Power gear shift gearbox for wheel excavator

A technology for power shifting and excavators, which is applied in transmission boxes, gear transmissions, gear lubrication/cooling, etc., and can solve the problem of difficulty in shifting gears, damage to splines of sliding teeth or related parts, and high labor intensity for operators and other issues, to achieve the effect of improved safety, good sealing performance and compact internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is described in further detail.

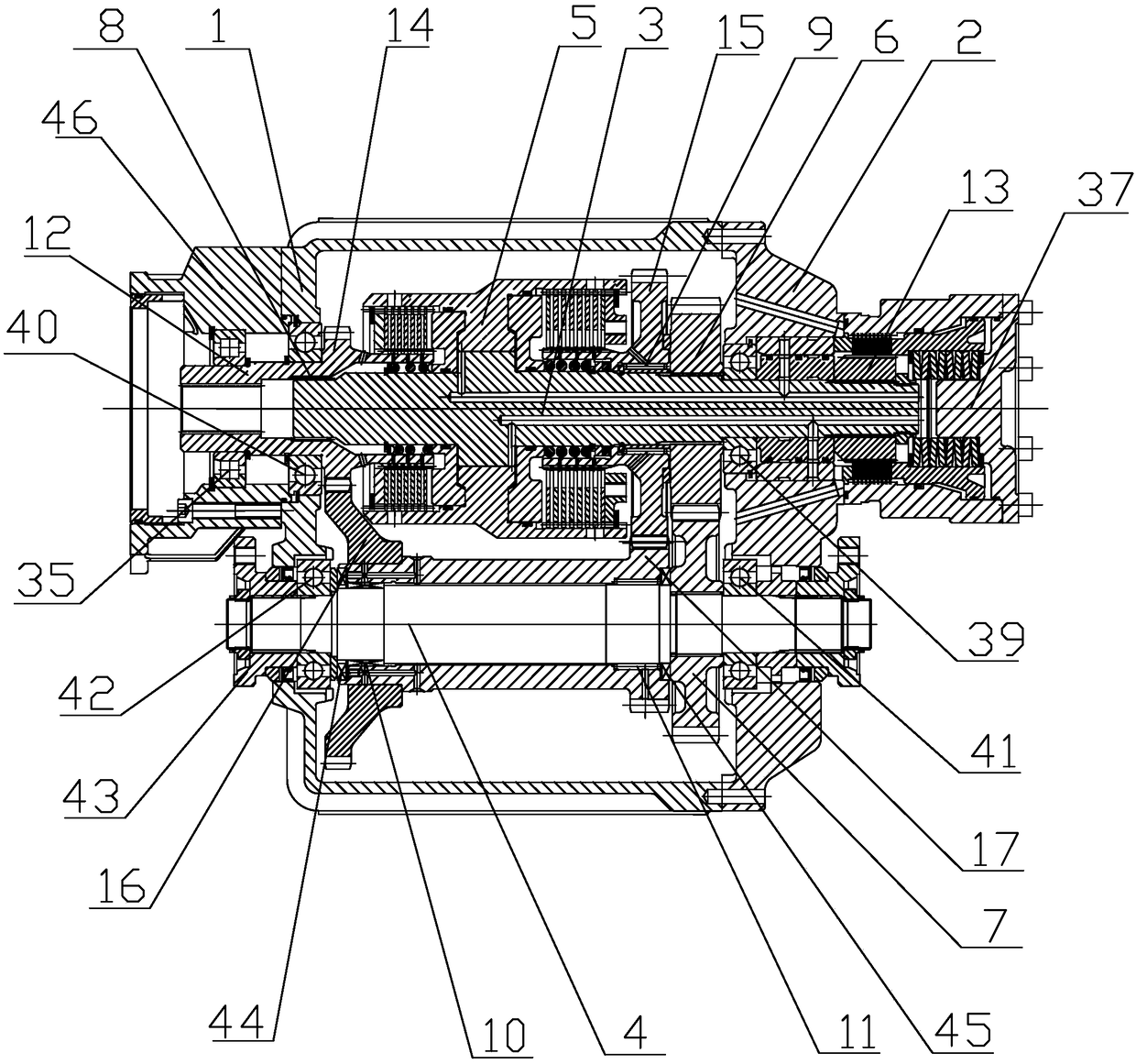

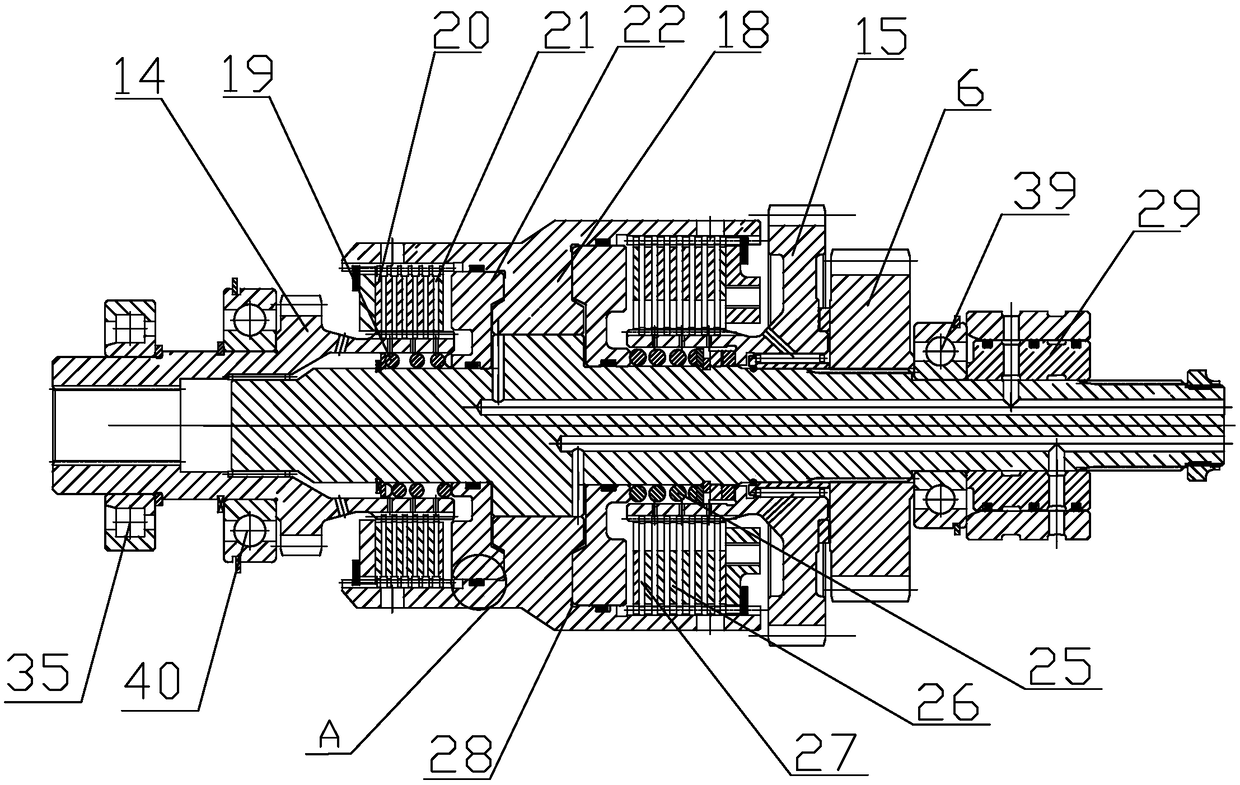

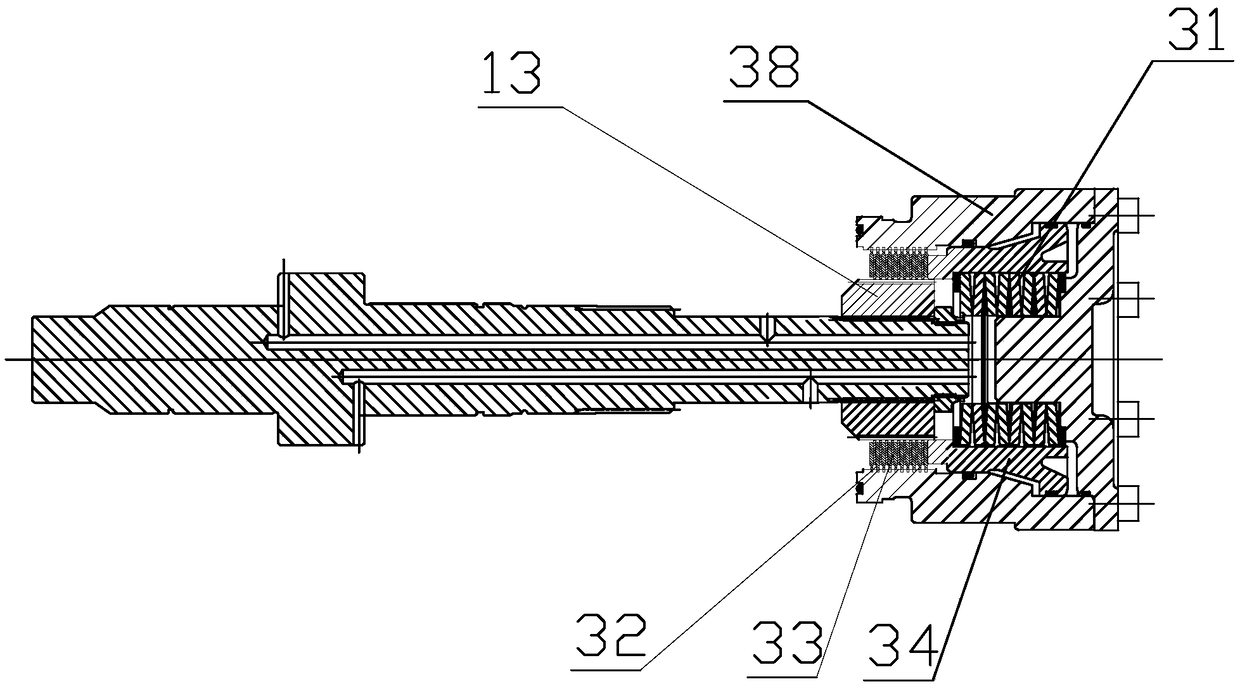

[0033] The present invention proposes a power shift gearbox for a wheeled excavator, such as Figures 1 to 4 As shown, it includes a box body, in which the input shaft 3 and the output shaft 4 are connected in rotation, the input shaft 3 is sequentially fixed with a needle roller bearing 8, a clutch 5 and an input gear 6, and the needle roller bearing 1 8 is connected with a spline Sleeve 12, one end of the spline sleeve 12 extends out of the box and is connected with the hydraulic motor 47 of the excavator. Through the spline connection, the centering error can be reduced, the transmission accuracy can be improved, and it can bear a larger load, so that the Force is more uniform, the other end of spline sleeve one 12 is provided with first gear 14 that is connected with clutch 5, is provided with second gear 15 that is connected with clutch 5 between clutch 5 and input gear 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com