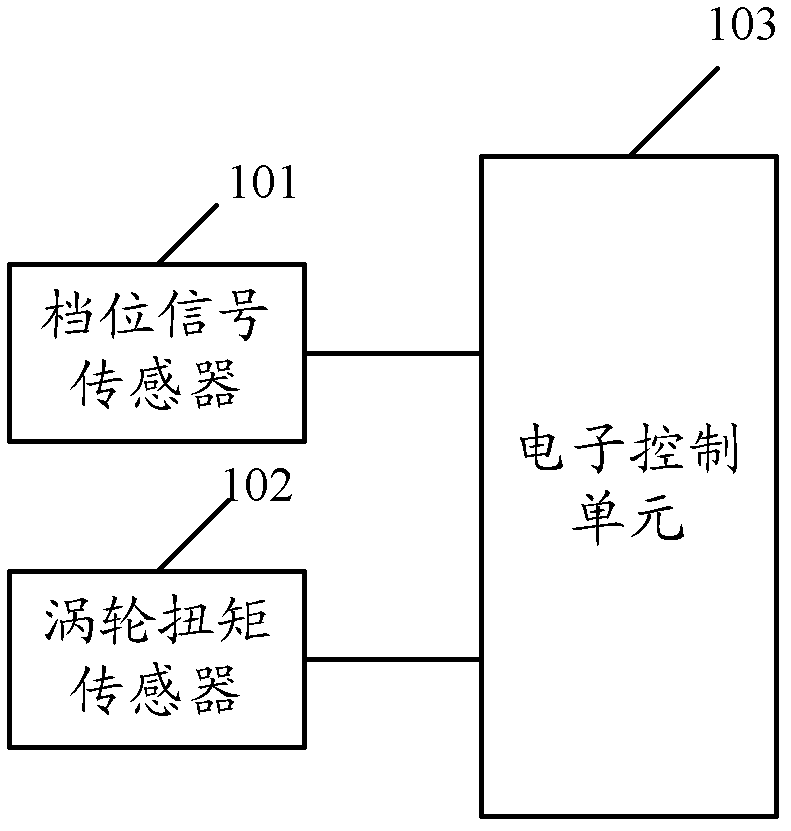

Automobile shift control system and automobile

InactiveCN102913612ARealize automatic shiftingLess shiftingGearing controlControl systemThrottle opening

The invention discloses an automobile shift control system, which comprises a sensing system, a control system and an execution system, wherein the sensing system comprises a throttle opening sensor, an engine rotating speed sensor, a vehicle speed sensor and a clutch state sensor. All the sensors are used for detecting the automobile condition information and generating sensing signals, wherein the throttle opening sensor is used for detecting the throttle opening of an engine and generating an throttle opening signal to be transmitted to the control system; the engine rotating speed sensor is used for detecting the rotating speed of the engine and generating an engine rotating speed signal to be transmitted to the control system; and the vehicle speed sensor is used for sensing the real-time speed of the automobile and generating an automobile speed signal to be transmitted to the control system. The invention provides an automobile, which comprises the engine, a clutch, a shifting component and the automobile shift control system. With the adoption of the automobile shift control system, the automatic shifting of the automobile can be realized, so that a driver does not need to shift the throttle frequently. Therefore, the fatigue of the driver in driving is lightened.

Owner:CHONGQING WUZHOULONG NEW ENERGY AUTOMOBILE

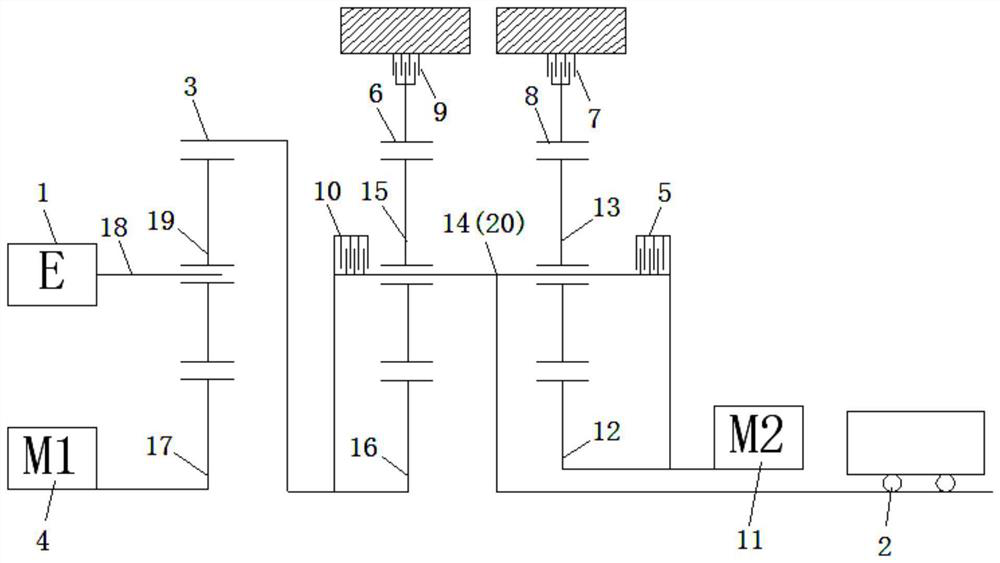

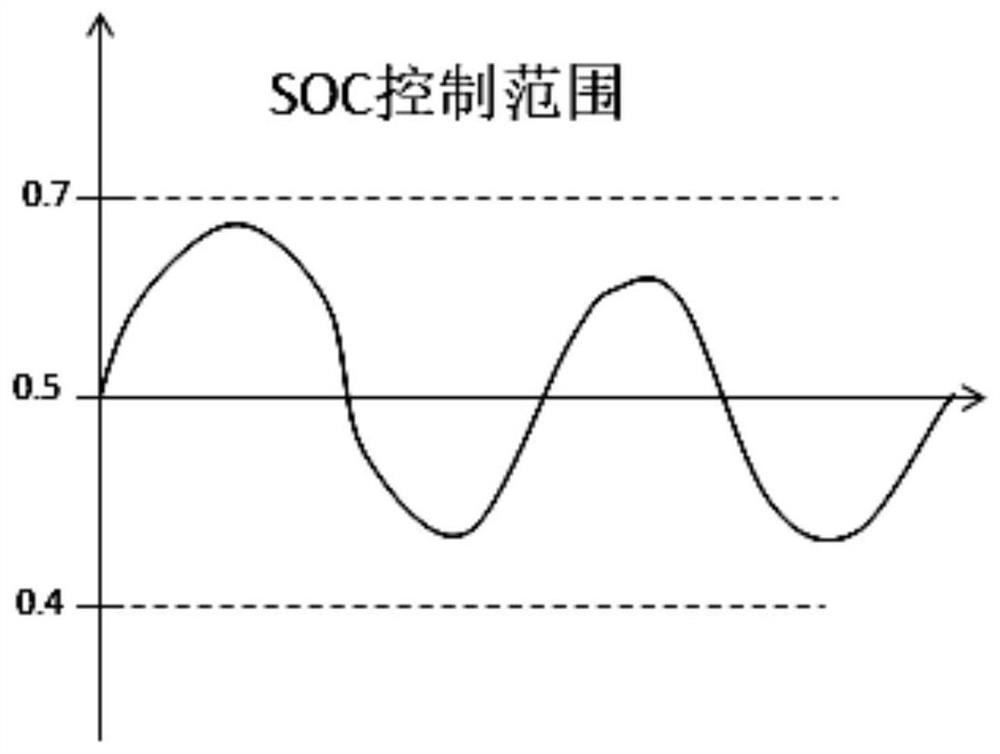

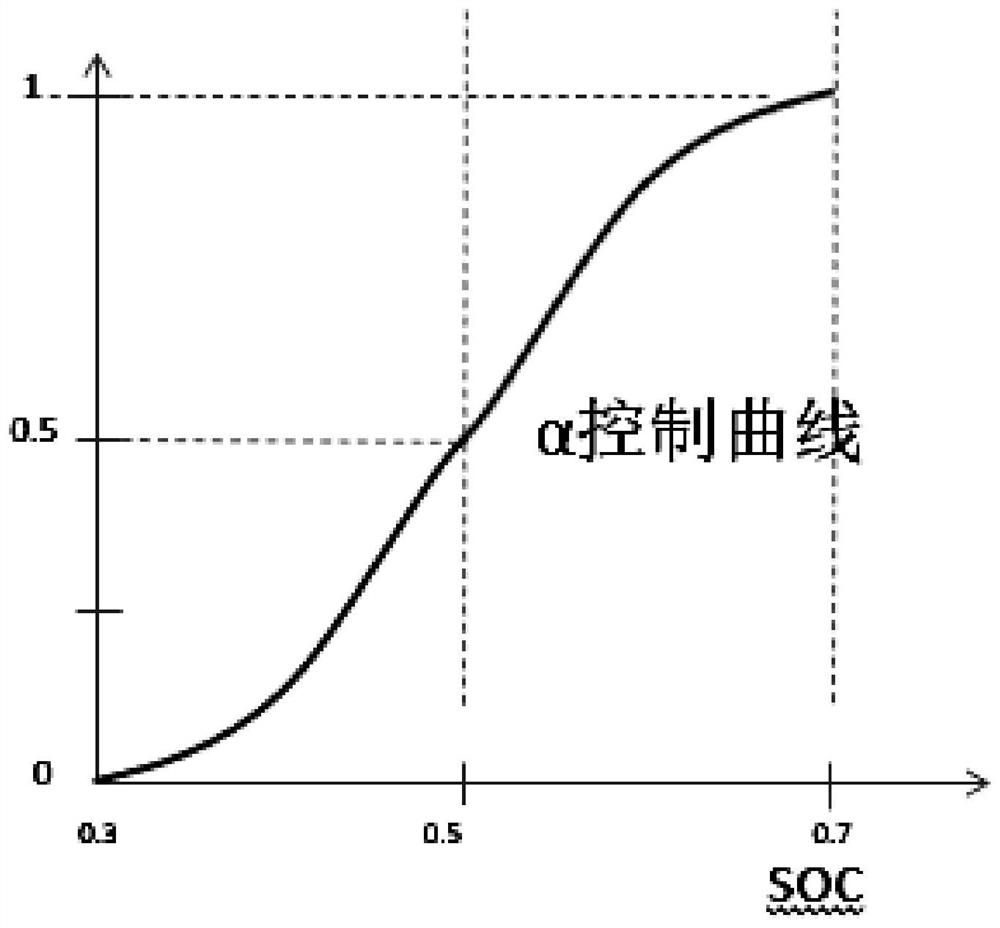

Power split type hybrid electric vehicle driving system and control method thereof

ActiveCN111845706AReduce output torqueMeet vehicle needsHybrid vehiclesGas pressure propulsion mountingPower splitGear wheel

A power split type hybrid electric vehicle driving system comprises an engine and wheels, and further comprises a first motor, a second motor, a first clutch, a second clutch, a first epicyclic gear train, a second epicyclic gear train, a third epicyclic gear train, a first brake and a second brake. A power split type hybrid power topological mechanism is adopted, the power of an internal combustion engine is distributed on two paths, one path is a mechanical path, acting force can be directly transmitted to the wheels through gear engagement, the other path is an electric path, and besides the internal combustion engine and a driving device, an electric motor can apply the acting force to planetary gears. An engine rotating speed and a vehicle speed are decoupled, a working rotating speedrange of the engine is adjusted in real time through the generator, an engine output torque, the wheel rotating speed, a required wheel torque and other driving requirements are adjusted through thedriving motor, a working point of the internal combustion engine is more ideal, and whole vehicle fuel economy is improved to the maximum degree. Automatic gear shifting is achieved, power is ensurednot to be interrupted in the gear shifting process, and driving stability is guaranteed.

Owner:SUZHOU ASIA PACIFIC METAL CO LTD

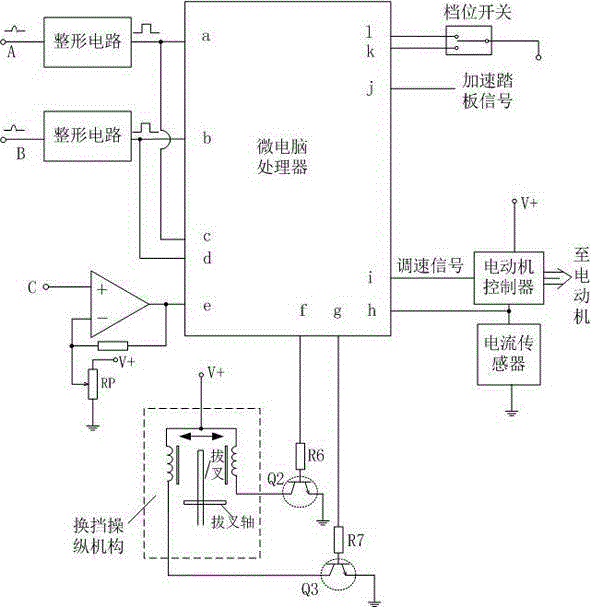

Manual-automatic integrated self-adaptive transmission sensing electric control automatic gear shifting device for engine

InactiveCN101823432AMeet the use requirementsRealize automatic shiftingGearing controlControl devicesClutchSelf adaptive

The invention discloses a manual-automatic integrated self-adaptive transmission sensing electric control automatic gear shifting device for an engine, and the device comprises a gearbox body, a clutch, a power input shaft, a power output shaft, a gear shifting drum, a self-adaptive transmission device, an automatic gear shifting control system and a manual gear shifting system; when a vehicle isin normal running, a controller controls the clutch and the gear shifting drum automatically to drive a servo motor to shift up or shift down automatically according to the resistance moment; when the resistance changes, a torque value is obtained, a rotational speed value of the output shaft is detected by a rotational speed sensor, and the gear shifting action and the gear shifting position aredetermined by torque-rotational speed change, thus realizing automatic gear shifting which is determined by the torque-rotational speed change and the opening degree of a throttle and meeting the operating requirements under the condition of complex roads; and automatic gear shifting can be switched to the manual gear shifting system according to actual conditions, and a gear shifting switch is utilized for inputting a gear position order to the controller and for controlling the clutch and the gear shifting drum to drive the servo motor to realize manual gear shifting.

