Winch with planetary gear transmission having function of automatic gear shifting

A planetary gear, automatic shifting technology, applied in the direction of hoisting device, spring mechanism, gear transmission device, etc., can solve the problem of slow lifting speed, speed regulation range and light-load energy-saving restrictions, uphill and energy-saving speed-up restrictions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

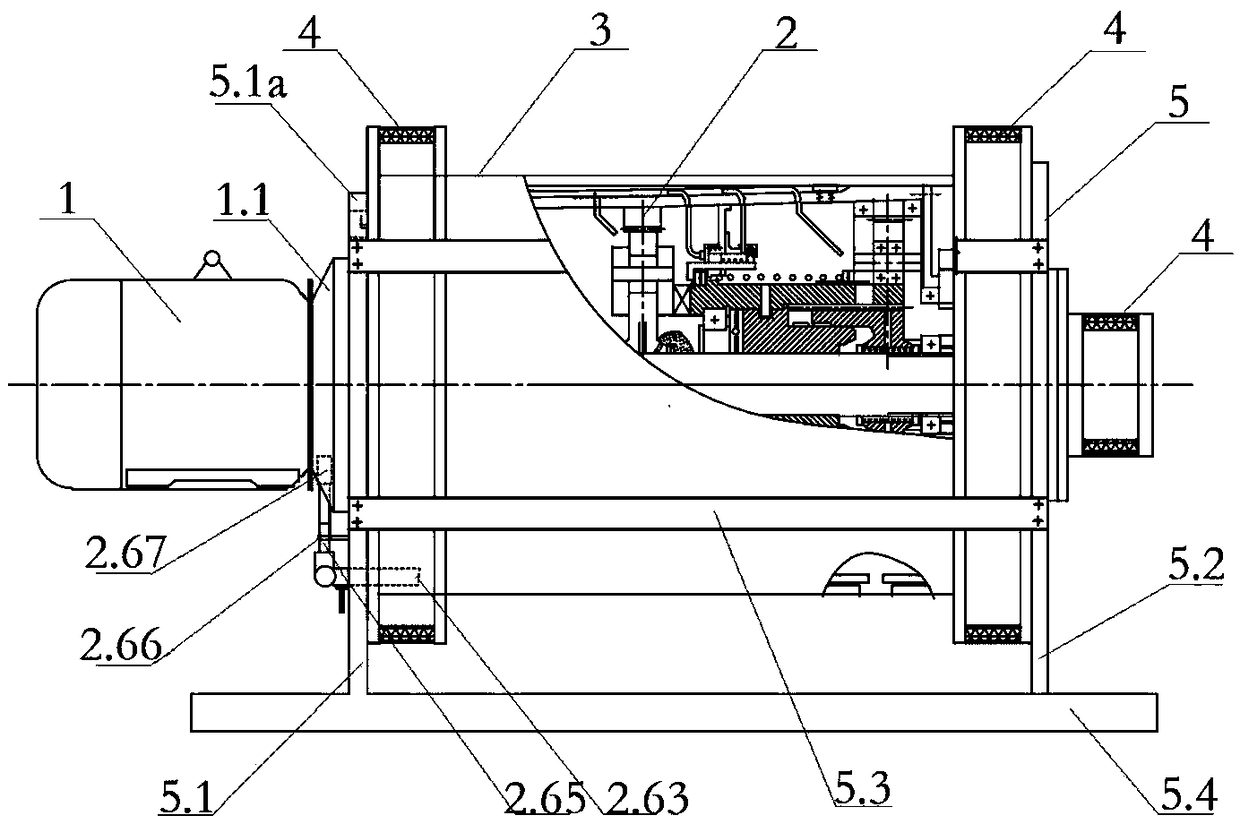

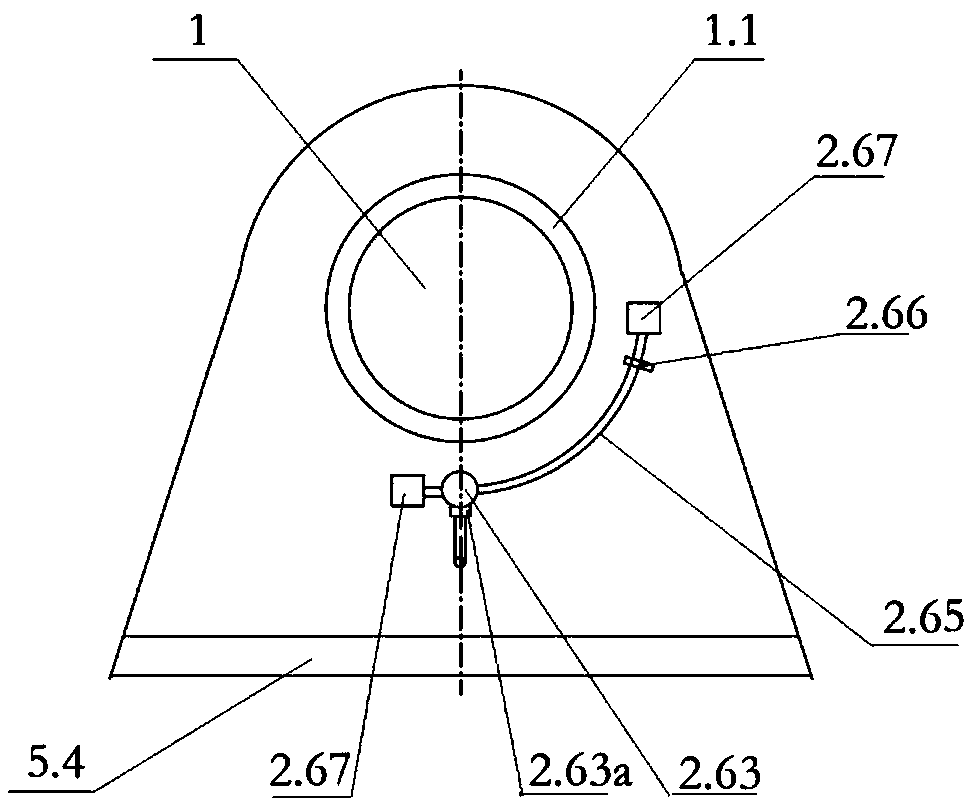

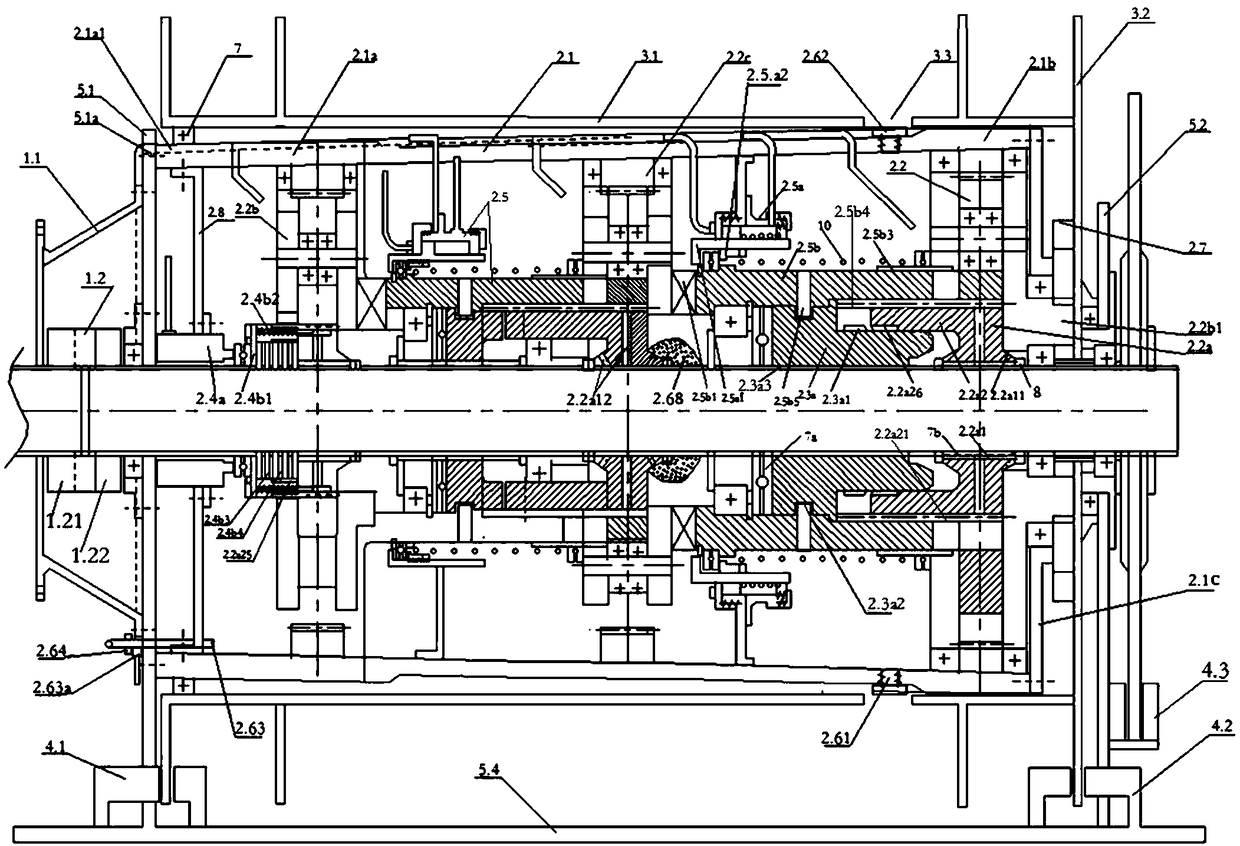

[0089] Figure 1(a), Figure 1(b), figure 2 is the overall structure diagram of the winch, Figure 4 , Figure 5It is a schematic diagram of the oil discharge hole of the ring gear and a schematic diagram of the external circulation lubrication system. The internal self-lubrication includes the lubricating oil penetration hole 2.2a12 arranged radially on the center sun gear and the slope foot, and the protection device is set between the right side of the center sun gear 2.2a and the execution unit 2.4b. Oil material 2.68; in order to prevent the left planetary gear center sun gear bearing 7a from being poorly lubricated due to long-term work