Automatic gear shifting system with synchronizer for electric vehicle

An automatic gear shifting and driving system technology, which is applied in electric vehicles, control drives, multi-ratio transmissions, etc., can solve the problems of fast power consumption, large current value, impact and tooth beating, etc., and achieve the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

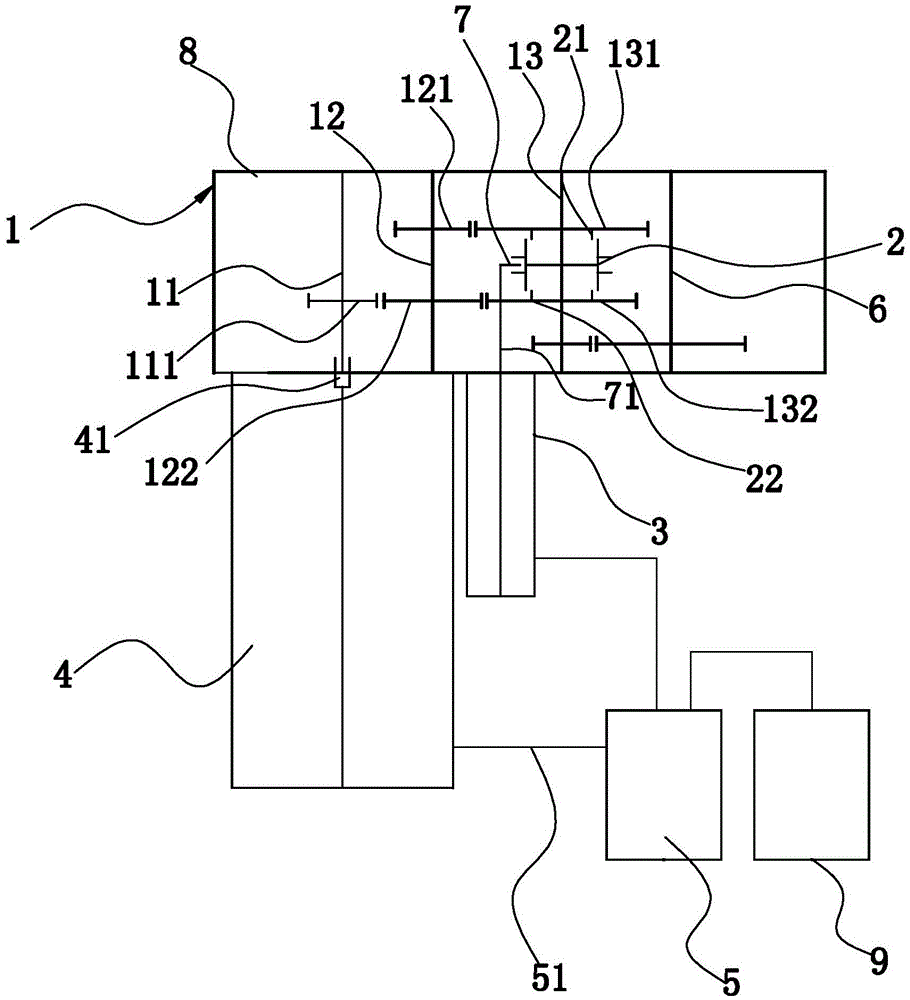

[0027] Such as figure 1 As shown, the present invention discloses an automatic shift drive system for an electric vehicle using a synchronizer, including a transmission 1 , a synchronizer 2 , an electromagnet 3 , a motor 4 and a controller 5 . The transmission 1 includes an input shaft 11 , an intermediate shaft 12 and an output shaft 13 . An input shaft gear 111 is fixed on the input shaft 11 . A first countershaft gear 121 and a second countershaft gear 122 are fixed on the countershaft 12 . The diameter of the first countershaft gear 121 is smaller than the diameter of the second countershaft gear 122 . The input shaft gear 111 is engaged with the second countershaft gear 122 . The first countershaft gear 121 is engaged with the first output shaft gear 131 , and the second countershaft gear 122 is engaged with the second output shaft gear 132 . The diameter of the first output shaft gear 131 is larger than that of the second output shaft gear 132 . The first output sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com