Patents

Literature

70results about How to "No mobility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

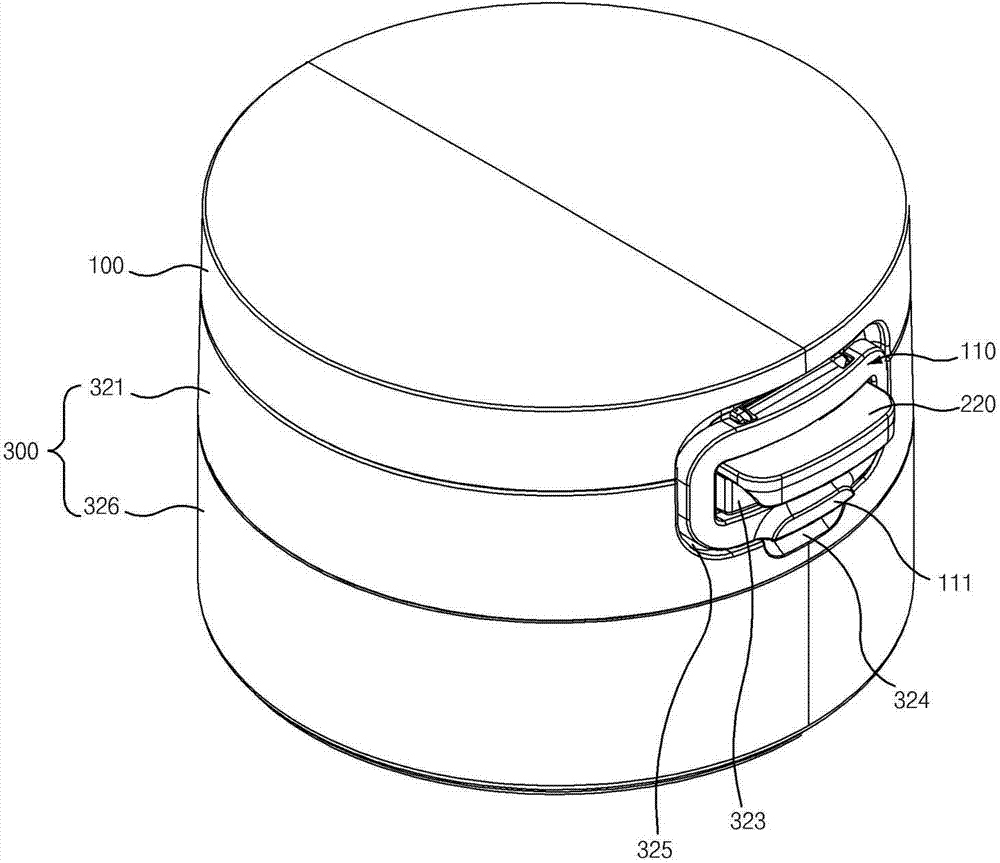

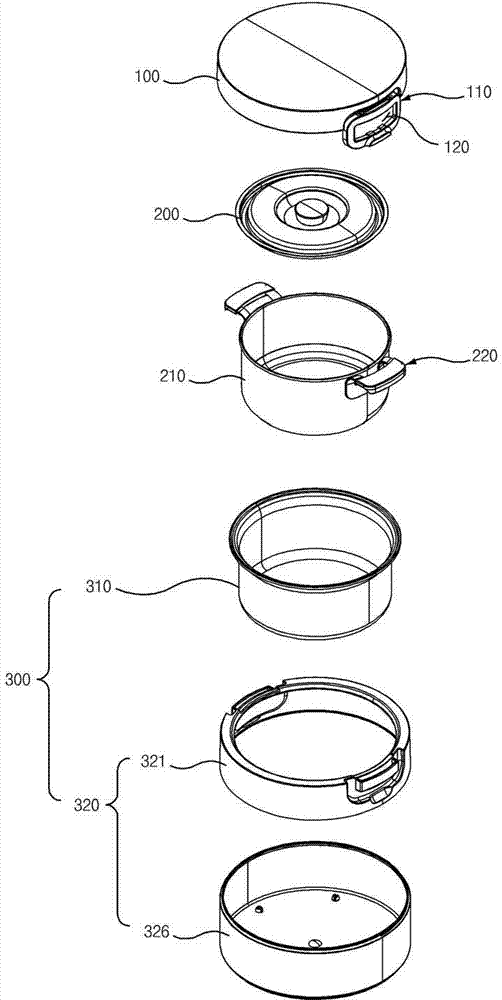

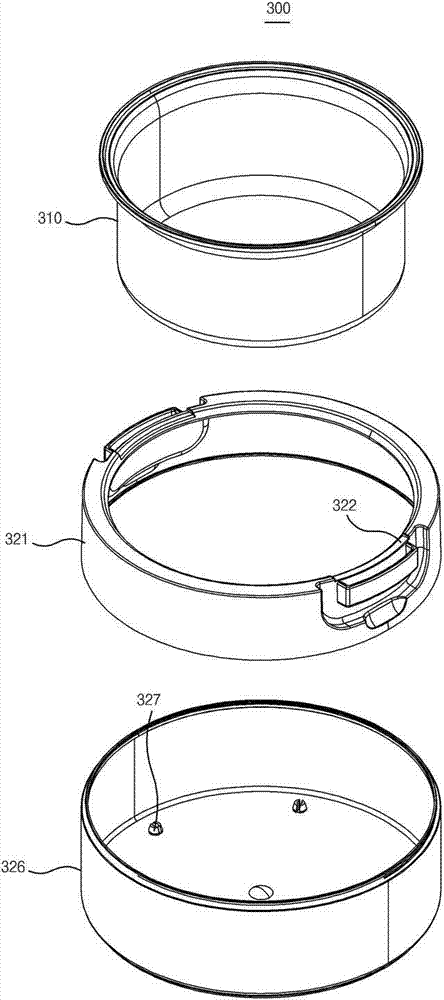

Thermally insulated container

InactiveCN103395565AStays Sealed EasilyImprove insulation effectDomestic cooling apparatusLighting and heating apparatusThermal insulationStore food

The invention relates to a thermally insulated container used for thermal insulation when storing food and the like. The thermally insulated container manufactured according to the technology of the invention is composed of the following structures: a thermally insulated outer cylinder; an inner cylinder disposed inside the thermally insulated outer cylinder; an inner cylinder cover used for covering the inner cylinder; and an outer cylinder cover used for covering the thermally insulated outer cylinder. In addition, the outer cylinder cover is provided with a locking ring and the thermally insulated outer cylinder is also provided with a hook used for hooking the locking ring so that in the state that the inner cylinder is disposed on the thermally insulated outer cylinder, the locking ring is hooked on the hook, thereby realizing the effect of locking the thermally insulated container. Since the thermally insulated container according to the technology of the invention is provided with the locking ring, the sealing state of the thermally insulated container can be easily maintained. Moreover, the thermally insulated outer cylinder is composed of an outer side cylinder, an inner side cylinder, and thermal insulation materials clamped between the outer side cylinder and the inner side cylinder, so that the thermal insulation performance of the thermally insulated container can be easily improved.

Owner:SUZHOU HAAN TECH +1

Moisture-preserved grass-proof ecological mat and manufacturing method thereof

ActiveCN106962079AStrong targetingImprove applicabilityPlant protective coveringsPlastic mulchEngineering

Owner:河北省林业和草原科学研究院

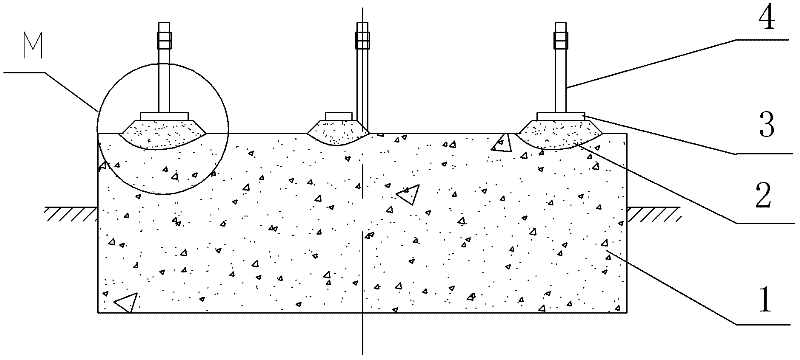

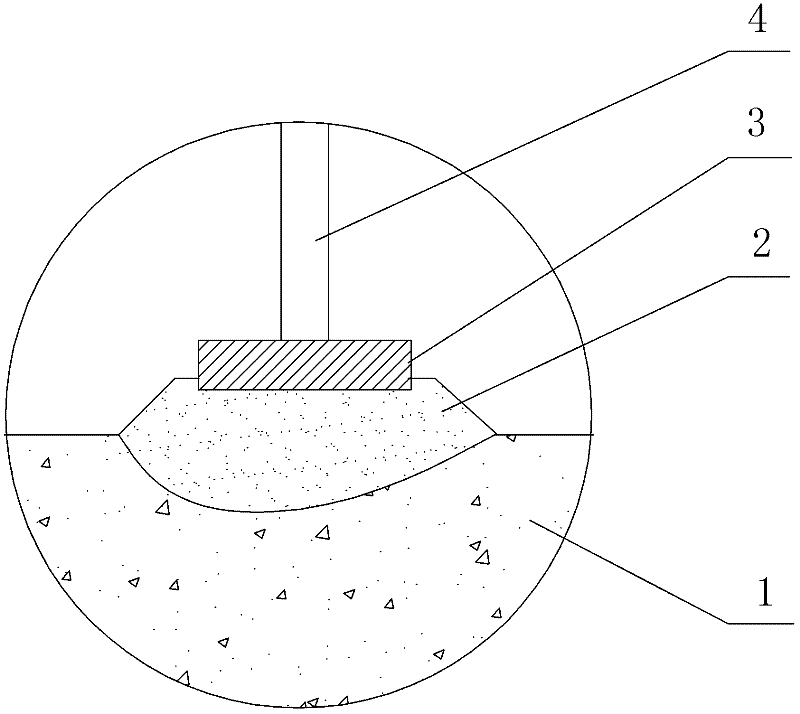

Method for mounting seat pulp cushion plates of petrochemical static equipment and foundation structure

The invention discloses a method for mounting seat pulp cushion plates of petrochemical static equipment and a foundation structure. The method includes that a plurality of concrete piers with cushion plates are manufactured on a concrete base, the minimum area of each single cushion plate is computed according to the sum of the weight of the equipment and pre-tightening force of anchor bolts, load added on the cushion plate and compressive strength of selective concrete, the concrete piers are trapezoidal tables, the seat pulp cushion plates are arranged on tops of the concrete piers, and surfaces of the cushion plates are positioned on the same horizontal plane. The equipment is seated on the cushion plates of the concrete piers by means of hoisting, and the various anchor bolts are fastened. A secondary grouting layer is formed by means of secondary grouting for a space between the bottom of the equipment and the concrete base. The trapezoidal table concrete piers which are positioned below a reinforcing plate of the equipment are arranged on the concrete base of the foundation structure, the cushion plates are disposed on the tops of the piers, and the surfaces of the cushion plates of the piers are positioned on the same horizontal plane. The secondary grouting layer is disposed between the bottom of the equipment and the concrete base. The method and the foundation structure have the advantages that wedge liners are omitted, materials are saved, the cushion plates of the concrete piers are integrally connected with the base, installation is carried out conveniently, installation quality is improved, and installation work period is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

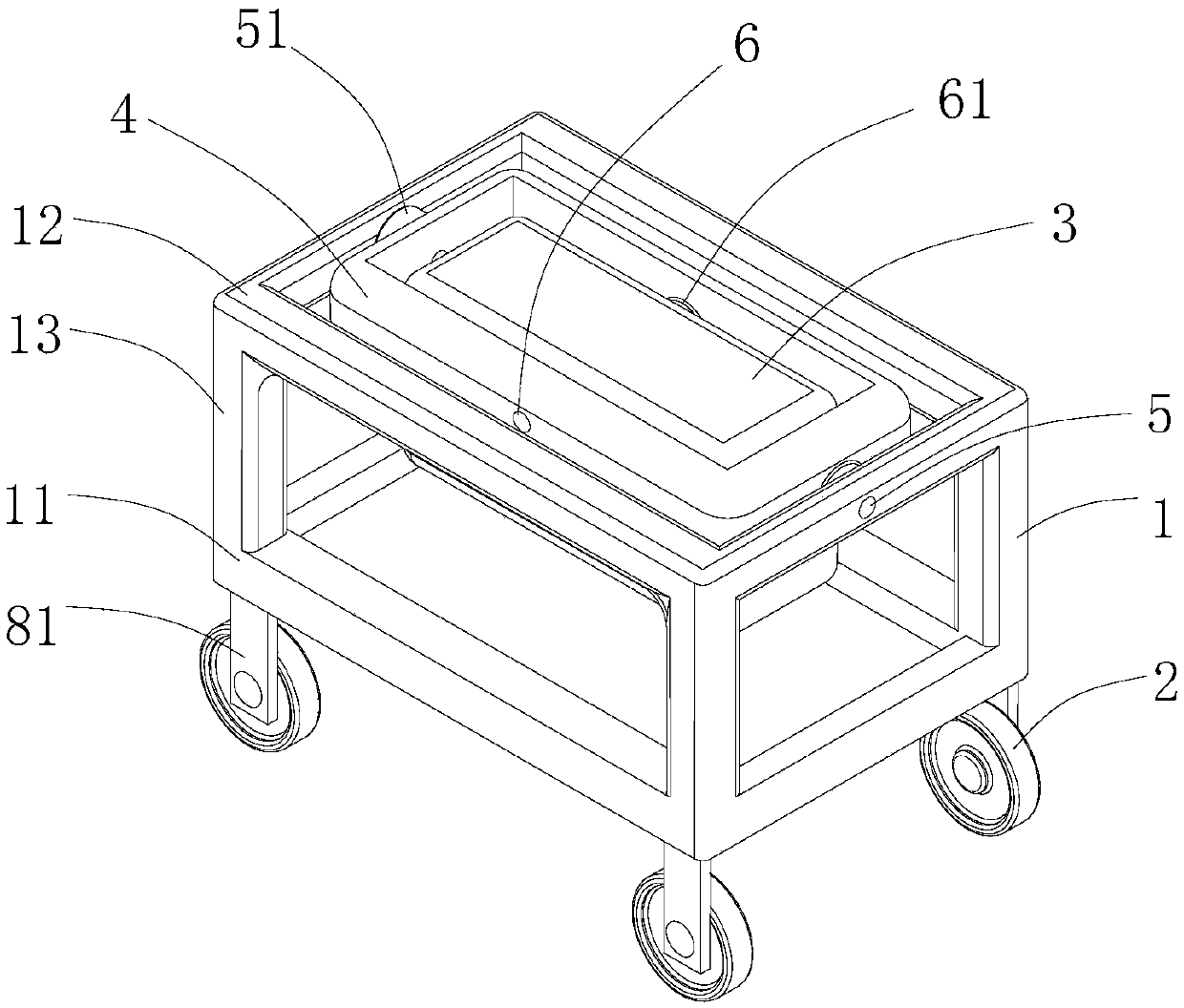

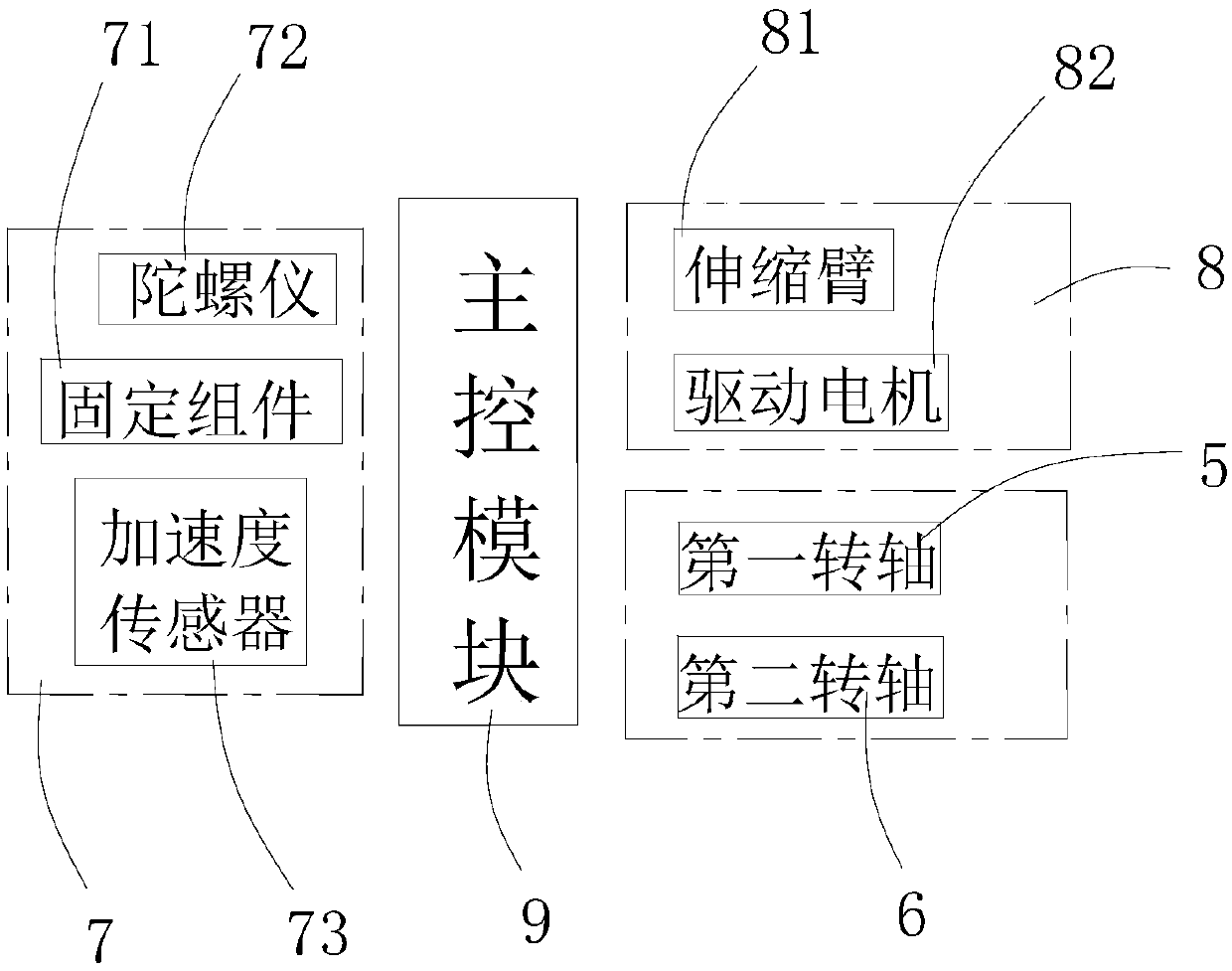

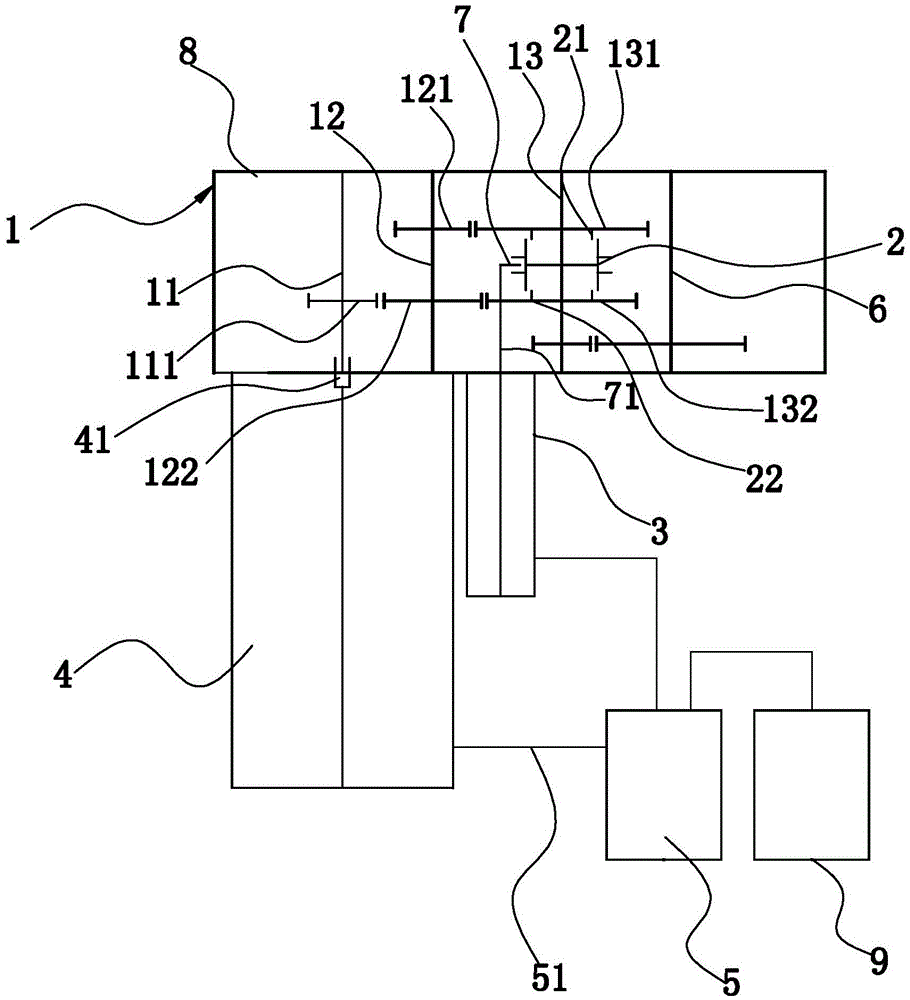

Novel balanced cart

InactiveCN107697120AWon't tiltNo mobilityHand carts with multiple axesHand cart accessoriesEngineeringTime dynamics

The invention provides a novel balanced cart which comprises a cart body, a balance adjusting device, a driving part and a balance detection device, wherein the cart body comprises a shell, wheels anda loading compartment provided with the balance adjusting device; the wheels are arranged at the shell; the balance adjusting device comprises a balance support frame, a first rotating shaft and a second rotating shaft; the balance support frame is rotationally arranged on the shell through the first rotating shaft; the loading compartment is arranged on the balance support frame through the second rotating shaft; the first rotating shaft and the second rotating shaft are perpendicular to each other; the driving part comprises a first power part for driving the balance support frame to rotatearound the first rotating shaft and a second power part for driving the loading compartment to rotate around the second rotating shaft; and the balance detection device for detecting the balance state of the loading compartment is arranged on the loading compartment. The novel balanced cart has the advantages of simple structure, stable transmission, good balance effect, automatic detection, real-time dynamic adjustment and high adaptability, and does not impact or squash objects in the loading compartment.