Owner:SOUTHWEST UNIVERSITY

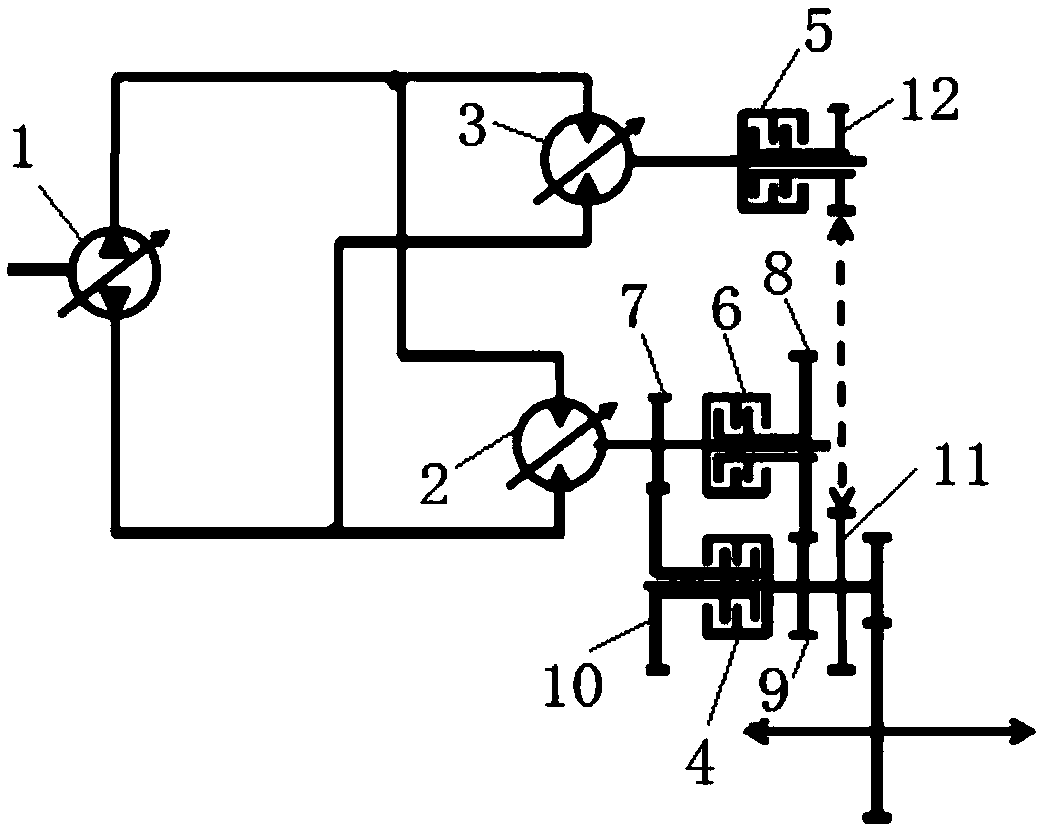

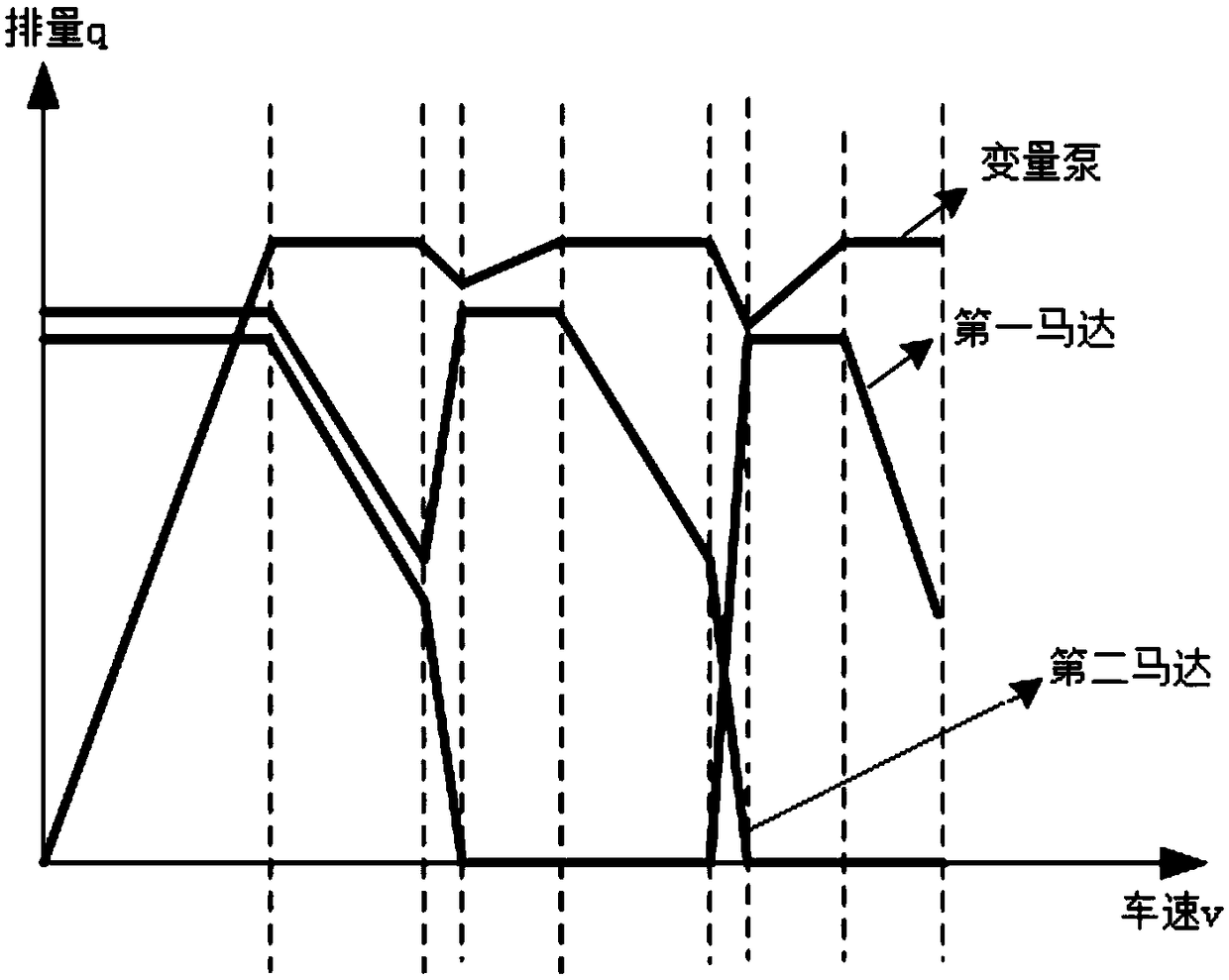

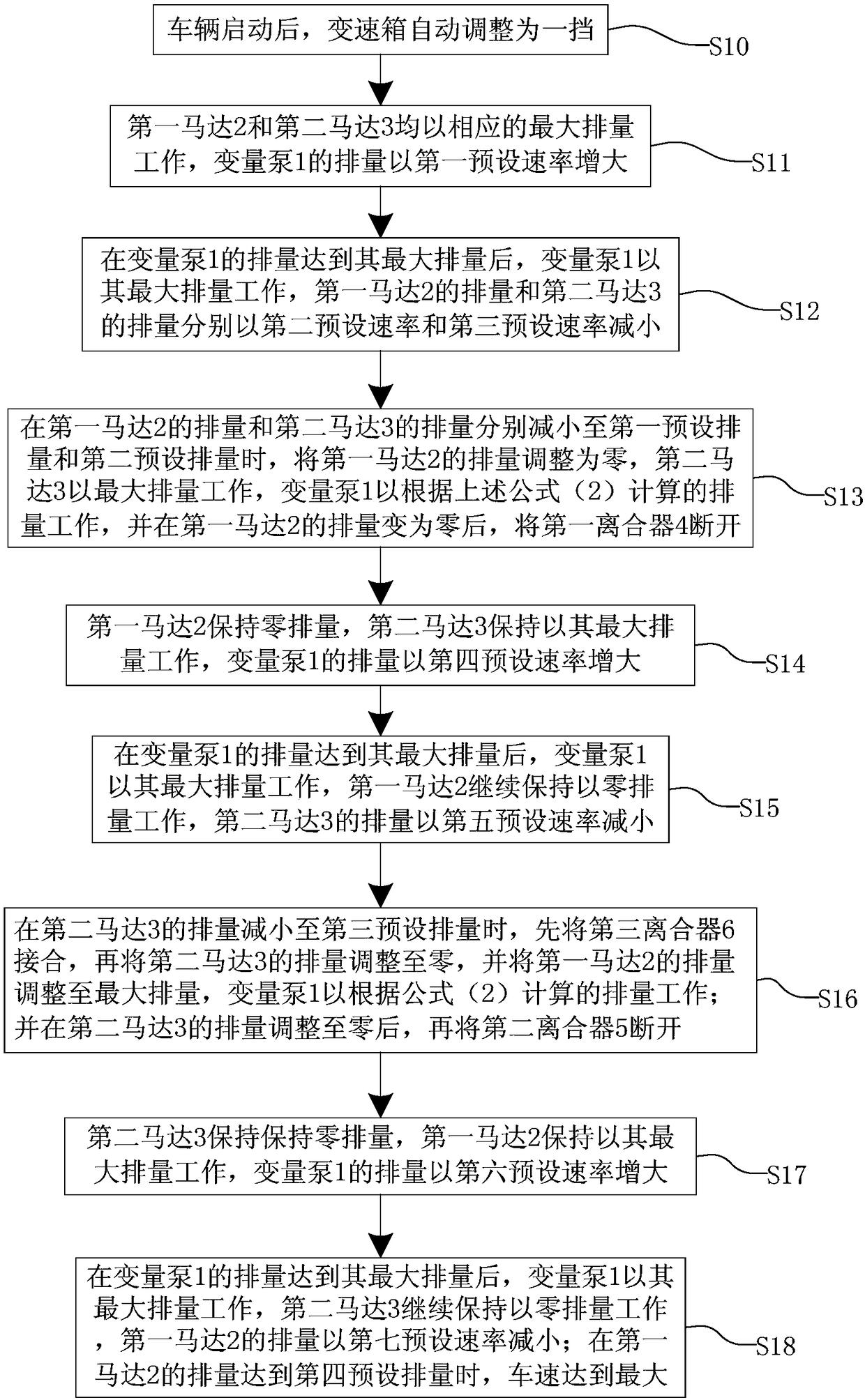

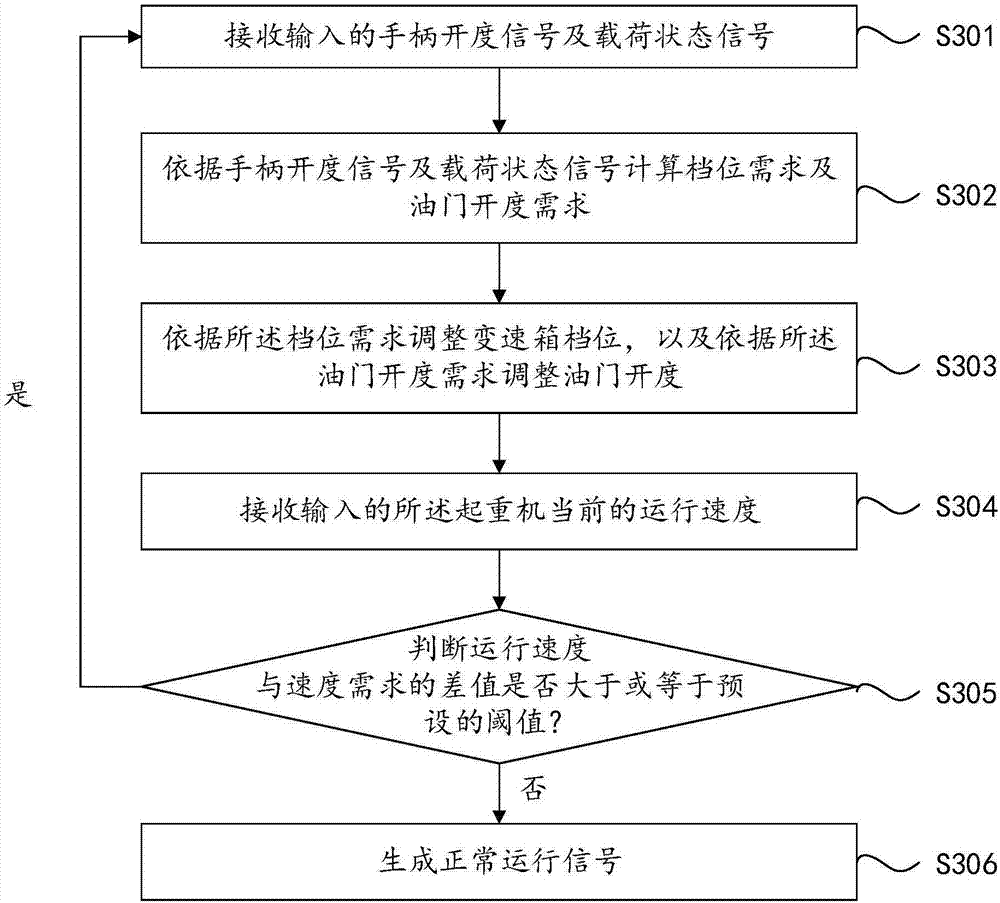

Vehicle gear shifting control system, driving gear shifting control method and loading machine

ActiveCN109372981ASmooth speed changeRealize automatic shiftingGearing controlMotor driveControl system

The invention relates to the field of vehicle gear shifting, and discloses a vehicle gear shifting control system, a driving gear shifting control method and a loading machine. The vehicle gear shifting control system comprises a variable pump, multiple motors and a multi-gear transmission. The motors are driven by the variable pump. The transmission comprises multiple clutches. Each motor drivenby the variable pump is connected with at least one clutch. At most one of the at least one clutch connected to the same motor is in the engaged state. According to the vehicle gear shifting control system, the driving gear shifting control method and the loading machine, when the gear of the transmission is adjusted, the clutch which needs to be adjusted to be in the engaged state from the disengaged state is engaged when the displacement of the motor driving rotation connection of the clutch is not equal to zero firstly, the clutch which needs to be adjusted to be in the disengaged state from the engaged state is then disengaged after the displacement of the motor driving the clutch to rotate is equal to zero, and therefore it is ensured that no power failure is caused in the gear shifting process, no impact on the vehicle speed is caused when the clutch is disengaged, and it is ensured that the vehicle speed of a whole vehicle is stably changed.

Owner:WEICHAI POWER CO LTD +1

Automatic gearbox for electric mini-truck

ActiveCN106949198AConvenient ArrangementSimple layoutToothed gearingsGearing controlEngineeringTruck

The invention belongs to the technical field of gearboxes, particularly relates to a gearbox of reverse input agricultural equipment and discloses an automatic gearbox for an electric mini-truck. The automatic gearbox for the electric mini-truck mainly comprises a clutch, a gearbox shell, a first shaft, a reverse idler shaft, a first-speed driven gear, a first-and-reverse gear hub, a reverse driven gear, a second-speed driven gear, a second-and-third speed gear hub, a third-speed driven gear, a second shaft, a first flange plate, a differential assembly, a second flange plate, a movable gear and the like, wherein the first shaft and the second shaft are sequentially arranged inside the gearbox shell of a hollow structure from bottom to top; a reverse driving gear, a first-speed driving gear, a second-speed driving gear and a third-speed driving gear are sequentially and fixedly connected to the portion, in the gearbox shell, of the first shaft from left to right; and the second shaft is sequentially provided with the reverse driven gear, the first-and-reverse gear hub, the first-speed driven gear, a vertical differential connection shaft, the second-speed driven gear, the second-and-third speed gear hub and the third-speed driven gear. According to the automatic gearbox for the electric mini-truck, the gear shifting operation is easy and convenient, the gear shifting force is small, gear distribution and gear speed are reasonable, the safety performance is good, reliability is high, and the service life is long.

