Numerical control mechanical automatic transmission

An automatic transmission, mechanical technology, applied in the direction of mechanical equipment, transmission boxes, transmission devices, etc., can solve the problems of reducing the life of the inverter, affecting the economy, increasing the auxiliary time, etc., to prolong the service life, high transmission efficiency, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

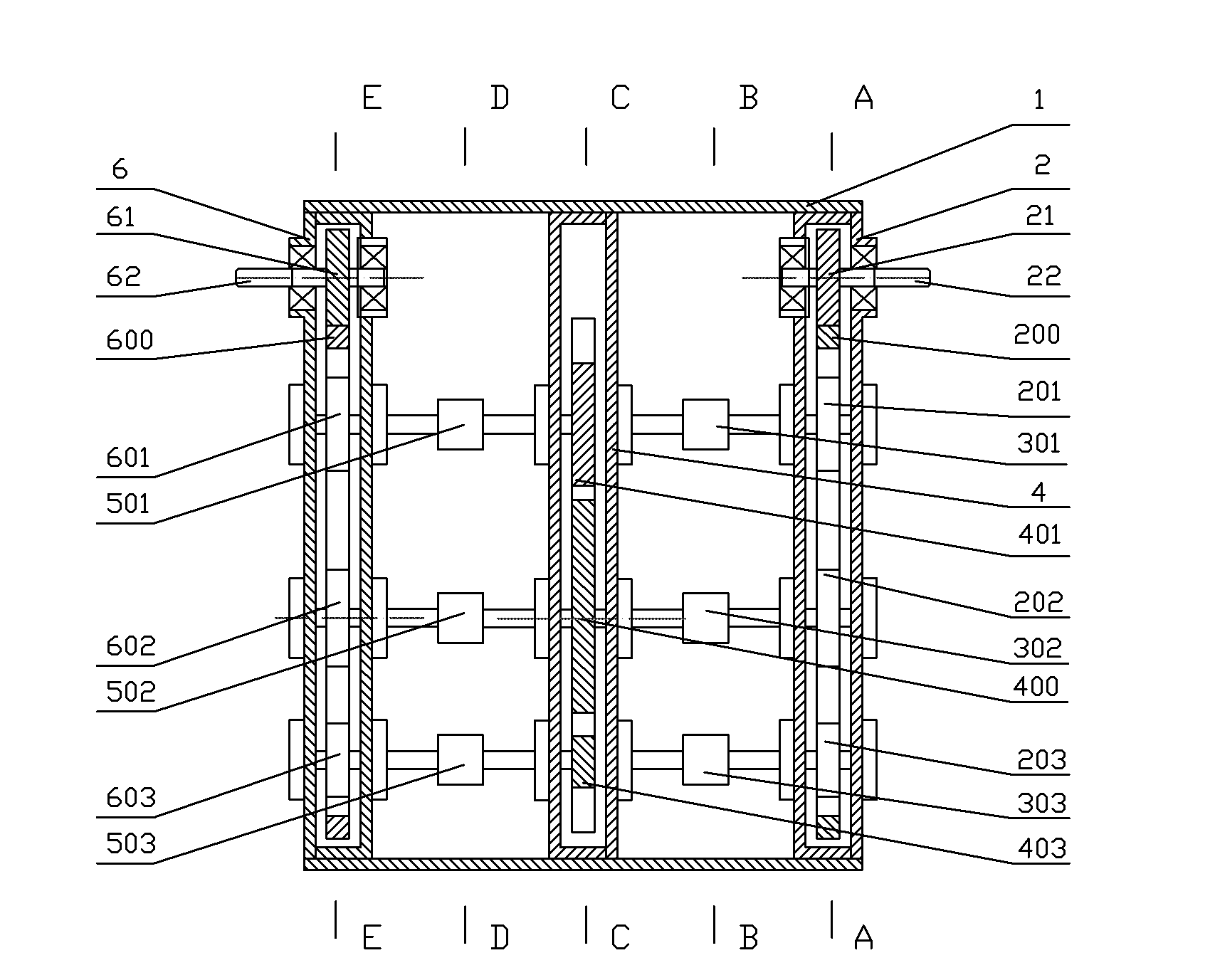

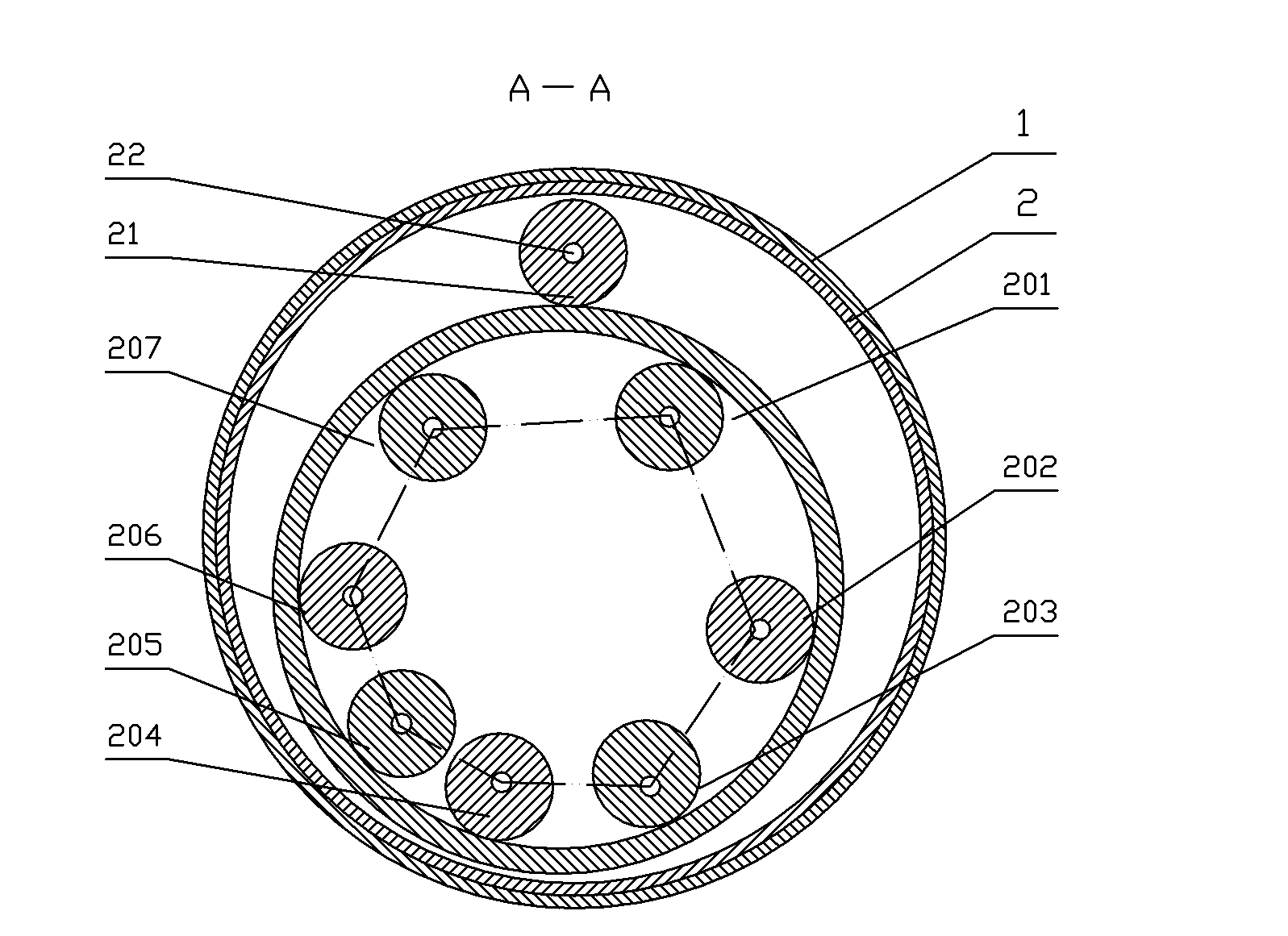