Owner:深圳市行者机器人技术有限公司

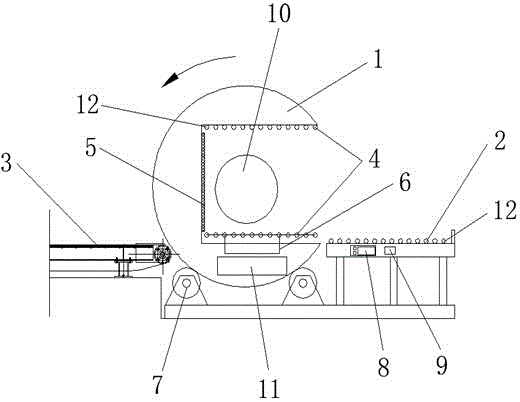

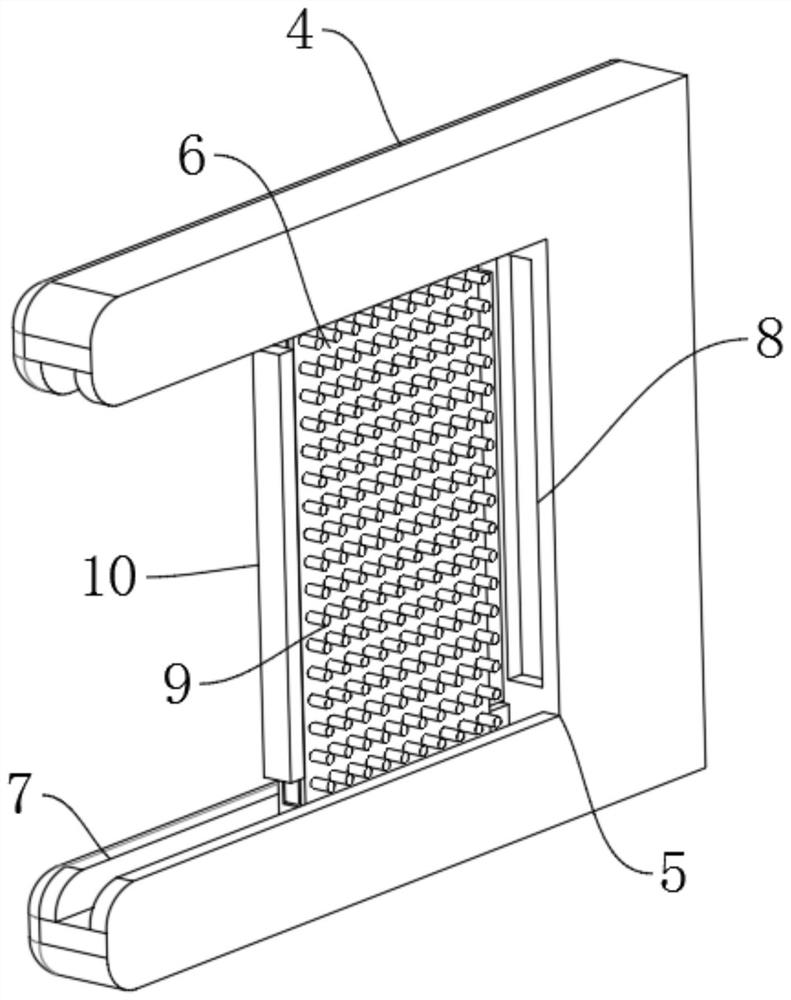

Device for turning transformer plate radiators during spraying paint

The invention discloses a device for turning transformer plate radiators during spraying paint. The device comprises a turning frame, a conveying belt and an operation waiting zone, wherein support pulleys are arranged at the bottom of the turning frame; transmitting belts, a cross beam, a pressing plate and a motor are arranged on the turning frame; the transmitting belts are arranged at the top and the bottom of the inside of the turning frame; servo motors are mounted inside the transmitting belts; the transmitting belts are in rolling shaft connection with the servo motors; the cross beam is arranged on the left side of the inside of the turning frame; the pressing plate is arranged at the bottom of one transmitting belt; a cylinder is mounted at the bottom of the pressing plate; a motor is mounted on the back of the turning frame; the conveying belt is arranged on the right side of the turning frame; a control panel, a control system and servo motors are arranged on the conveying belt; the servo motors are mounted inside the conveying belt; the servo motors are in rolling shaft connection with the conveying belt; the operation waiting zone is arranged on the left side of the turning frame. Through the device for turning transformer plate radiators during spraying paint, the operation efficiency can be improved; the device is capable of turning three groups of plate radiators at 180 degrees.

Owner:山东东升成套电气股份有限公司

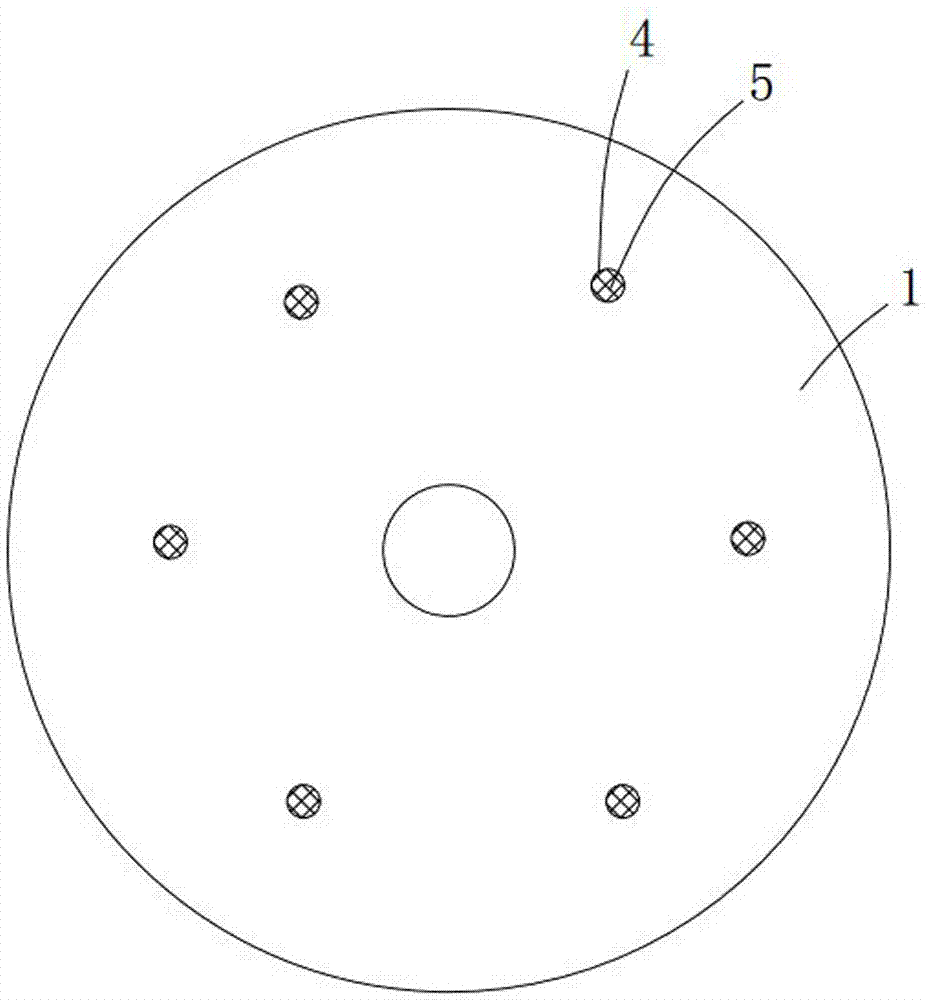

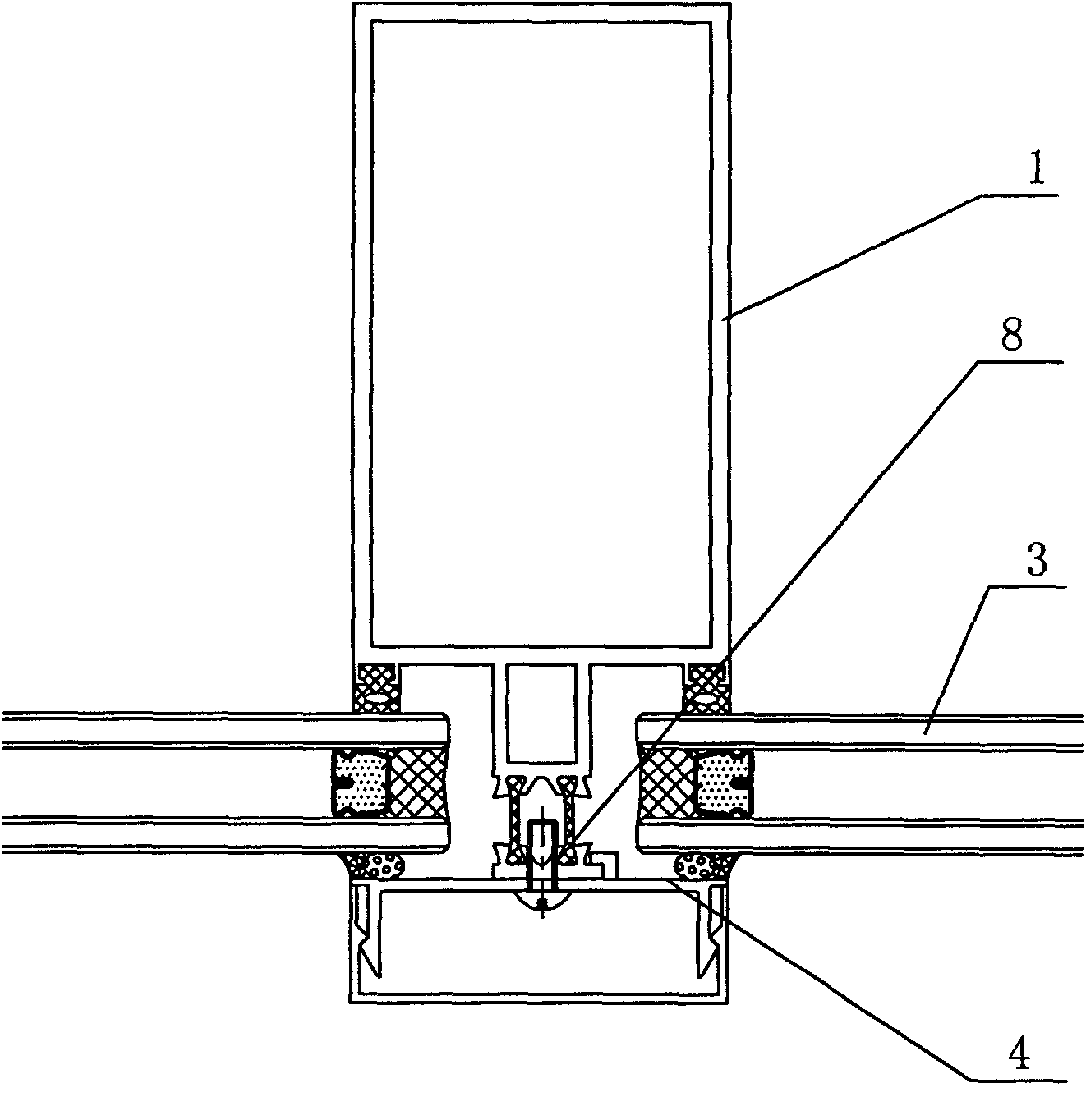

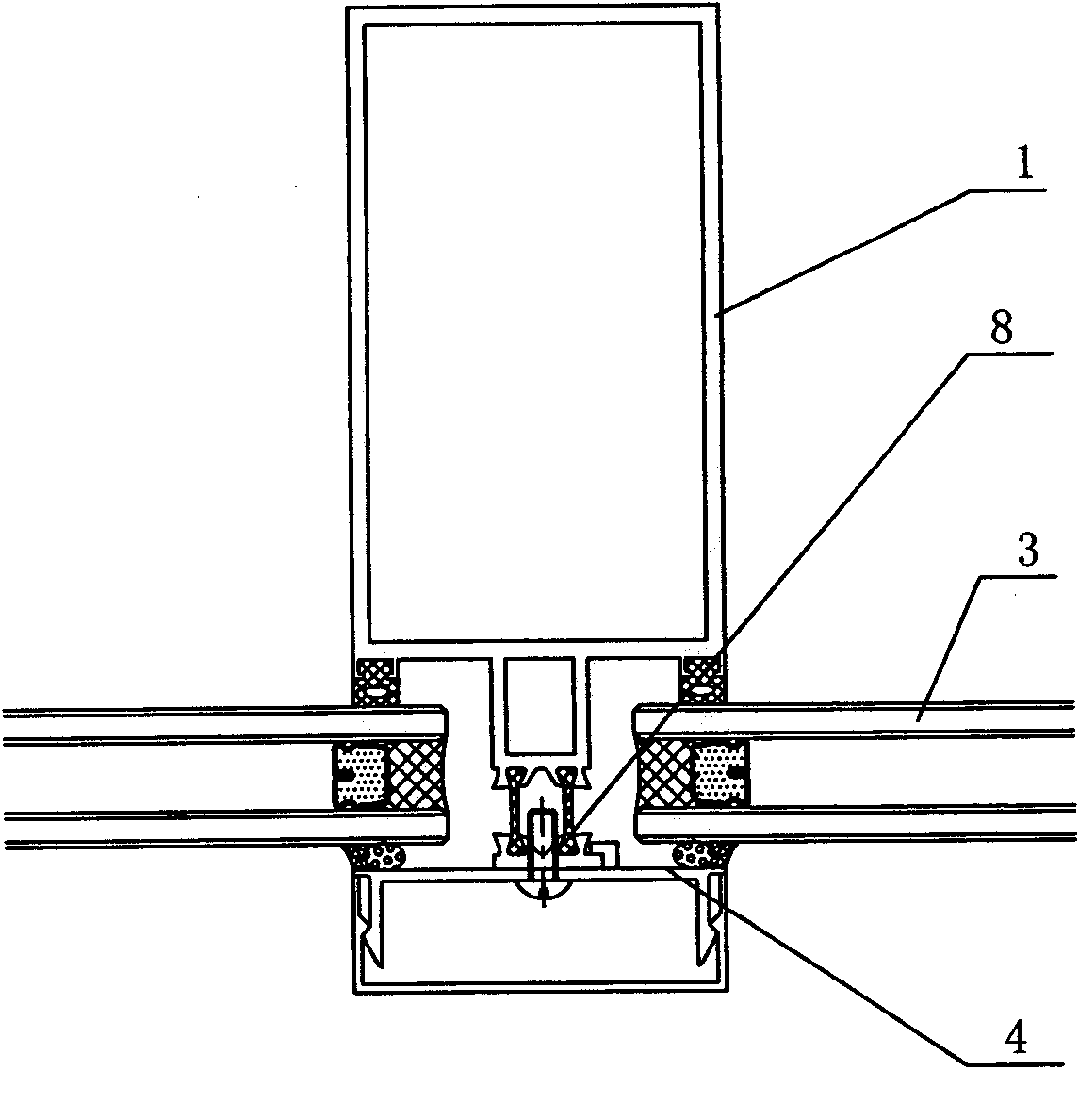

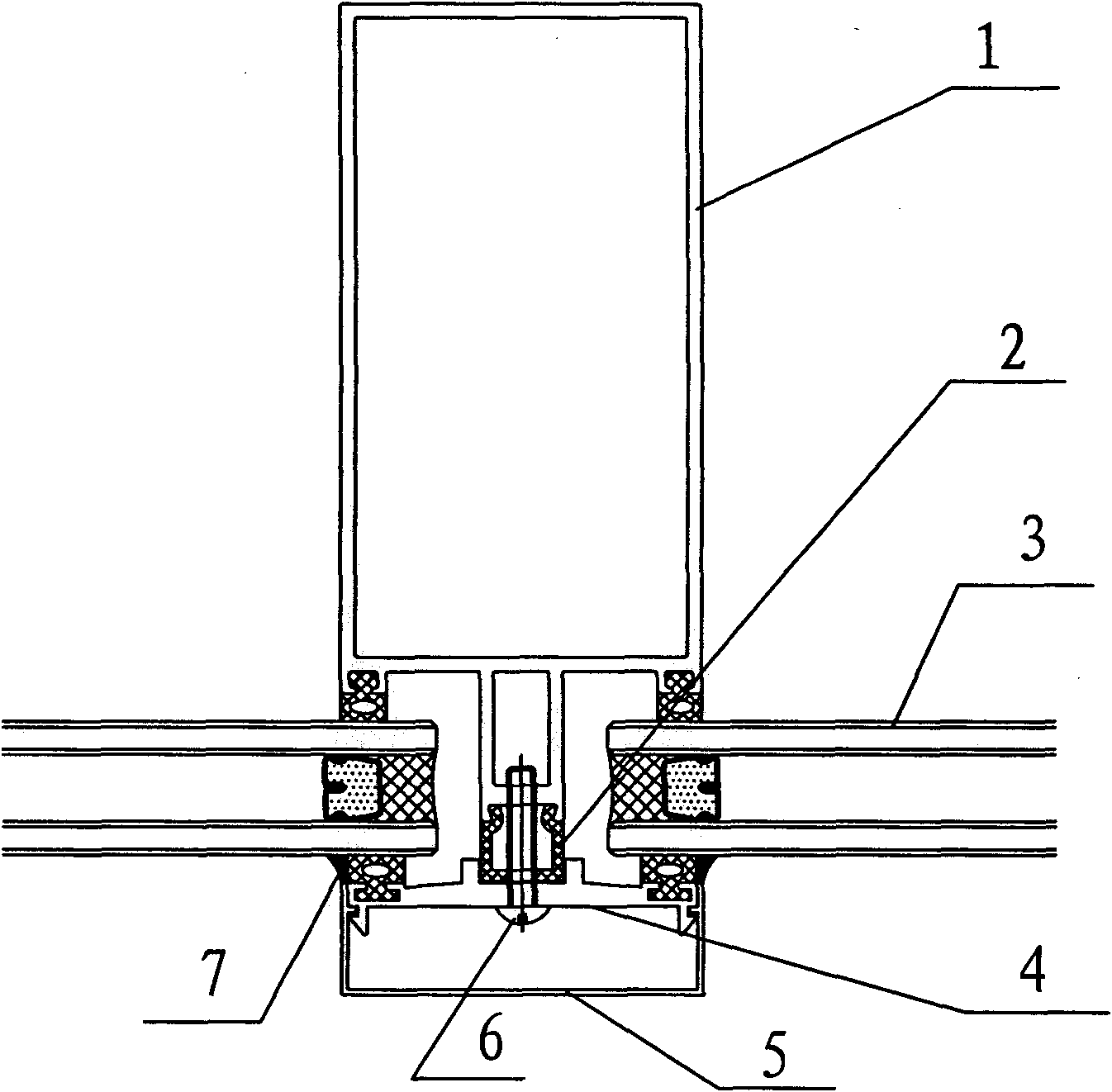

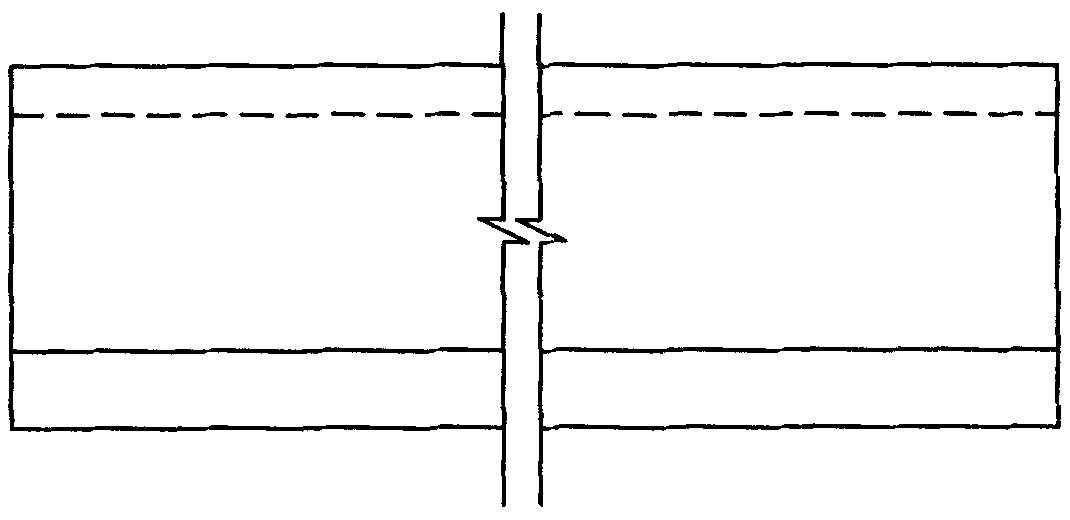

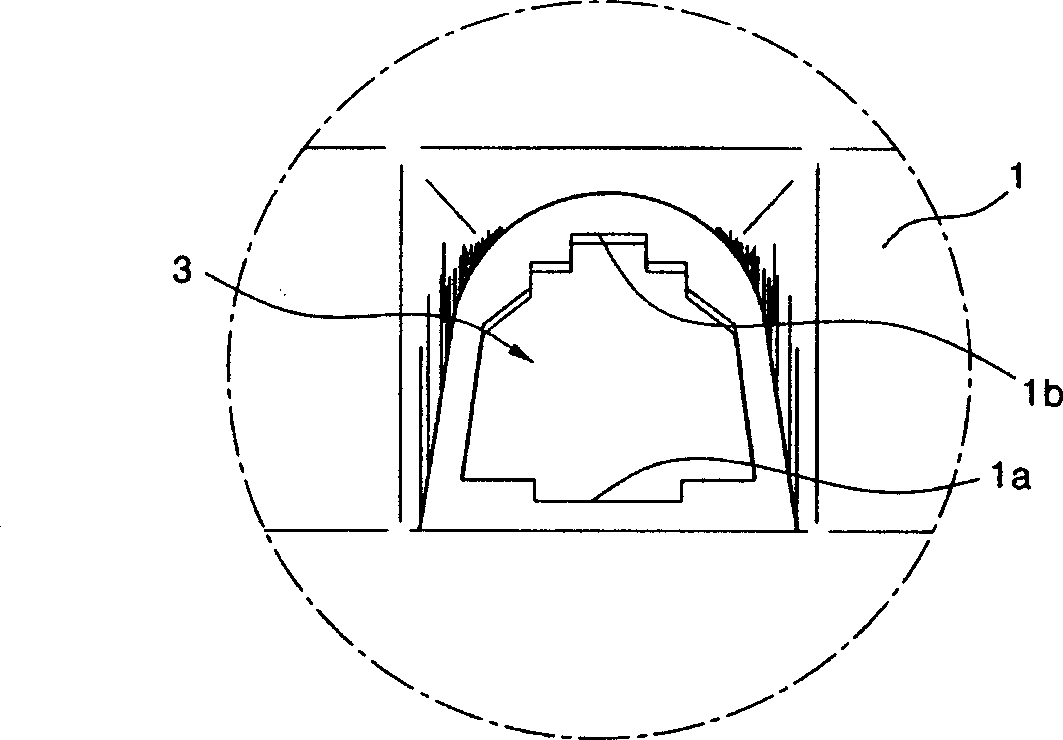

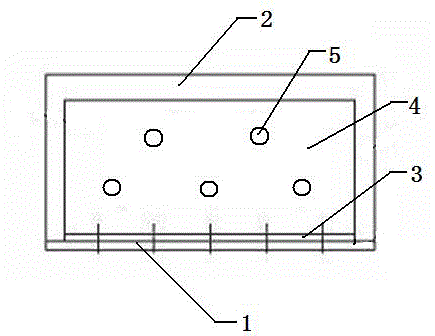

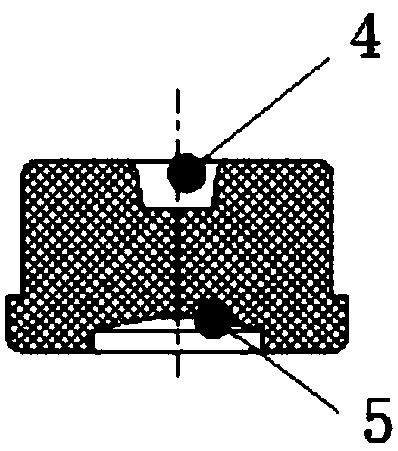

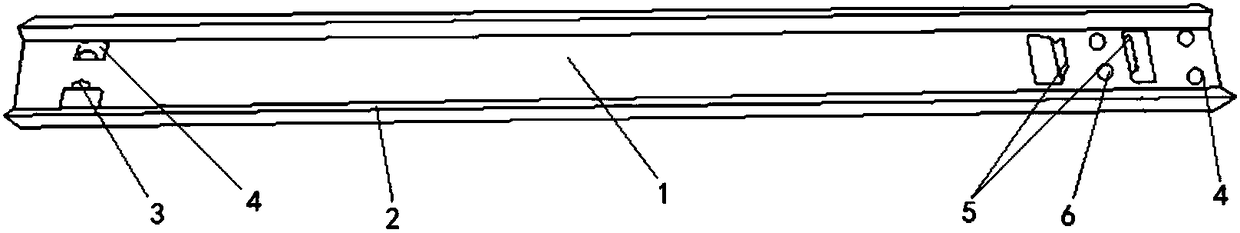

Exposed frame glass curtain wall with Poly vinyl chloride (PVC) heat-insulation block

InactiveCN102213015AStrong heat insulation abilityLow priceWallsHeat proofingEngineeringPoly vinyl chloride

The invention relates to an exposed frame glass curtain wall with a poly vinyl chloride (PVC) heat-insulation block. The exposed frame glass curtain wall comprises a stand column and hollow glass (3). The stand column comprises an aluminum section (1), an inner cover plate (4) of the aluminum section, an outer cover plate (5) of the aluminum section and a screw (6), wherein the inner cover plate (4) of the aluminum section is covered on the aluminum section (1); and the outer cover plate (5) of the aluminum section is covered outside the inner cover plate (4) of the aluminum section. The hollow glass (3) is embedded between the aluminum section (1) and the inner cover plate (4) of the aluminum section through a sealing joint strip (7); the PVC heat-insulation block (2) is embedded between the aluminum section (1) and the inner cover plate (4) of the aluminum section; the PVC block (2) is connected with the aluminum section (1) in a dovetailing mode, and the inner cover plate (4) of the aluminum section, the PVC heat-insulation block (2), and the aluminum section (1) are fixed by inserting the screw (6). The glass curtain wall has high heat-insulation capability and low cost.

