Hydraulic gearshift of tractor

A technology for shifting devices and tractors, applied in the direction of mechanical control devices, transmission device control, mechanical equipment, etc., can solve problems such as operational errors and high labor intensity, and achieve the effect of accurate action and light shift operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

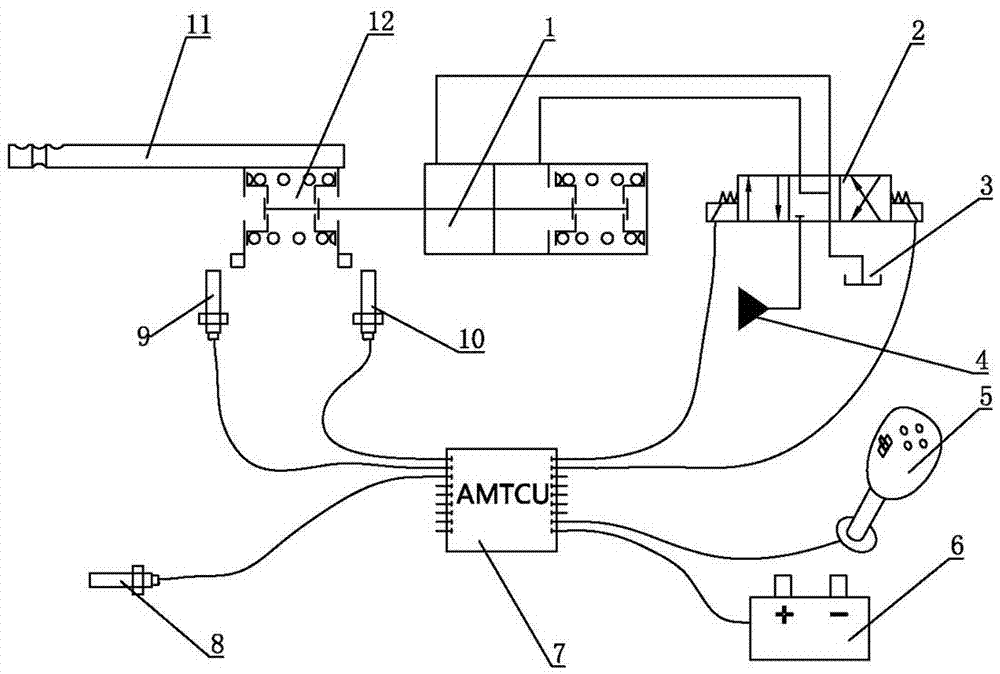

[0014] Such as figure 1 As shown, the tractor hydraulic shift device of the present invention includes a shift handle 5, a shift lever 11 and a clutch. A handle position sensor is installed on the shift handle 5 to detect the position information of the shift handle 5 in different gears. The handle position sensor can be a micro switch or other sensors such as travel switches. The signal output end of the handle position sensor is connected to the shift signal input end of the shift controller 7 to transmit the position state information of the shift handle 5 to the shift controller 7 .

[0015] A clutch position sensor 8 is installed on the clutch to detect whether the clutch is in a disengaged state. The signal output end of the clutch position sensor 8 is connected to the clutch signal input end of the shift controller 7, and the clutch position sensor can adopt a micro switch or a travel switch to judge whether the clutch is disengaged by the on and off of the switch. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com