Owner:山东蒙沃变速器有限公司

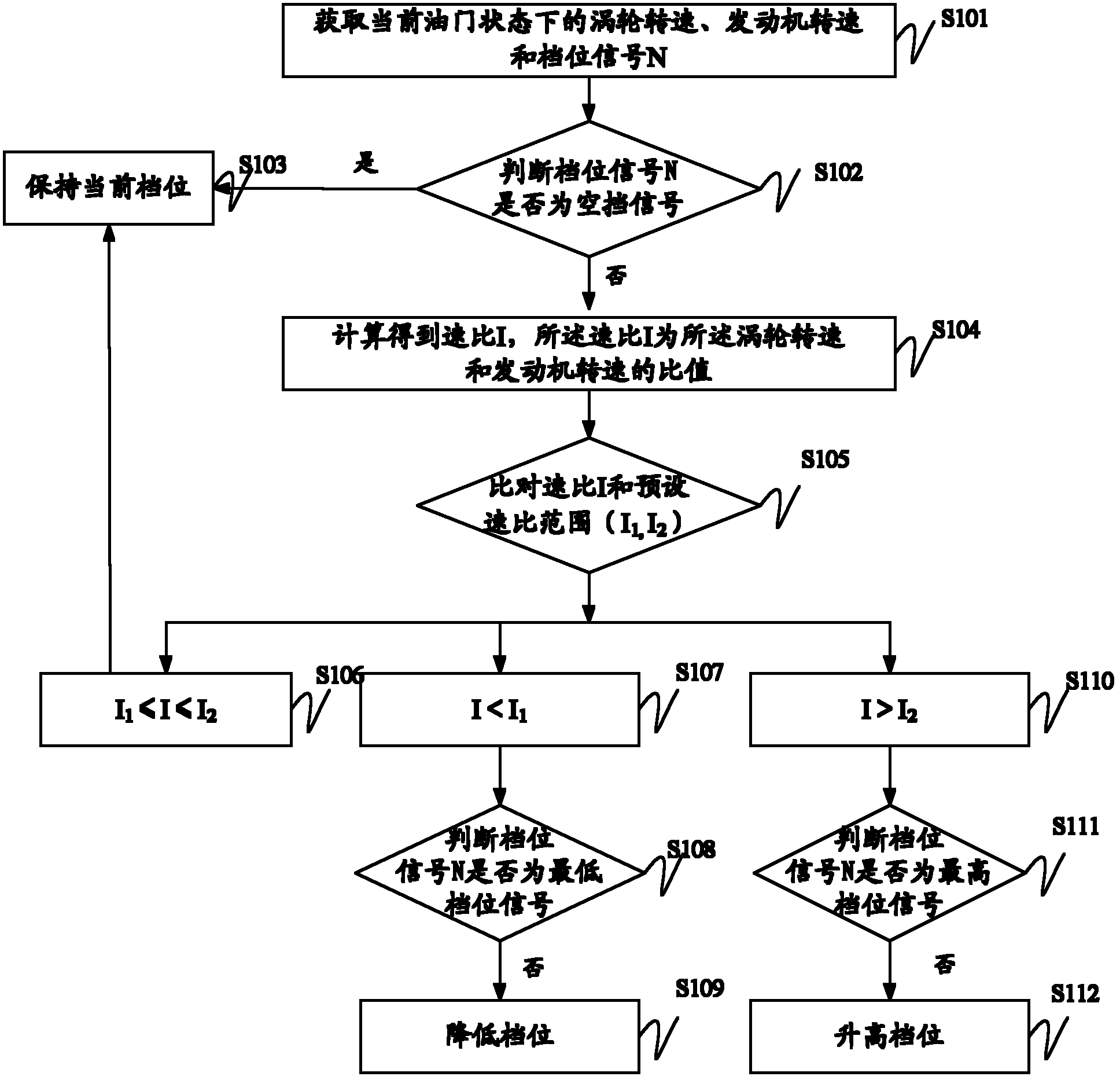

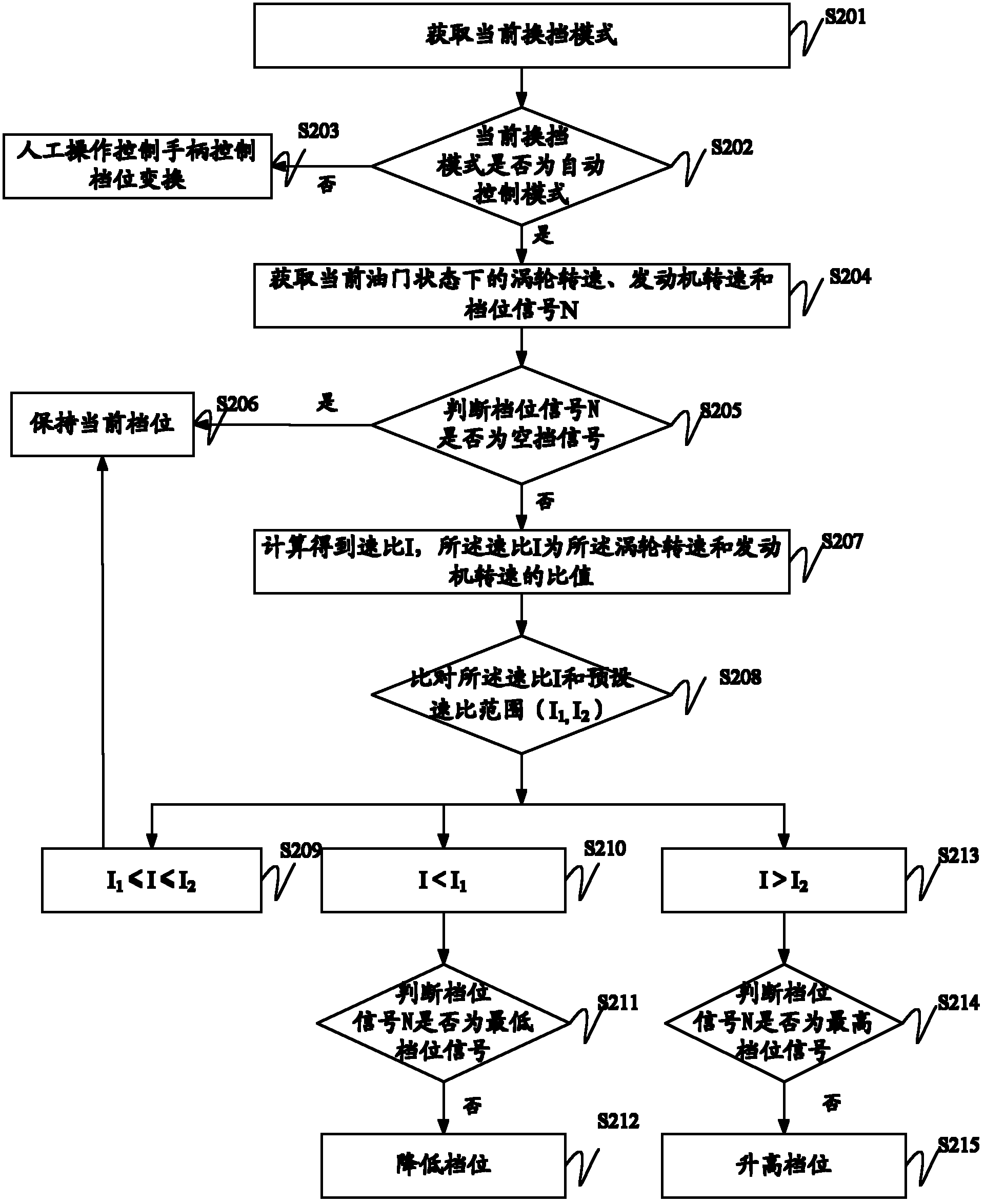

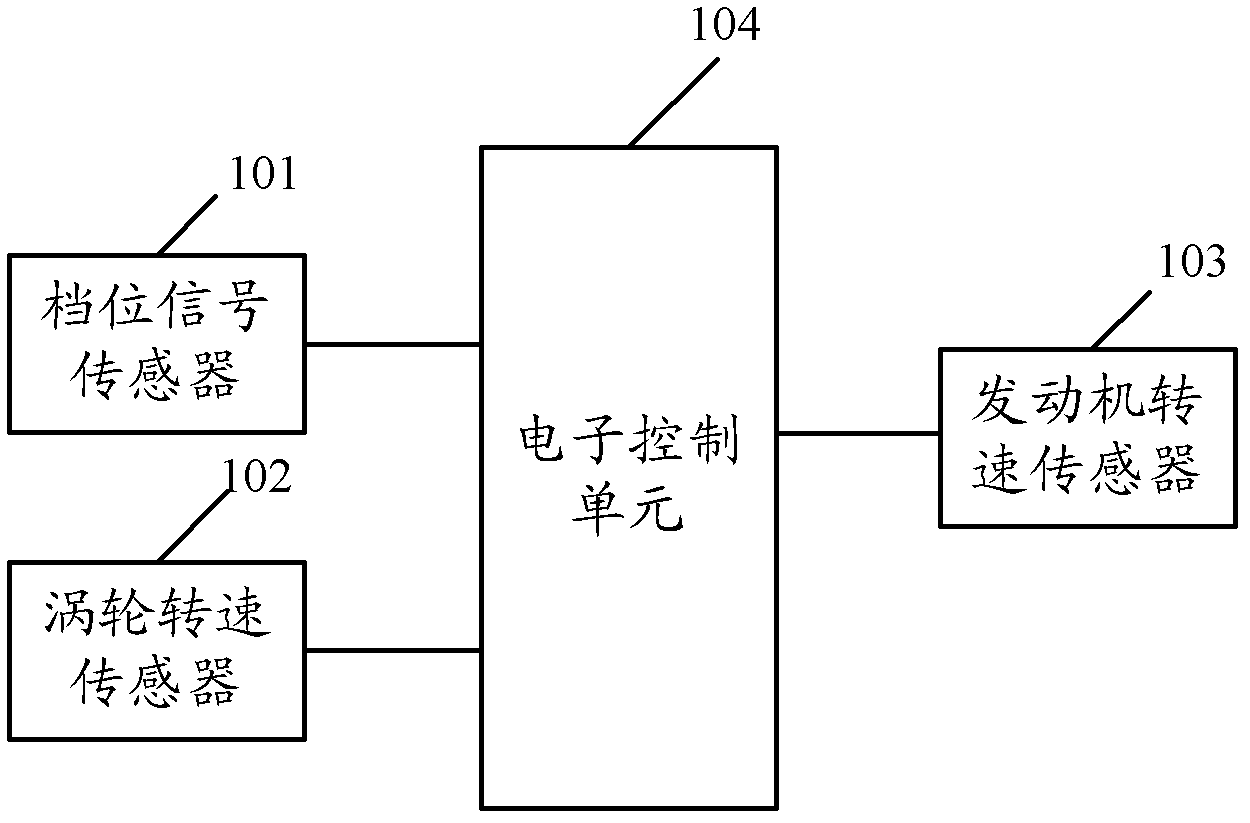

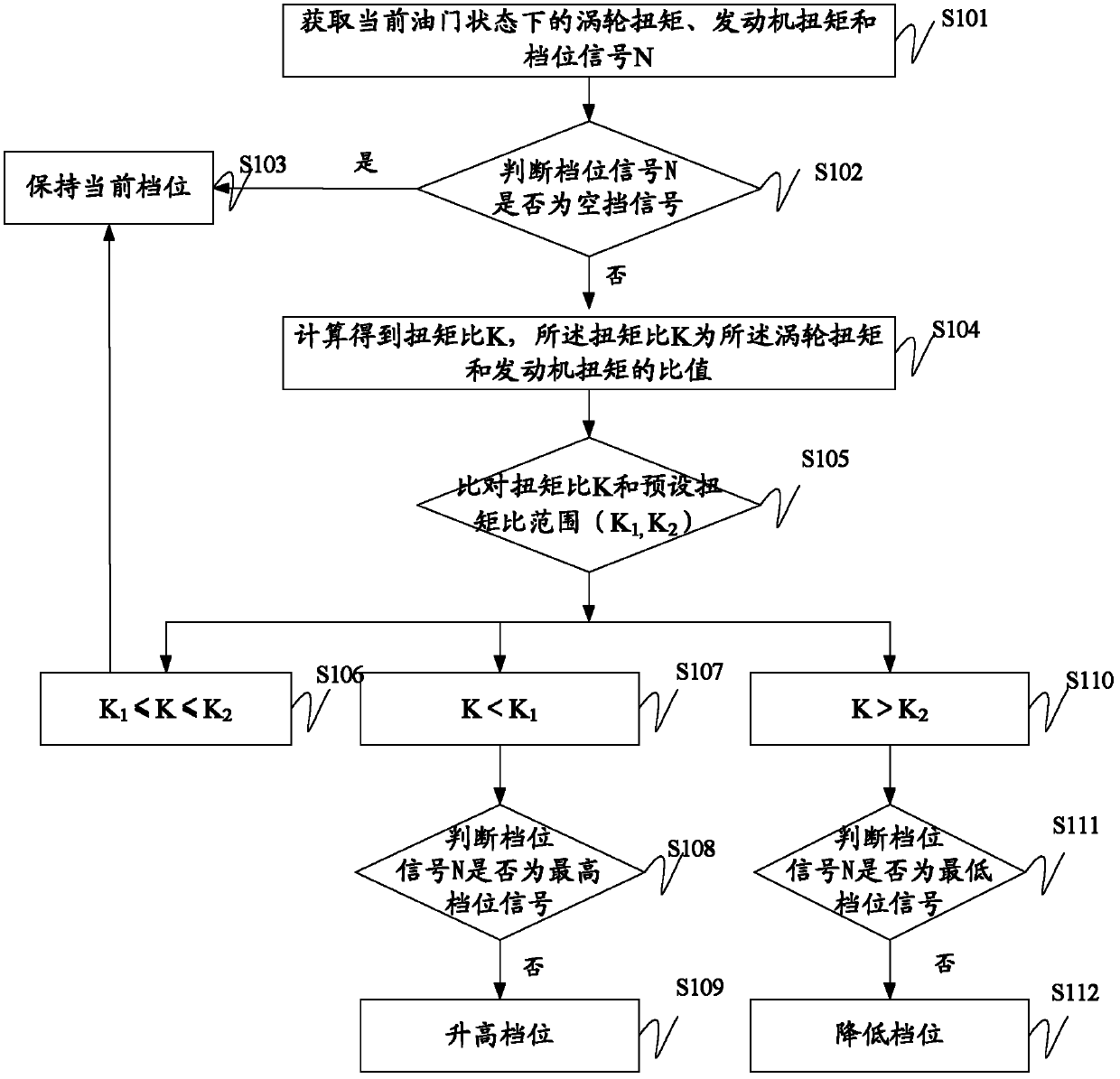

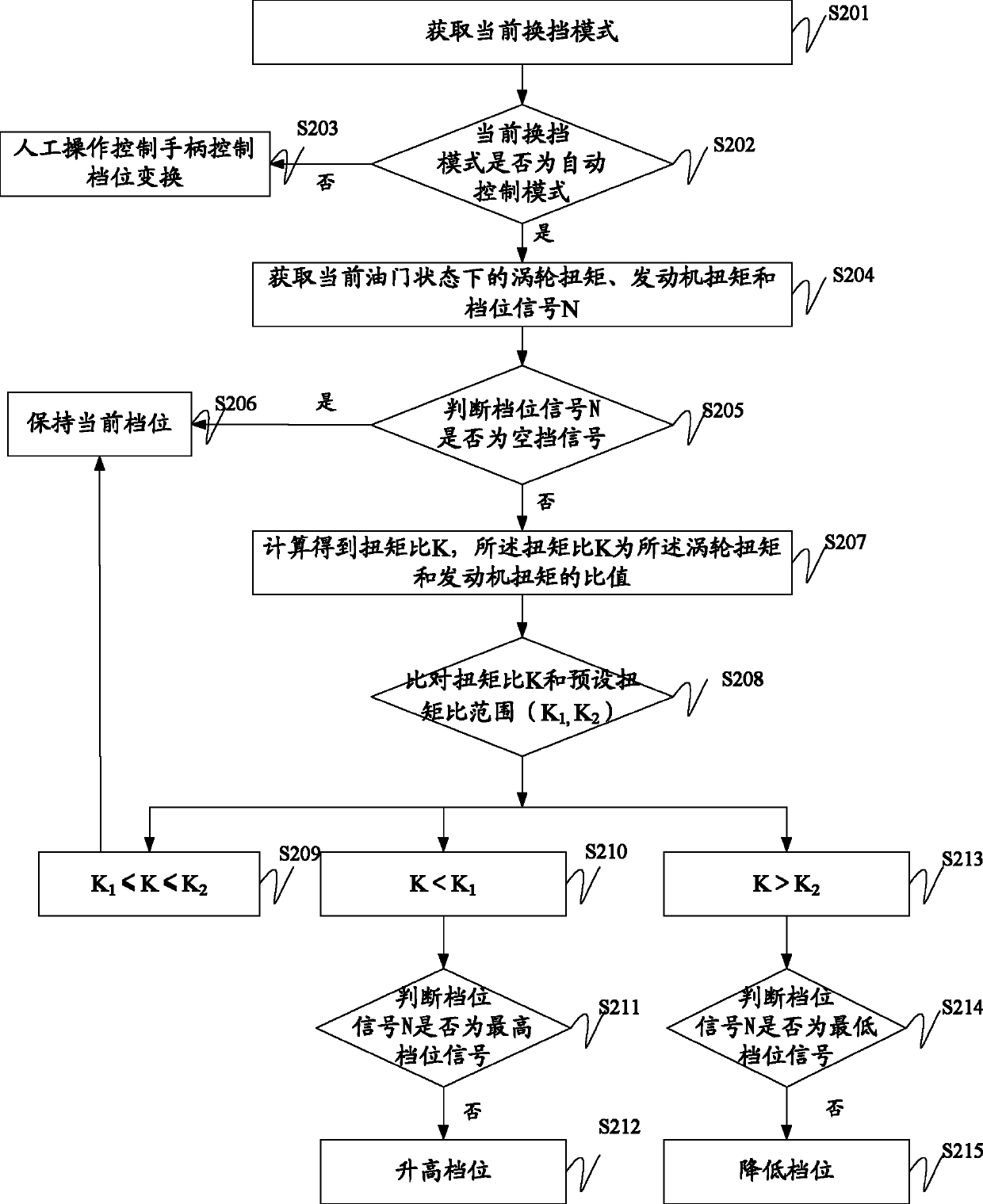

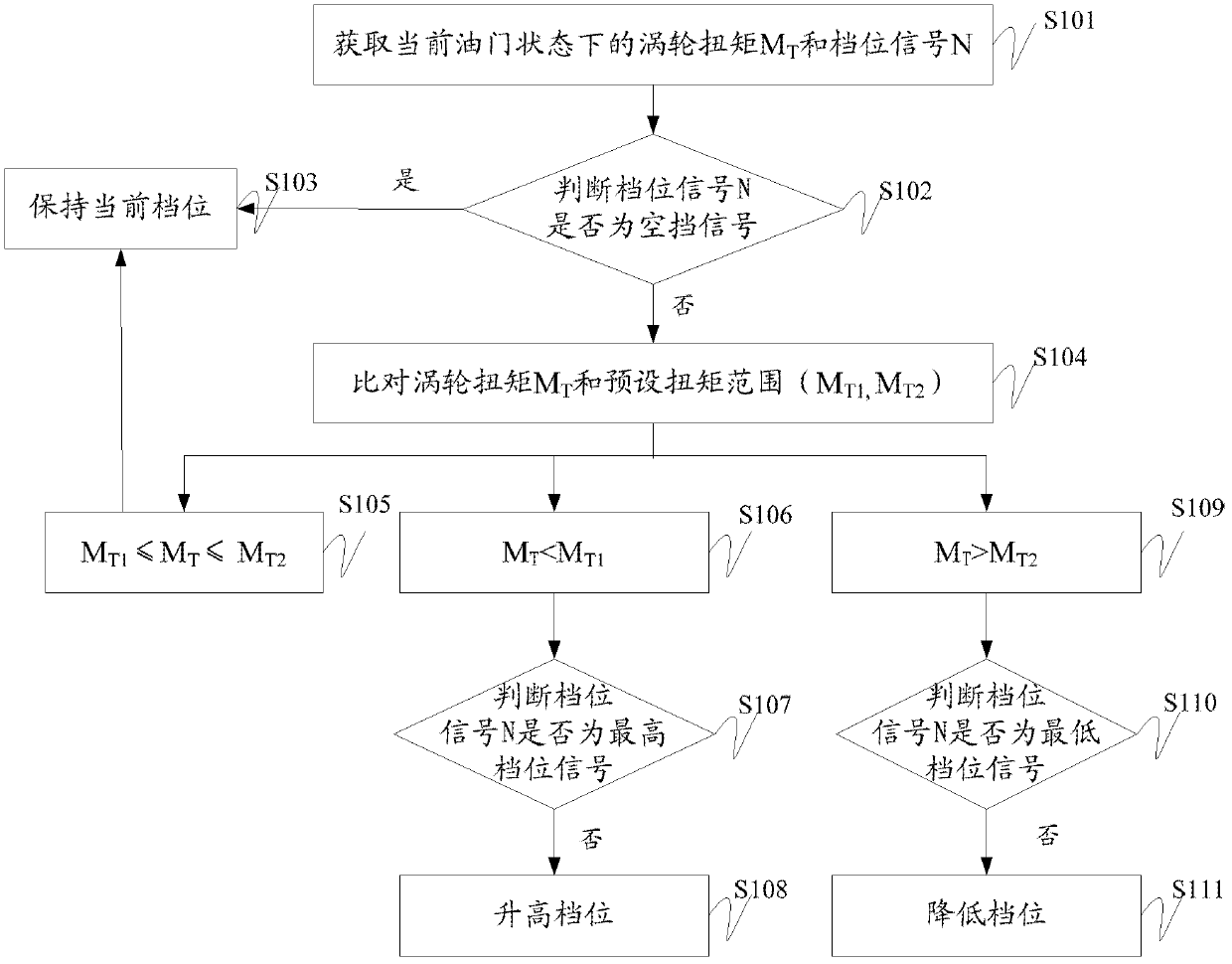

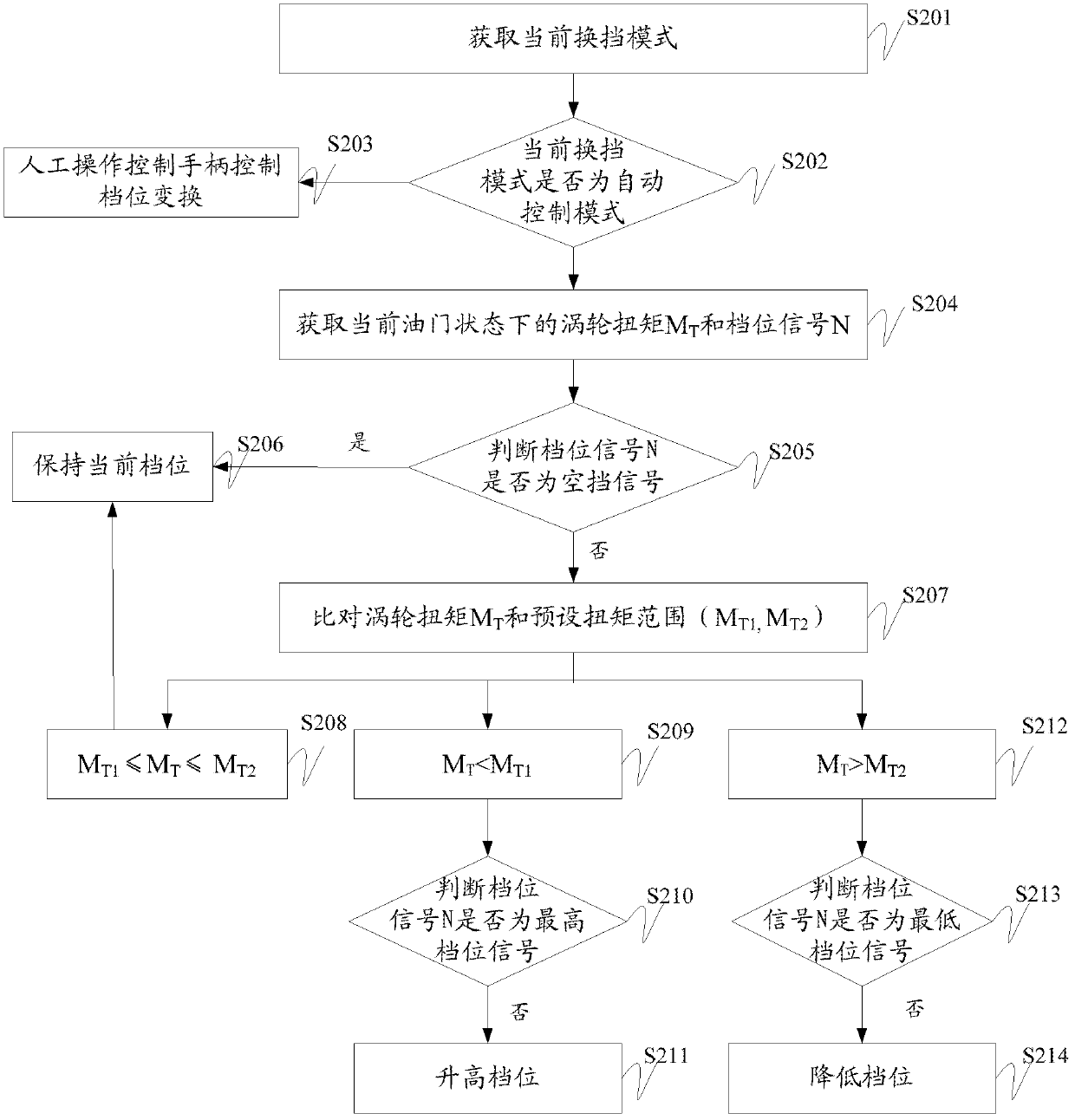

Gear-shifting control method and system and engineering machinery for traction operation

The invention discloses a gear-shifting control method, a gear-shifting control system and engineering machinery for traction operation. The gear-shifting control method comprises the following steps of: acquiring turbine speed, engine speed and a gear signal in the current accelerator state; keeping the current gear when the gear signal is a neutral position signal, otherwise calculating to obtain a speed ratio, wherein the speed ratio is a ratio of the turbine speed to the engine speed; keeping the current gear if the speed ratio is in a preset speed ratio range; reducing the gear when the speed ratio is lower than the minimum speed ratio in the preset speed ratio range and the gear signal is not the lowest gear signal; and raising the gear when the speed ratio is higher than the maximum speed ratio in the preset speed ratio range and the gear signal is not the highest gear signal.