Owner:江苏金宇幕墙装饰工程有限公司

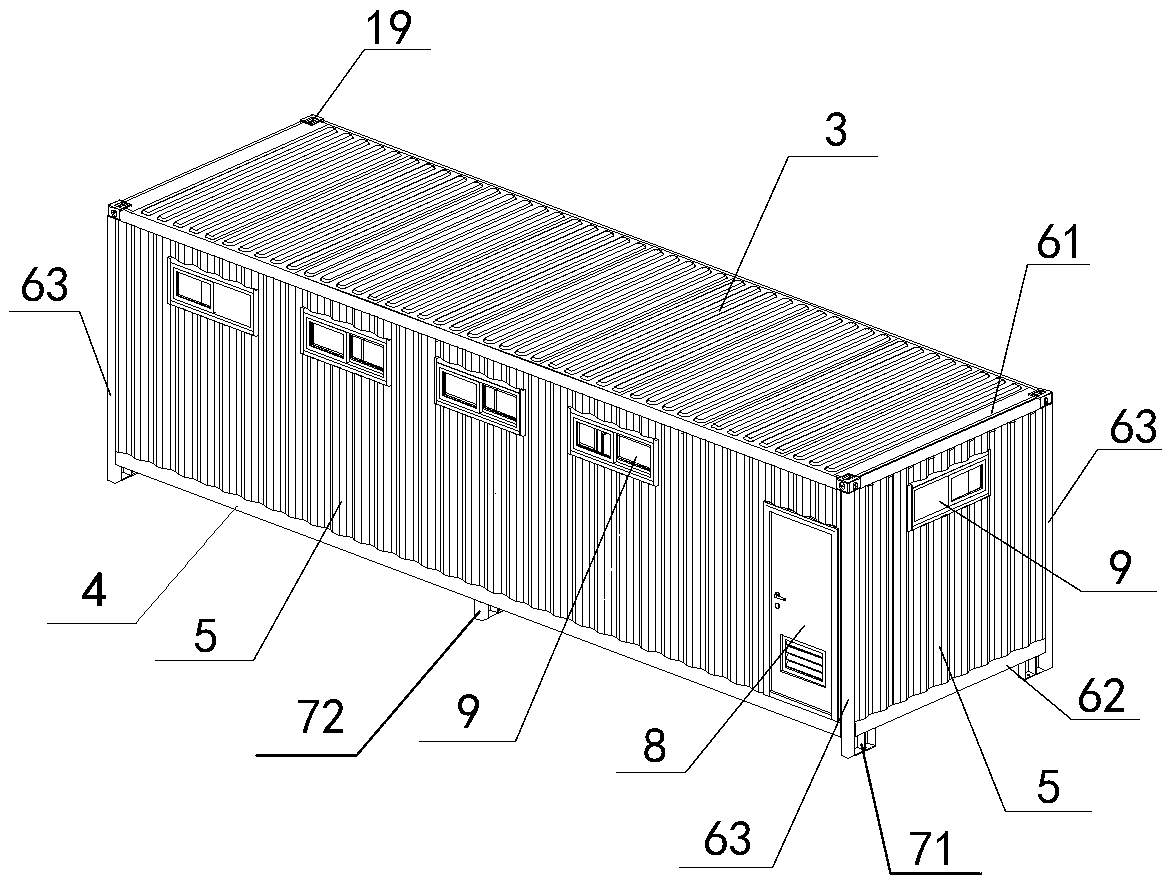

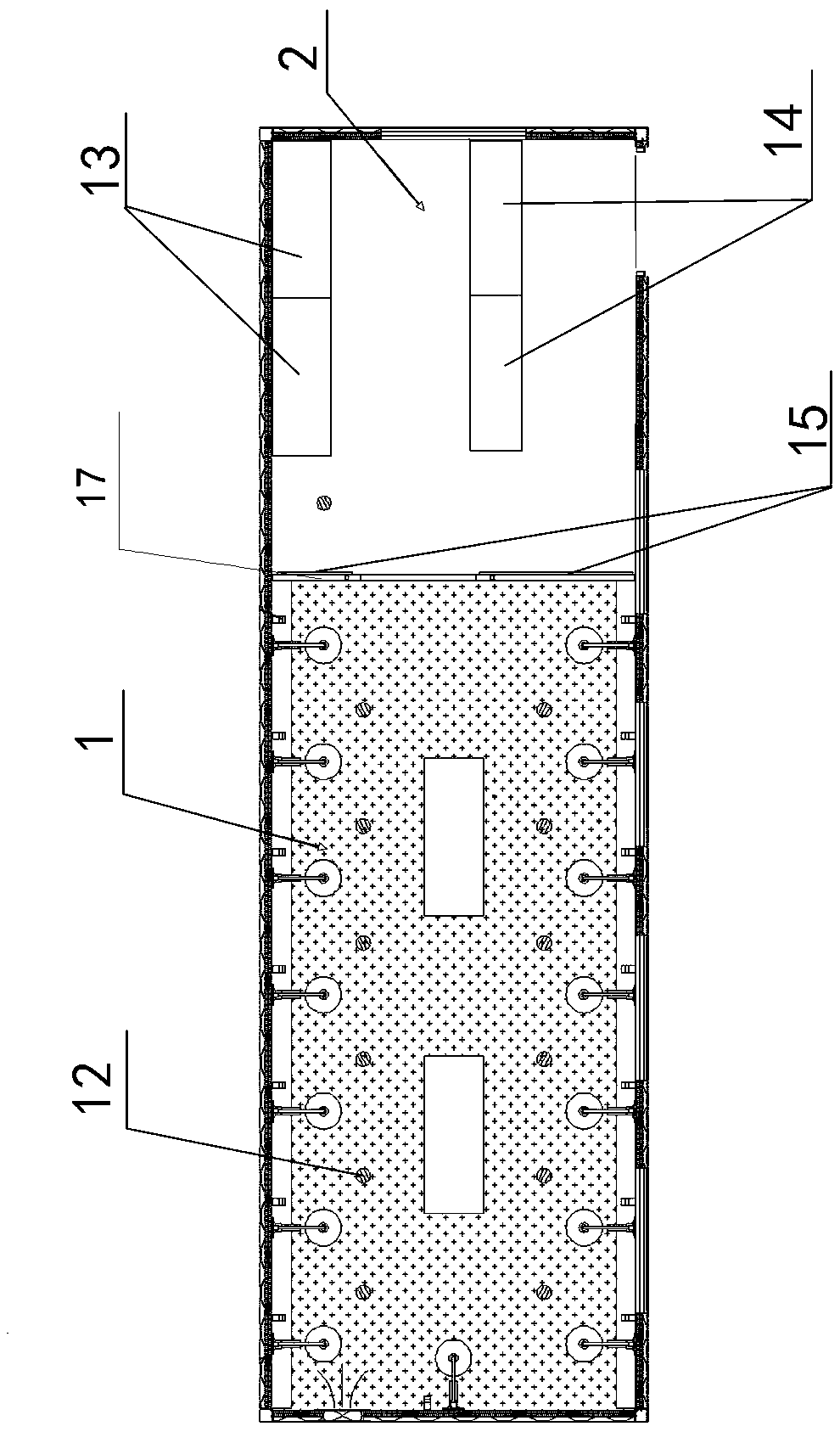

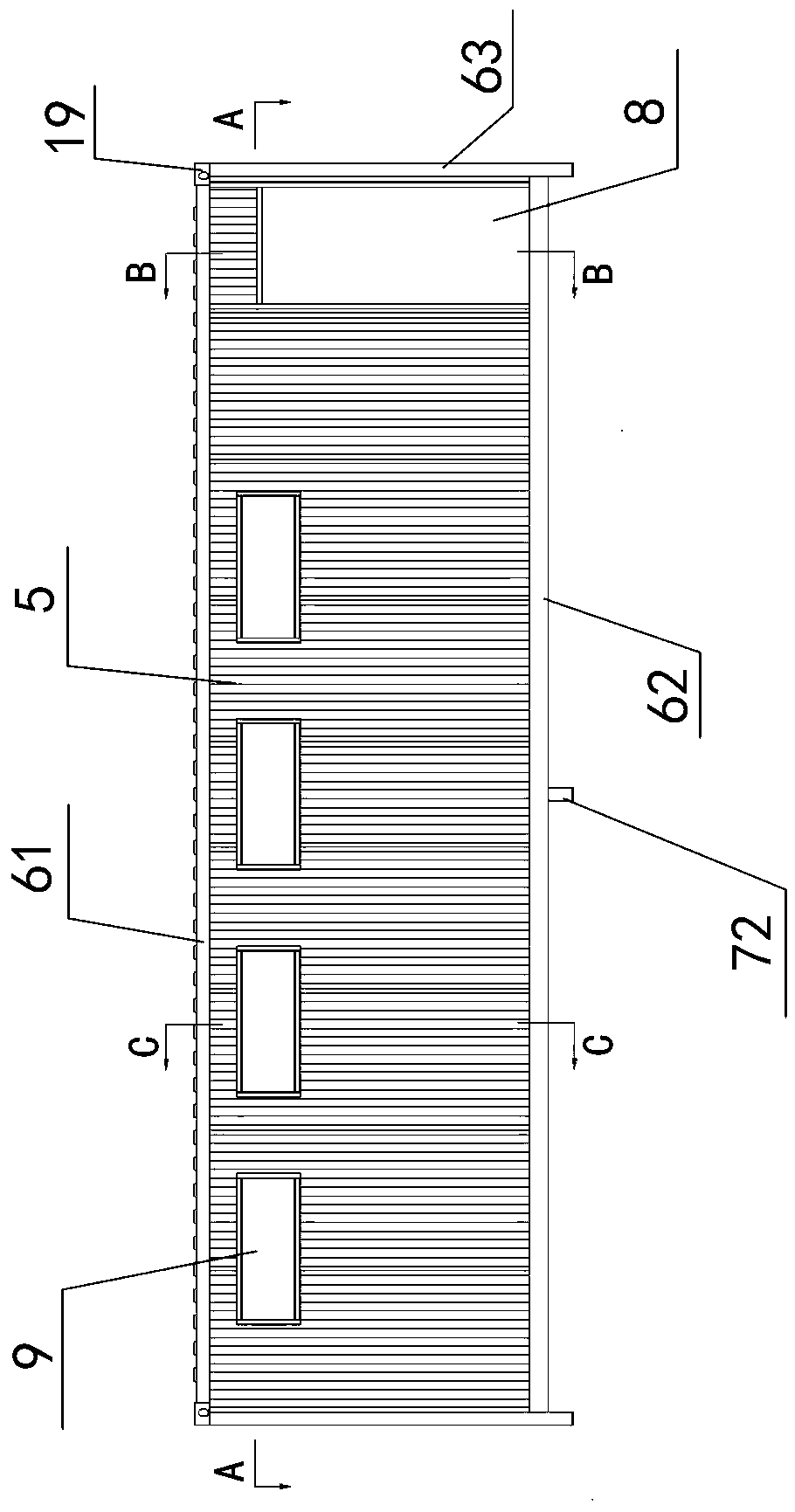

Container shower room module and construction method thereof

The invention relates to a container shower room module. The container shower room module comprises a container body, wherein the container body is divided into a shower cubicle and a dressing room bya partition; the container body comprises a steel frame system, top keels, bottom keels, a top plate, a bottom plate and wall plates; the steel frame system is formed by welding a top frame, a bottomframe and corner columns; the top keels are connected between borders of the top frame; the top plate is laid on the top frame; the bottom keels are connected between borders of the bottom frame; thebottom plate is laid on the bottom frame; and the wall plates arranged among the top frame, the bottom frame and the corner columns in a surrounded manner. The bottom ends of the corner columns exceed the bottom frame, and supporting legs are separately welded to a space between the bottom end of each corner column and the bottom frame and the midspan portion of a cross beam of the bottom frame.According to the container shower room module, the dressing room and the shower cubicle are centralized in a container module, the partition is arranged between the shower cubicle and the dressing room, and thus, the container shower room module is reasonable in function layout and humanized in use. The module is connected with the ground through the supporting legs and bolts, it can be ensured that the container shower room module cannot fall or move in a using process, and safety of users is ensured.

Owner:中建集成科技有限公司 +1

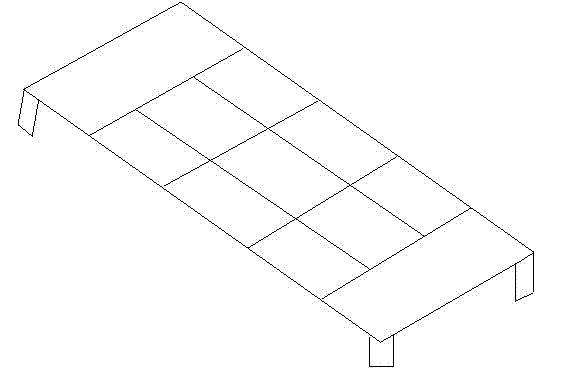

Portable device for preparing fiber reinforced composite material and using method of device

The invention provides a portable device for preparing a fiber reinforced composite material and a using method of the device. One side face of a fixed support plate and one side face of a movable support plate are opposite; threaded holes uniformly distributed are formed in each of the opposite side faces of the fixed support plate and the movable support plate; all the threaded hole in the fixedsupport plate and the movable support plate are corresponding pairwise in position; each pull ring is provided with threads; the pull rings are fixed by the corresponding threaded holes in the fixedsupport plate and the movable support plate; an opening is formed in each of pairwise opposite ends of the pull rings; and the openings are used for twining a fiber material. The device provided by the invention is simple in structure, low in manufacturing cost, has a low demand on the operating skill of operating personnel, and is easy to use; processing can be performed as needed according to different specifications; an electromagnetic inductor is capable of accurately controlling sensitivity and the force measuring range of the device, so that error brought by the device is reduced; distribution of an internal force is more uniform after the material is molded by the device, so that mechanical property of the material is improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

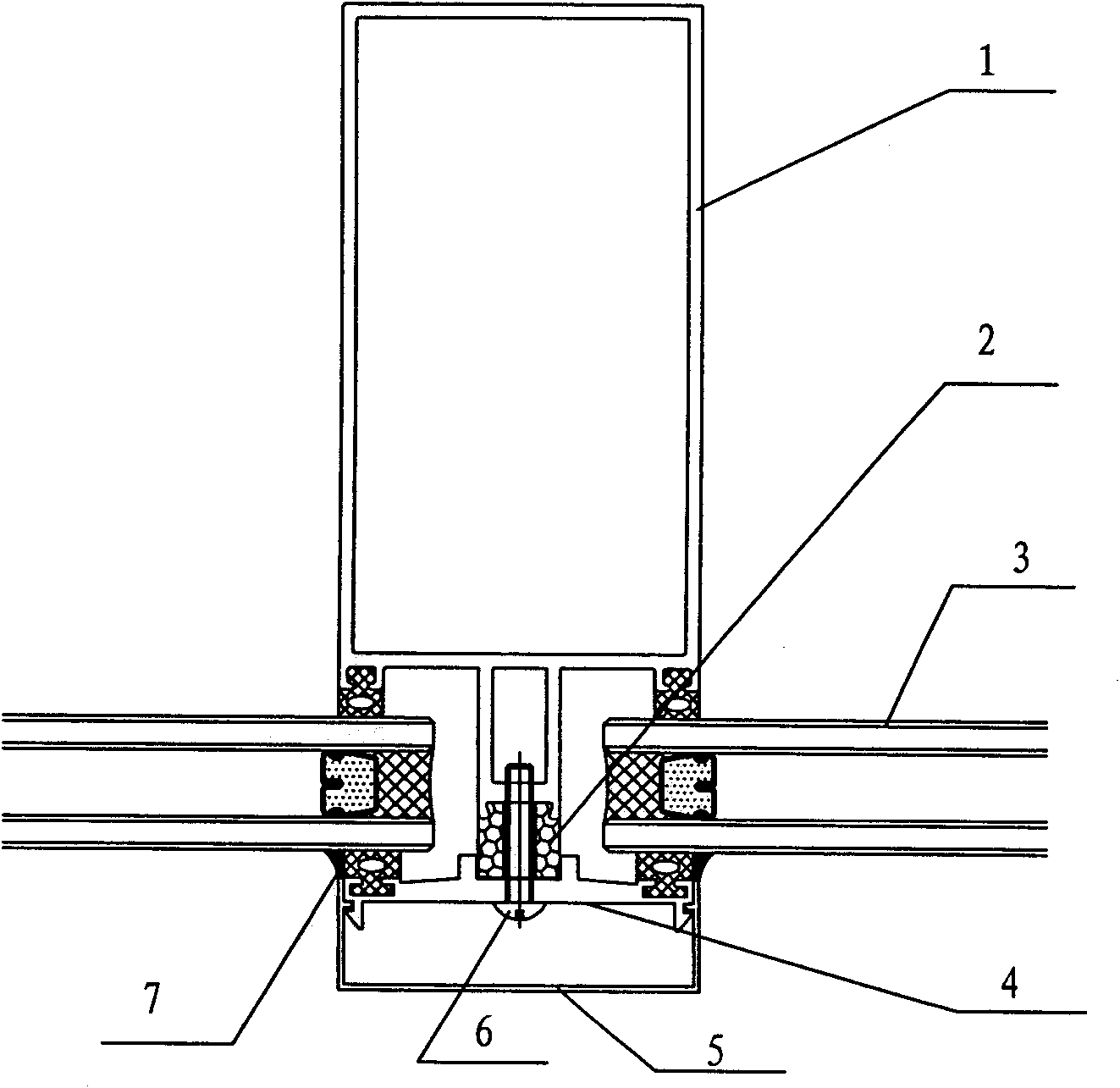

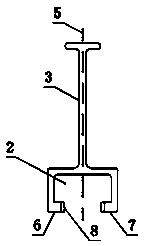

Exposed frame glass curtain wall adopting PVC (polyvinyl chloride) heat insulation bar structure

InactiveCN102213016AStrong heat insulation abilityLow priceWallsHeat proofingPolyvinyl chlorideEngineering

The invention relates to an exposed frame glass curtain wall adopting a PVC (polyvinyl chloride) heat insulation bar structure. The glass curtain wall comprises a vertical column and hollow glass (3), wherein the vertical column comprises an aluminium profile (1), an aluminium profile inner cover plate (4),an aluminium profile outer cover plate (5) and a screw (6); the aluminium profile inner cover plate (4) covers the aluminium profile (1); the aluminium profile outer cover plate (5) covers the aluminium profile inner cover plate (4); and the hollow glass (3) is embedded between the aluminium profile (1) and the aluminium profile inner cover plate (4) by sealing rubber strips (7). The glass curtain wall is characterized in that a PVC heat insulation bar (2) is embedded between the aluminium profile (1) and the aluminium profile inner cover plate (4) and is connected with the aluminium profile (1) in a dovetail manner; and the screw (6) is used for directly penetrating through and fixing the aluminium profile inner cover plate (4), the PVC heat insulation bar (2) and the aluminium profile (1). The glass curtain wall has strong heat insulation capability and lower cost.

