Gearshift mechanism extreme position self-learning control method for AMT system

A shifting mechanism and limit position technology, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of motor precision and response speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

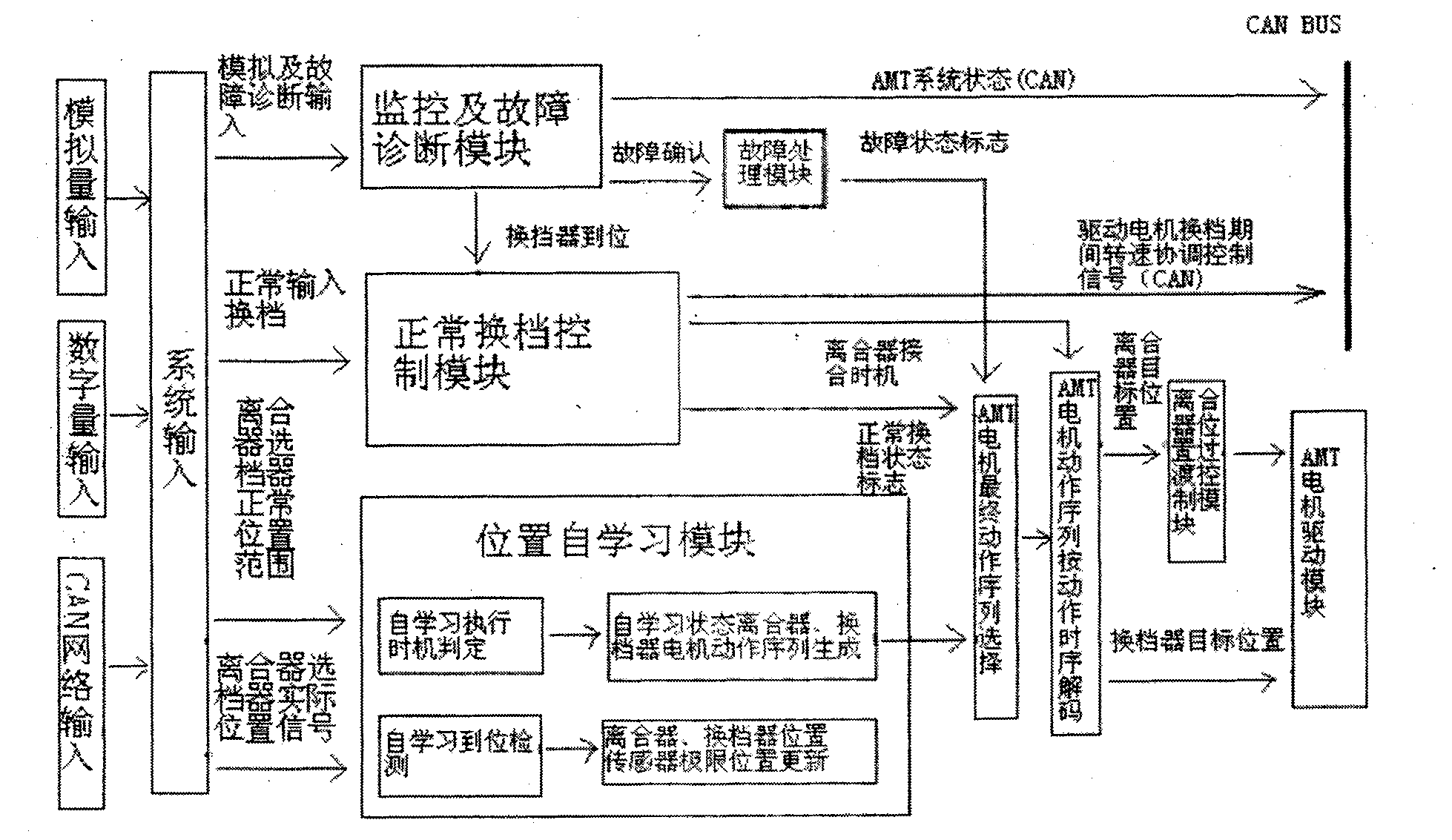

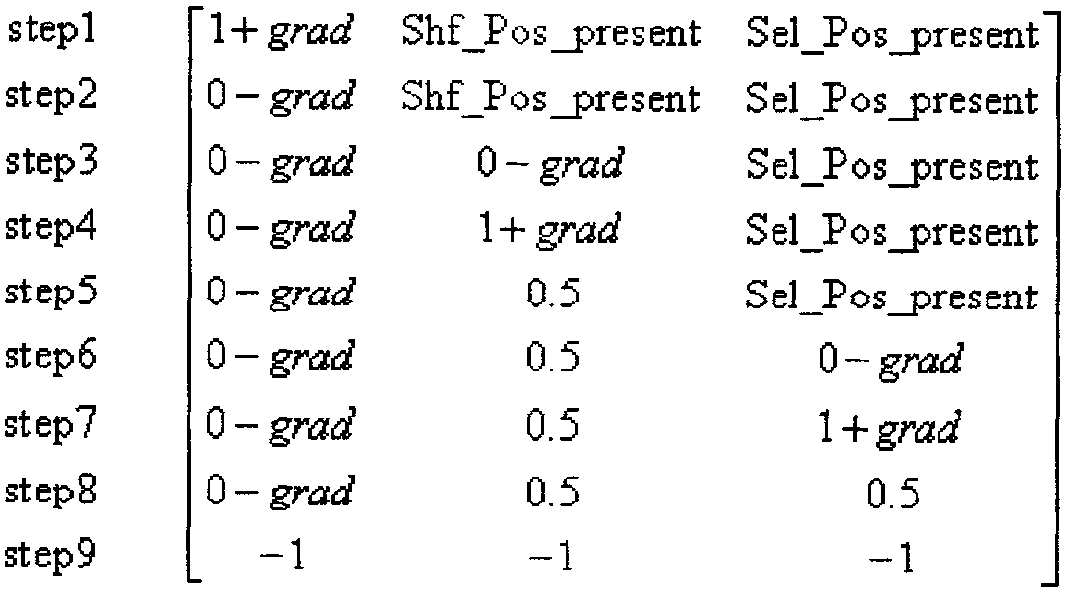

[0020] Such as figure 1 The shown self-learning method controls the working order of AMT: first, the input signal of the self-learning module is collected and input by the TCU, and the self-learning flag is output to other modules of the subsequent AMT, and then the AMT action sequence module selects the action sequence matrix according to the flag, and presses the action The time sequence is decoded to obtain the target position of each shifting mechanism, and finally the motor drive module drives the shifting mechanism to operate. The self-learning module will perform in-position detection according to the actual position of the shift mechanism, and if the self-learning is completed, it will automatically update and save the limit position parameters of the mechanical mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com