Heavy 12-gear AMT transmission assembly

A transmission and transmission housing technology, which is applied to transmission parts, elements with teeth, belts/chains/gears, etc., can solve problems such as large driver's subjective influence, poor vehicle economy, and poor vehicle comfort. To achieve the effect of simple and convenient operation, high reliability and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

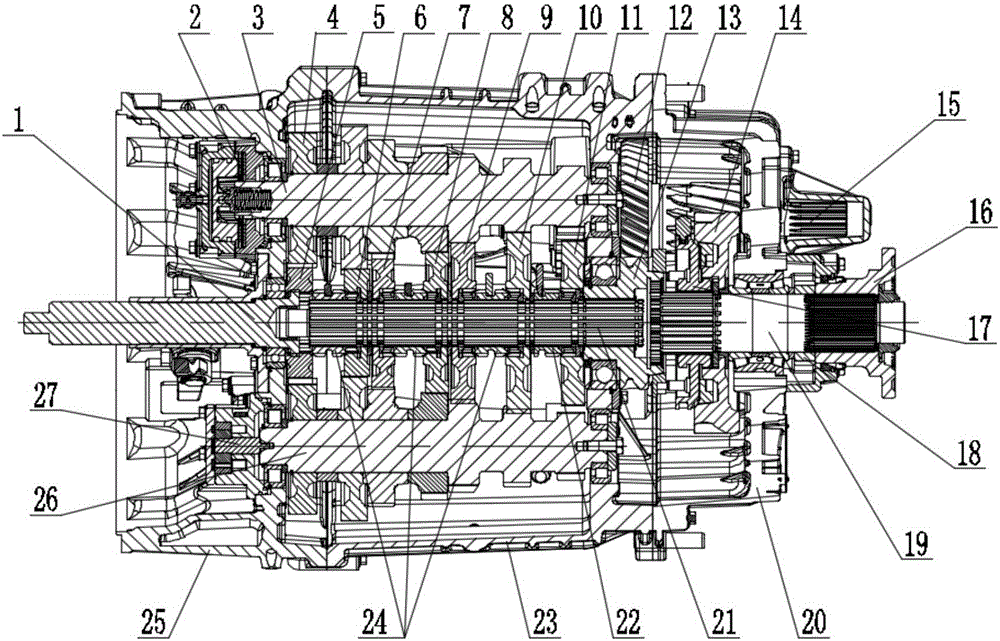

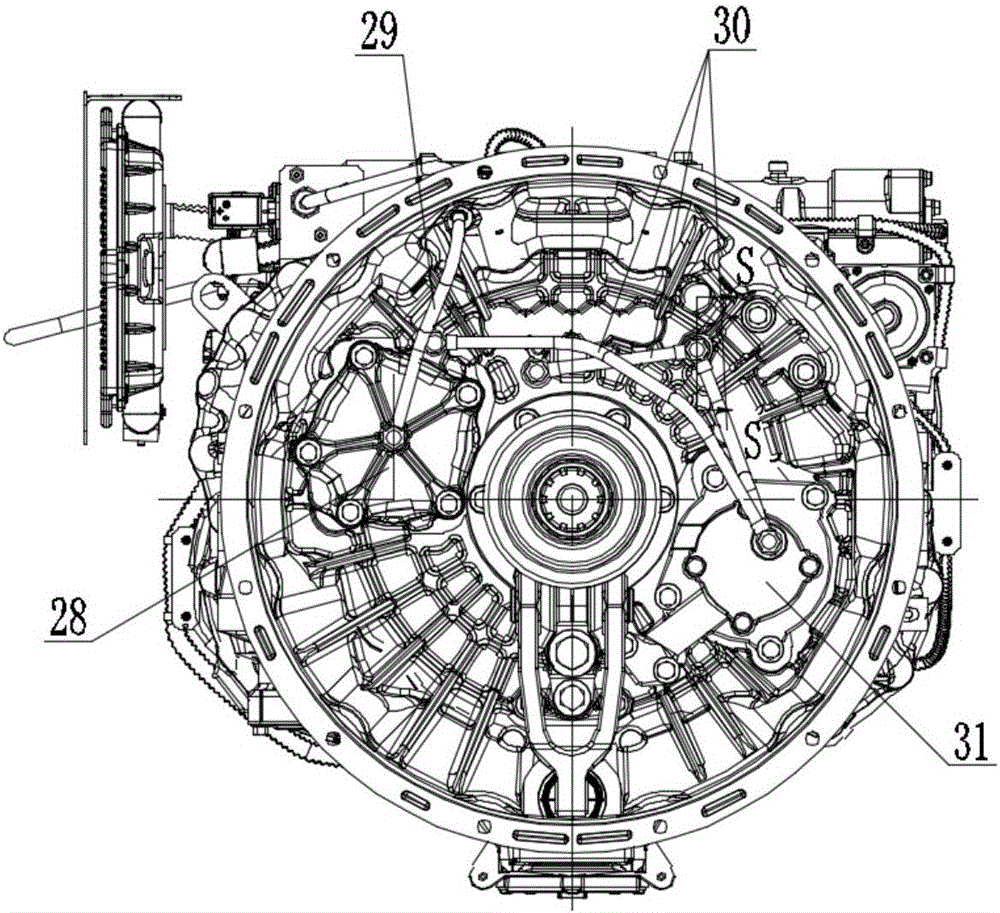

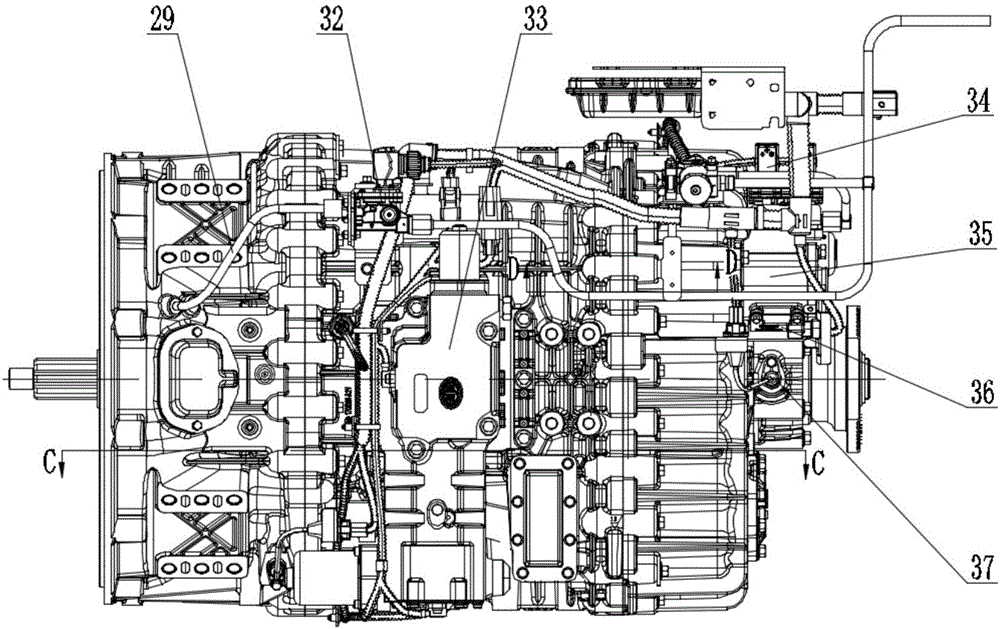

[0033] like Figure 1 to Figure 4 As shown, a heavy-duty 12-speed AMT transmission assembly includes a transmission housing, a main case, an auxiliary case, an automatic shift control device and a lubricating assembly.

[0034] The entire shell of the transmission body is preferably made of aluminum alloy to achieve lightweight transmission, which is 100kg lighter than the same structure of the iron casing transmission, and at the same time improves the heat dissipation capacity of the transmission assembly; all shaft gears of the auxiliary box of the transmission body are helical The structure improves the bearing capacity of the transmission assembly, so that the input torque of the transmission assembly can reach 2300Nm, and the service life of the transmission assembly can reach 1.5 million kilometers.

[0035] The casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com