Owner:江苏金宇幕墙装饰工程有限公司

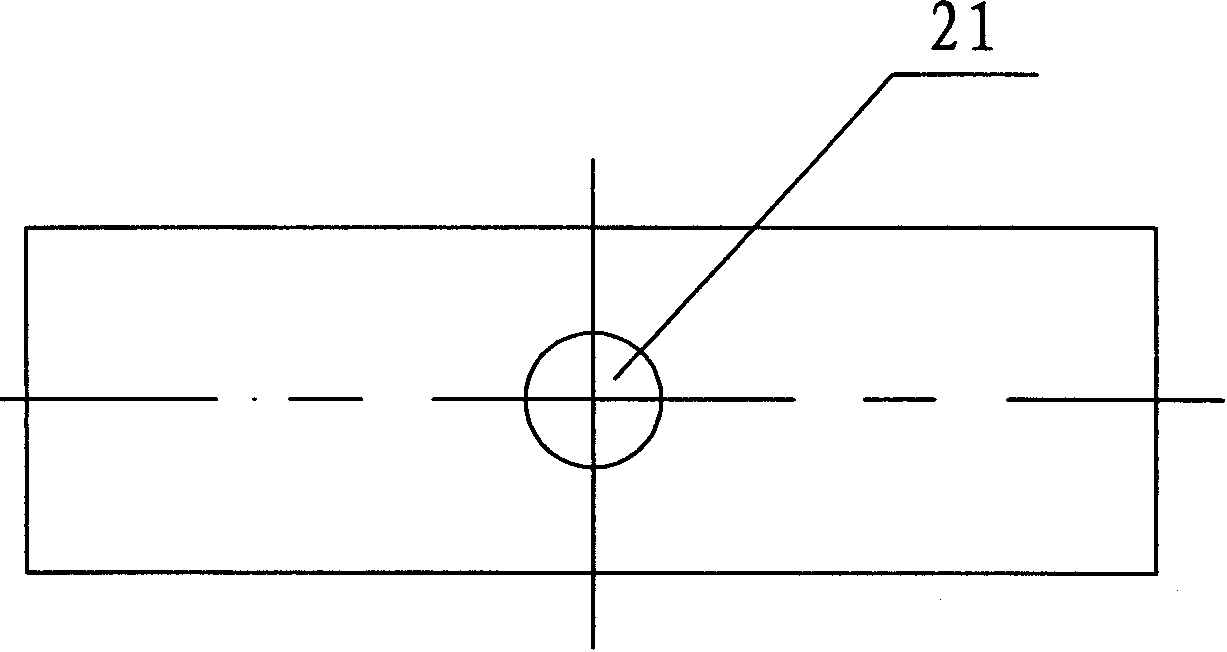

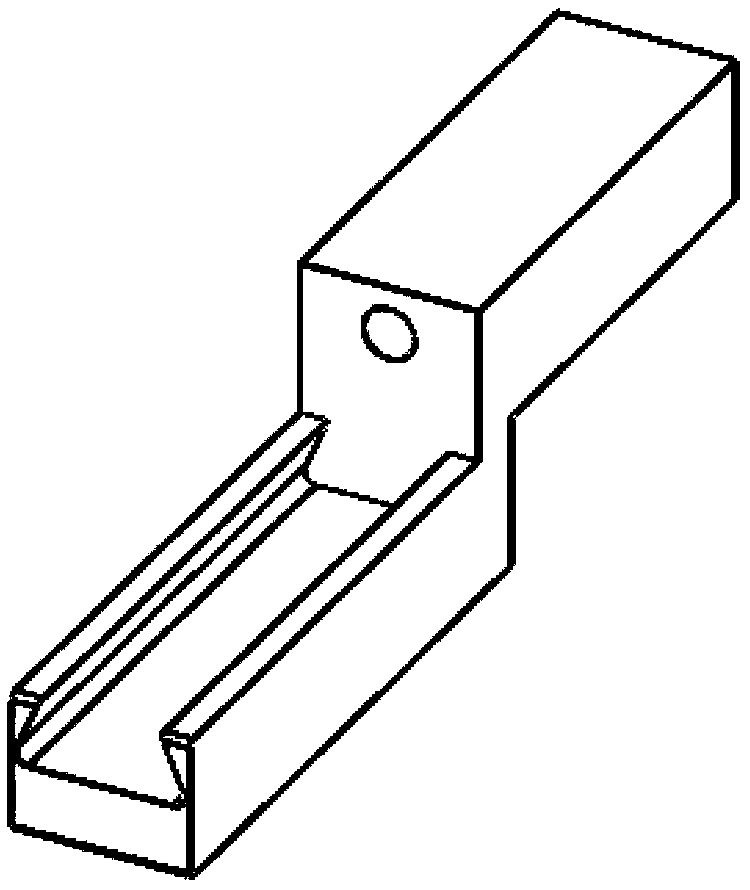

High-strength aluminum alloy embedded channel module and embedded channel forming process

InactiveCN109139665AHigh strengthIncrease loading capacityNutsScrewsMiddle lineUltimate tensile strength

The invention discloses a high-strength aluminum alloy embedded channel module. The high-strength aluminum alloy embedded channel module comprises an embedded channel and a T-shaped bolt; the embeddedchannel consists of a C-shaped groove, and an anchor rod fixedly connected to the back surface of the groove bottom of the C-shaped groove; the anchor rod and the C-shaped groove form an integral structure through pushing molding; a notch of the C-shaped groove is two inner flange structures symmetrical about the middle line of the C-shaped groove; the opposite surfaces of the two inner flanges are of rack structures; a bolt head of a T-shaped bolt consists of a first cuboid and a second cuboid; the second cuboid is joined with a bolt rod of the T-shaped bolt; the first cuboid and the secondcuboid are the same in width, and are both narrower than the notch of the C-shaped groove; the length of the first cuboid is larger than the width of the notch of the C-shaped groove; and engagement teeth engaged with corresponding racks are arranged on two width side surfaces of the second cuboid. The high-strength aluminum alloy embedded channel module has the following advantages: the strengthand the load capacity of the embedded channel are improved; and the density of high-strength aluminum alloy materials is lower, so that consumed materials are fewer under the same load, and the toothantiskid capacity is improved.

Owner:河南厚德电力科技有限公司

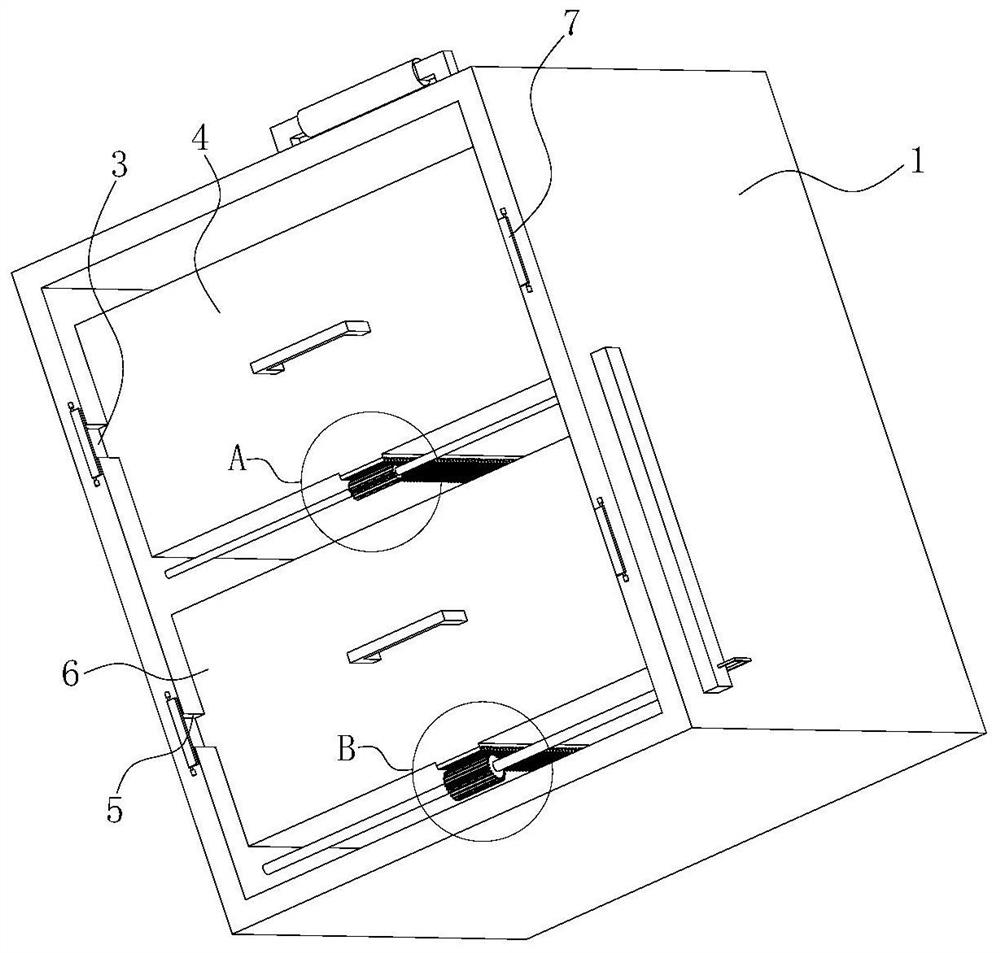

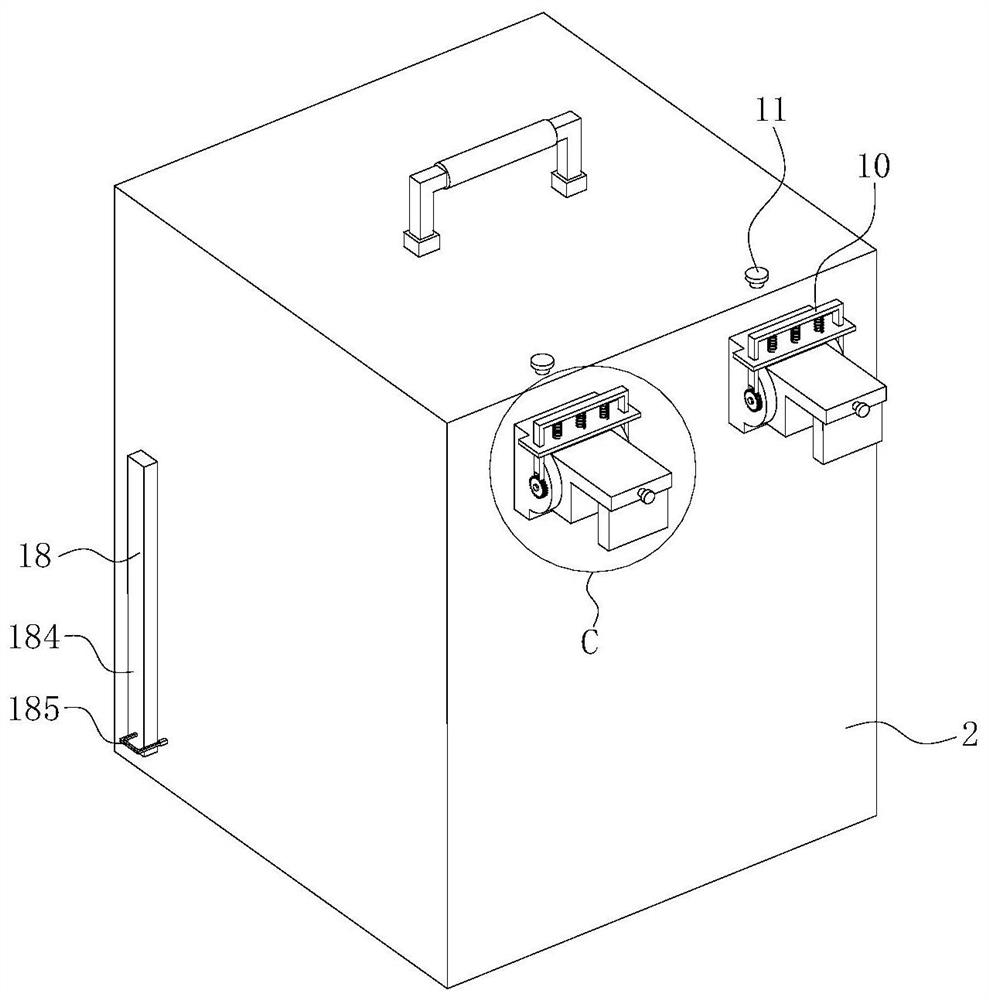

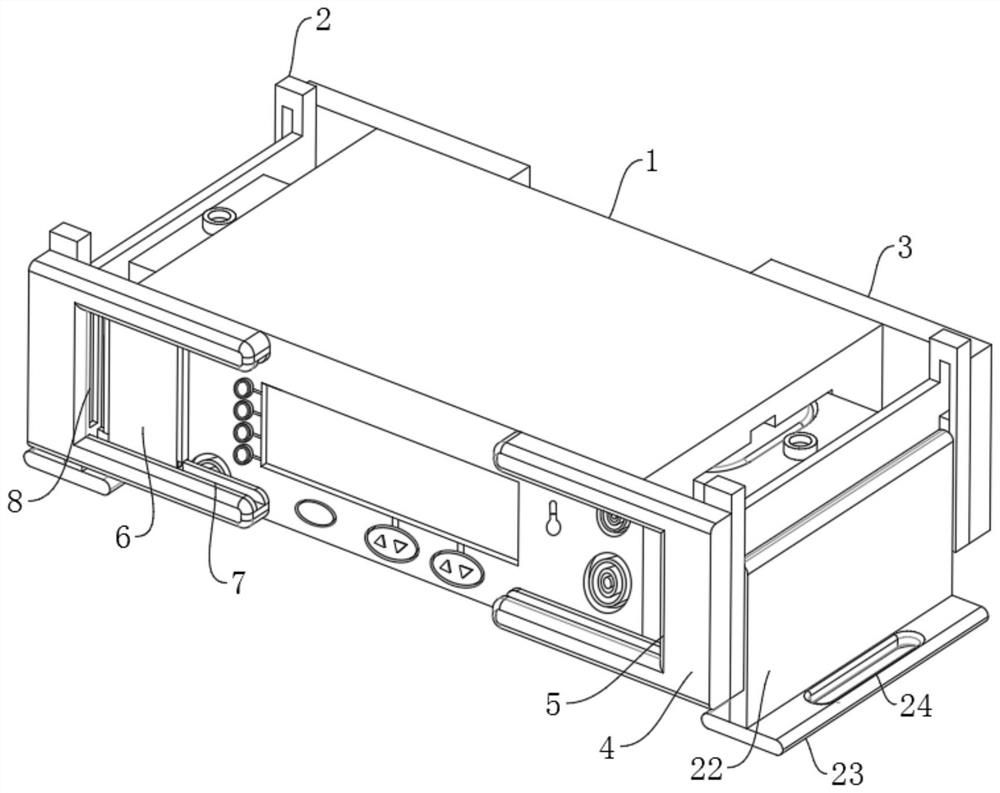

Medical box for obstetric nursing

InactiveCN111772810ANo mobilityNo shakingSurgical furnitureNursing accommodationNursing careEngineering

The invention belongs to the technical field of nursing instruments, and in particular relates to a medical box for obstetric nursing. The medical box for obstetric nursing comprises a frame, the front end face of which forms an opening; a back plate is installed on the rear end face of the frame; the left and right inner side walls of the frame are symmetrically provided with horizontal first sliding grooves, and glidingly matched with a first storage box; the left and right inner side walls of the frame are symmetrically provided with horizontal second sliding grooves below the first slidinggrooves, and glidingly matched with a second storage box; a baffle is installed on the front end face of the frame; the front end face of the first storage box and the front end face of the second storage box are each installed with a handle; two vertical plates are rotatably installed on the rear end face of the back plate; and the rear end faces of the vertical plates are hinged with a clampingguide mechanism through a supporting plate. According to the medical box for obstetric nursing in the invention, the whole medical box can be hung on the fence bar of a hospital bed through the clamping guide mechanism, so that the medical box is convenient for a medical worker to take and use; furthermore, when in use, the height of the gravity centre of the whole medical box cannot be influenced; and thus, the stability of the medical box in the use process can be ensured.

Owner:枣庄市妇幼保健院

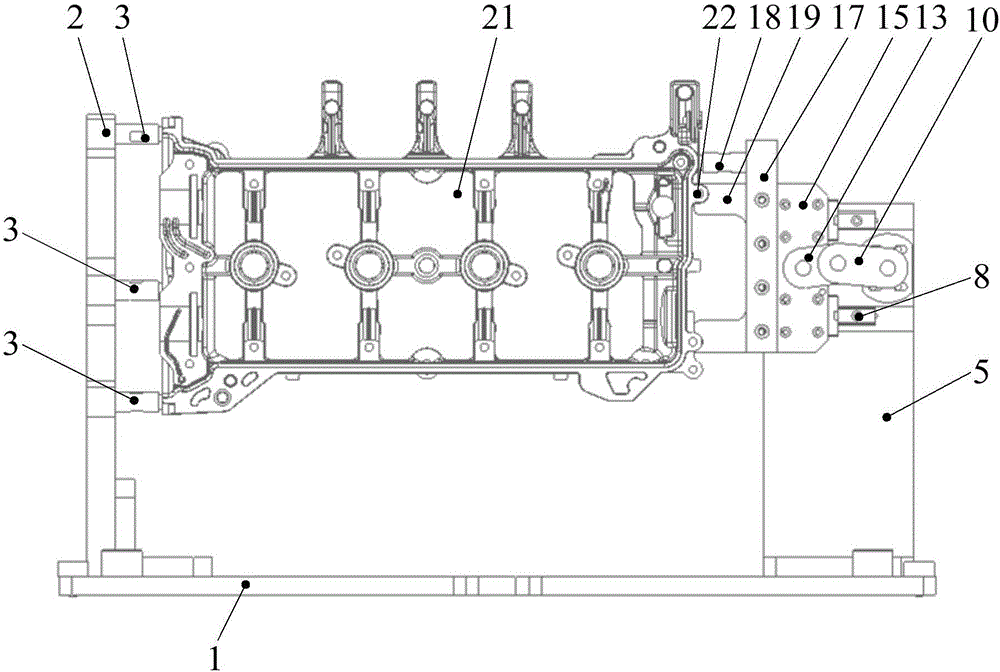

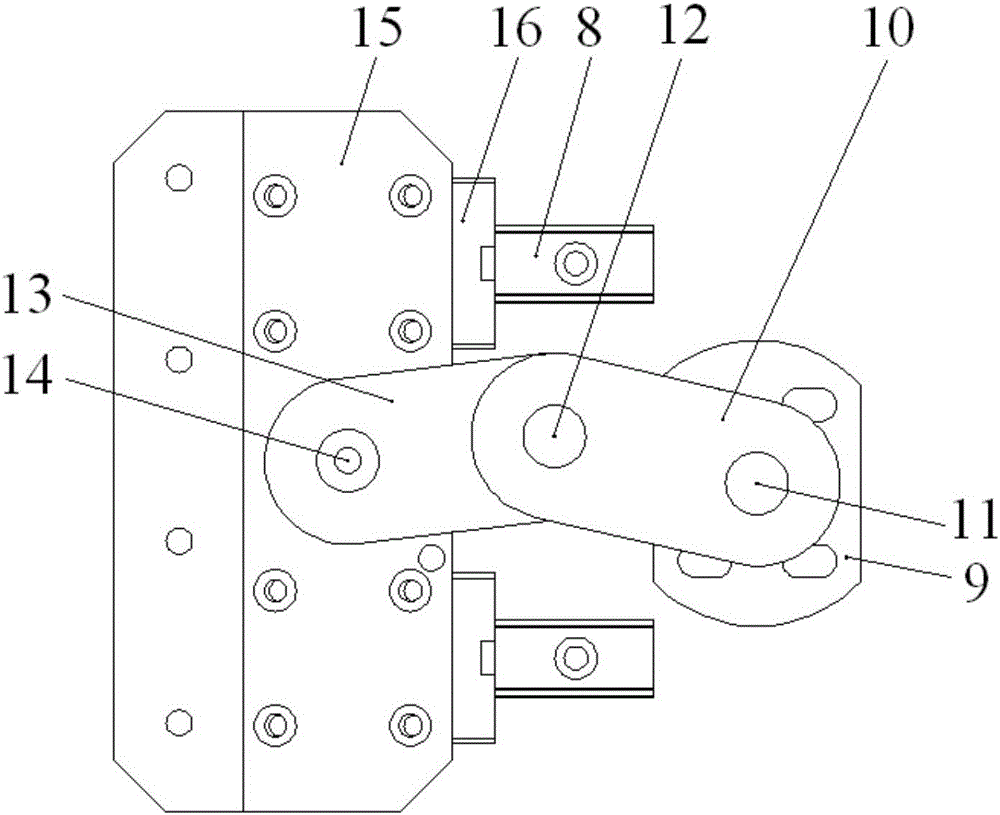

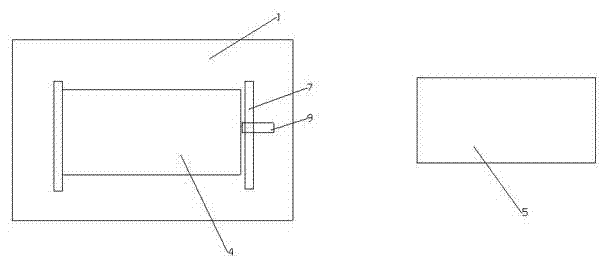

Fixture for grinding pressure casting

ActiveCN106475904AAchieve clampingAchieve positioningGrinding work supportsLocking mechanismPressure casting

The invention discloses a fixture for grinding a pressure casting. The fixture comprises a bottom plate; the bottom plate is vertically provided with a first side plate and a second side plate; the first side plate is horizontally and convexly provided with a first cylindrical pin towards the second side plate; the first cylindrical pin is matched with a round hole in one end surface of the pressure casting; the second side plate is provided with a locking mechanism comprising a first connecting plate, a second connecting plate, a push plate and a clamping plate; one end of the first connecting plate is connected to the second side plate through a first screw, and the other end of the first connecting plate is connected to one end of the second connecting plate through a movable screw; the other end of the second connecting plate is connected to the push plate through a second screw; the surface, close to the second side plate, of the push plate is fixedly provided with a slide block; the second side plate is horizontally provided with a guide rail; the slide block is arranged on the guide rail; the clamping plate is fixedly arranged on the push plate; the clamping plate is horizontally and convexly provided with a second cylindrical pin and a clamping block towards the first side plate; and the second cylindrical pin and the clamping block are matched with a round hole and a boss which are formed in the other end surface of the pressure casting. The fixture disclosed by the invention is precise in location, simple in clamping, suitable for large-scale processing of products and capable of increasing the production efficiency.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

