Centrifugal gear shifting device

A technology for shifting devices and shifting parts, which is applied in transportation and packaging, bicycle gear transmission mechanisms, bicycle accessories, etc., and can solve problems such as the inability to realize overrunning clutches and shifting at the same time, the inability to realize automatic shifting, and the difficulty of maintenance by workers. problems, to achieve the effect of compact structure, reliable shifting and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

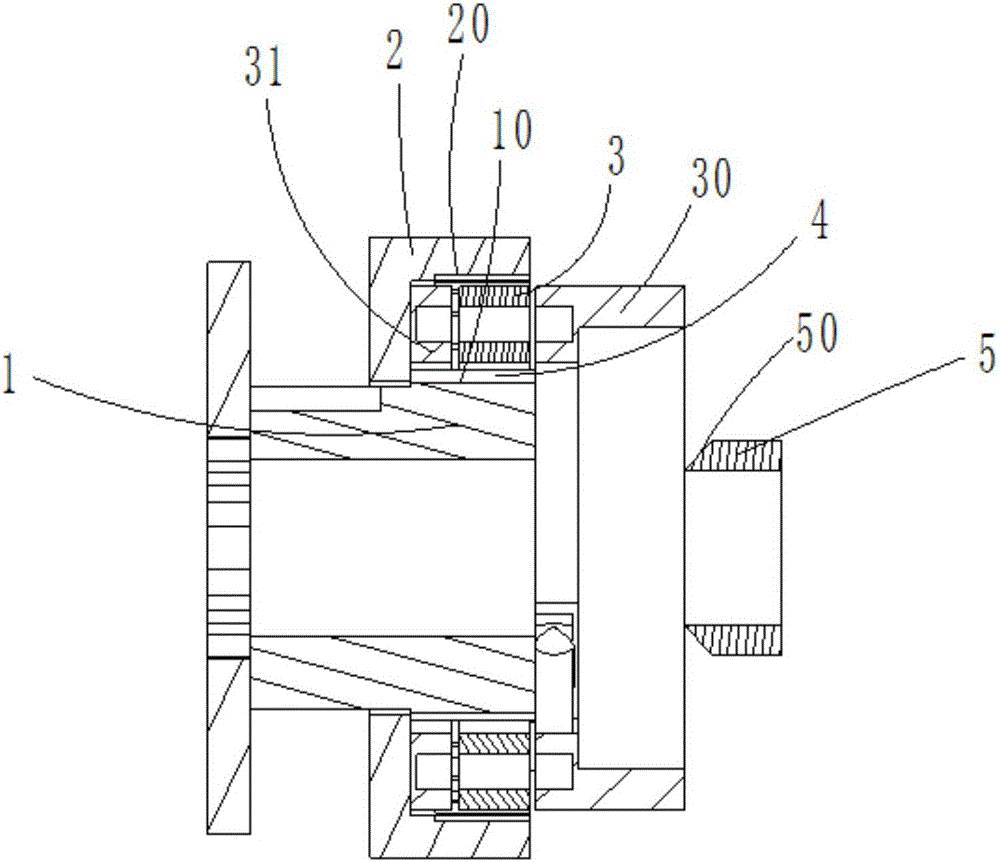

[0023] Please refer to the attached figure 1 As shown, the present invention is a centrifugal shifting device, which is mainly composed of a first transmission member 1, a second transmission member 2 and a shift mechanism 3.

