On-line loading test stand shift mechanism of manual transmission

A manual gearbox and loading test technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of low automation of manual gearbox test bench, undetectable force and displacement of gear shifting, difficulty in starting time and ending time Measurement and other issues, to achieve the effect of compact structure, no pollution of power source, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

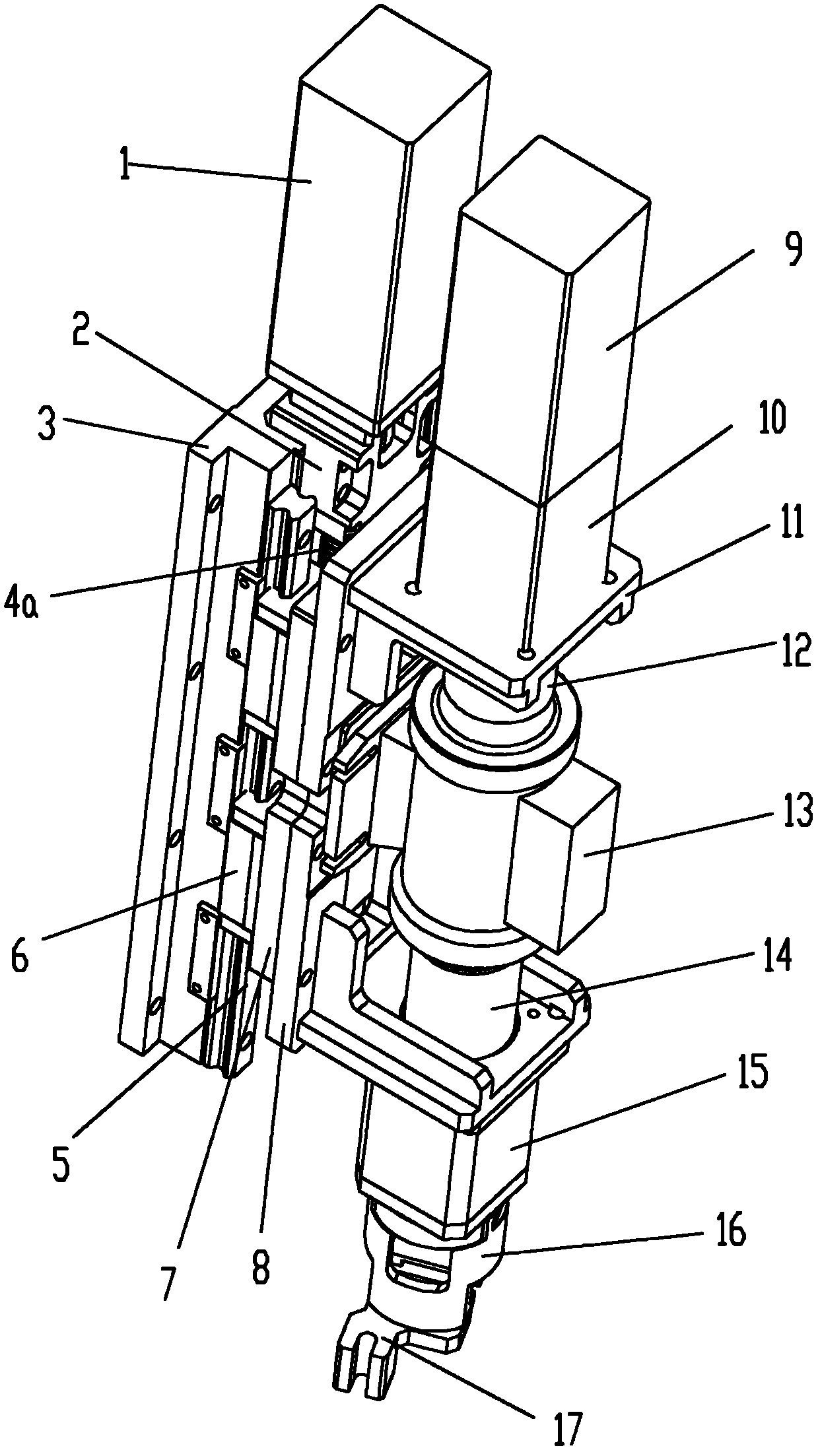

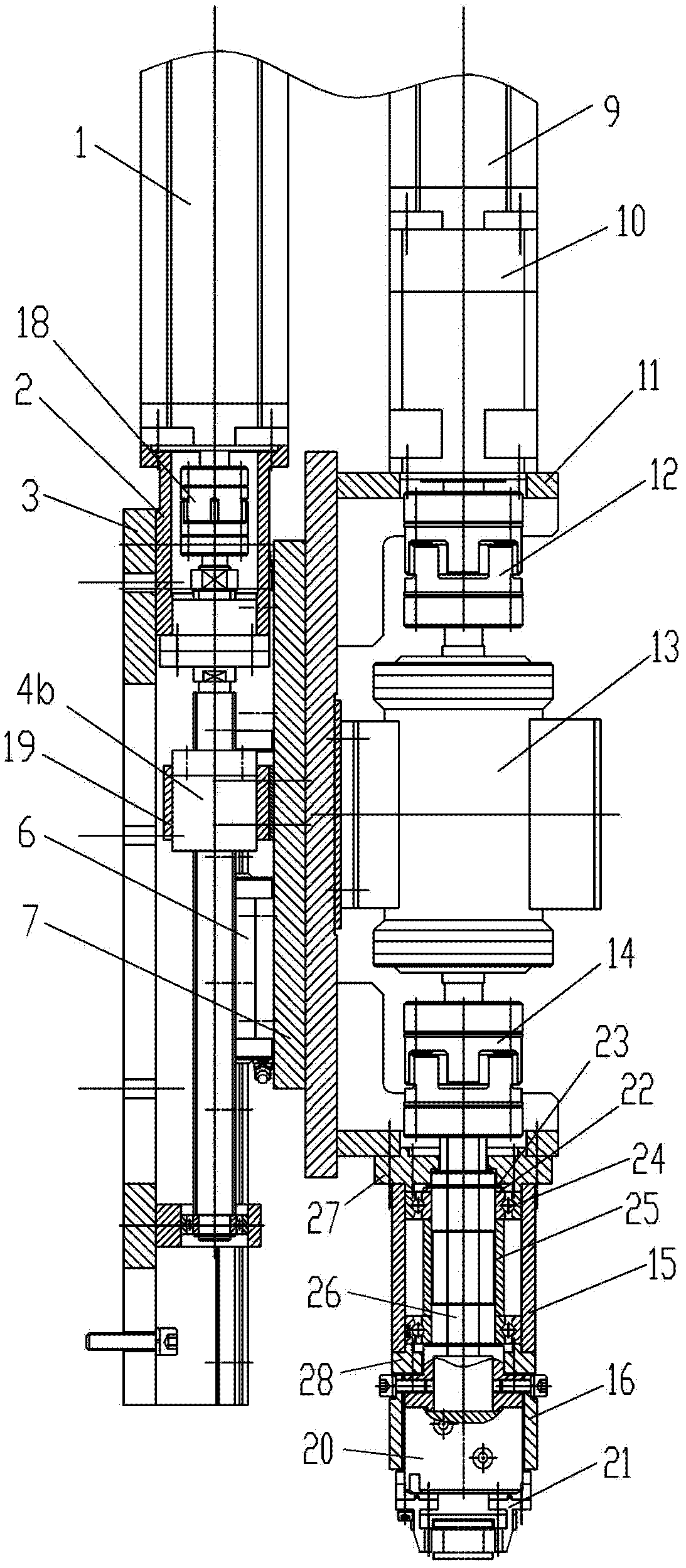

