Apparatus on a spinning preparation machine having at least two driven drafting systems

A preparation machine and equipment technology, applied in the direction of drafting equipment, spinning machine, continuous winding spinning machine, etc., can solve the problems of increasing effectiveness and efficiency, and achieve the effect of increasing efficiency and productivity and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

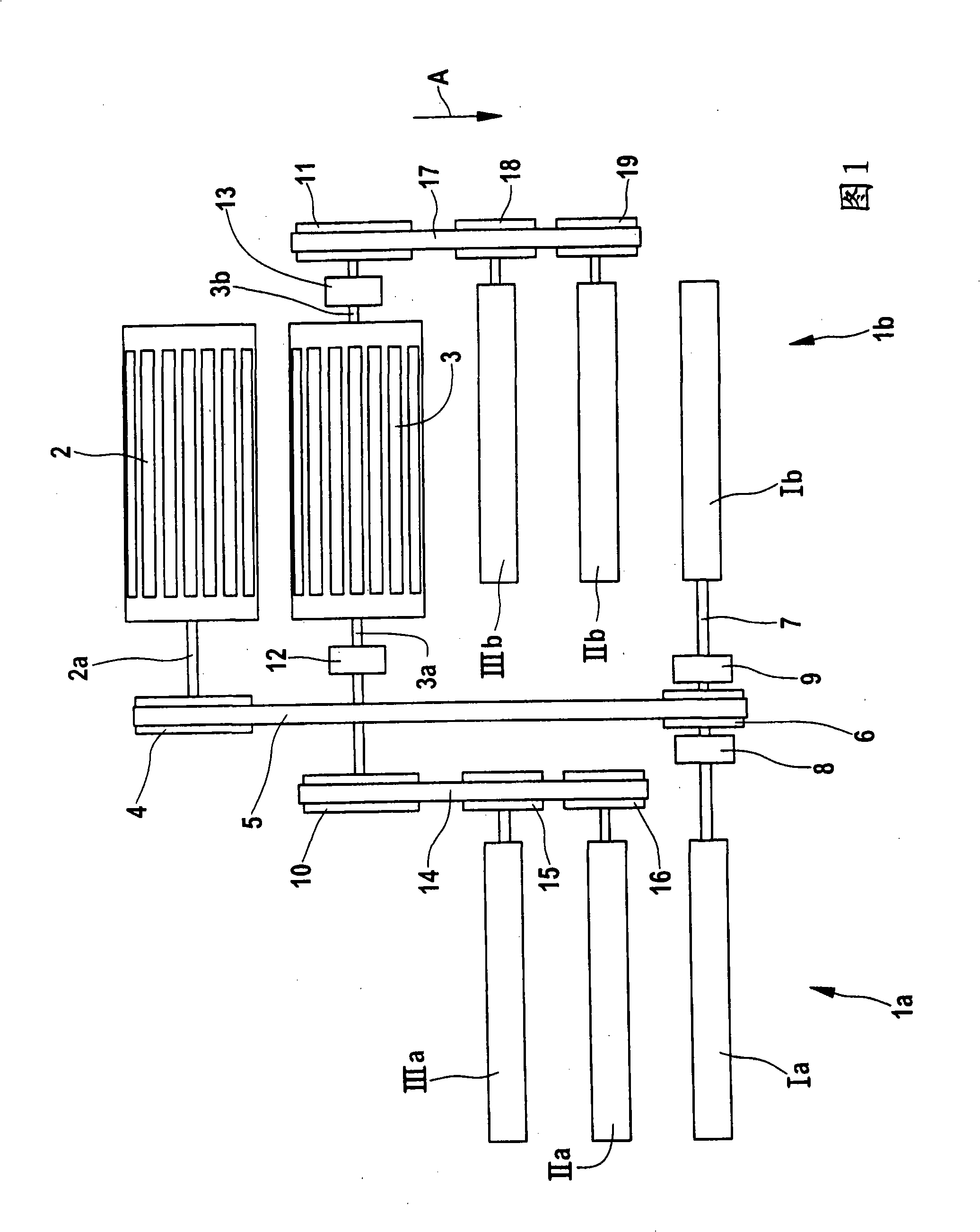

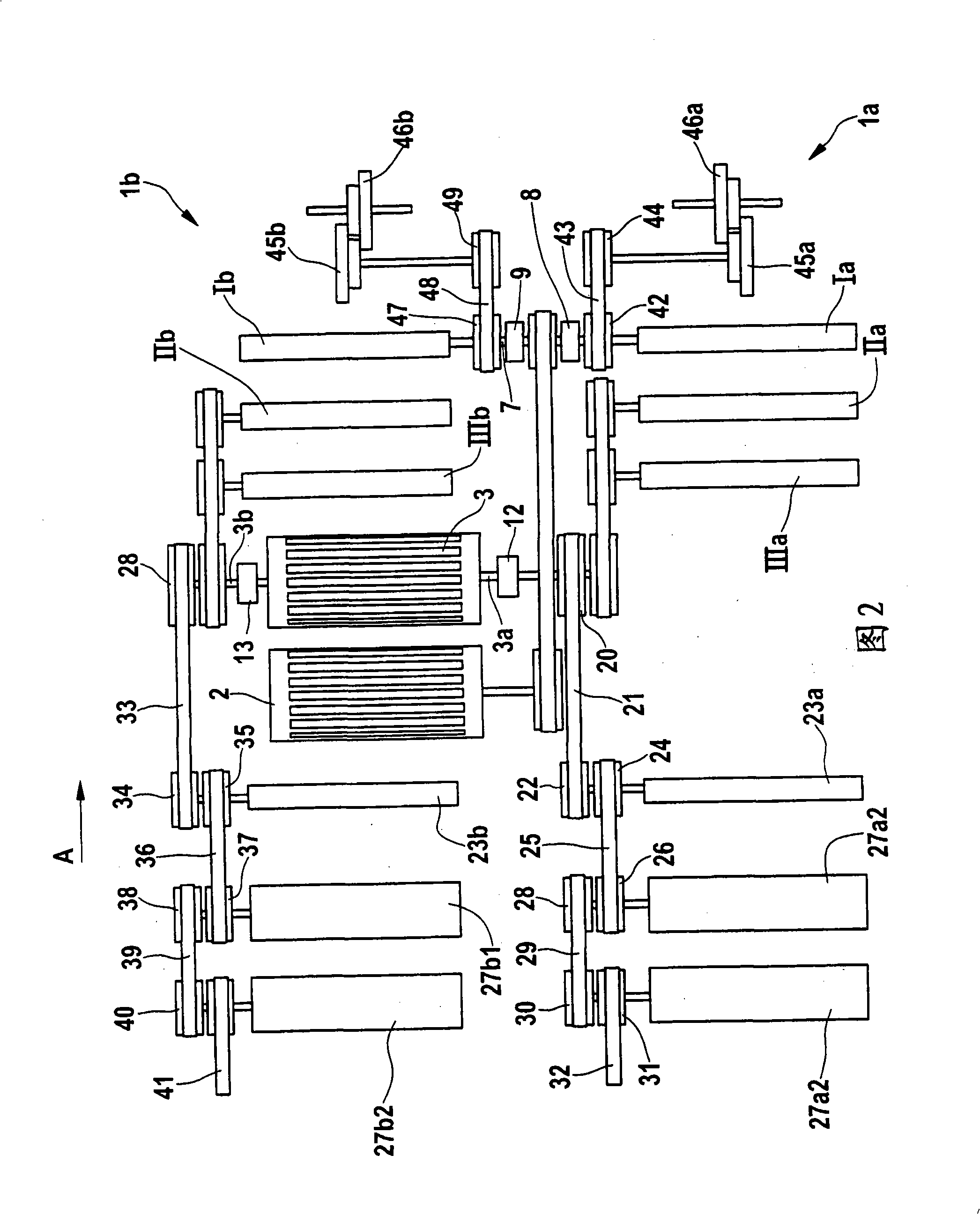

[0022] The transmission design of the two drafting systems 1a, 1b of the double-head draw frame shows two electric motors 2 and 3 and the lower rolls of the drafting system I a, II a, III a and I b, II b, III b respectively the connection between. The lower rolls I a, II a, III a and I b, II b, III b of the drafting system are specifically driven by toothed belts. The rotation of the upper roll of the drafting system (see Figure 7) is affected by the contact pressure of the upper roll on the lower roll.

[0023] A driving pulley 4 is non-rotatably mounted on a shaft extension 2 a of a motor 2 (main motor), and is connected with a driven pulley 6 non-rotatably provided on a main shaft 7 through a continuously rotating toothed belt 5 . The main shaft 7 coaxially drives the two lower rollers Ia and Ib. An electromagnetic coupling 8 is provided between the pulley 6 and the lower roller 1a, and an electromagnetic coupling 9 is provided between the pulley and the lower roller 1b. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com