Owner:SHANTUI CONSTR MASCH CO LTD

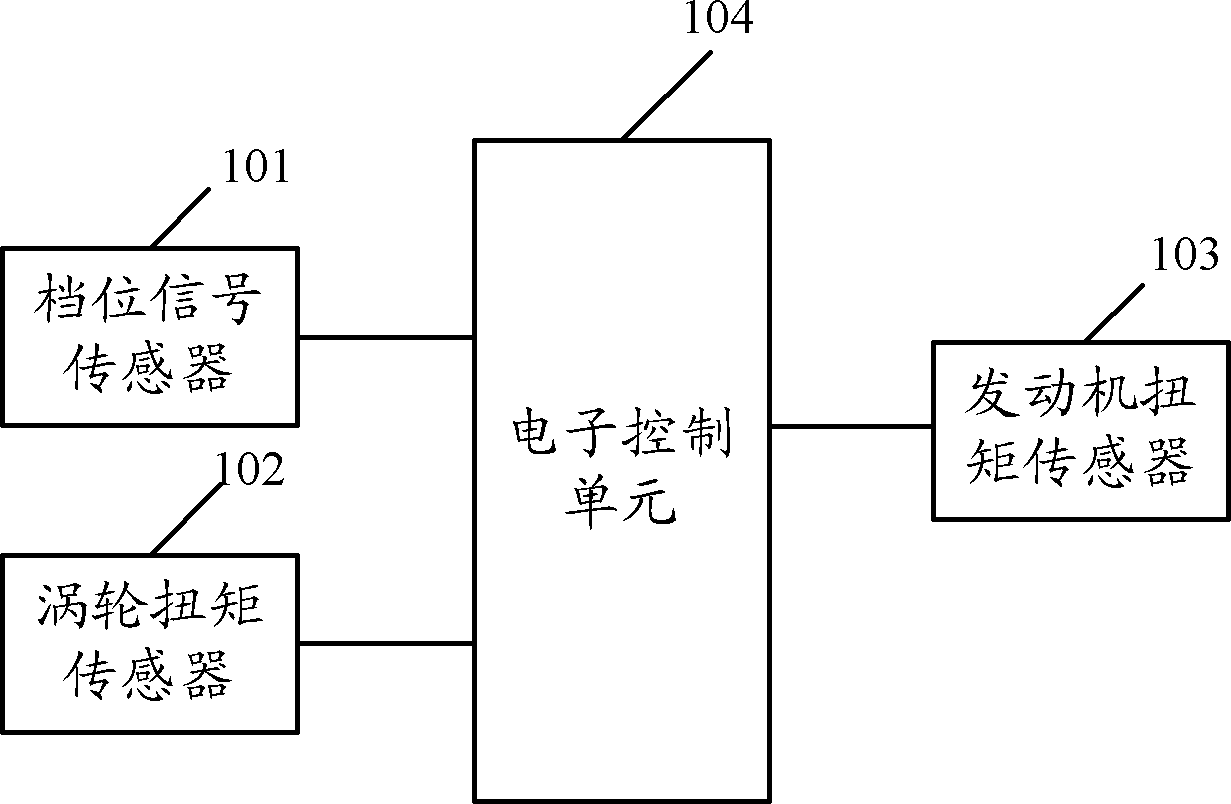

Gear shifting control method, system and engineering machinery used for traction operation

ActiveCN102635687ARealize automatic shiftingGearing controlSoil-shifting machines/dredgersMaximum torqueControl theory

The invention discloses a gear shifting control method, a system and engineering machinery used for traction operation, wherein the gear shifting control method comprises the following steps of: obtaining turbine torque, engine torque and gear position signals under the current throttle state; keeping a current gear position when judging the gear position signals are hollow gear signals, or else, calculating to obtain the torque ratio, wherein the torque ratio is a ratio of the turbine torque to the engine torque; if the torque ratio is in the range of the preset torque ratio, keeping the current gear position; rising the gear position when the torque ratio is less than the minimal torque ratio in the preset torque ratio range, and the gear position signals are judged not the highest gear signals; and lowering the gear position when the torque ratio is greater than the maximum torque ratio in the preset torque ratio range, and the gear position signals are judged not the lowest gear signals.