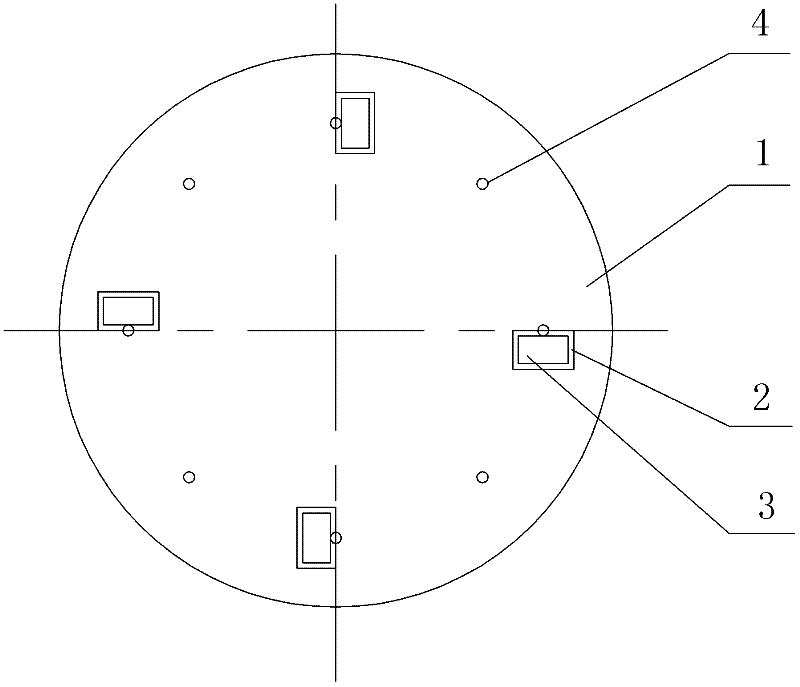

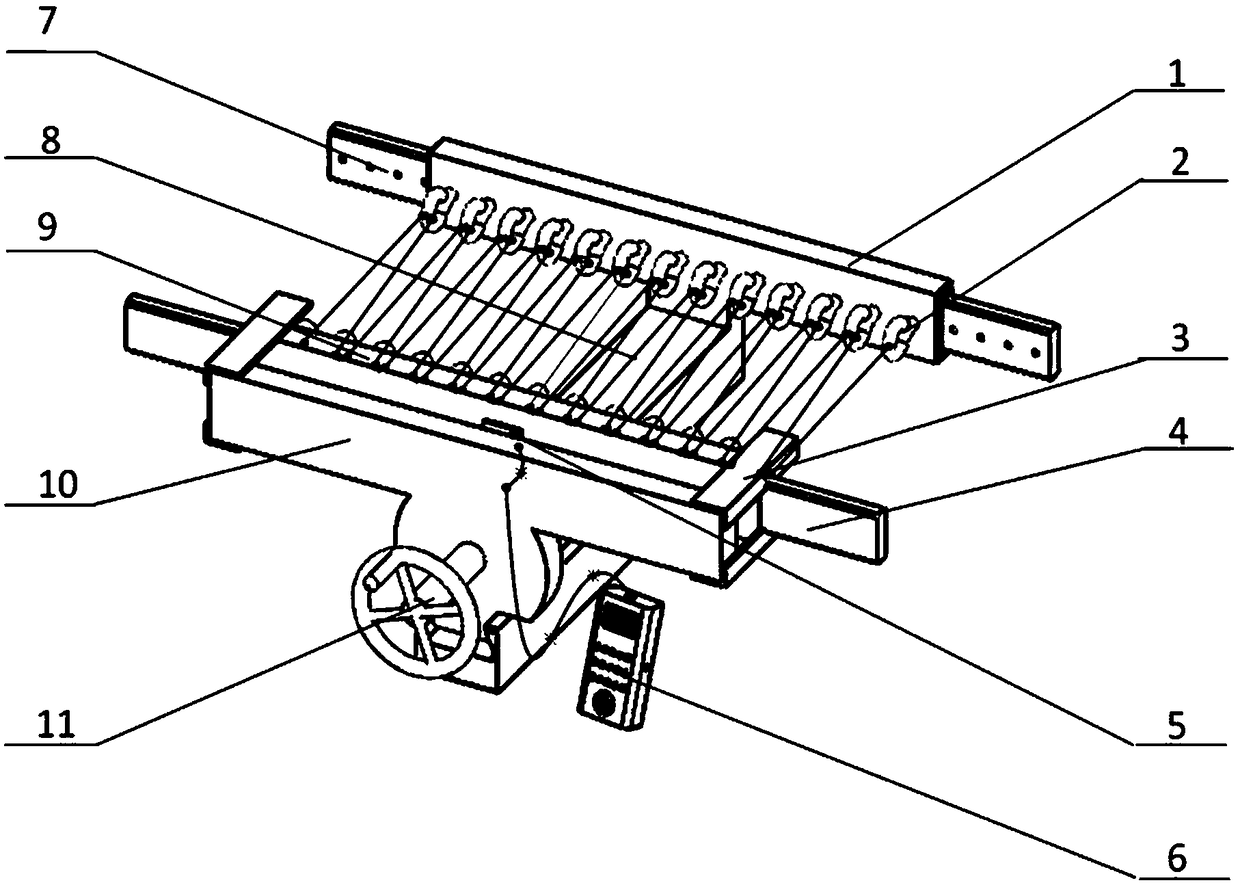

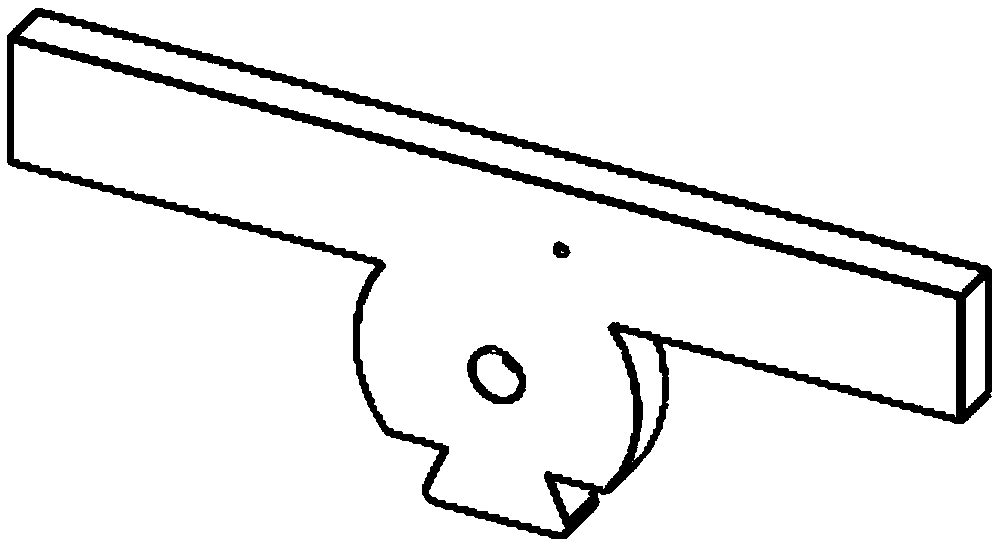

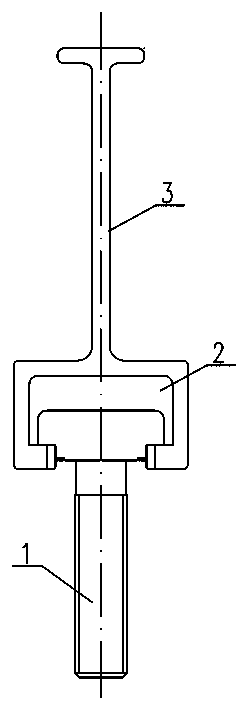

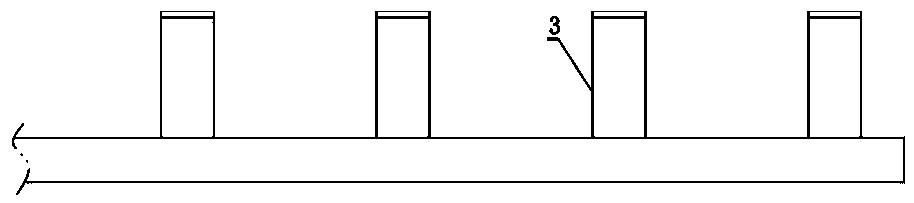

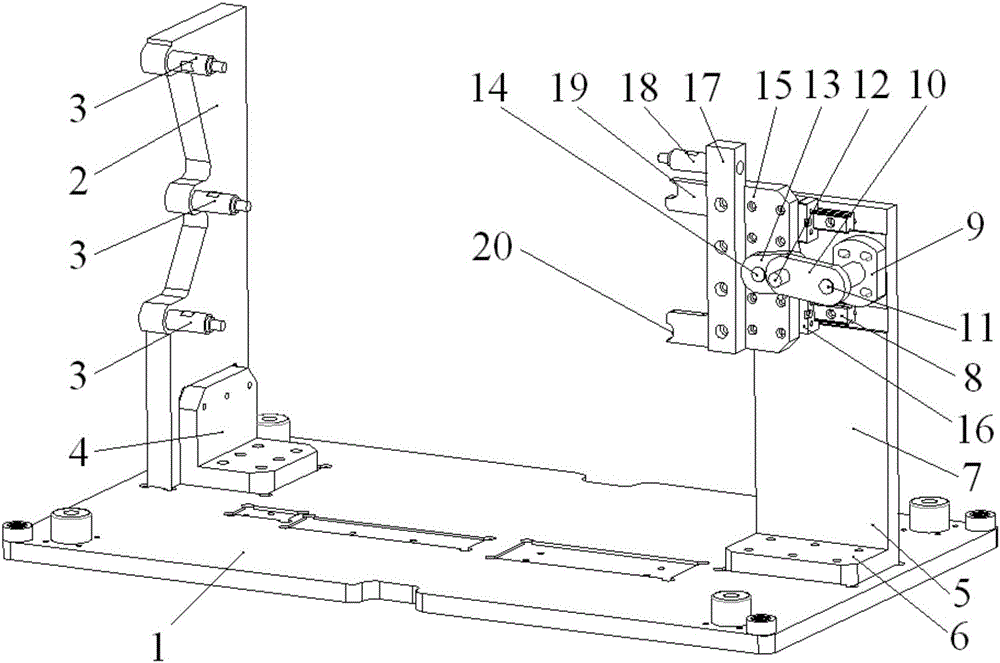

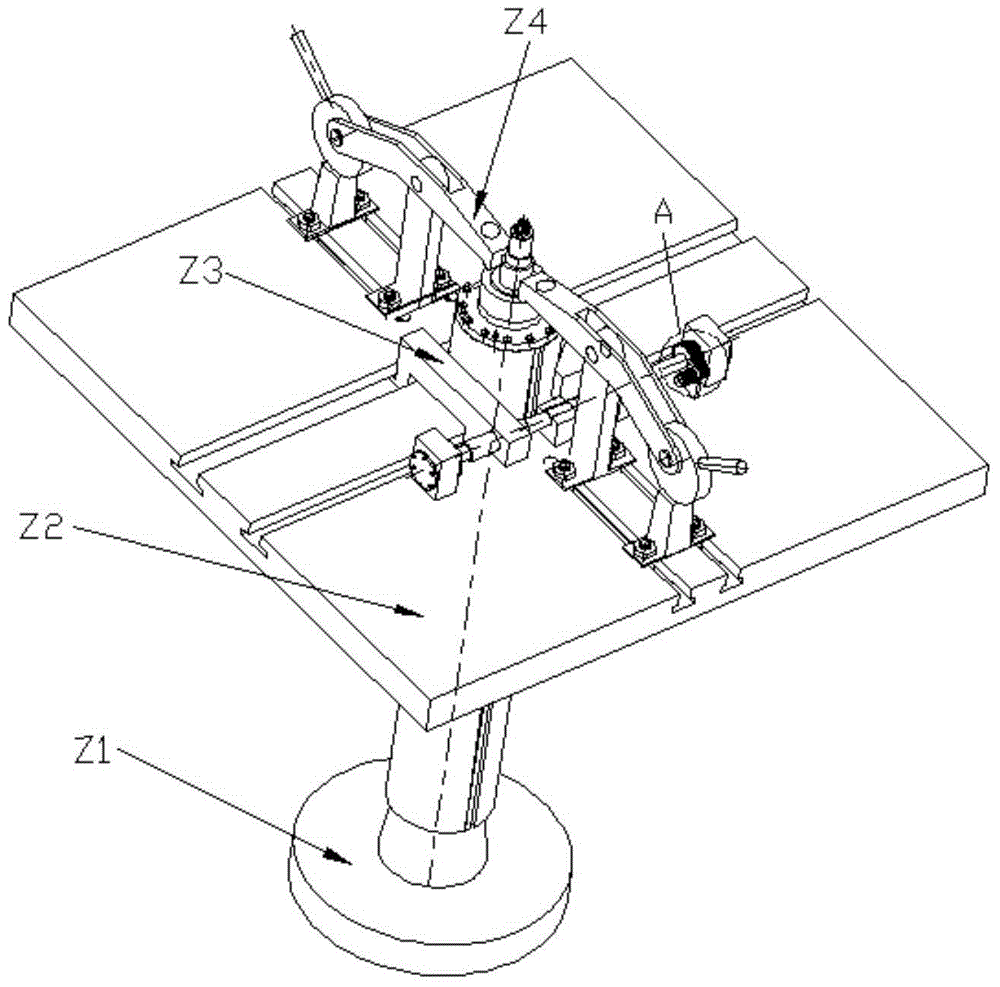

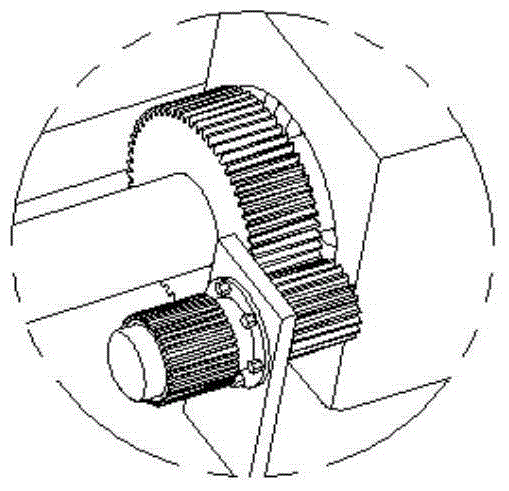

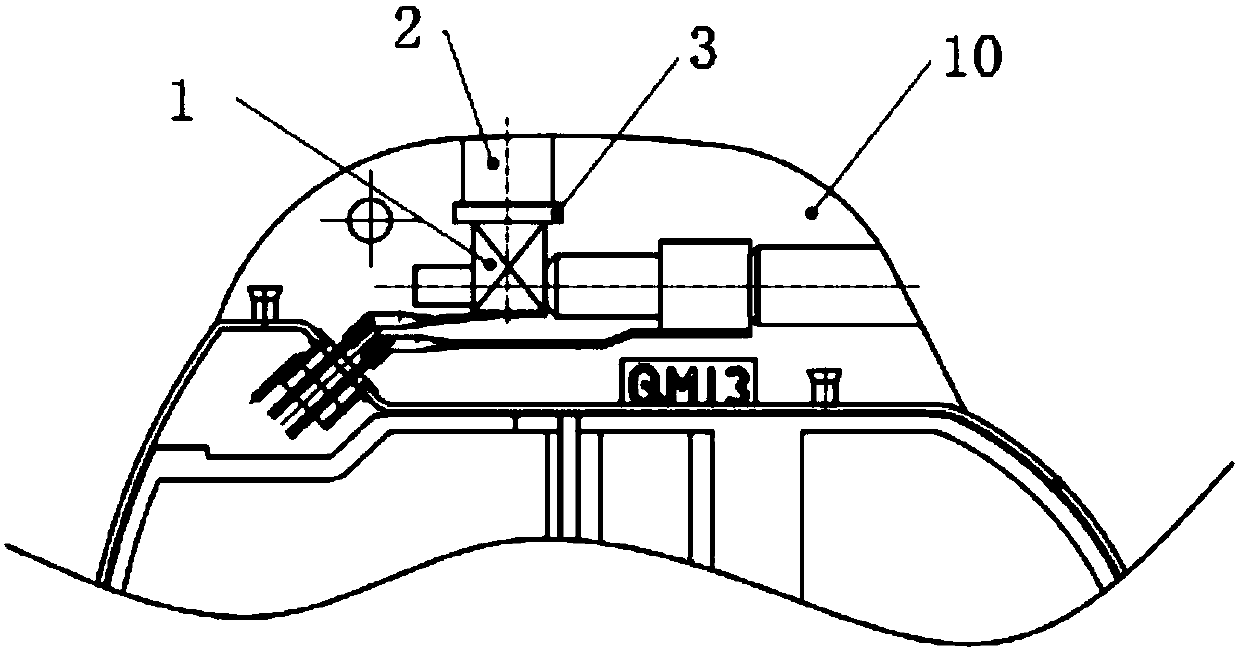

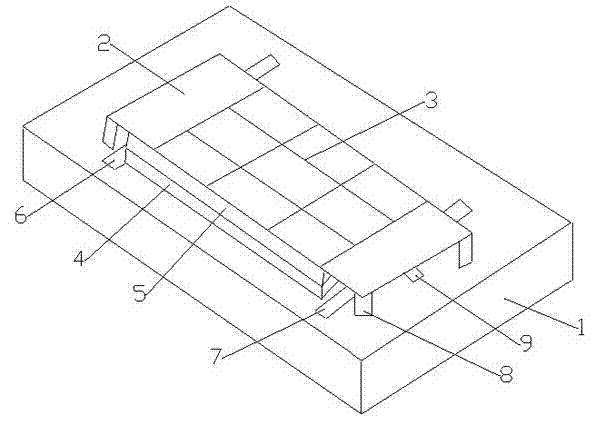

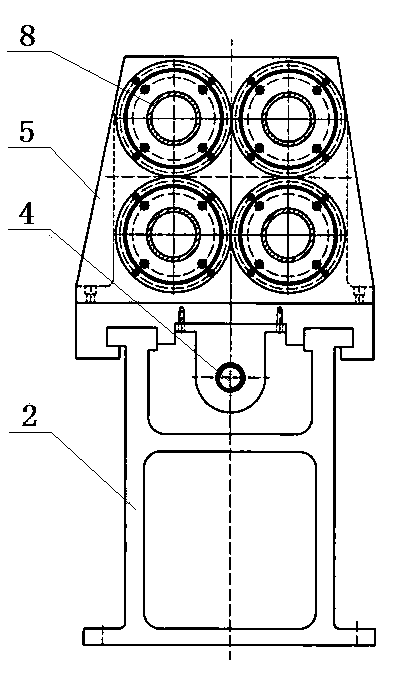

Drill clamp universal for large high-speed printing roller

InactiveCN105127794APrecise positioningNo mobilityWork clamping meansPositioning apparatusMotor driveEngineering

The invention provides a drill clamp universal for a large high-speed printing roller. The drill clamp comprises an underground workbench, a ground workbench, a self-centering device and diametral plane cam clamping devices. A flat tip is arranged on the underground workbench. The self-centering device and at least one set of diametral plane cam clamping device are installed on the ground workbench. The positions of the diametral plane cam clamping devices can be adjusted along a T-shaped groove in a sliding mode. The self-centering device is composed of a coaxial double-helix linkage mechanism, a left thread sliding block, a right thread sliding block and a motor driving device. The motor driving device is connected with the coaxial double-helix linkage mechanism in a driving mode. The left thread sliding block and the right thread sliding block oppositely move simultaneously along a transverse T-shaped guide rail by driving a double-helix threaded rod in the coaxial double-helix linkage mechanism and are combined with the flat tip for workpiece positioning. The drill clamp is suitable for drilling and reaming (match working) procedures of a series of assembly holes of the large high-speed printing roller, workpiece positioning is rapid and accurate, clamping is rapid, operation is easy, machining quality is guaranteed, investment is low, and cost is low.

Owner:SHANGHAI INST OF TECH

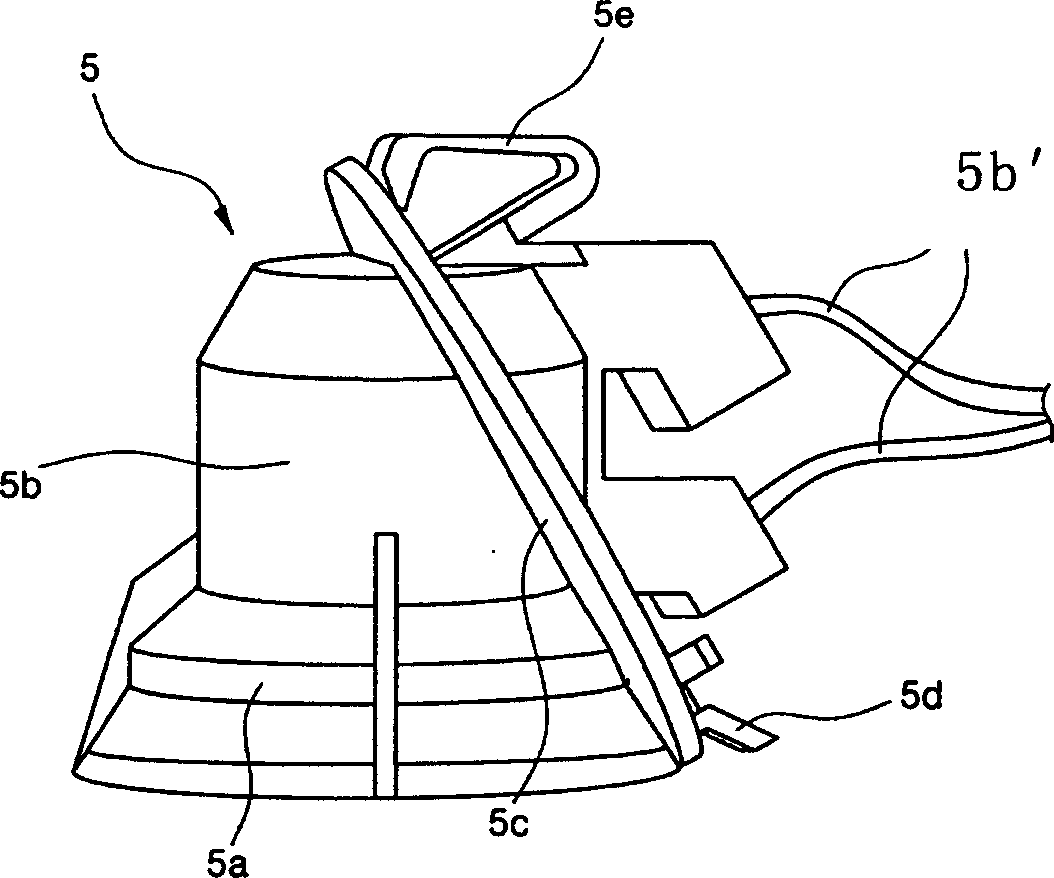

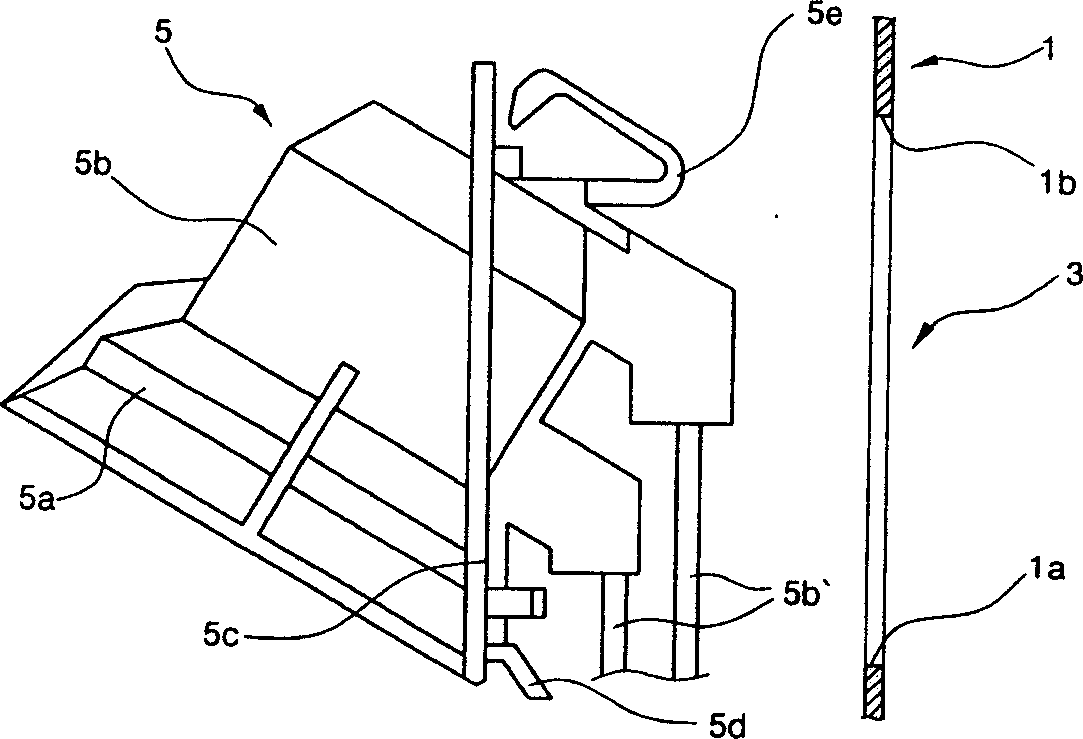

Headlamp socket installing structure of refrigerator

InactiveCN1584464ANo mobilityDisengagement will not occurDomestic cooling apparatusLight fasteningsHeadlampEngineering

An install arrangement of refrigerator lamp consists of a guiding plate and a lamp holder thereon. An installing hole is located on the guiding plate. Two grooves are respectively formed on the upper and lower edges of the hole. A flange is located from a side of lamp cover to a central portion on top of the screw portion in a declined way. A fixing hook is arranged at lower portion of the flange in a downward declined way. An elastic hook integrated with the holder on top of the holder with corrugated portion at its upper location to form a platform section, an upward declined section and a downward declined one. Its advantages include simple structure, easy opration, and tight installation with surface contact between the elastic hook and the lower edge of concave groove.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

