Electronic control pneumatic gear shifting device of tractor transmission

A technology of pneumatic shifting and transmission, applied in transmission control, mechanical equipment, components with teeth, etc., can solve the influence of tractor fuel economy and shifting smoothness, poor operation stability and operation control, Driver fatigue and other problems, to achieve the effect of improving flexibility, simple structure, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below based on specific embodiments and in conjunction with the accompanying drawings.

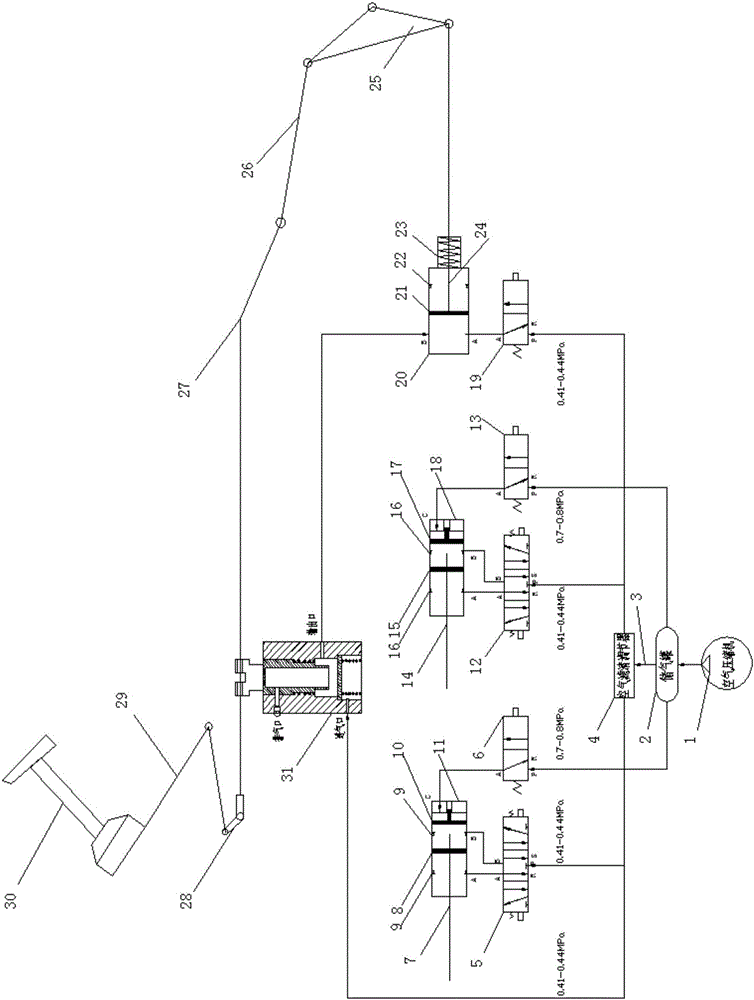

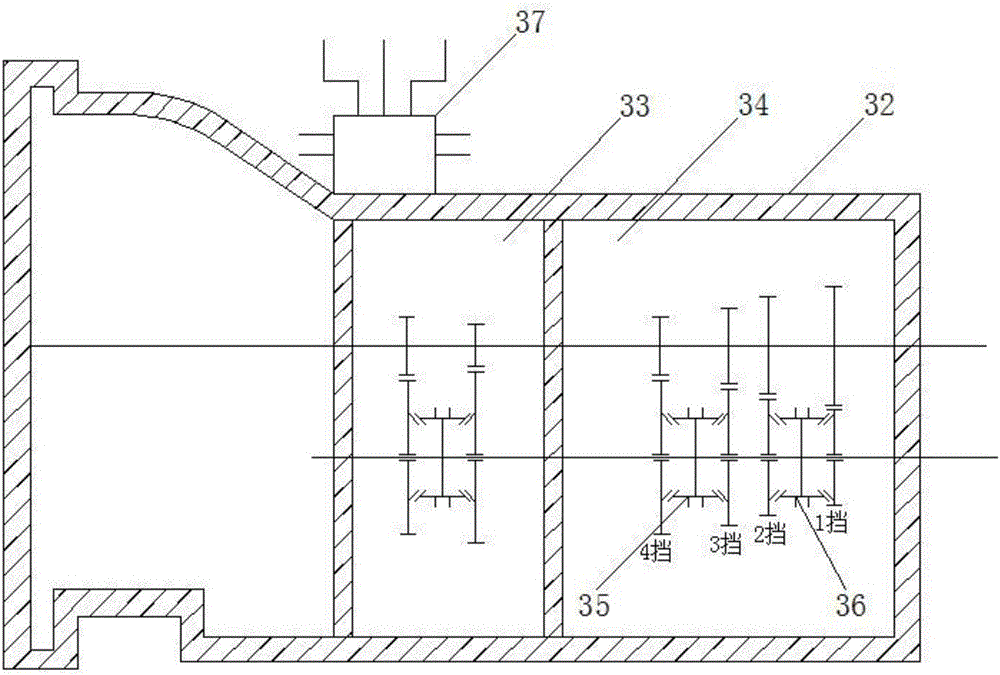

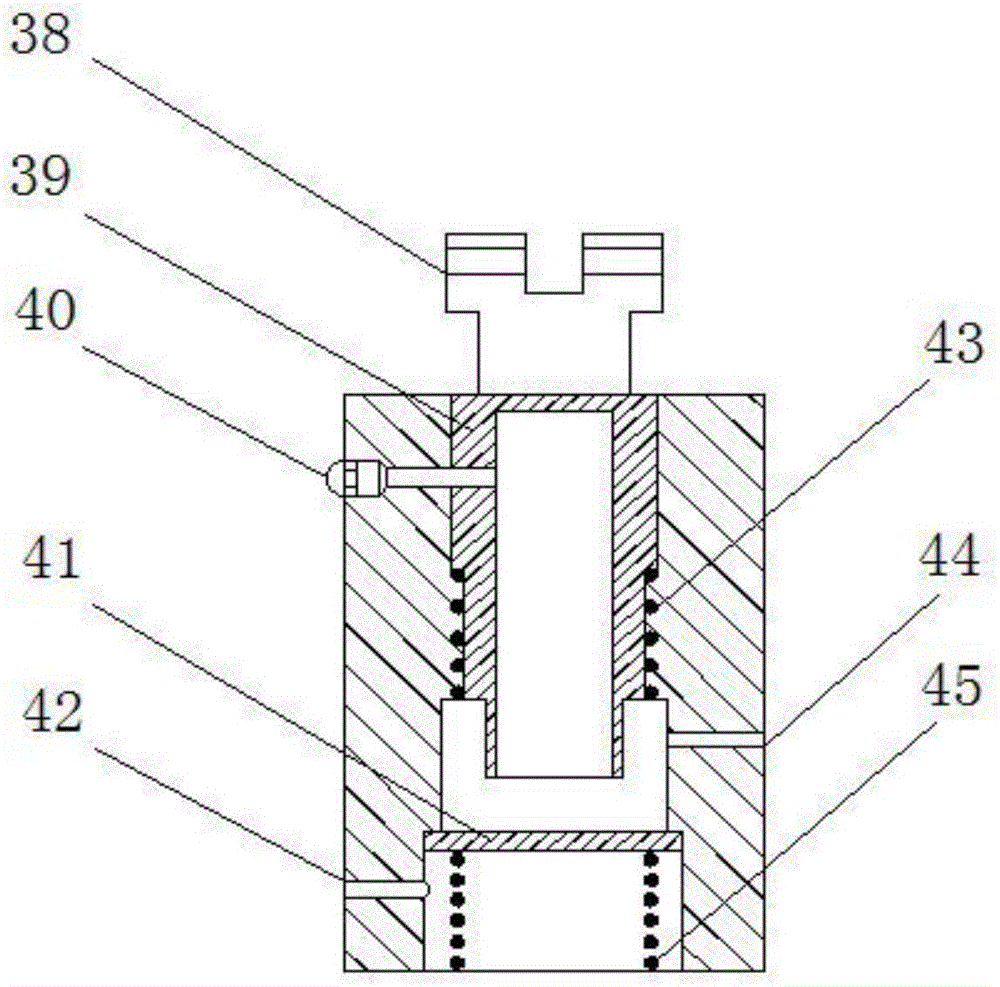

[0021] refer to figure 1 As shown, the tractor transmission electronically controlled pneumatic shifting device according to the present invention includes a vehicle air source, a gear shift actuator, a clutch operating mechanism and a controller, wherein the vehicle air source includes an air compressor 1, an air storage tank 2. The air filter regulator 4, the shift actuator includes the first three-position five-way pneumatic solenoid valve 5, the first two-position three-way pneumatic solenoid valve 6, the second three-position five-way pneumatic solenoid valve 12, the second two One-position three-way pneumatic solenoid valve 13, first shift cylinder 11, second shift cylinder 18, clutch operating mechanism includes third two-position three-way pneumatic solenoid valve 19, booster cylinder 20, control valve 31 and pedal me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com