Novel automatic transmission without clutch and synchronizer and speed change method thereof

An automatic transmission, clutchless technology, applied in the direction of elements with teeth, transmission control, belt/chain/gear, etc., can solve the problems of reducing driving difficulty, high cost, easy to burn friction plates, etc., to shorten the time, The effect of prolonging the life and shortening the shift time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

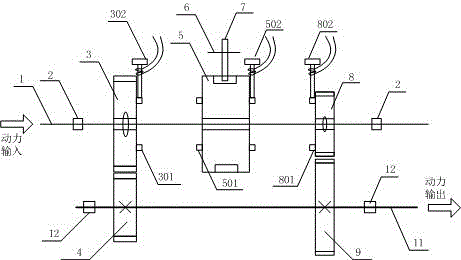

[0022] Such as figure 1 Shown is the mechanical structure diagram when the electric vehicle automatic transmission of the present invention has a two-speed transmission. In the figure, 1 is the driving shaft, 2 is the bearing, 11 is the driven shaft, 12 is the driven bearing, the first gear driving gear 3 and the driving shaft 1 are clearance fit, and the right side of the first gear driving gear 3 is provided with a claw 301 , a rotation speed sensor 302 is installed on the corresponding direction of the claw 301, the first gear driven gear 4 meshes with the first gear driving gear 3; Protruding pawl 801, a rotational speed sensor 802 is installed on the corresponding direction of protruding pawl 801, the second gear driven gear 9 meshes with the second gear driving gear 8; the second gear driven gear 9 and the first gear driven gear 4 are fixed to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com