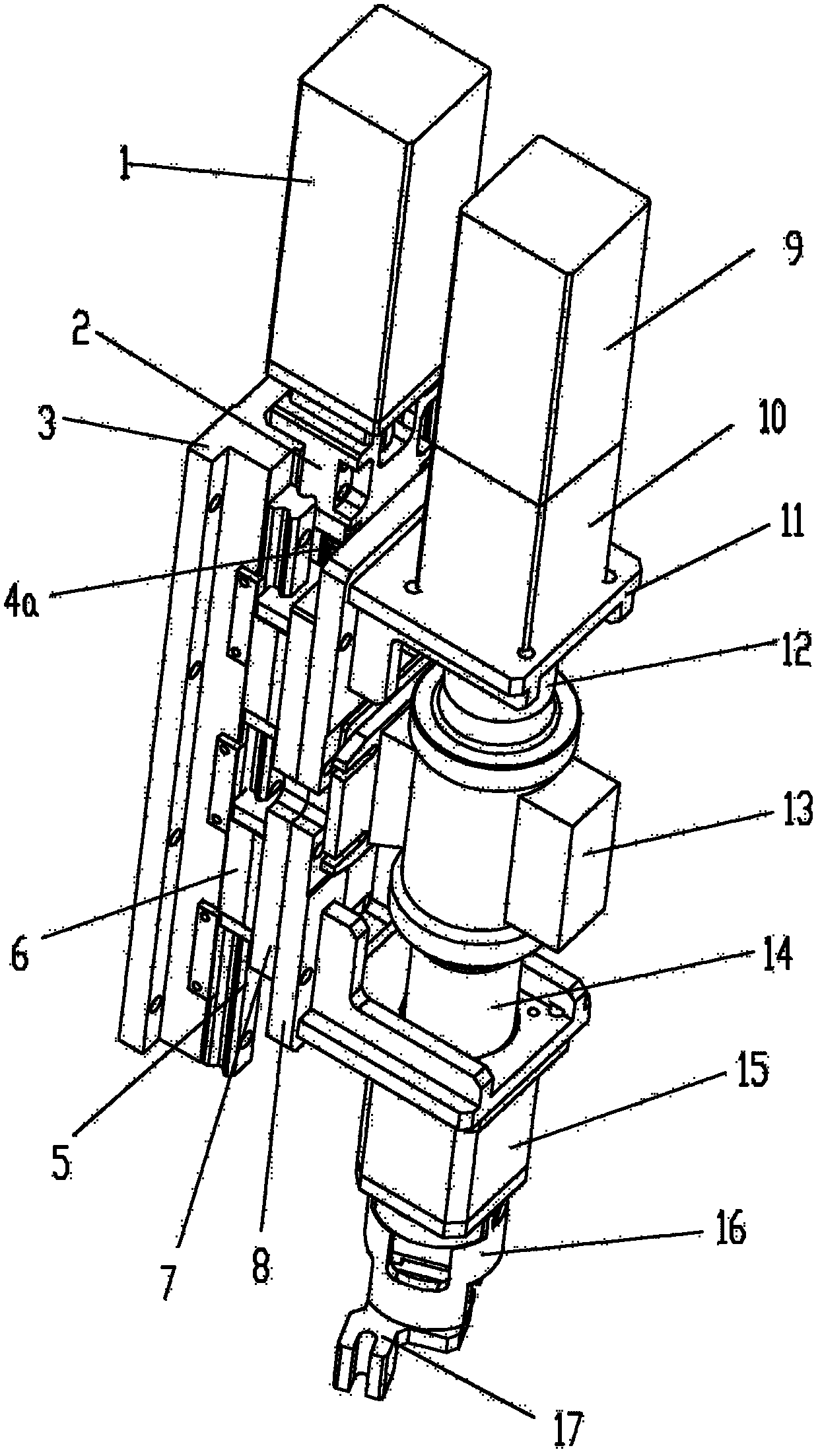

[0024] see figure 1 , figure 2 , the manual gearbox in this embodiment is provided with:

[0025] The gear selection unit is to fix the gear selection servo motor 1 on the base frame 3 through the motor mounting base 2, the gear selection servo motor 1 is axially connected with the ball screw 4a through the first coupling 18, and the screw slide 7 is connected through the nut The bracket 19 is fixedly connected with the lead screw nut 4b, and the lead screw nut 4b is threadedly matched with the ball screw 4a, and the gear selection servo motor 1 drives the lead screw slide 7 to slide along the axial direction of the ball screw 4a;

[0026] The gear shift unit is directly connected to the gear reducer 10 by the gear shift servo motor 9, the gear reducer 10 is coupled to the torque sensor 13 through the second coupling 12, and the torque sensor 13 is coupled to the drive shaft 26 through the third coupling 14. A gear shift head is arranged at the shaft end of the power transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com