Power split type hybrid electric vehicle driving system and control method thereof

A hybrid electric vehicle and drive system technology, which is applied to the layout of multiple different prime movers of hybrid vehicles, motor vehicles, and general power plants, etc., can solve the impact of unsustainable free selection of drive systems, rotational speeds, and free selection of operating points and other issues to achieve the effect of improving fuel economy, ensuring driving stability, and ensuring power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

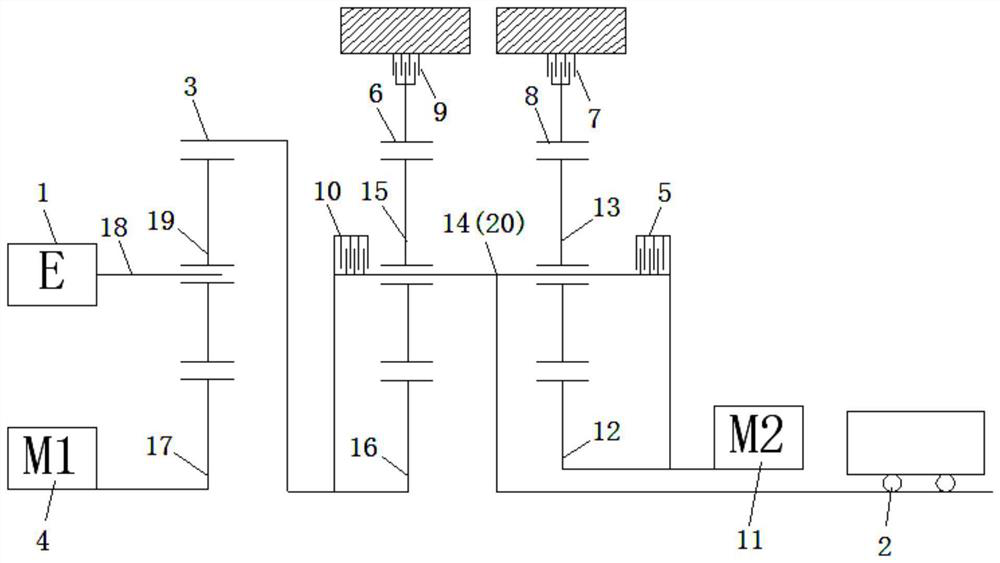

[0048] Example: such as figure 1 As shown, a power-split hybrid vehicle drive system includes an engine 1 and wheels 2, and also includes a first motor 4, a second motor 11, a first clutch 10, a second clutch 5, a first epicyclic wheel train, The second epicyclic gear train, the third epicyclic gear train, the first brake 9 and the second brake 7; the first epicyclic gear train includes the first planetary gear 13, the first sun gear 12, the first ring gear 8 and the first planet frame 14, the first planetary gear 13 is connected with the first sun gear 12 and the first ring gear 8 respectively, and the first planetary gear 13 is connected with the first planetary carrier 14; the second epicyclic gear train includes the second planetary gear 15, the second The sun gear 16, the second ring gear 6 and the second planet carrier 20, the second planet gear 15 is connected with the second sun gear 16 and the second ring gear 6 respectively, and the second planet gear 15 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com