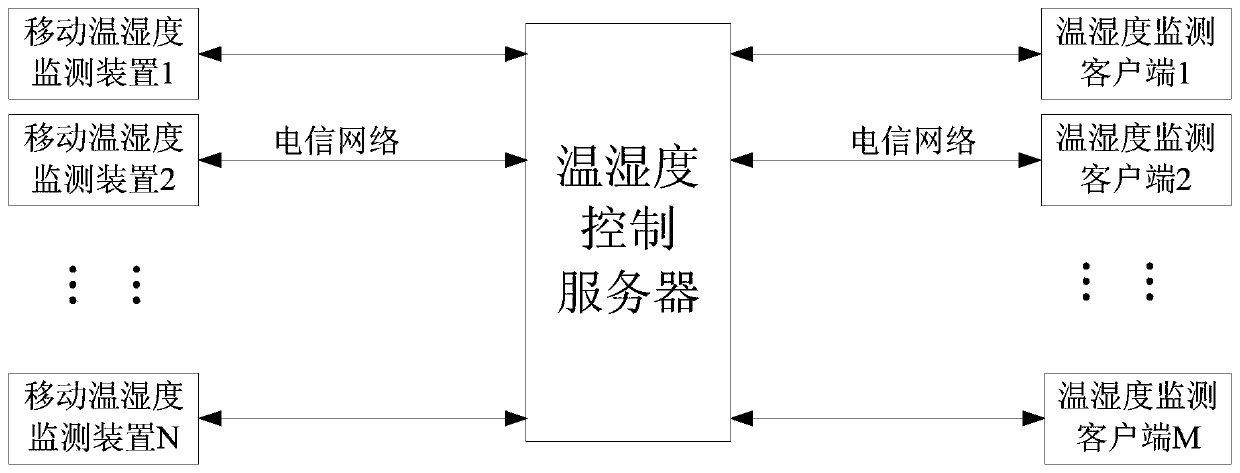

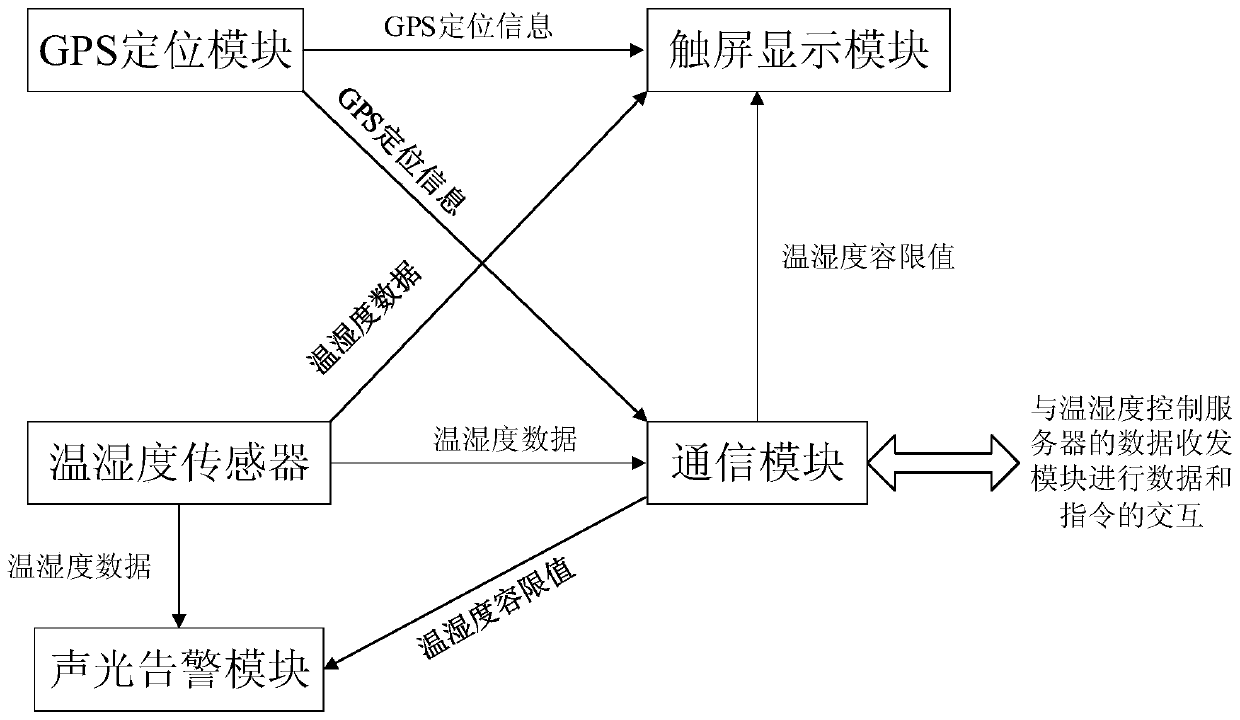

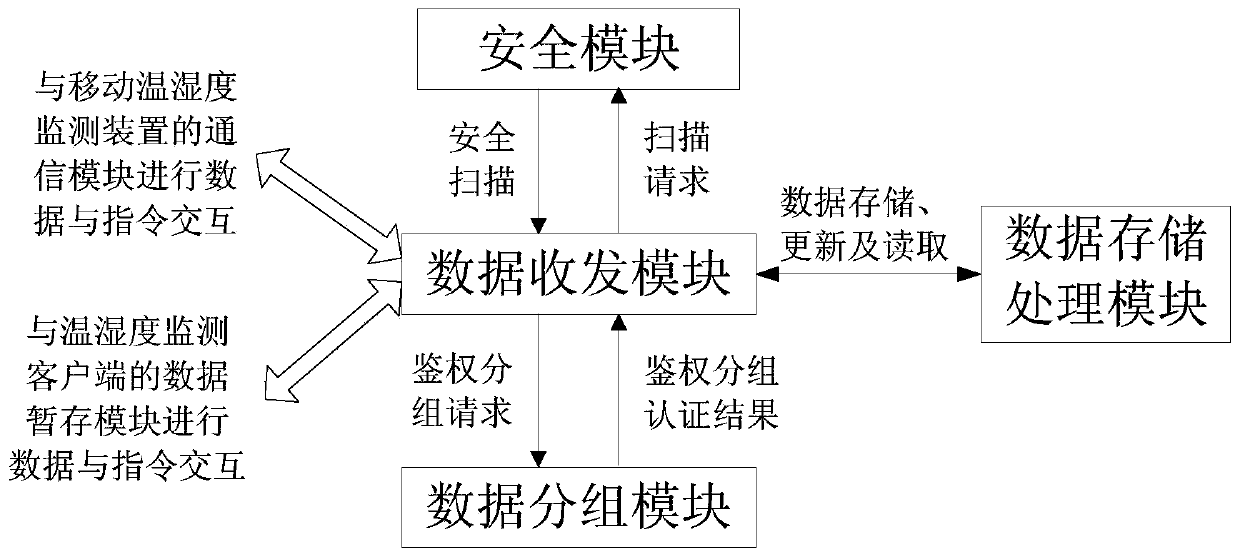

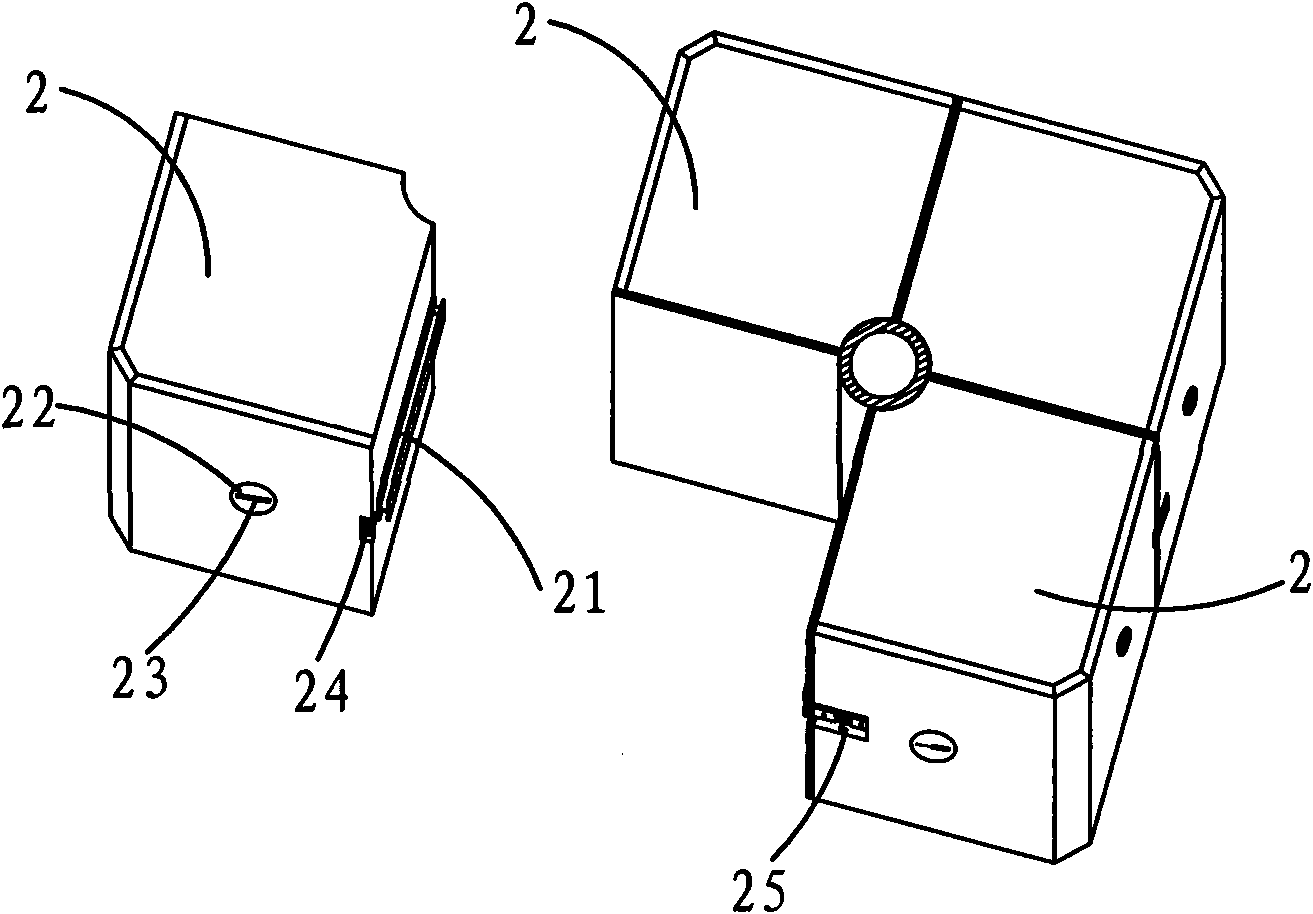

IoT (Internet of Things) whole-course temperature-humidity monitoring system and method for fresh food transport

InactiveCN109945919AComplete recordAchieve freshnessSatellite radio beaconingAlarmsTransport systemTelecommunications network

The invention relates to an IoT whole-course temperature-humidity monitoring system and method for fresh food transport. The system is composed of mobile temperature and humidity monitoring devices mounted in vehicle counters independently, a temperature and humidity control server connected with the mobile temperature and humidity monitoring devices via the telecommunication network, and temperature and humidity monitoring clients. Each temperature and humidity monitoring client is in remote network connection with the corresponding mobile temperature and humidity monitoring device. The integrated performance of a fresh food transport system can be improved effectively, and loss of fresh food in the transport process is reduced greatly; the ambient temperature and humidity in the vehiclecounters are monitored in the transport process, and alarm is raised the moment the temperature / humidity exceeds a set tolerance value; a mobile phone client serves as a receiver, mobility, popularization and portability of a mobile phone are utilized fully, a monitoring staff can obtain alarm information immediately needless of staying at the specific position, and great convenience is provided for the monitoring staff.

Owner:SHENZHEN SUNSEA IOT TECHNOLOGY CO LTD +1

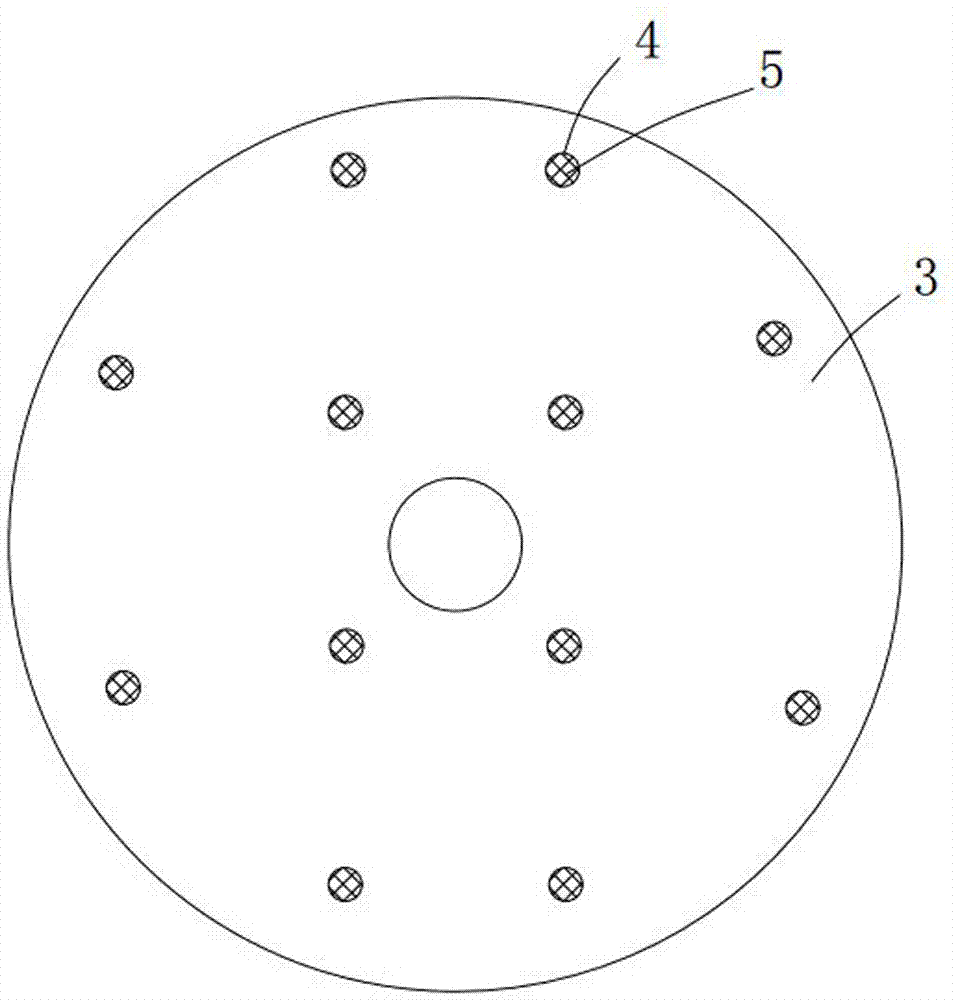

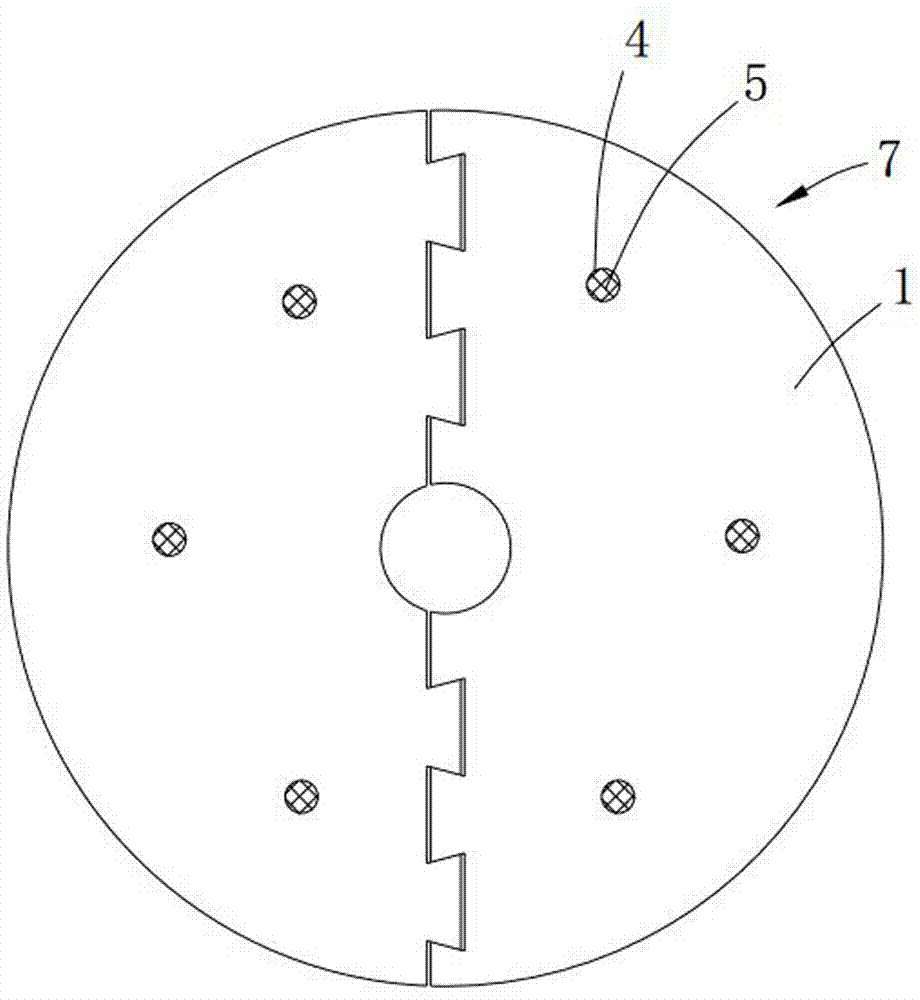

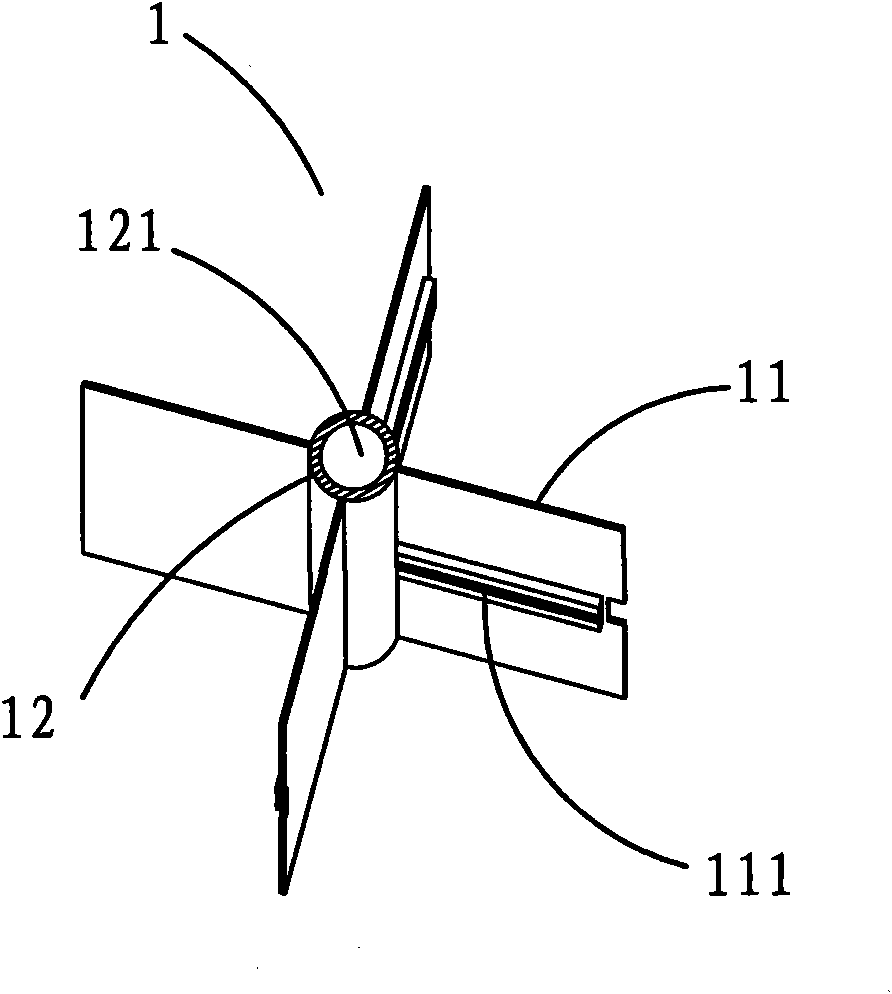

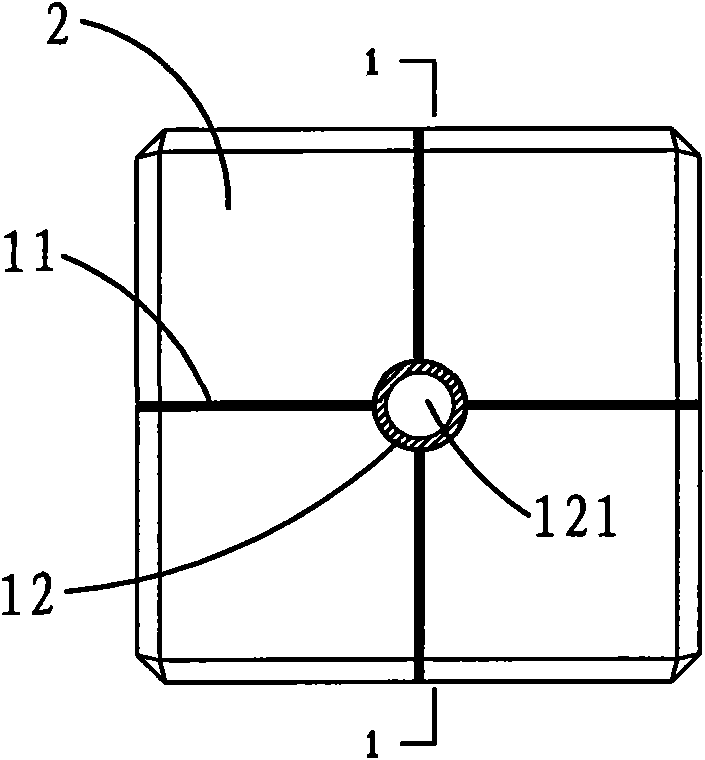

Freely combined diamond die with fixed bracket

ActiveCN102051976AOptimize layoutImprove the forceBuilding componentsForms/shuttering/falseworksReinforced concreteRebar

The invention relates to a reinforced concrete internal model, in particular to a freely combined diamond die with a fixed bracket, which comprises a fixed bracket and a plurality of small diamond dies, wherein adaptive sliding rails are respectively arranged on the fixed bracket and the small diamond dies, and the small diamond dies form the combined diamond die through arranging the sliding rails on the bracket. The fixed bracket comprises a cylinder shaft and four high-strength blades, wherein the blades are mutually vertically and uniformly fixed on the side wall of the cylinder shaft, and sliding rails adapted to the side walls of the square diamond dies are respectively arranged on the side surfaces of the blades along a clockwise direction or anticlockwise direction. The invention is convenient for positioning and easy for construction, is favorable for conveniently solving the contradiction of medium-small embedded parts and the installation of the box body, and is easy to ensure that the concrete is compact.

