Vehicle gear shifting control system, driving gear shifting control method and loading machine

A technology of a control system and a control method, which is applied in the field of vehicle gear shifting, can solve the problems such as the inability to realize driving gear shifting, and achieve the effect of ensuring vehicle speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

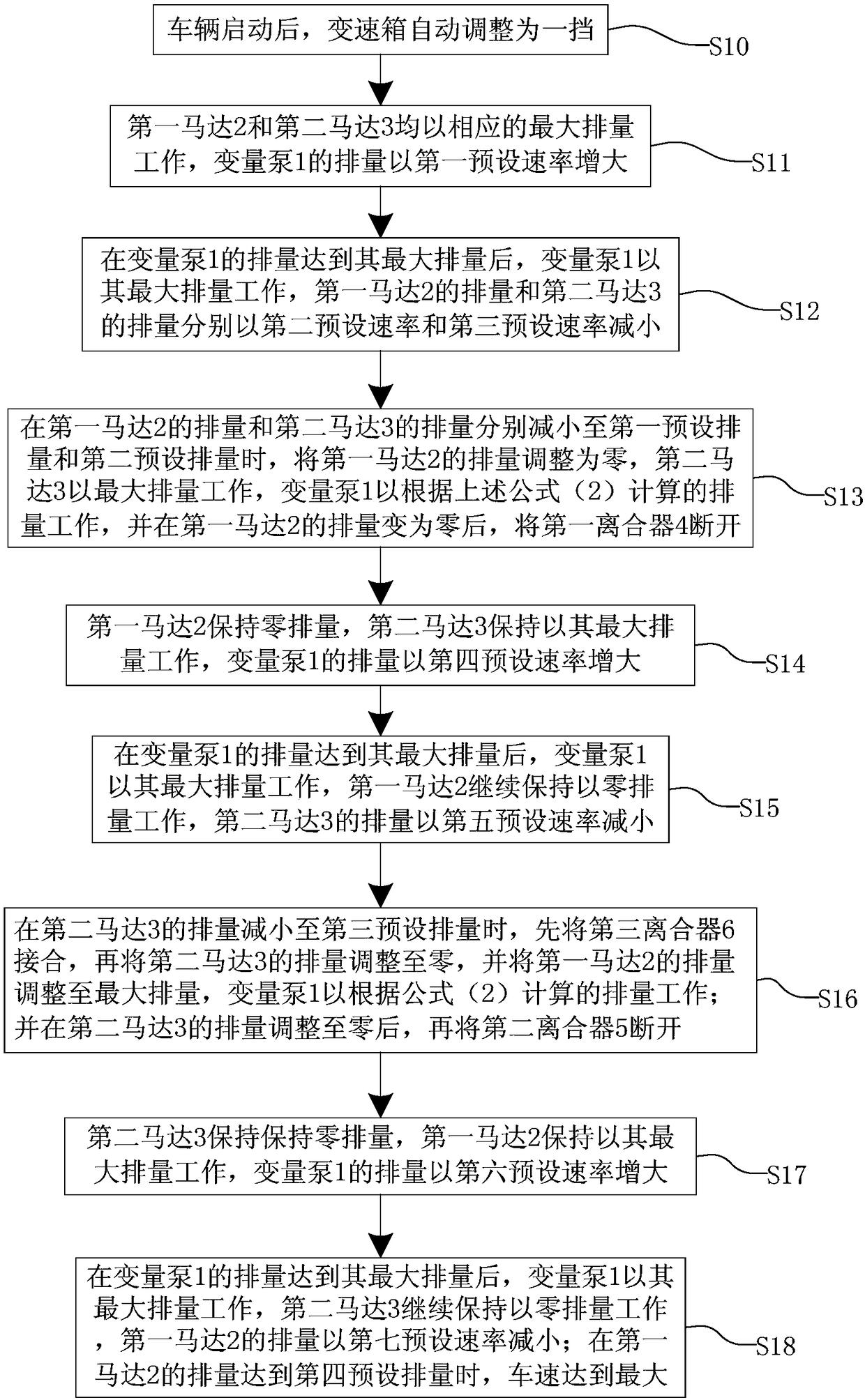

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

