Automatic gearbox for electric mini-truck

An automatic transmission and miniature technology, which is applied in vehicle transmissions, multi-gear ratio transmissions, transmission components, etc., can solve the problem that many gears do not conform to the working habits of domestic staff, the main structure of the transmission is complex, and the gear transmission efficiency is low. and other problems, to avoid the phenomenon of random blocking, save physical strength, and achieve the effect of less gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

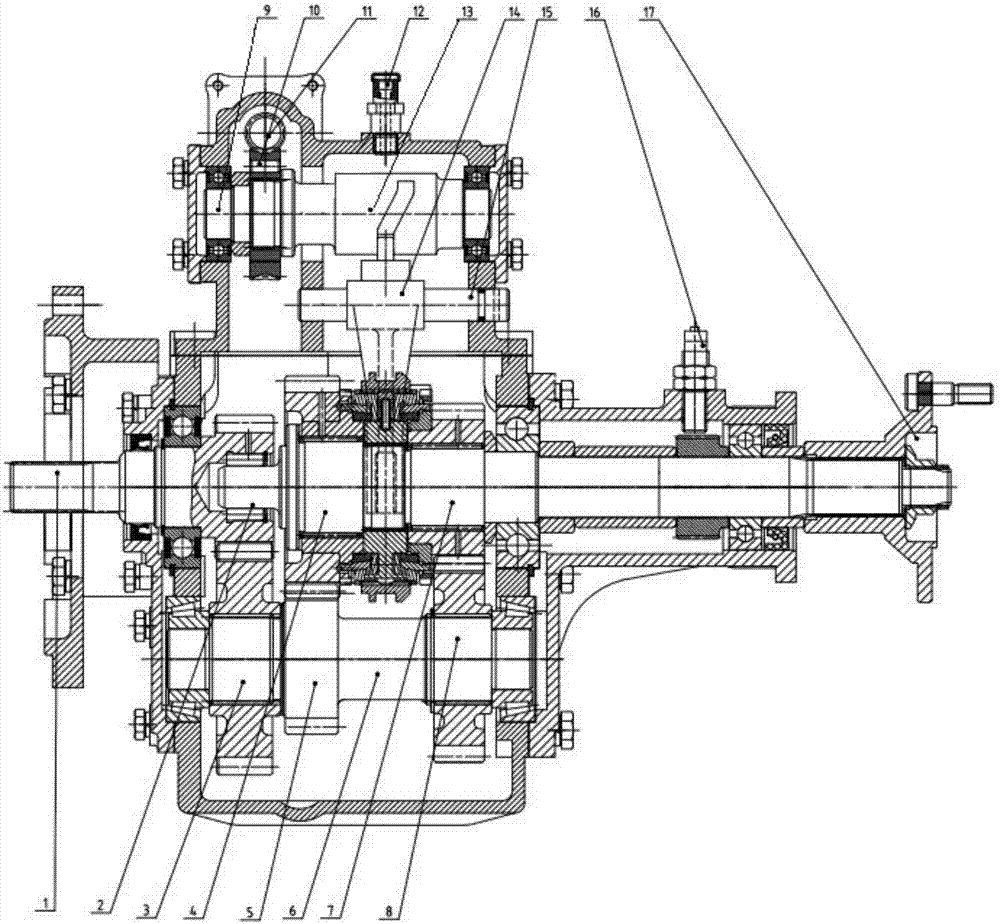

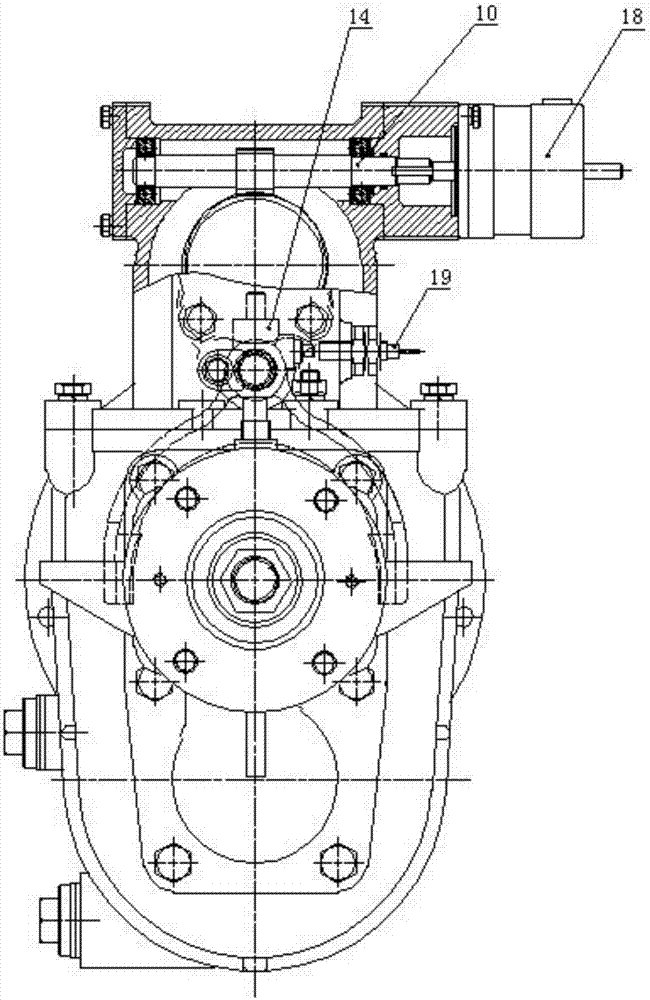

[0014] The main structure of the automatic gearbox for electric mini trucks involved in this embodiment includes: input shaft 1, output shaft 2, constant gear 3, low-range passive gear assembly 4, low-range active gear 5, intermediate shaft 6, high-grade passive gear Gear assembly 7, high-grade drive gear 8, worm gear shaft 9, worm 10, worm gear 11, ventilation plug assembly 12, cam hub 13, shift fork 14, shift fork shaft 15, vehicle speed sensor 16, flange 17, replacement gear motor 18 and proximity switch sensor 19; the interior of the gearbox housing of the hollow structure is sequentially provided with an intermediate shaft 6, an output shaft 2, a shift fork shaft 15 and a worm gear shaft 9; the two ends of the intermediate shaft 6 pass through bearings It is fixed on the shell, and the intermediate shaft 6 is fixed with the normal gear 3, the low-grade driving gear 5 and the high-grade driving gear 8 sequentially from left to right; The bearing fixed on the housing is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com