Owner:林荣

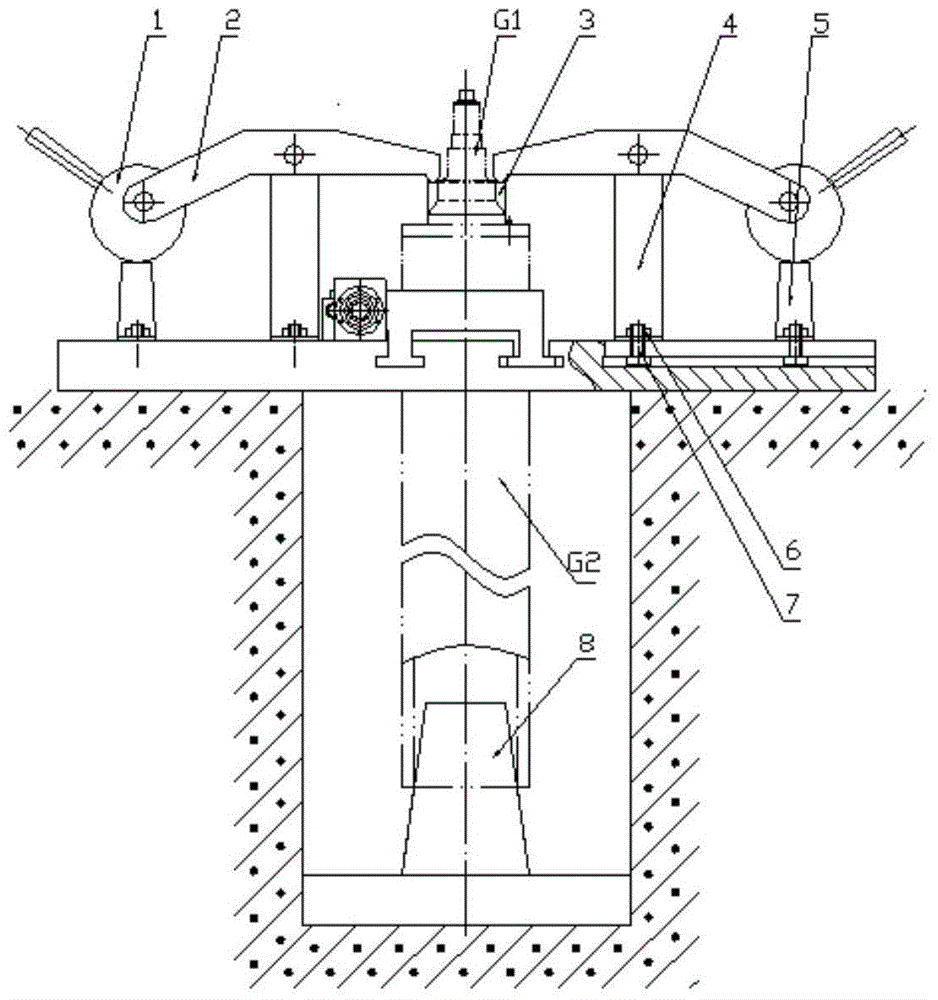

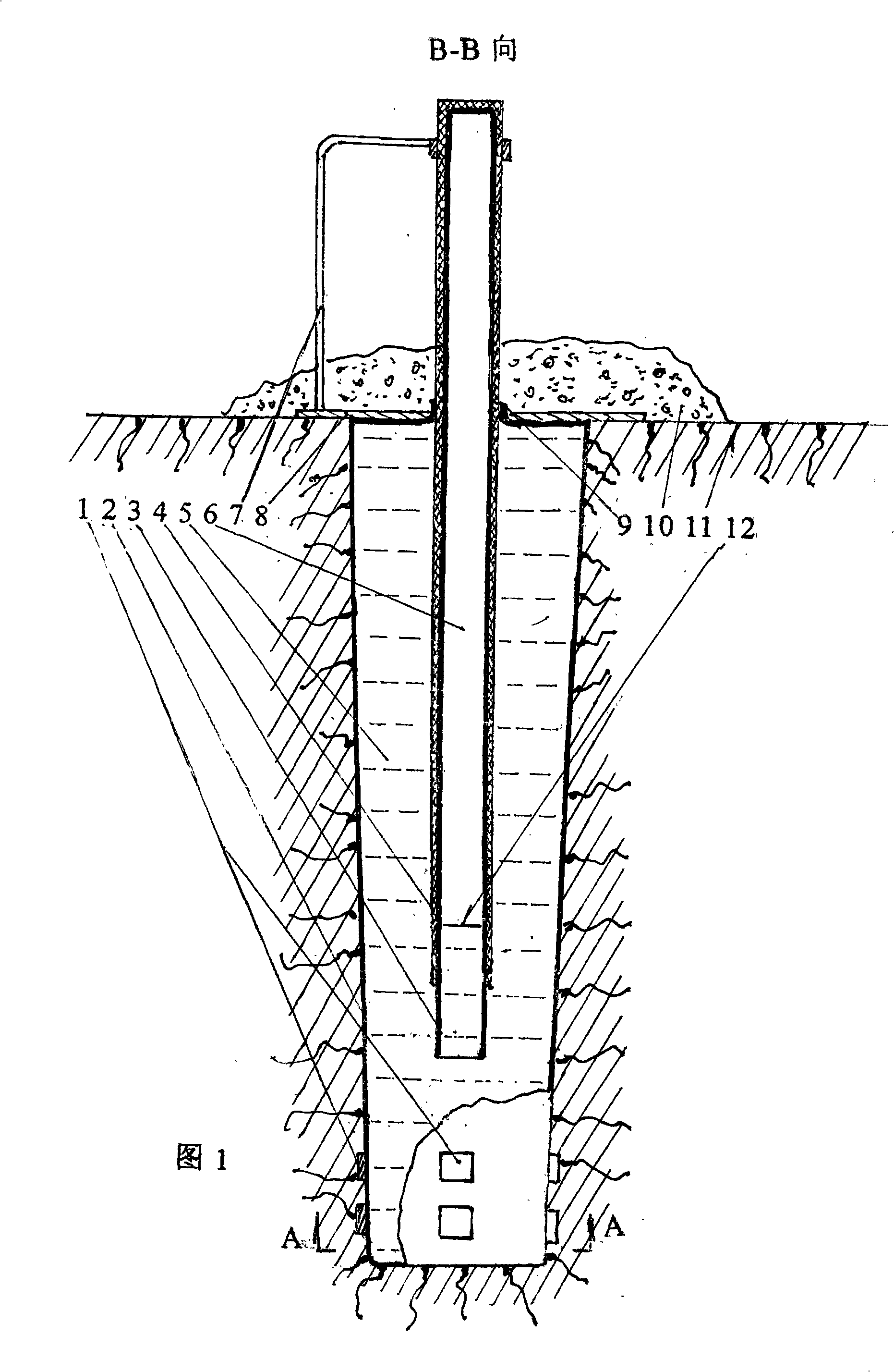

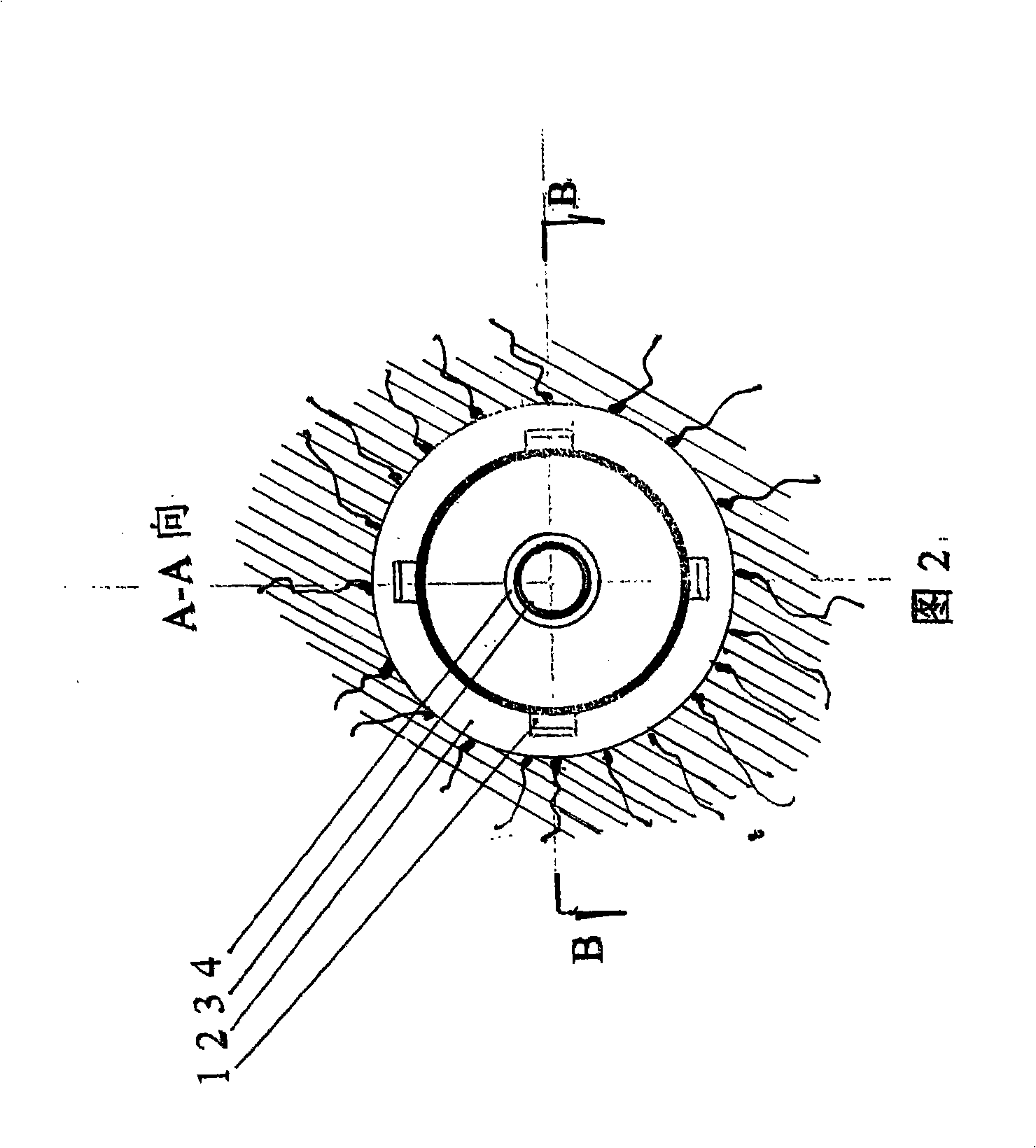

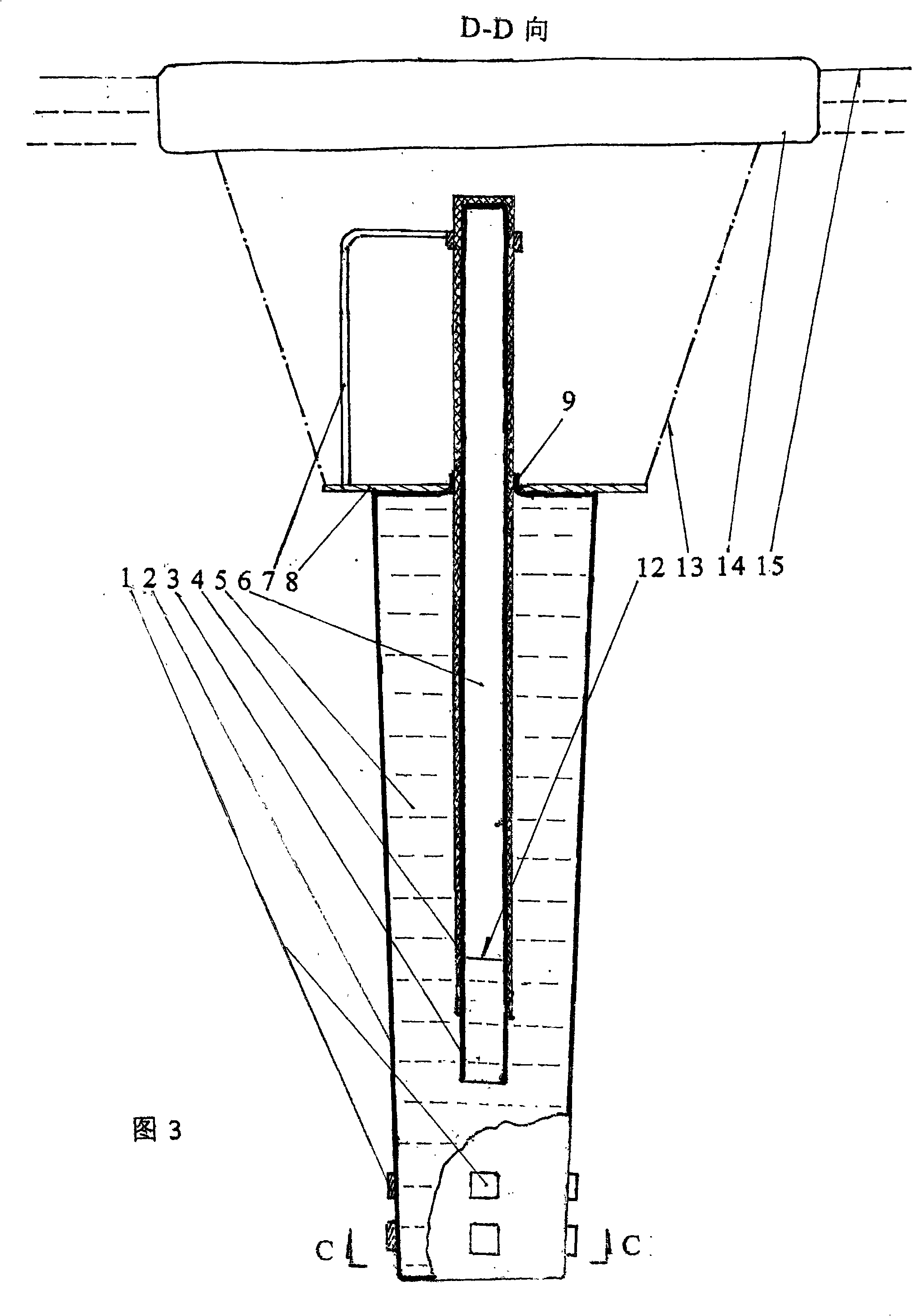

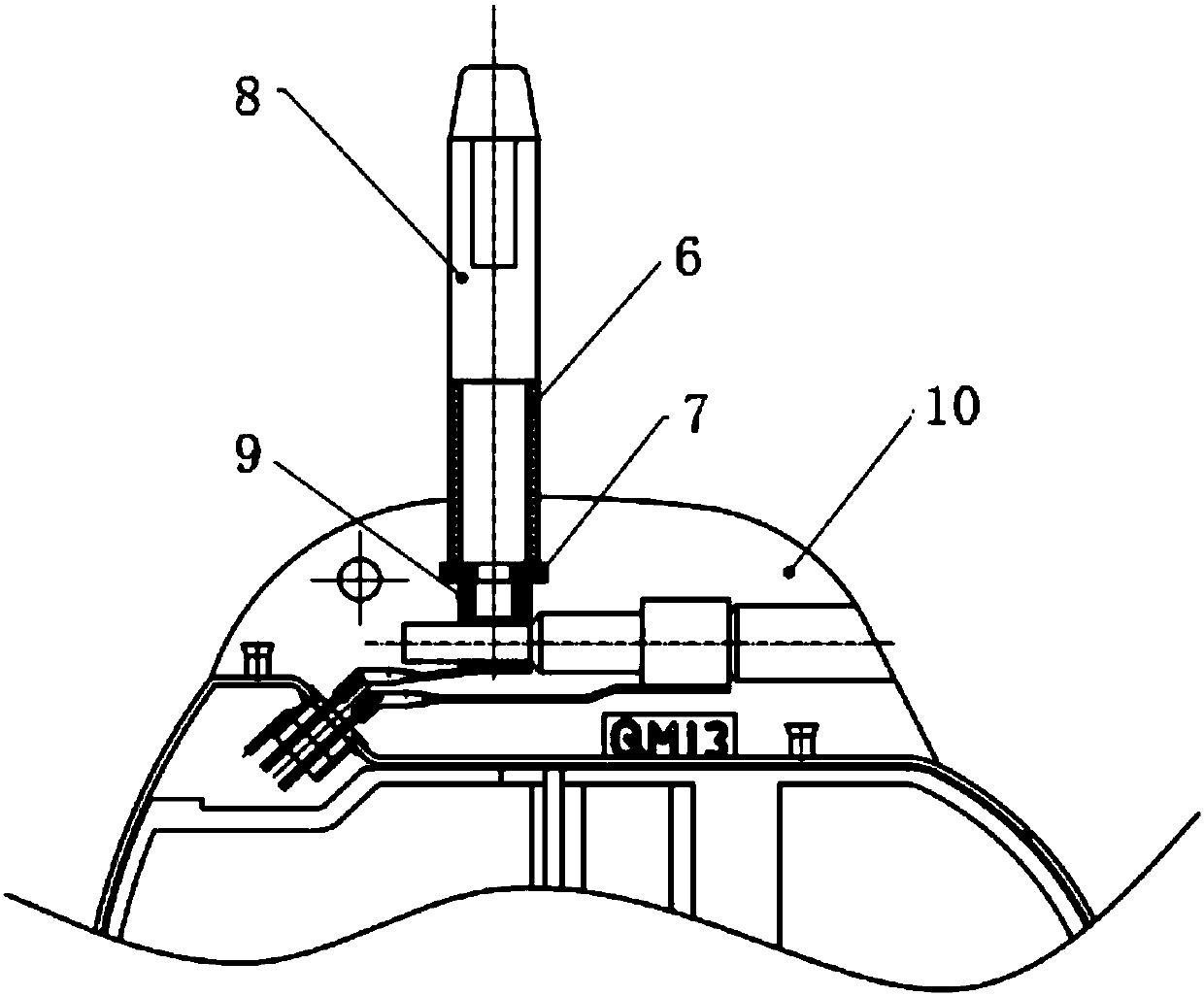

Deep well bag liquid storage type earthquake or tsunami forecasting device

InactiveCN101266298AAvoid solid state interferenceCall the police earlySeismologyEarly warning systemEngineering

An earth-quake or tsunami prediction device of deep-well liquid-storage sack type uses a press-pasted sensor of liquid-storage soft sack type to detect the tendency of the deep layer or seawater so as to predict earth quake or tsunami. The device can effectively avoid the problems that rigid connection is hard for constituting and the solid-state interference geological sensor needs to be arranged near the quake wave source as much as possible for high effective monitoring. The device has low cost and reliable performance, is suitable for widely being arranged all over the world for long-term pre-warning, and can be easily produced. Each device can qualitatively detect the coming direction of the quake wave even quantificationally detect the quake degree, and better performance can be obtained by jointing a plurality of the devices into a network. Further, the invention relates to a soft sack liquid-storage method which disposes a soft sack in a pit deepened by explosion, which can avoid water leak or pollution of the concrete cistern, and is suitable for storing oil gas or chemicals thereby avoiding the overturn danger of vertical tank.

Owner:罗晓晖

Automatic gear shifting system with synchronizer for electric vehicle

PendingCN105605165ARealize automatic shiftingNo radialSpeed controllerToothed gearingsElectric vehicleControl theory

The invention discloses an automatic gear shifting system with a synchronizer for an electric vehicle. The automatic gear shifting system comprises a gearbox, the synchronizer, an electromagnet, a motor and a controller. The gearbox comprises an input shaft, an intermediate shaft and an output shaft, the synchronizer is movably penetratingly arranged on the output shaft and is connected with a shifting fork, the shifting fork is connected with a shifting fork shaft, the electromagnet is connected with the shifting fork shaft, the motor is connected with the input shaft, and the controller is connected with the motor and the electromagnet. The automatic gear shifting system has the advantages that electric signals can be transmitted to the electromagnet by the controller, the shifting fork shaft can be controlled via the electromagnet, the shifting fork can traverse up and down under the control of the electromagnet via the shifting fork shaft, the synchronizer can be driven by the shifting fork to traverse up and down between a first output shaft gear and a second output shaft gear when the shifting fork traverses up and down, accordingly, the synchronizer can work with the first output shaft gear or the second output shaft gear, and automatic gear shifting effects can be realized.

