Intelligent variable speed control method, device and system

A control method and control device technology, applied in engine control, transmission control, transportation and packaging, etc., can solve problems such as large handle opening, hydraulic system overflow, flameout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

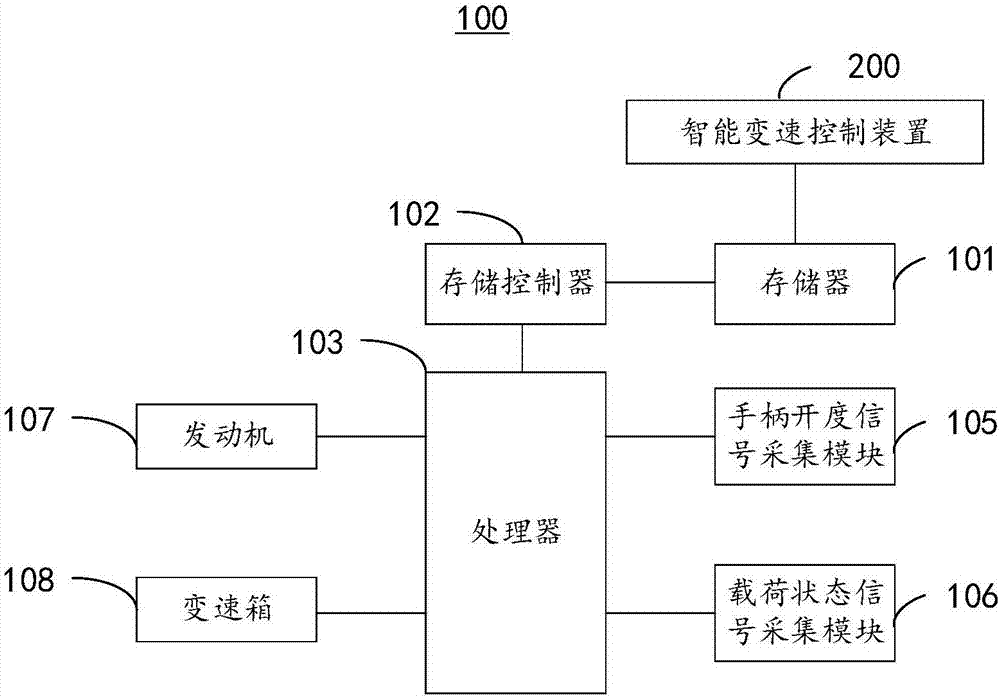

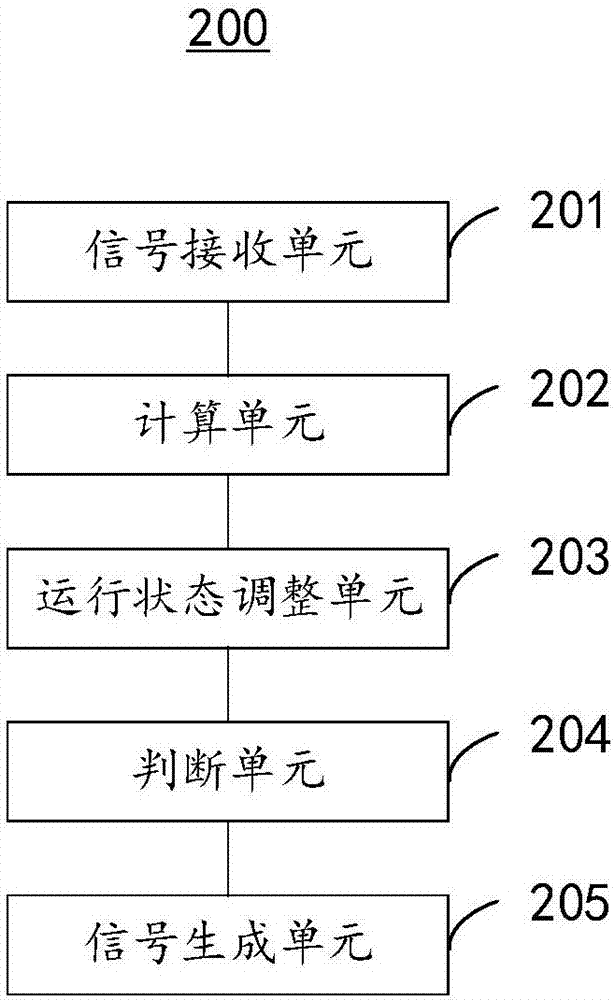

[0040] see figure 2 , shows a functional block diagram of the intelligent shift control device 200 provided by the embodiment of the present invention. The intelligent shift control device 200 includes a signal receiving unit 201 , a computing unit 202 , an operating state adjusting unit 203 , a judging unit 204 and a signal generating unit 205 .