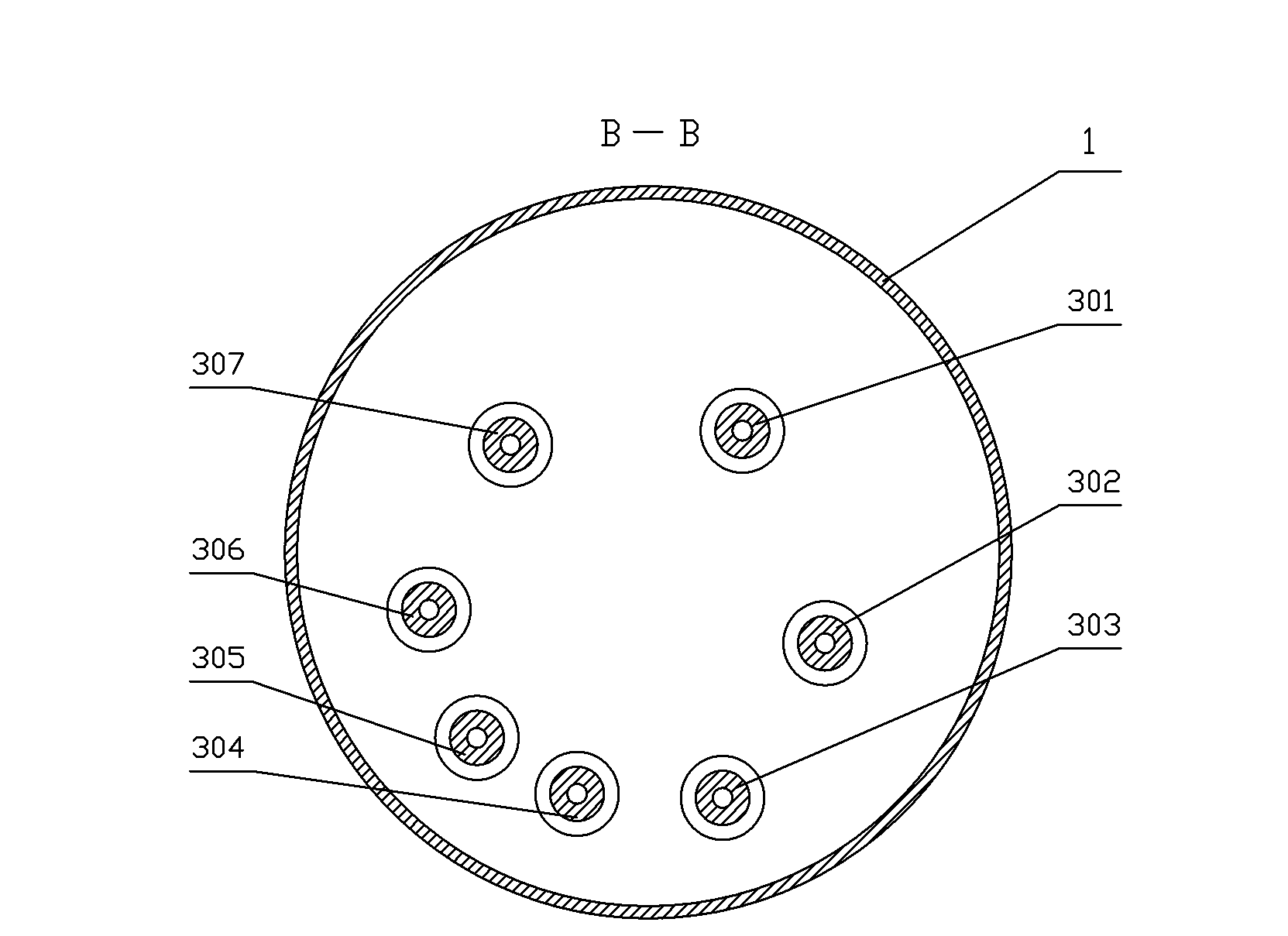

[0013] Such as Figure 1~6 As shown, it consists of the first sun gear 200 arranged in the box body of the front box 2 and the input gear 21 meshing with the outer teeth of the first sun gear and the circumferential direction is arranged in the first sun gear circle and respectively connected with the first sun gear The output gears 201-207 that are meshed with each other, the central bridge gear 400 arranged in the middle box 4 and the speed change gears 401- 407, the second sun gear 600 arranged in the case body of the rear case 6 and the output gear 61 which is engaged with the external teeth of the second sun gear and the output gear 61 which is circumferentially arranged in the ring of the second sun gear and respectively engaged with the internal teeth of the second sun gear Each input gear 601-607 is composed of a housing 1 and a numerical control machine. The output gears 201-207 meshed with the internal teeth of the first sun gear in the front box 2, the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com