Owner:SHANTUI CONSTR MASCH CO LTD

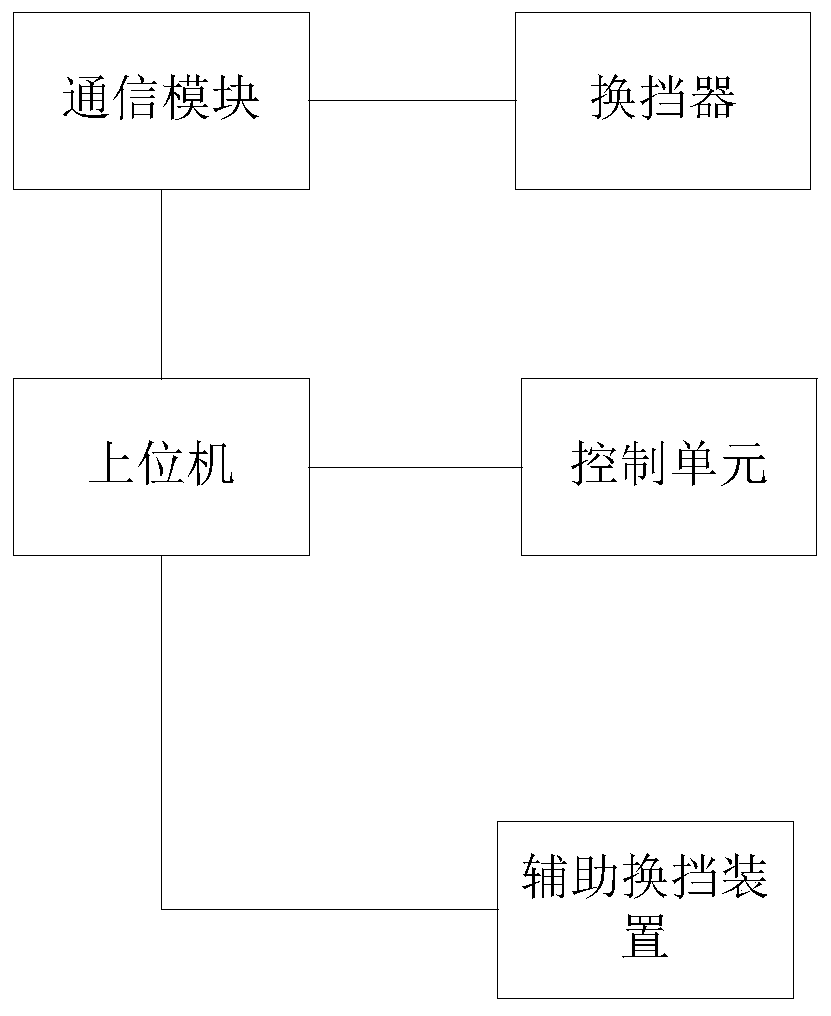

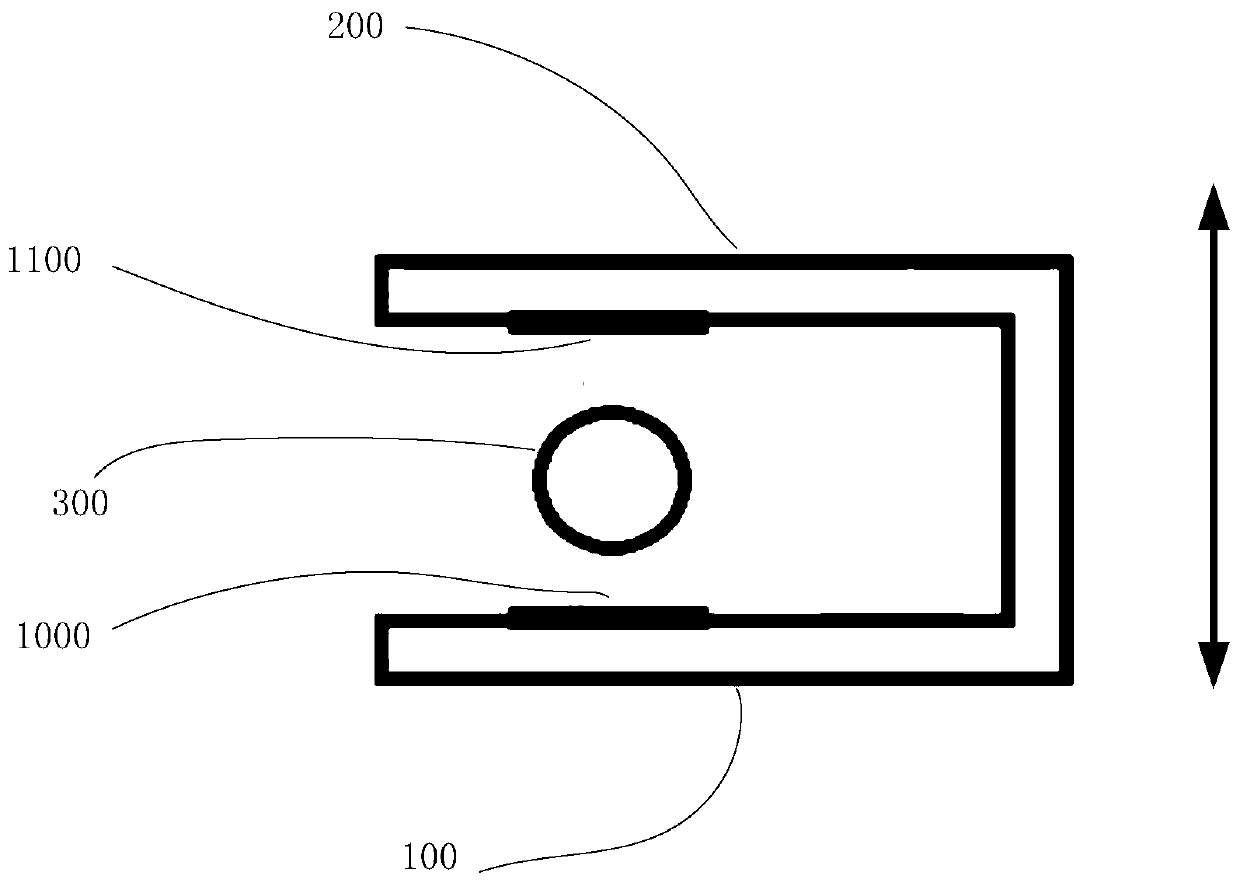

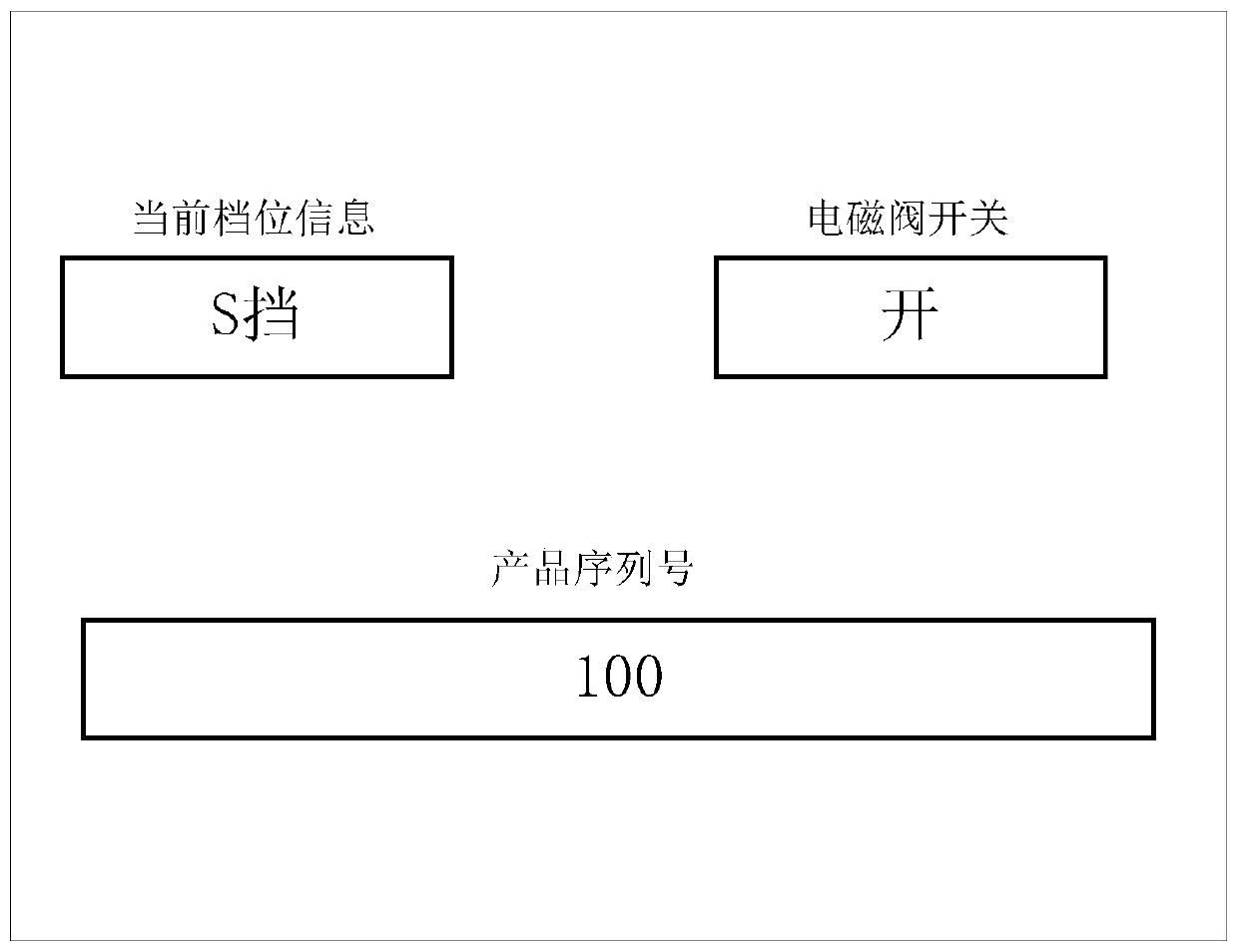

Shifter detection method and system

PendingCN111579240AEfficient detectionReduce labor costsVehicle testingMachine part testingControl engineeringSwitching signal

The invention discloses a shifter detection method and system, and the method comprises the following steps: obtaining gear information, and judging whether a current gear of a shifter is a first gearor not according to the gear information; sending a control instruction to the auxiliary gear shifting device to control a gear shifting rod of the gear shifter to move; receiving a switching signalsent by a control unit, and judging that the current gear of the gear shifter is shifted from a first gear to a second gear when the touch switches are all in a release state; obtaining gear information, and judging whether the current gear of the gear shifter is a second gear or not according to the gear information; and sequentially circulating the steps, and completing detection of the third gear, the fourth gear and the fifth gear of the shifter. The auxiliary gear shifting device can be controlled through the upper computer to achieve automatic gear shifting, gear information is detectedin real time through the upper computer, and therefore automatic detection of the gear shifter is achieved, and the defects of missing detection and false detection of the gear shifter in the detection process are overcome.

Owner:SHENZHEN HUAMEIHE AUTOMOBILE PARTS MFG CO LTD

Automatic gear shifting system with synchronizer for electric vehicle

PendingCN105605165ARealize automatic shiftingNo radialSpeed controllerToothed gearingsElectric vehicleControl theory

The invention discloses an automatic gear shifting system with a synchronizer for an electric vehicle. The automatic gear shifting system comprises a gearbox, the synchronizer, an electromagnet, a motor and a controller. The gearbox comprises an input shaft, an intermediate shaft and an output shaft, the synchronizer is movably penetratingly arranged on the output shaft and is connected with a shifting fork, the shifting fork is connected with a shifting fork shaft, the electromagnet is connected with the shifting fork shaft, the motor is connected with the input shaft, and the controller is connected with the motor and the electromagnet. The automatic gear shifting system has the advantages that electric signals can be transmitted to the electromagnet by the controller, the shifting fork shaft can be controlled via the electromagnet, the shifting fork can traverse up and down under the control of the electromagnet via the shifting fork shaft, the synchronizer can be driven by the shifting fork to traverse up and down between a first output shaft gear and a second output shaft gear when the shifting fork traverses up and down, accordingly, the synchronizer can work with the first output shaft gear or the second output shaft gear, and automatic gear shifting effects can be realized.