in the selected gear, install the oil suction pipe 2.63b from the hollow pipe joint 2.63a of the oil inlet and outlet pipe on the left, and filter it through the oil with bypass Device 2.63c is connected with hydraulic oil pump 2.63e, relief valve 2.63f, pressure sensor 6.3, and flow sensor 6.4 are set on lubricating oil pipe 2.63d, and th...

Embodiment 3

[0092] Figure 6(a) and Figure 6(b) are schematic diagrams of a clutch shifter installed between the n-stage planetary gear and the reel, the outer diameter of the clutch shifter executive unit tubular part 2.5b is provided with an external spline 2.5b6 and the right end cover bearing of the transmission 7 The inner spline of the inner ring is combined and can slide axially, or it can be set as a sliding bearing connection and can slide axially. The spline 2.5b4 on the right side of the tubular part is combined with the outer spline 2.712 of the central tubular part of the coupling half and can Axial sliding, the outer spline 2.712 on the right side of the central tubular part of the half-coupling is interfering with the inner spline 2.72 on the driving part of the half-coupling, and the left end is provided with teeth or cogs III 2.711 and the power output gear The tooth shape or tooth cog I 2.3a1 is dynamically combined, and the inner diameter is provided with 2 bearings with ...

Embodiment 4

[0094] Figure 3(a) is a schematic diagram of the normally open clutch I. Under the action of the spring 10, the jaw clutch I is separated, the power output gear 2.3a of the drive shaft rotates idly with the drive shaft 2.3, and the drive unit I2.4a pushes the thrust bearing 7a to the right The tooth shape or tooth cog I2.3a1 of the power output gear of the side-moving driving shaft is combined with the tooth shape or tooth cog I2.2a26 of the end surface of the ring shaft extension, the displacement sensor 6.2 is an inductive proximity switch, the conduction gear indicator light is on and The power mechanism 1 is connected, and the driving shaft drives the central sun gear to drive the reel to rotate step by step; Figure 3(b) is a schematic diagram of the combination of the external teeth of the central sun gear and the internal teeth of the power output gear of the driving shaft, and the drive unit 2.4a drives the thrust The bearing 7a combines the tooth shape or tooth cog I2.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com