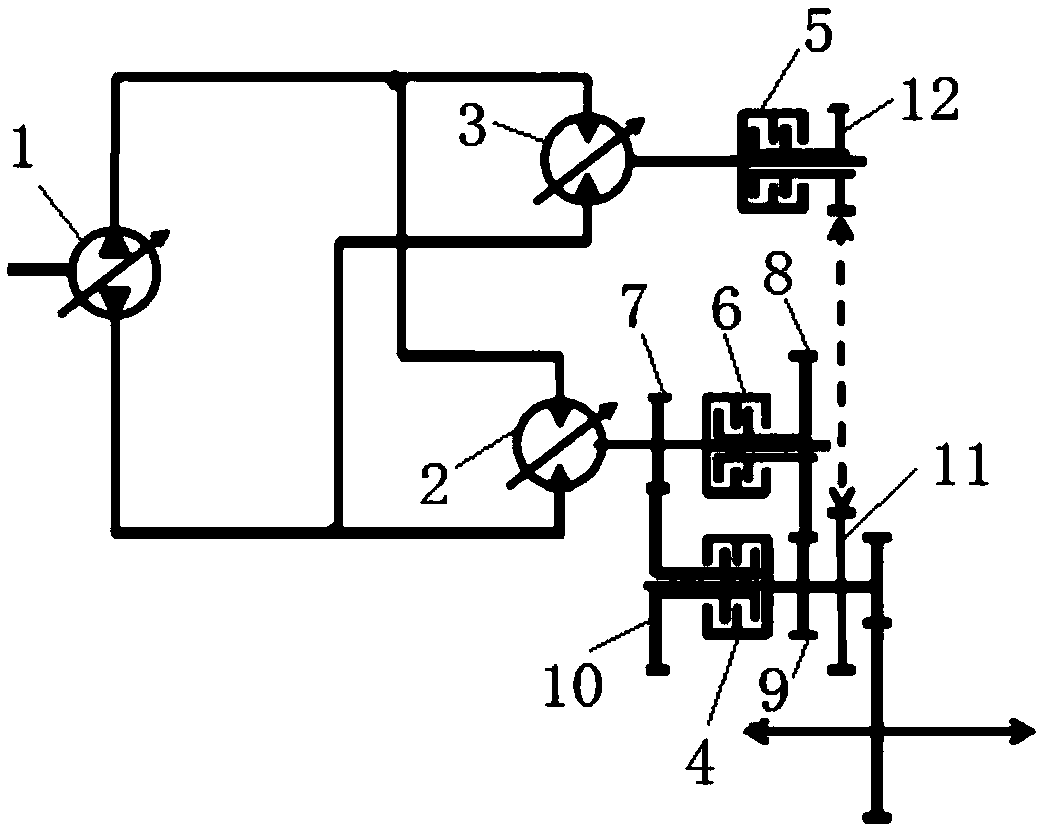

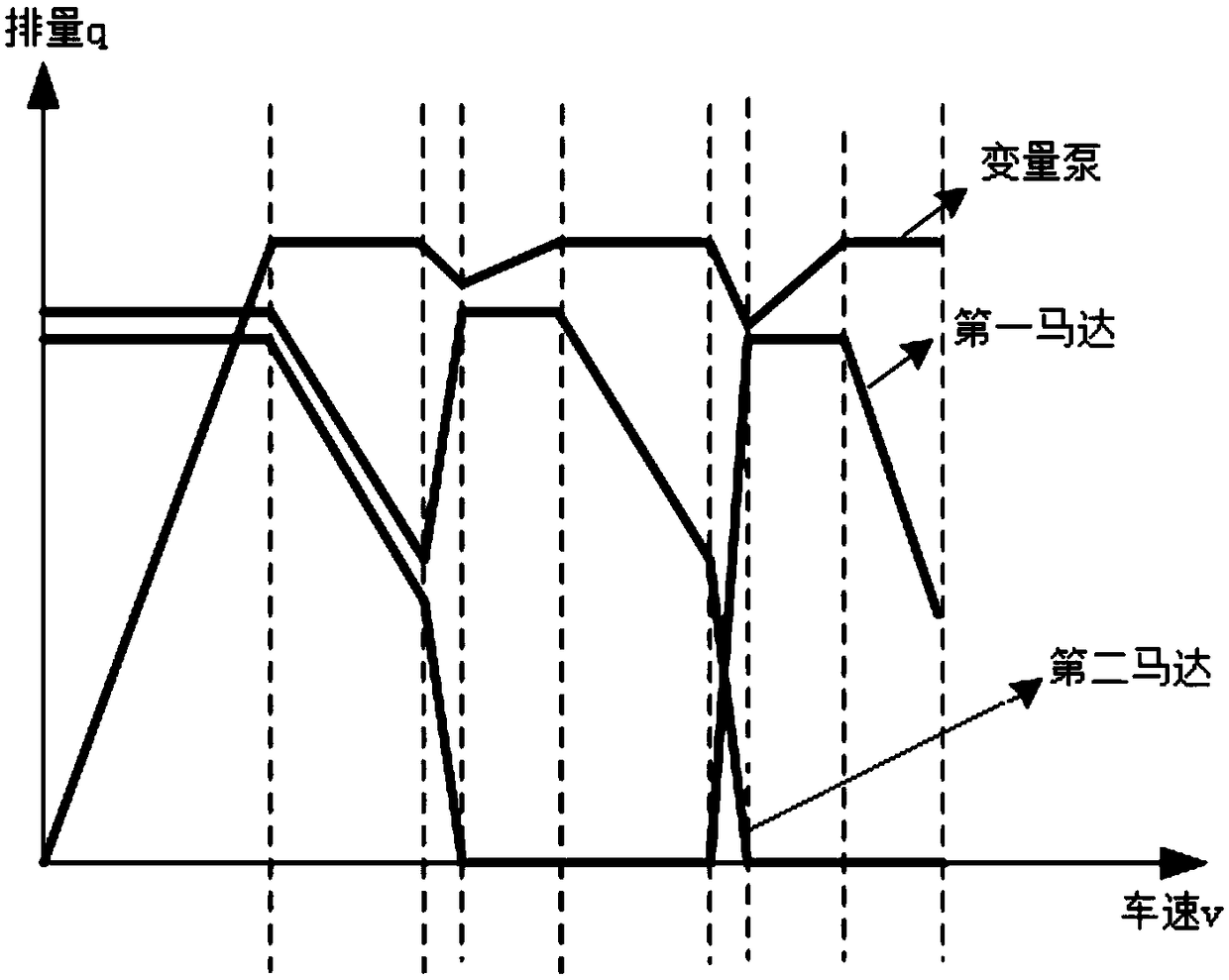

[0037] Such as figure 1 As shown, this embodiment provides a vehicle gear shift control system, which is mainly applied to hydrostatic loaders. By coordinatingly controlling the clutch of the gearbox, the variable pump 1 and the displacement of the two motors, the vehicle speed can be changed smoothly, and the gear shift No power interruption during the process.

[0038] refer to figure 1 , the vehicle shift control system includes a variable pump 4, a plurality of motors driven by the variable pump 1 and a multi-speed gearbox, the gearbox includes a plurality of clutches, each motor driven by the variable pump 1 is connected to at least one clutch, connected to At most one of at least one clutch of the same motor is engaged. In this embodiment, there are two motors, respectively the first motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com