Owner:JIANGSU CRRC ELECTRIC CO LTD

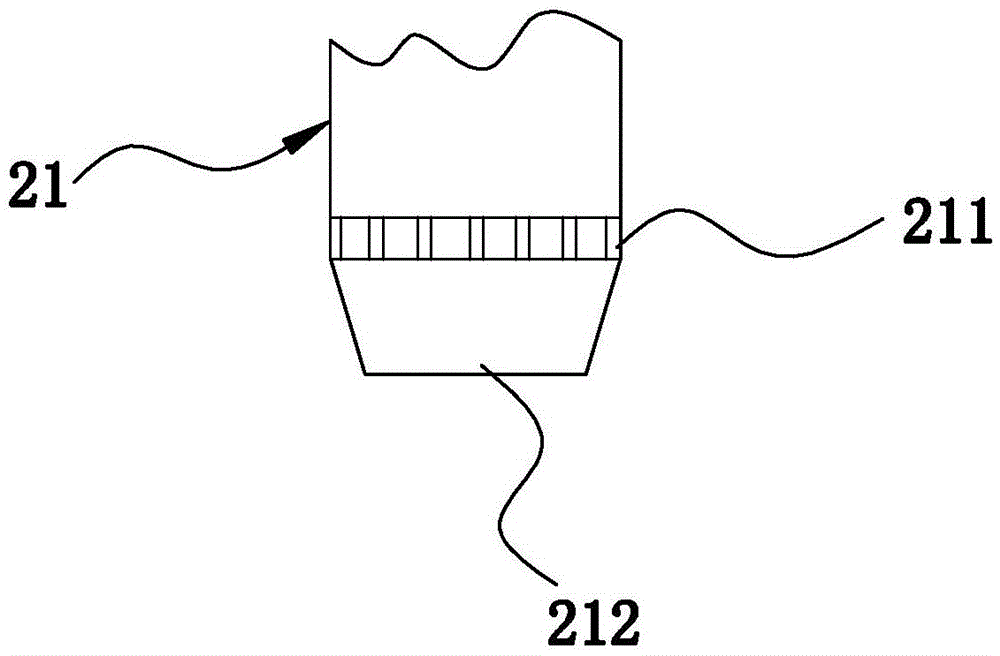

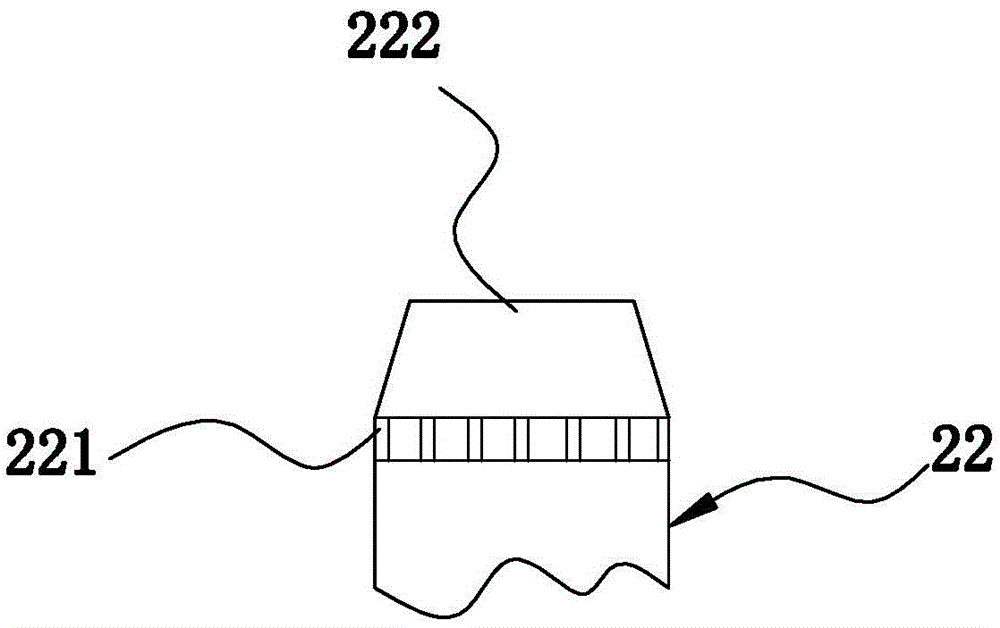

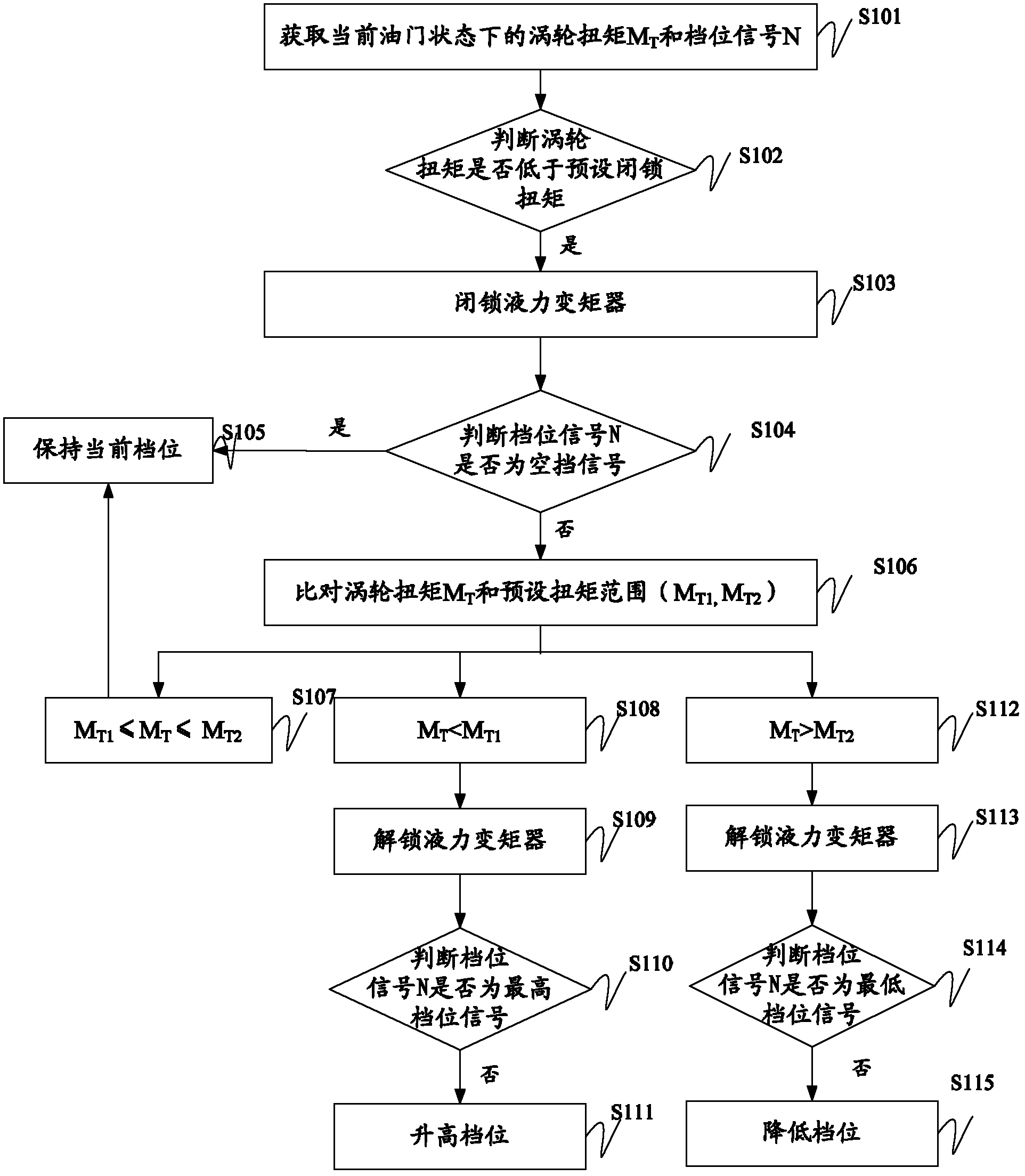

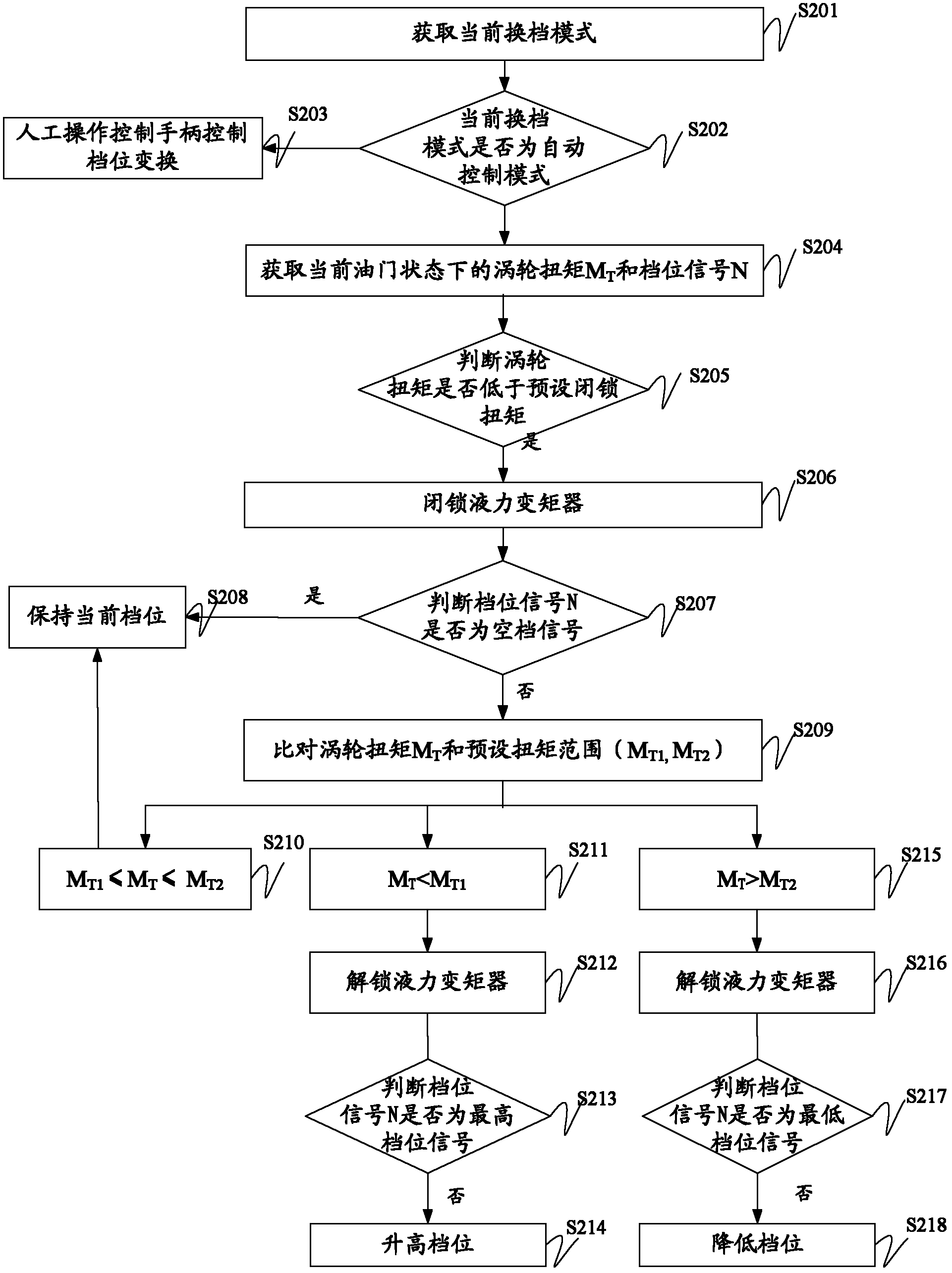

Gear-shifting control method, gear-shifting control system and engineering machinery for traction work

ActiveCN102644728AImprove work efficiencyRealize automatic shiftingGearing controlControl systemTorque converter

The invention discloses a lockable gear-shifting control method. The lockable gear-shifting control method comprises obtaining turbine torque and a gear signal under a current accelerator state; comparing the turbine torque with a preset locking torque corresponding to the gear signal; locking a hydraulic torque converter when the turbine torque is lower than the preset locking torque; maintaining the current gear when judging that the gear signal is a neutral position signal, or else comparing the turbine torque with a preset gear-shifting torque range; maintaining the current gear when the turbine torque is within the preset gear-shifting torque range; unlocking the hydraulic torque converter when the turbine torque is smaller than the minimum torque within the preset gear-shifting torque range, and raising the gear when judging that the gear signal is not the highest gear signal; and unlocking the hydraulic torque converter when the turbine torque is larger than the maximum torque within the preset torque range, and lowering the gear when judging that the gear signal is not the lowest gear signal.

Owner:SHANTUI CONSTR MASCH CO LTD

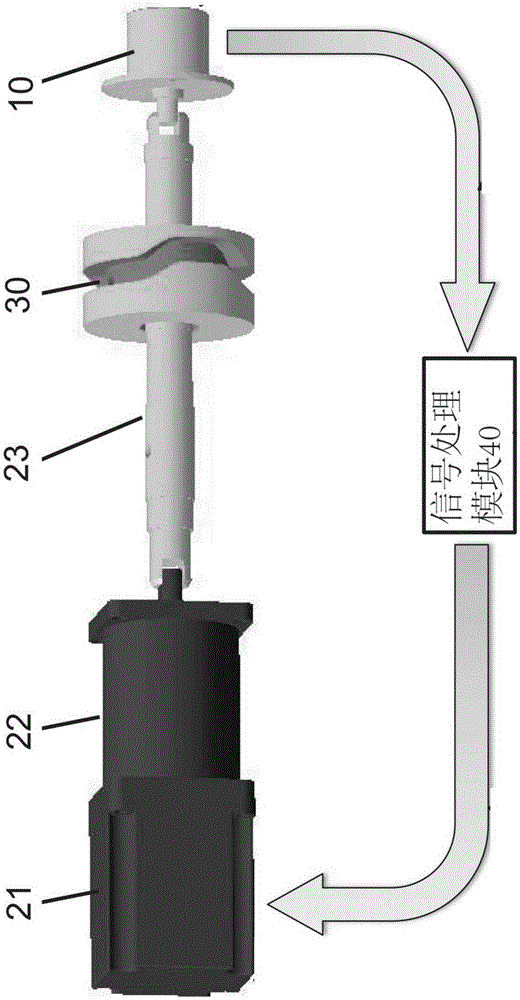

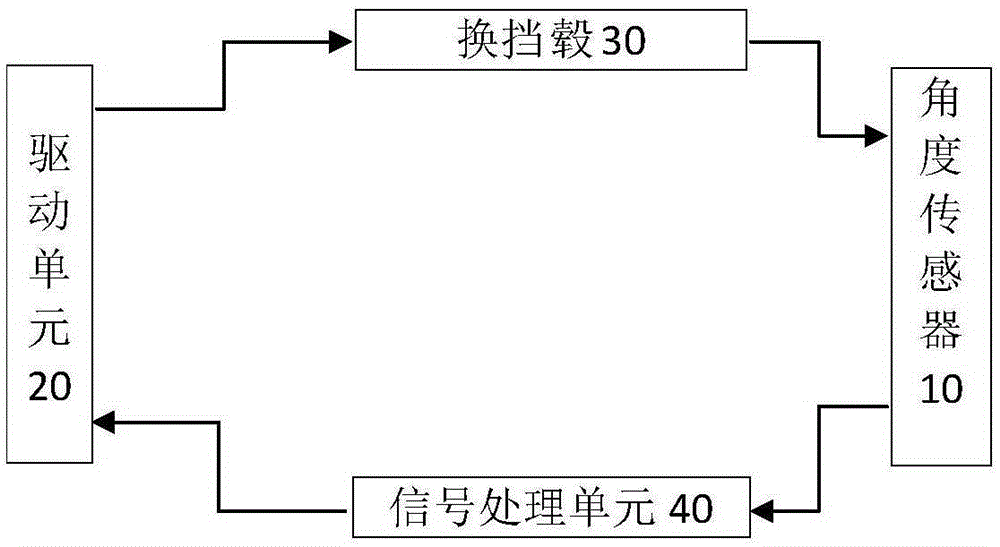

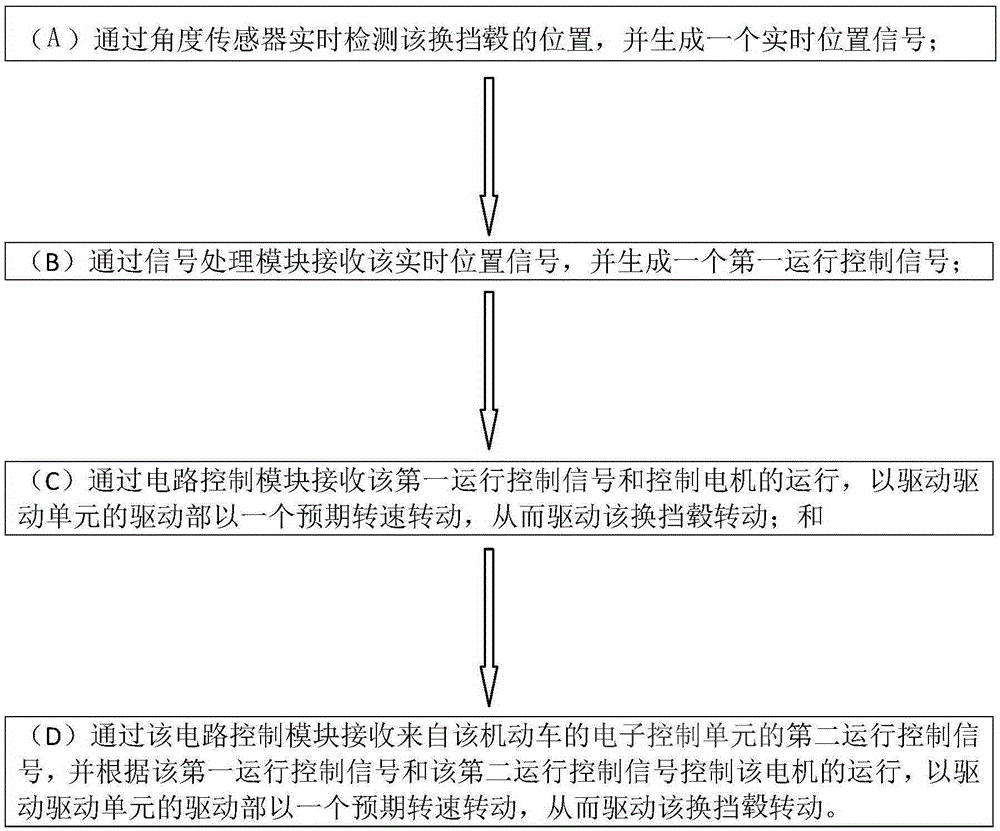

Gear shifting device for motor vehicle

InactiveCN105422838AStable and fast shiftingRealize closed-loop shift controlGearing controlControl signalControl theory

The invention discloses a gear shifting device for a motor vehicle. The gear shifting device comprises an angle sensor, a driving unit and a gear shifting hub. The angle sensor is arranged to face towards the gear shifting hub so as to detect the real-time position of the gear shifting hub and generate a real-time position signal and a signal processing module. The angle sensor is electrically connected with the signal processing module. The signal processing module can receive the real-time position signal from the angle sensor and generate a first operation control signal according to the real-time position signal. The signal processing module is electrically connected with the driving unit. The driving unit can receive the first operation control signal from the signal processing module and operate according to the first operation control signal so as to drive the gear shifting hub to rotate.