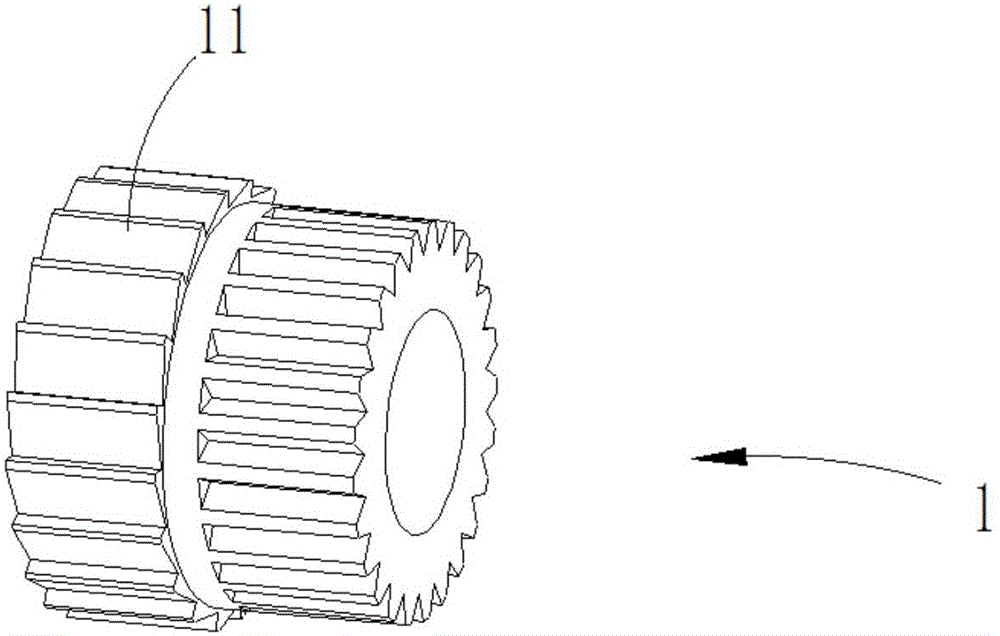

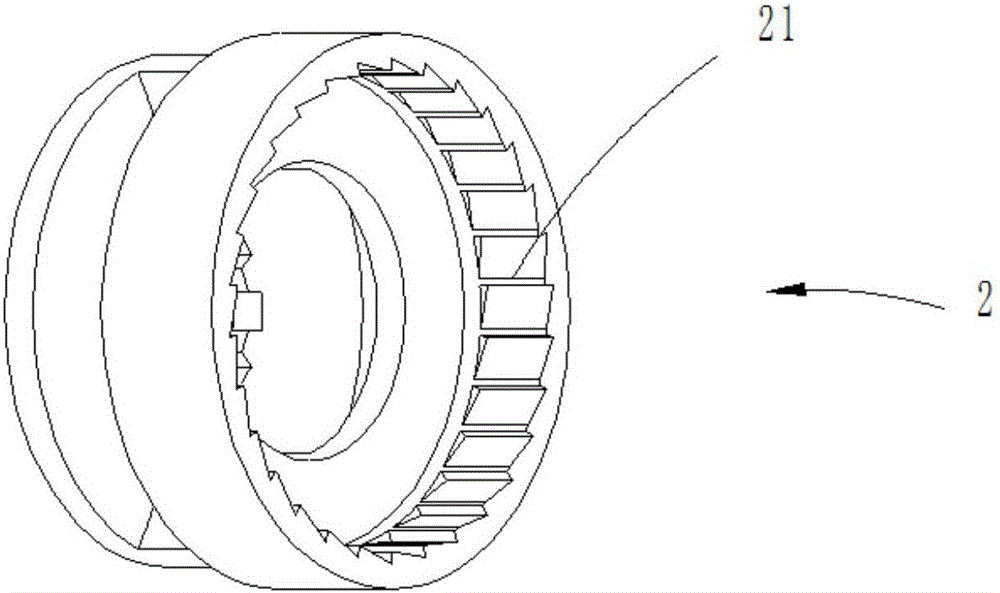

[0024] read on Figure 2 to Figure 5 , the second transmission member 2 is sheathed on the first transmission member 1, a storage chamber 4 is formed between the second transmission member 2 and the first transmission member 1, and the second transmission member 2 is provided with a 4, the first transmission member 1 is provided with an outer wall 10 located in the receiving chamber 4, the outer wall 10 of the first transmission member 1 is provided with a first ratchet 11, and the second transmission member 2 The inner wall 20 is provided with a second ratchet 21 , the first ratchet 11 is integrally formed with the first transmission member 1 , and the second ratchet 21 is integrally formed with the second transmission member 2 . The shifting mechani...

Embodiment 2

[0028] see Figure 6 , the rest of the structure of the centrifugal shifting device in this embodiment is the same as that of Embodiment 1, the difference lies in the structure of the shift member 310, in this embodiment, the counterweight 3101 and the first pawl 3105, the second The pawl 3106 is set at the same end of the mounting part 3100. The working principle of the centrifugal shifting device in this embodiment is: the initial position of the two shifting parts 310 is controlled by the elastic part. axis, the first pawl 3105 of the shifting member 310 meshes with the first ratchet 11, and the first transmission member 1 is meshed with the shifting member 310. As the speed of the first transmission member 1 increases, the shifting The gear frame 30 synchronously rotates faster, and under the action of centrifugal force, the weight 3101 of the gear shifter moves away from the axis, and the second pawl 3106 of the gear shifter 310 engages with the second ratchet 21. At this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com