[0041] The signal receiving unit 201 is used for receiving the input handle opening signal and load state signal.

[0042] After the handle opening signal collection module 105 collects the handle opening signal and the load state collection module collects the load state signal, the handle opening signal collection module 105 and the load state collection module respectively transmit the handle opening signal and the load state signal to the signal receiving unit 201.

[0043]It should be noted that the handle opening signal is a signal generated by the operator operating the handle when the operating speed of the crane needs to...

no. 2 example

[0063] The basic principles and technical effects of the intelligent variable speed control method provided by the embodiment of the present invention are the same as those of the above embodiment. For brief description, for the parts not mentioned in this embodiment, reference may be made to the corresponding content in the above embodiment.

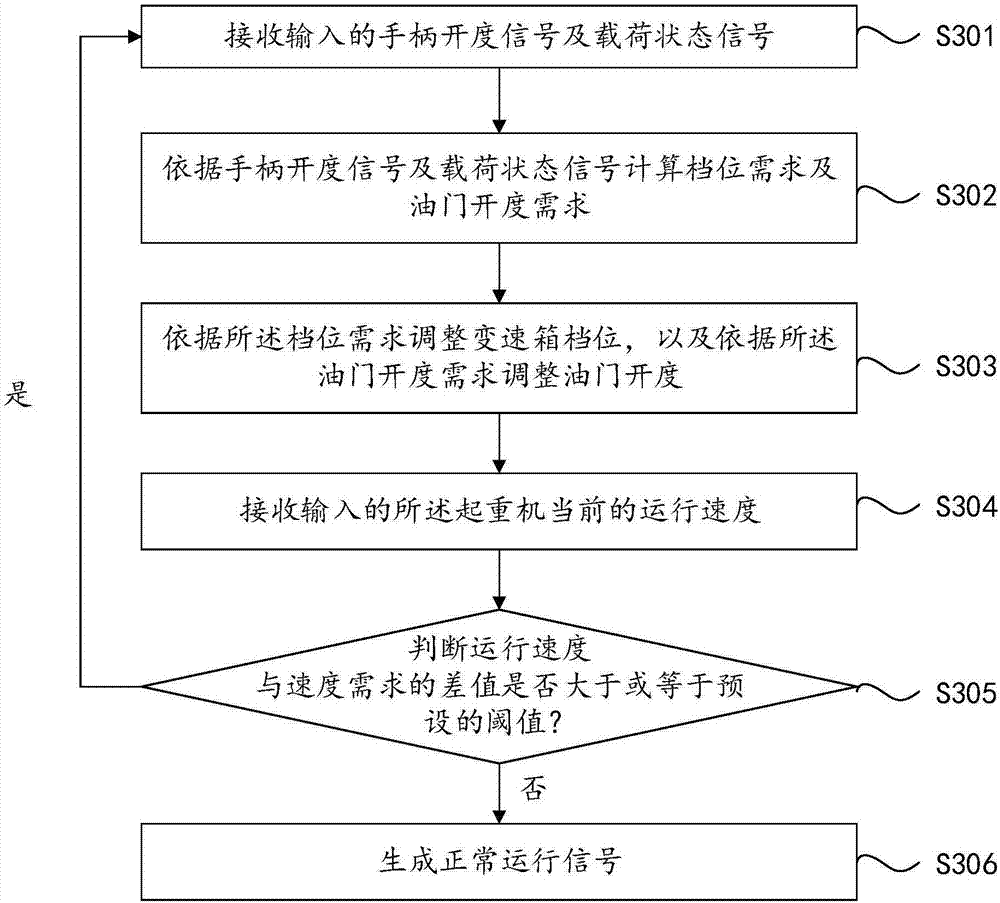

[0064] see image 3 , shows a flow chart of the intelligent shift control method provided by the embodiment of the present invention.

[0065] Step S301: Receive the input handle opening signal and load state signal.

[0066] Understandably, step S301 may be executed by the signal receiving unit 201 .

[0067] It should be noted that the handle opening signal is a signal generated by the operator operating the handle when the operating speed of the crane needs to be changed, and is used to represent the current opening of the handle.

[0068] In addition, in a preferred embodiment, the load status signal includes the oil pump pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com