Owner:SHANGHAI ECOTORC VEHICLE TECH INC

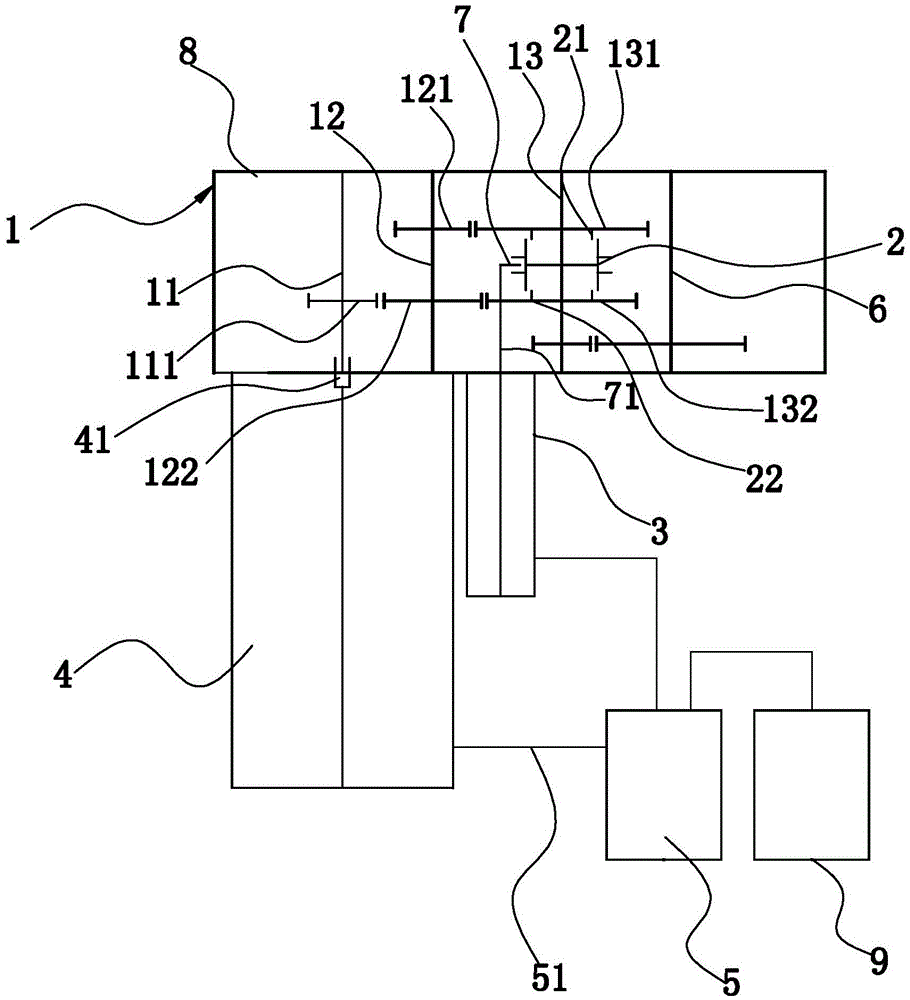

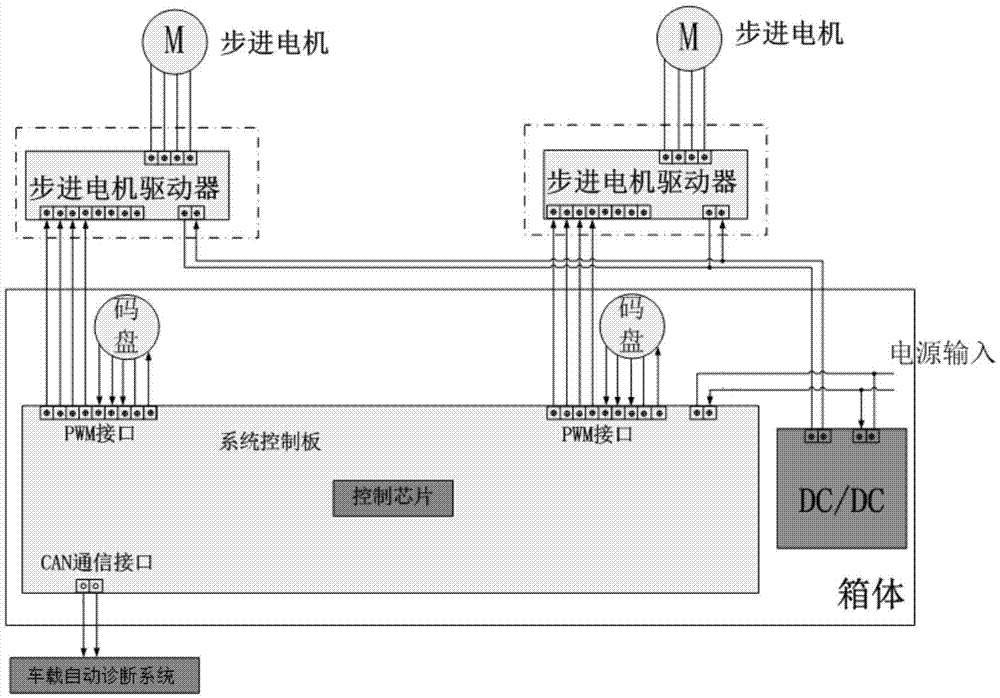

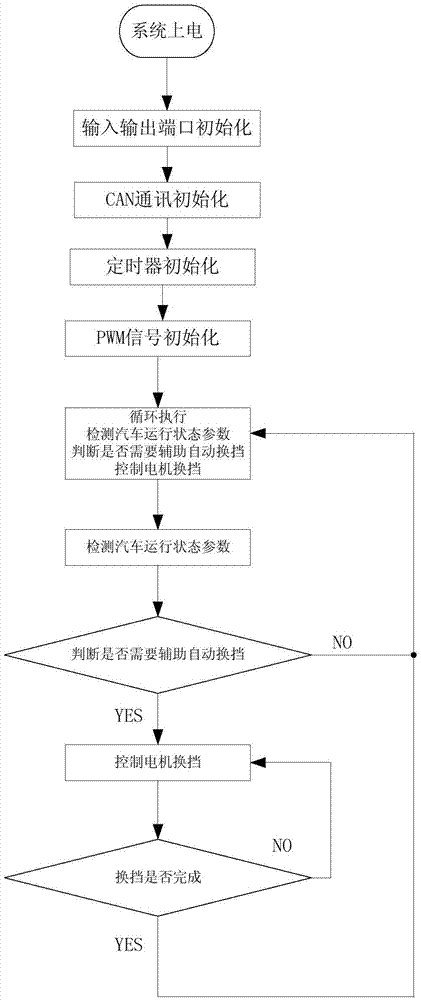

Assisted automatic shifting device and method of manual transmission car

The invention relates to an assisted automatic shifting device and method of a manual transmission car. The device comprises a code wheel, a system control panel, a stepping motor driver, a stepping motor and a DC / DC power module, wherein the code wheel is mounted at an axis of the stepping motor and is used for detecting whether the stepping motor is rotated in place in real time; the system control panel is connected with the code wheel and the stepping motor driver and is connected to a vehicle-mounted automatic diagnosis system through a CAN bus interface; the stepping motor driver is connected with the stepping motor; the stepping motor is connected with a gear handle; the DC / DC power module is used for supplying electricity. The method is characterized in that a car running state signal is acquired by the system control panel through the CAN bus interface which is integrated on the system control panel and is determined through an inner control chip; and then a PWM signal is output to the stepping motor driver so as to control the stepping motor to rotate to drive the gear handle to move so as to achieve assisted automatic shifting. The device meets the advantages of the manual transmission car and an automatic transmission car, and realizes automatic shifting of the manual transmission car, so that the oil can be saved; and the price is low.

Owner:DALIAN ROILAND SCI & TECH CO LTD

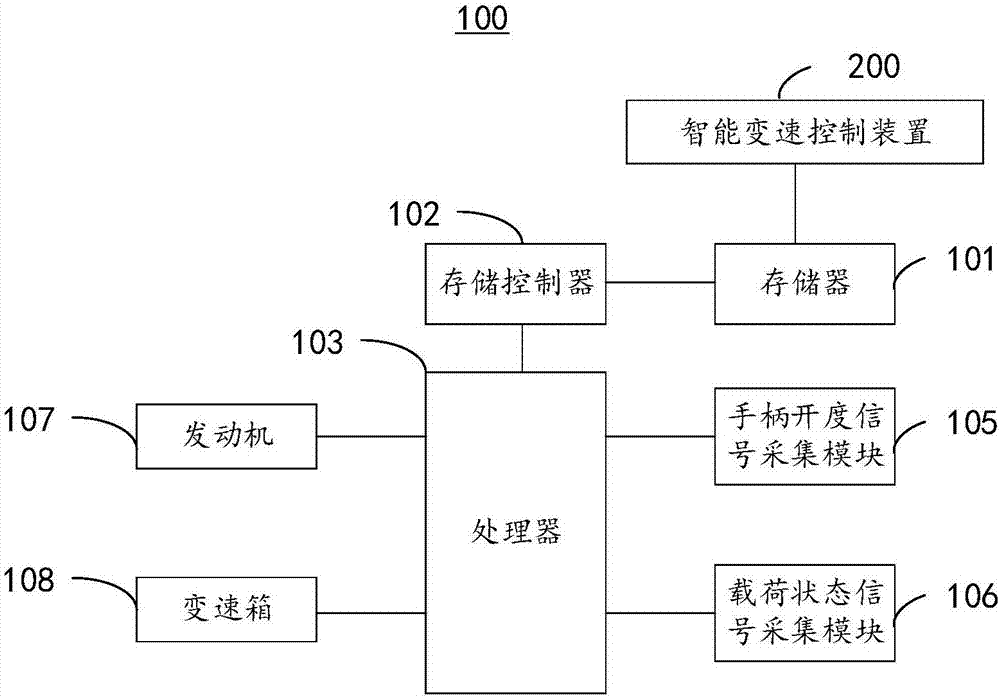

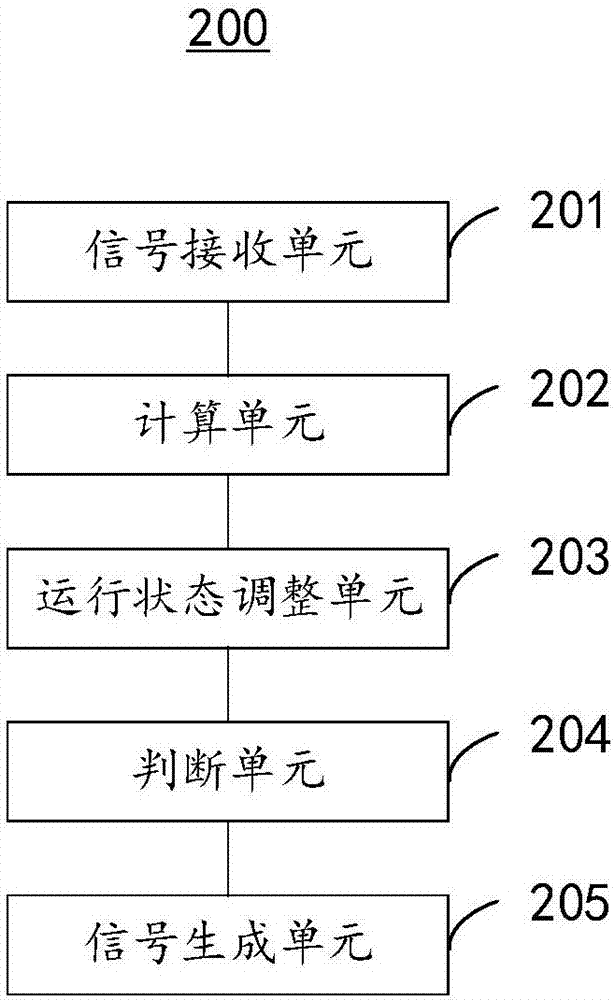

Intelligent variable speed control method, device and system

InactiveCN107324216AEasy to operateAvoid poor opening fitGearing controlEngine controllersAutomatic controlManipulator

The embodiment of the invention provides an intelligent variable speed control method, device and system, and relates to the field of variable speed control. According to the intelligent variable speed control method, device and system, the gear of a gearbox is adjusted according to a calculated gear demand, the throttle opening is adjusted according to a throttle opening demand, and thus, through cooperation of the gear demand and the throttle opening demand, the throttle opening is controlled to be collaborated with the operation of gear shifting so that the two effects of fuel oil saving and sufficient power can be met simultaneously while automatic gear shifting can be achieved; in addition, automatic control over the gear of the gearbox can be achieved by controlling opening of a hand shank by a manipulator, and the hoisting operation of the manipulator through a crane is simplified; and finally, due to the fact that the throttle opening demand is calculated through a hand shank opening signal and a load state signal instead of controlling the throttle opening through a traditional accelerator pedal, the situation that the throttle opening and the opening of the hand shank are not matched well can be avoided.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

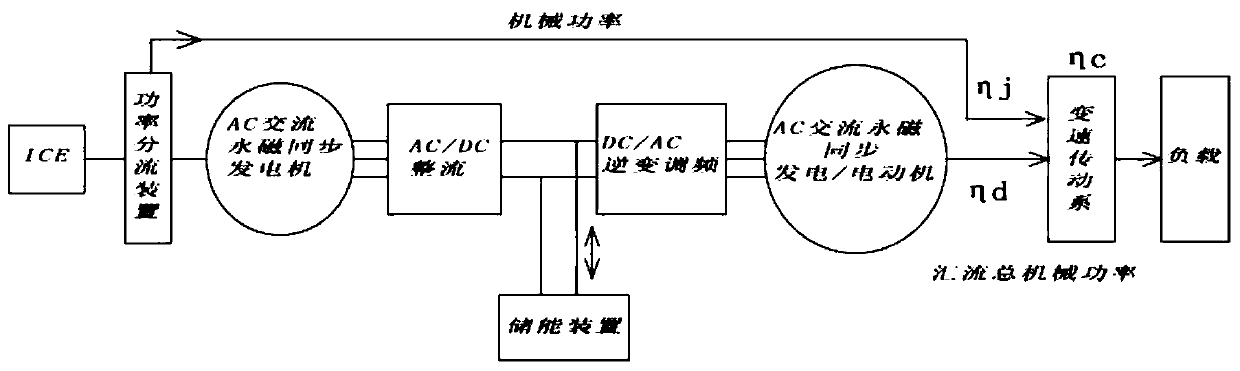

Stepless variable drive system for series dual-motor differential power dividing

PendingCN110303865AGuaranteed to workQuick responseElectric propulsion mountingControl devicesElectric machineElectric power system

The invention discloses a stepless variable drive system for series dual-motor differential power dividing. The system comprises an engine output / differential input shaft, a first motor, a second motor, a motor controller, a power dividing device, a clutch, a gearbox, an engine power output shaft and a storage battery; the first motor and the second motor are connected in series, power of an engine is transmitted to the first motor through the engine output / differential input shaft for power generation, and meanwhile, the engine output / differential input shaft outputs power outwards through the power dividing device, the clutch and the gearbox to form a first power path; the first motor supplies power to the second motor and the storage battery through the motor controller, and the secondmotor outputs power outwards through the power dividing device, the clutch and the gearbox to form a second power path. The stepless variable drive system has the two power paths of mechanical power and electric power.

Owner:GUANGXI YUCHAI MASCH CO LTD

Gearshift control method and system as well as engineering machinery for dragging operation

ActiveCN102635689ARealize automatic shiftingGearing controlSoil-shifting machines/dredgersAutomatic controlTurbine

The invention discloses a gearshift control method. The method comprises the following steps of: acquiring the turbine torque and a gear signal under the current accelerator state; keeping the current gear when the gear signal is determined to be a neutral gear signal, or comparing the turbine torque and a preset torque range; keeping the current gear when the turbine torque is in the preset torque range; raising the gear when the turbine torque is less than the minimum torque in the preset torque range and the gear signal is determined not to be the maximal gear position; and lowering the gear when the turbine torque is greater than the maximal torque in the preset torque range and the gear signal is determined not to be the minimum gear signal. In the gearshift control method disclosed by the invention, the encountered working conditions are determined according to the turbine torque, and further the automatic control of the gear is carried out.

Owner:SHANTUI CONSTR MASCH CO LTD

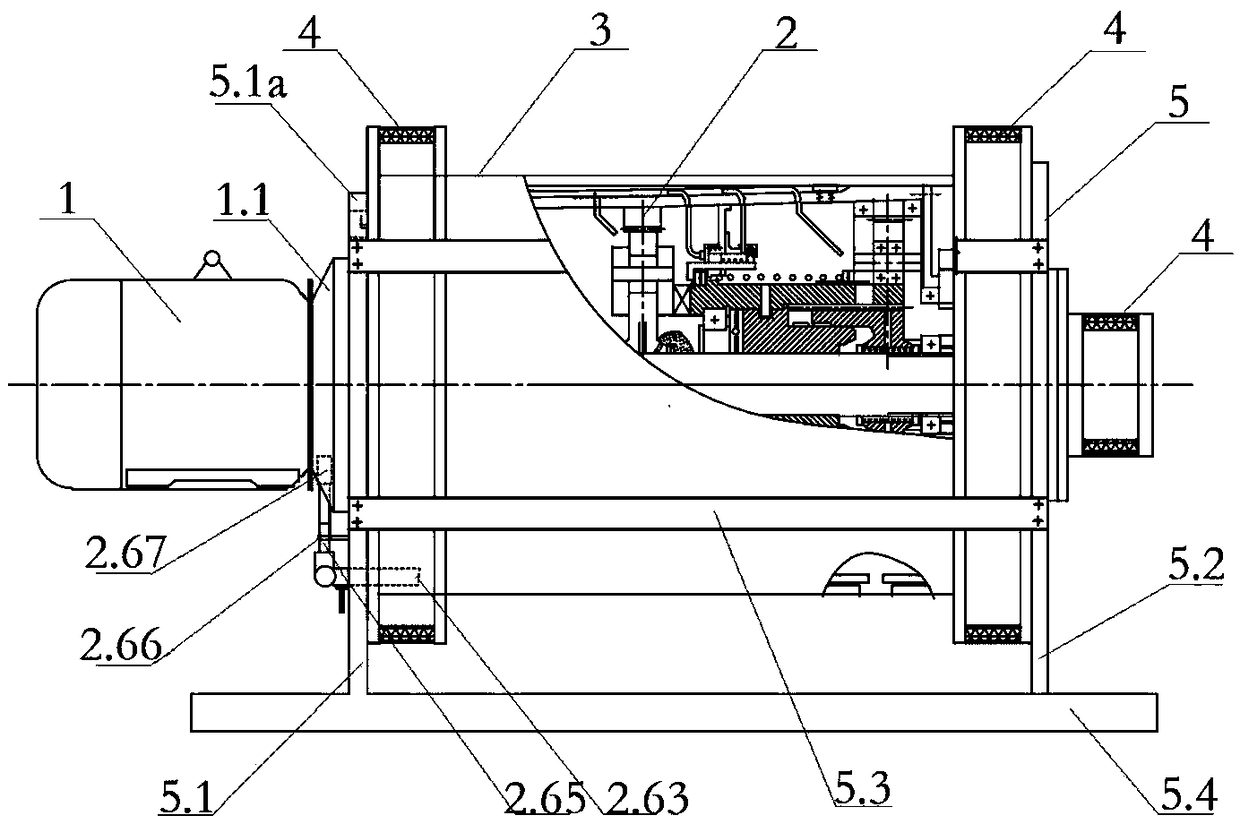

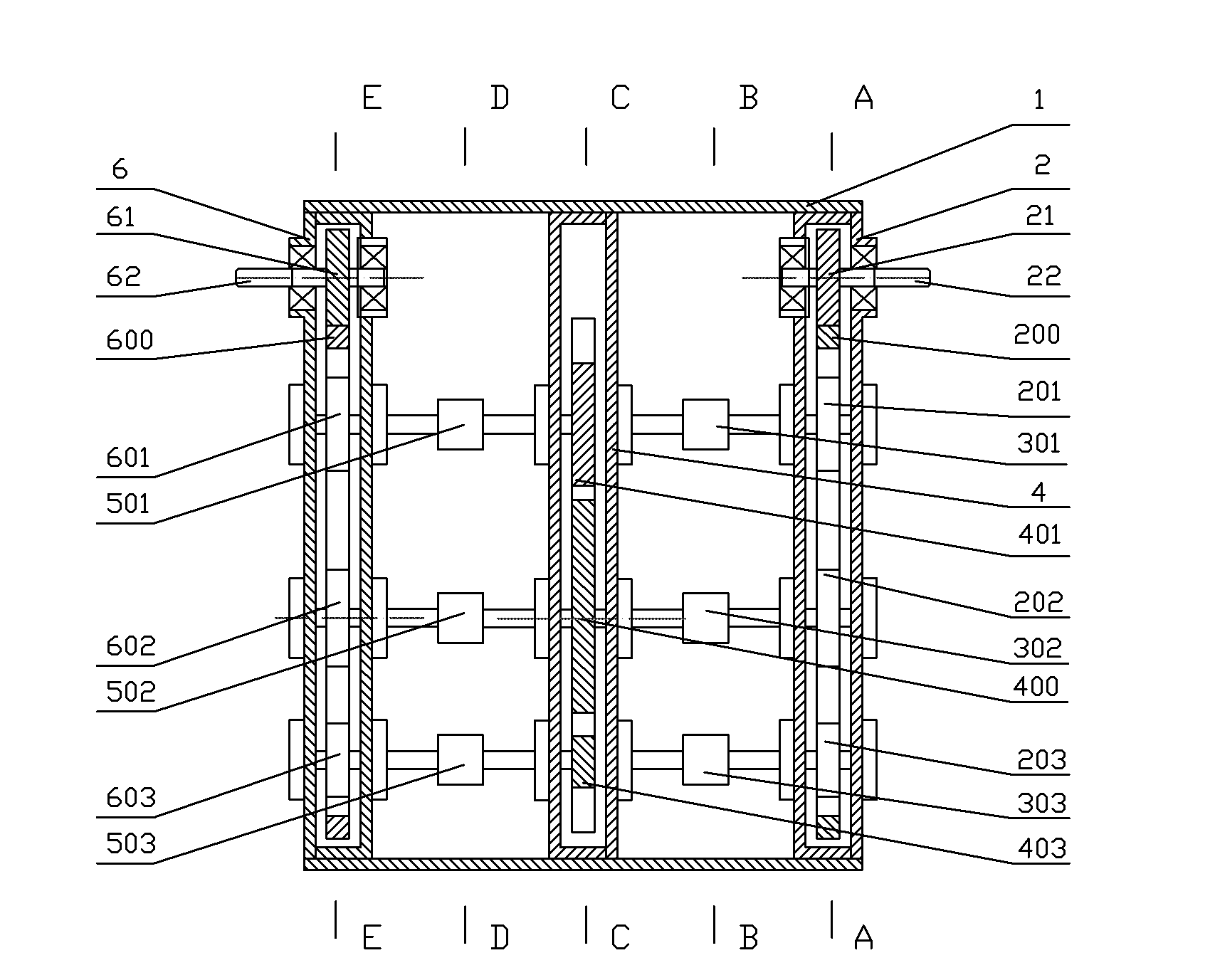

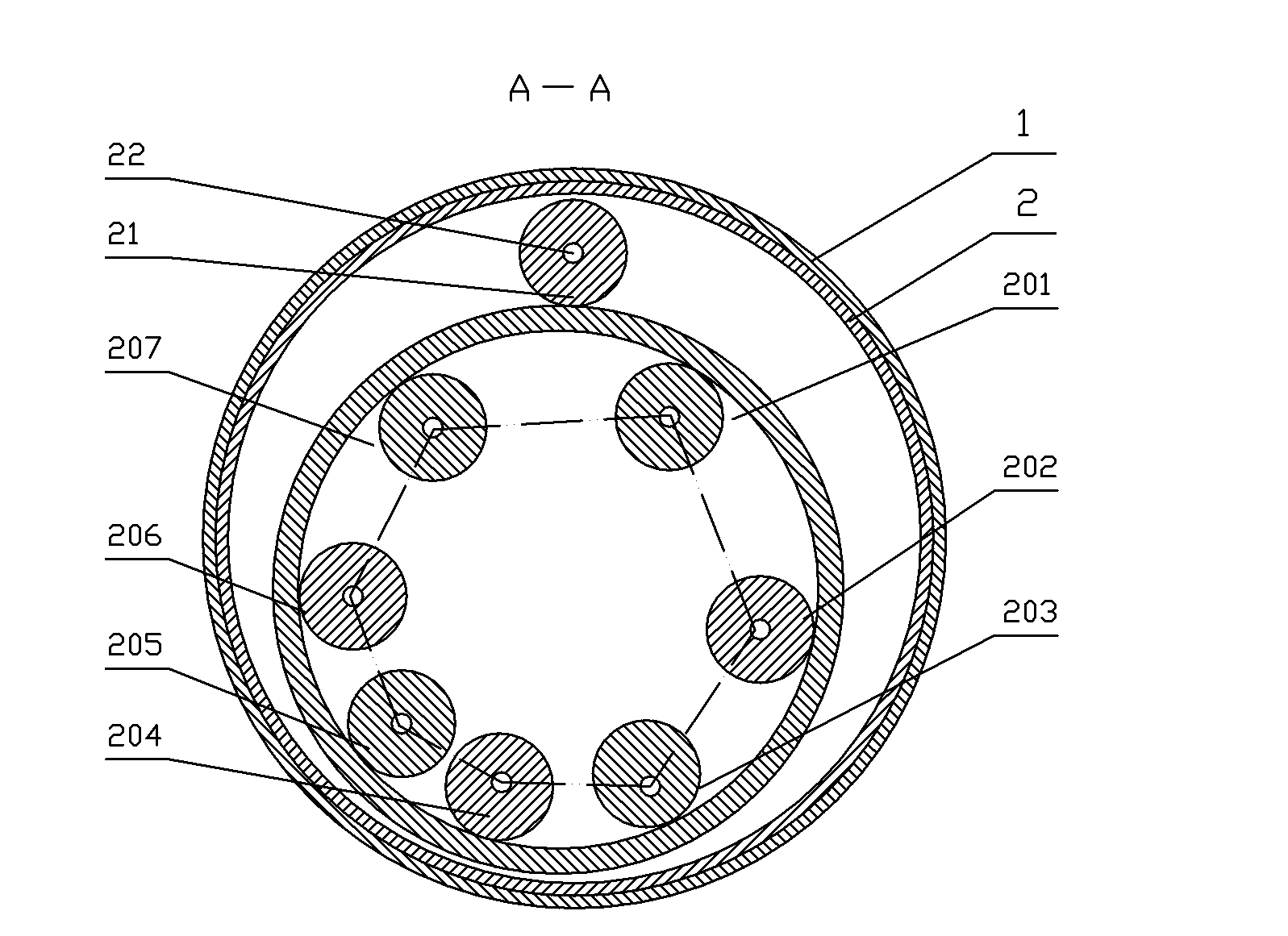

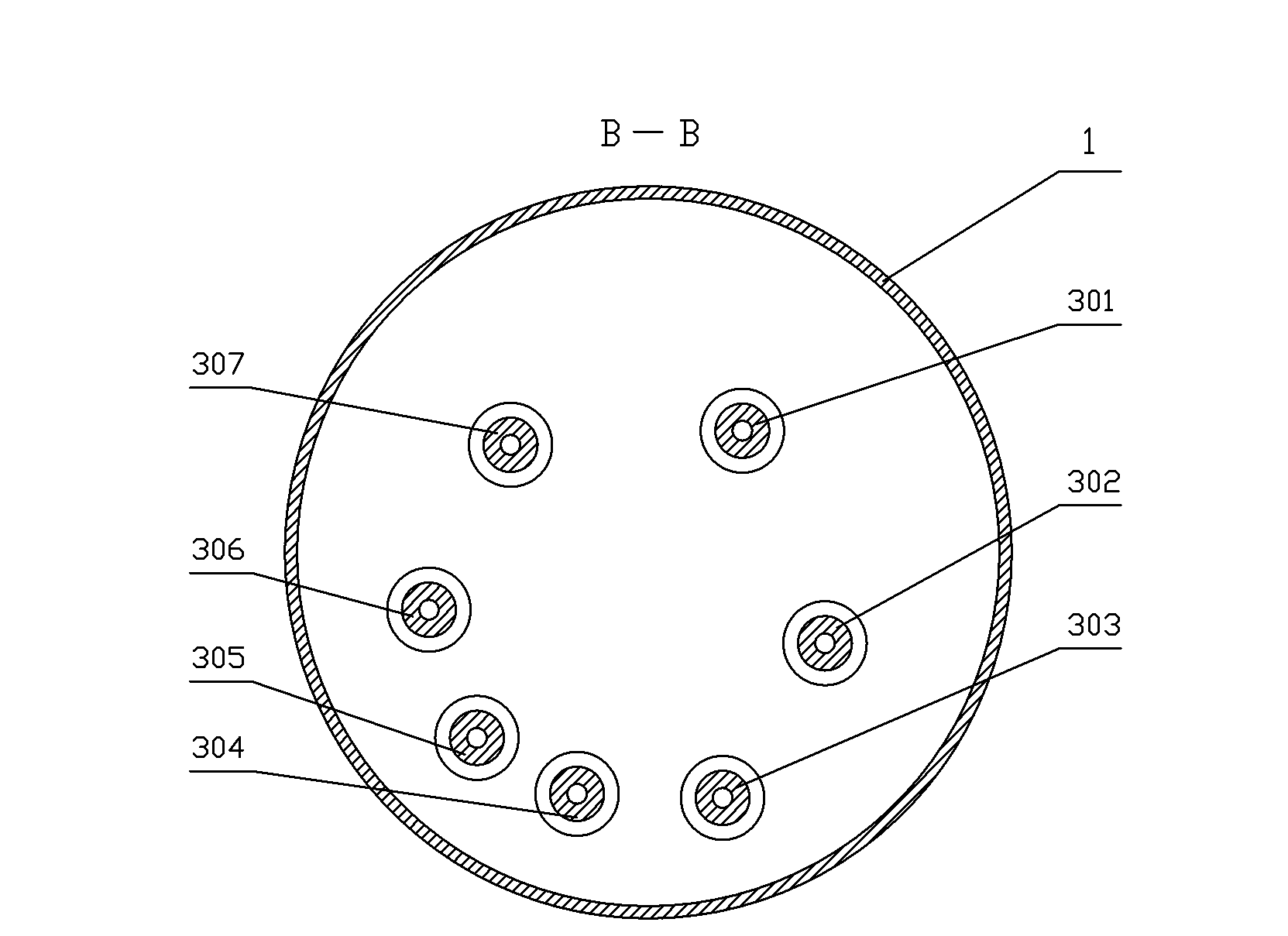

Numerical control mechanical automatic transmission

InactiveCN102359559AExtended service lifeImprove reliabilityGearboxesToothed gearingsNumerical controlAutomatic transmission

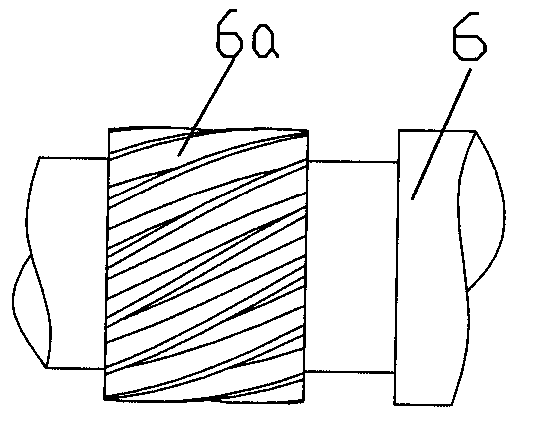

The invention discloses a numerical control mechanical automatic transmission which comprises a first sun gear (200) arranged in a front box (2) and an input gear (21) meshed with external teeth of the first solar gear, and output gears (201-207) meshed with internal teeth of the first sun gear, a middle carrier gear (400) arranged in a middle box (4) and change gears (401-407) meshed with external teeth of the middle carrier gear, a second sun gear (600) arranged in a rear box (6) and an output gear (61) meshed with external teeth of the second sun gear and input gears (601-607) meshed with internal teeth of the second sun gear, a shell and a numerical control machine, wherein the output gears meshed with the internal teeth of the first sun gear, the change gears meshed with the external teeth of the middle carrier gear in the middle box and the input gears meshed with the internal teeth of the second sun gear in the rear box are respectively correspondingly arranged, axial lines among the correspondingly-arranged gears are coaxial and coaxial gear shafts are respectively provided with front box electromagnetic clutches (301-307) and rear box electromagnetic clutches (501-507), which are electrically controlled by the numerical control machine.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com