Owner:JIANGSU CRRC ELECTRIC CO LTD

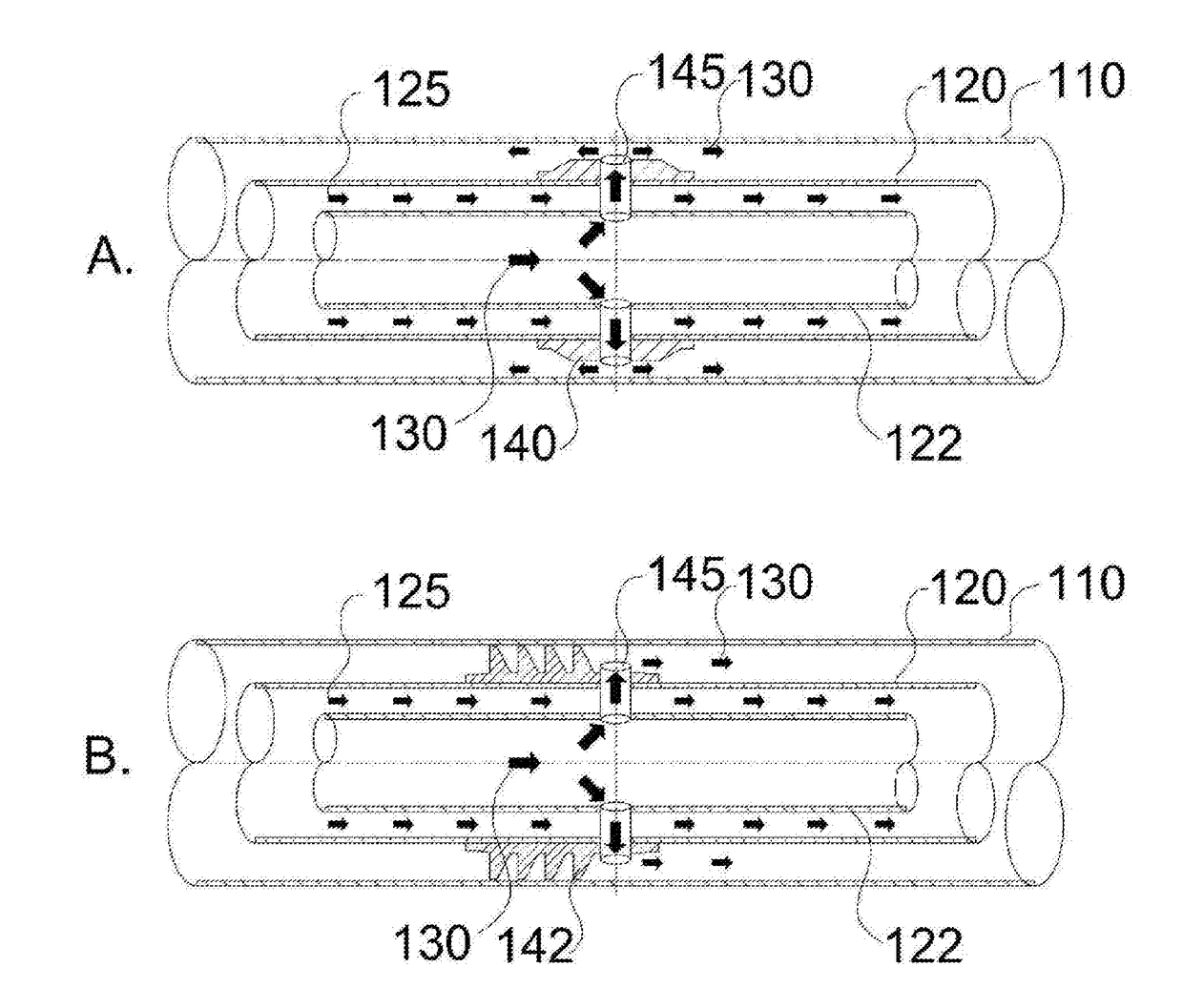

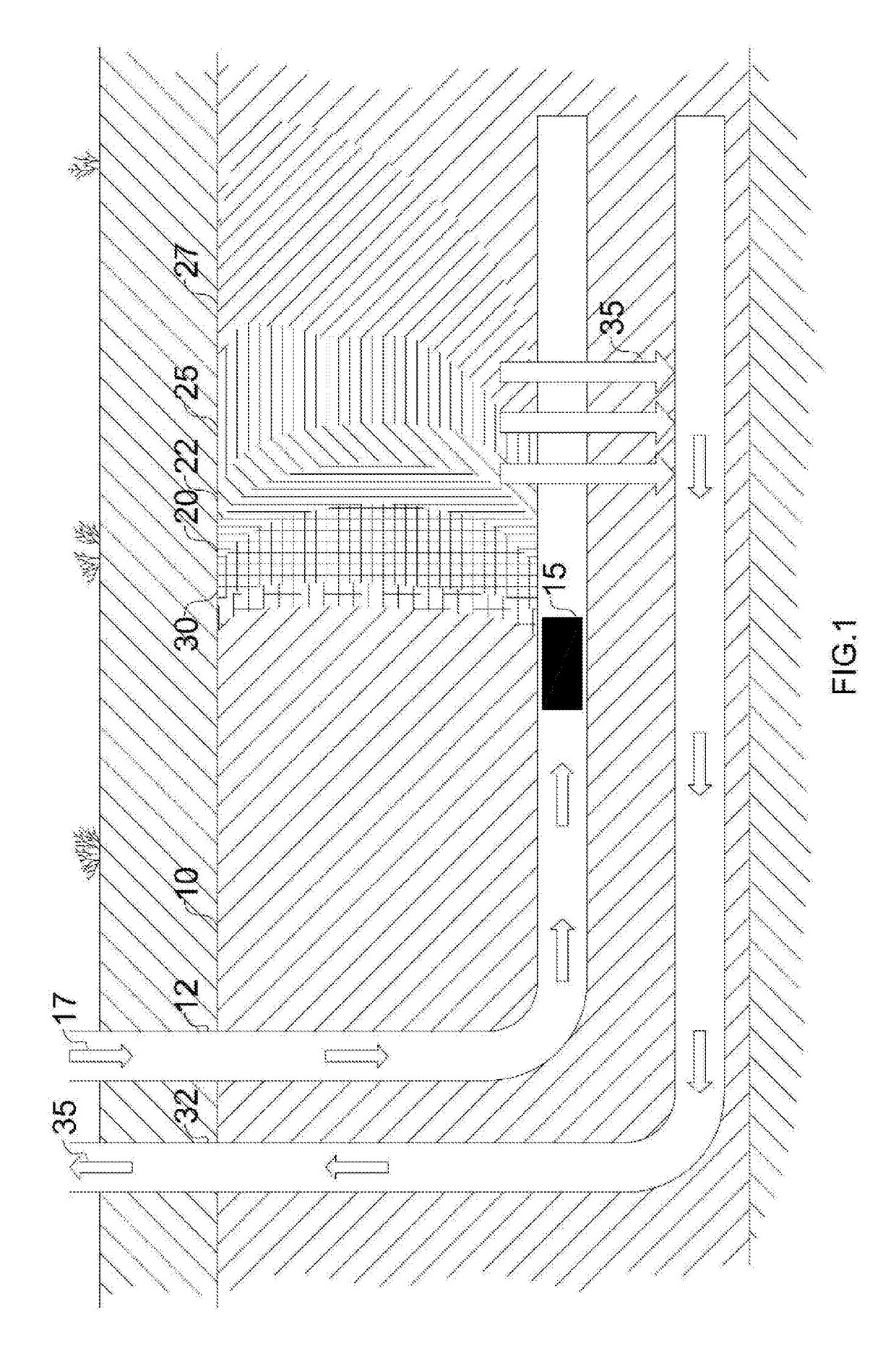

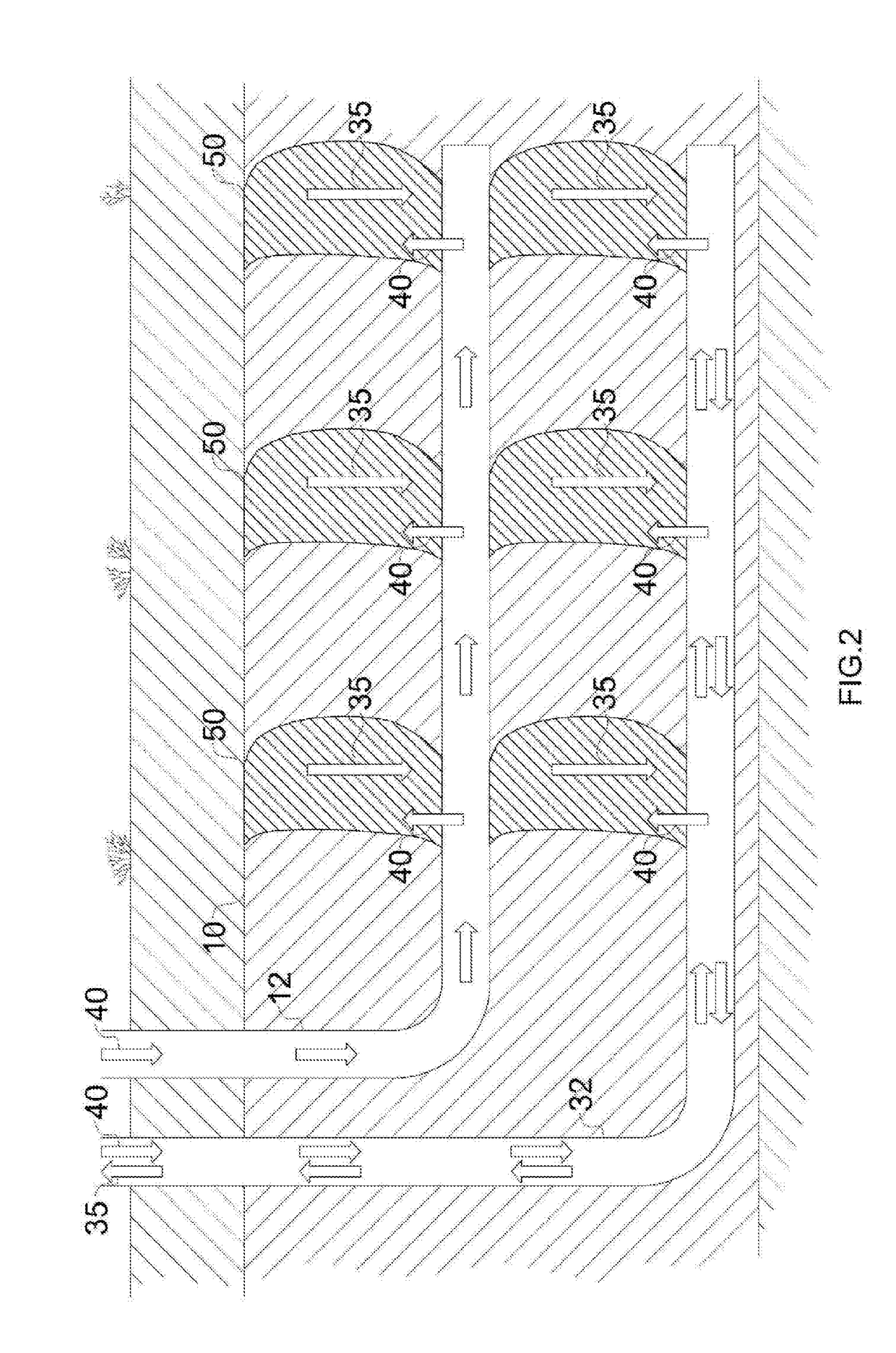

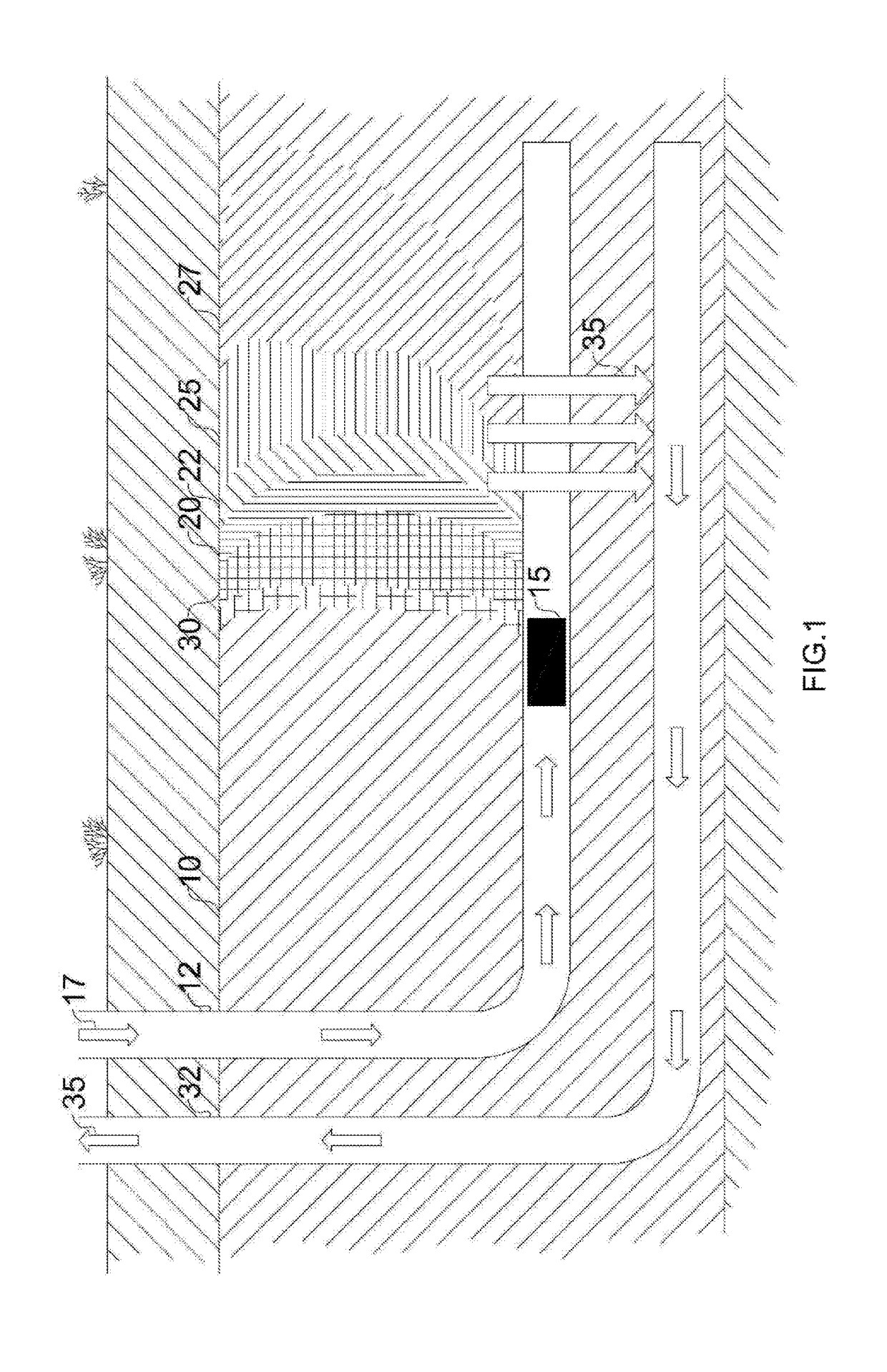

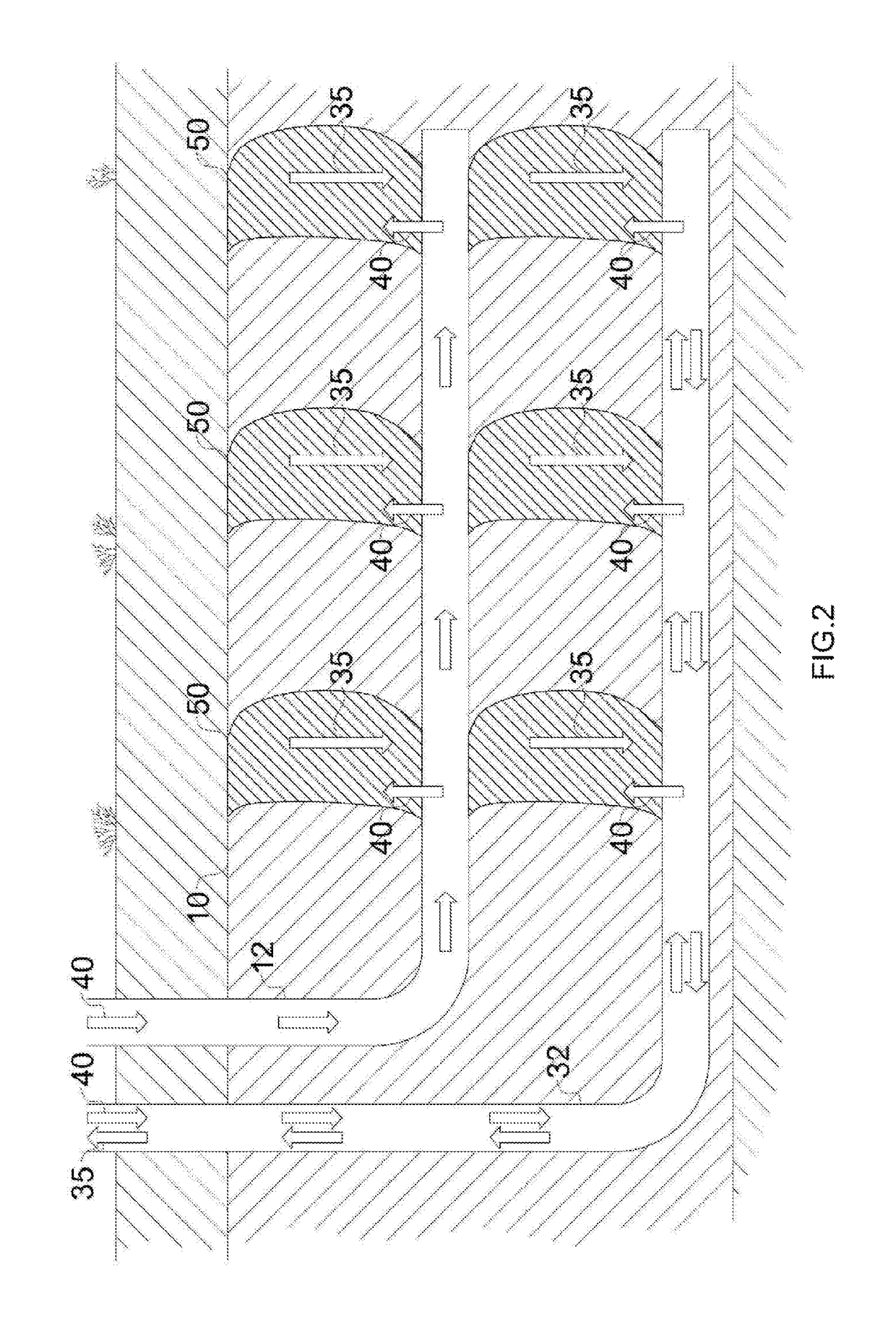

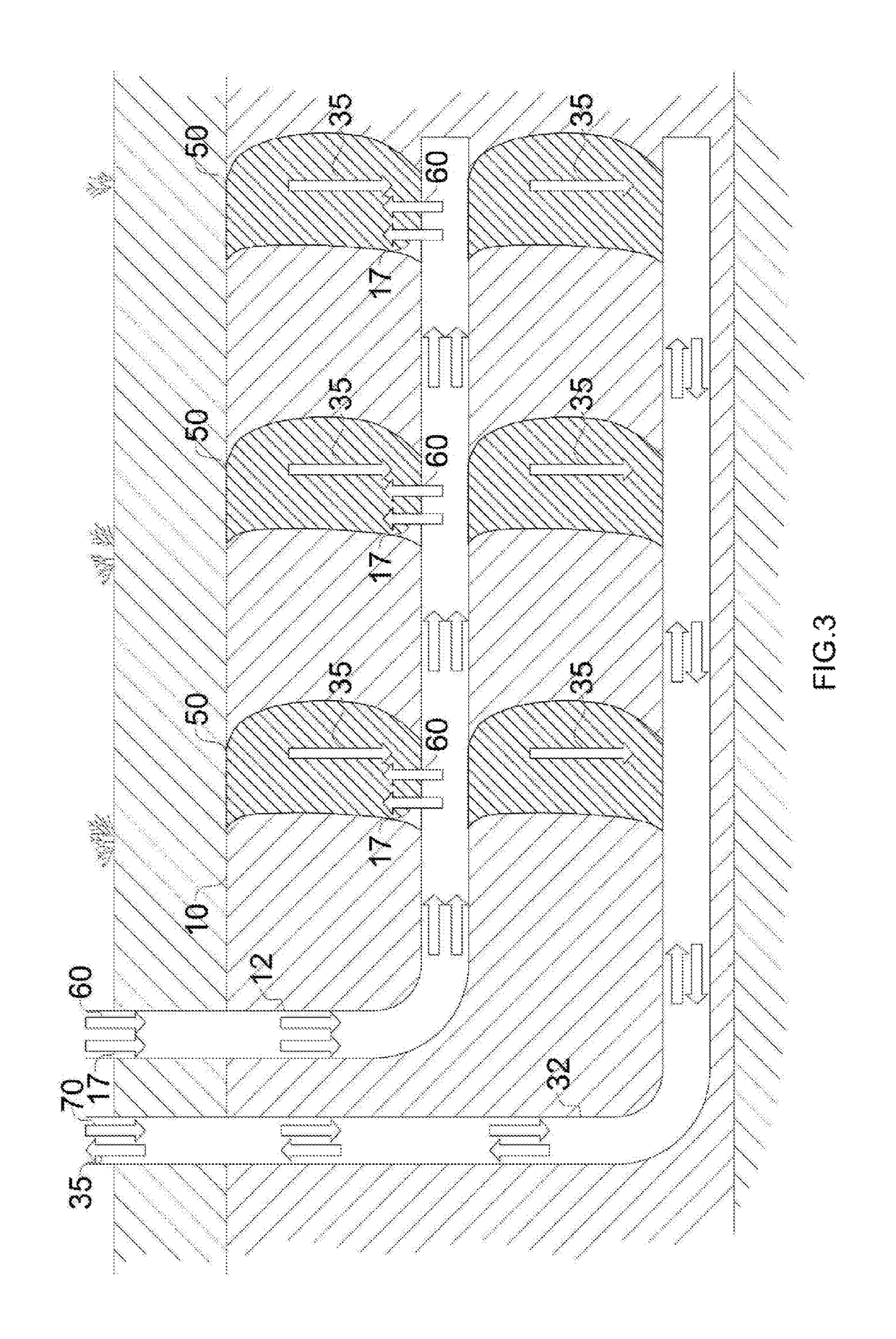

Moving injection gravity drainage for heavy oil recovery

The invention provides methods for mobilising and recovering petroleum from subterranean formations by in situ combustion.

Owner:MARTIN PARRY TECH PTY LTD

High-strength welding device

InactiveCN105583559ASimple structureEasy to useWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHigh intensity

Provided is a high-strength welding device. The high-strength welding device is characterized in that the high-strength welding device comprises a horizontal welding plate, a vertical welding plate, a first limiting plate, a second welding plate and welding holes; the horizontal welding plate is vertical to the vertical welding plate; and the welding holes, two to five, for the horizontal welding plate and the vertical welding plate are uniformly arranged in the first limiting plate and the second limiting plate.The high-strength welding device has advantages: the high-strength welding device is simple in structure and convenient to install and use and has good welding effect and is not easily deformed; no movement or deformation is caused; and the device is easy in process, convenient in operation and low in production cost.

Owner:刘海棠

Moving injection gravity drainage for heavy oil recovery

The invention provides methods for mobilizing and recovering petroleum from subterranean formations by in situ combustion.

Owner:MARTIN PARRY TECH PTY LTD

High-temperature resistant and highly-condensed type waterproof seal puddle

InactiveCN102993578AOptimizing the Group Distribution RatioNo overflowOther chemical processesEngineeringButyl rubber

The invention discloses a high-temperature resistant and highly-condensed type waterproof seal puddle. The seal puddle is characterized by comprising the following raw materials in parts by weight: 30 to 45 parts of butadiene rubber, 30 to 45 parts of polyisobutene, 5 to 10 parts of carbon black, 0.5 to 1 parts of ebonite, 5 to 10 parts of nano calcium carbonate, 5 to 10 parts of superfine talcum powder, 0.3 to 1 part of antioxidant 1010, and 0.3 to 1 parts of anti-aging agent RD. The high-temperature resistant and highly-condensed type waterproof seal puddle has the advantages that the component proportion in the prescription is optimized, and the nano calcium carbonate is prepared, thus the puddle cannot overflow, flow and move at high temperature of 130 to 150 DEG C or under the external force of the type mentioned above, and has higher resistance to high temperature and high coagulative power.

Owner:无锡昆成新材料科技有限公司

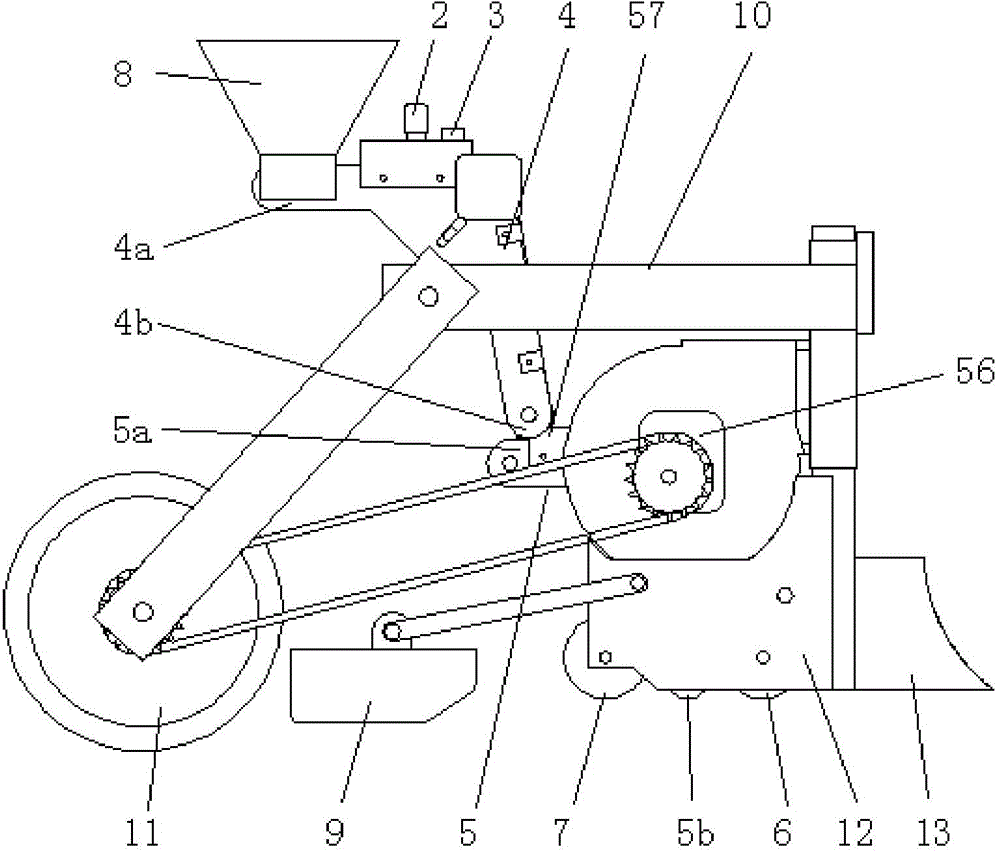

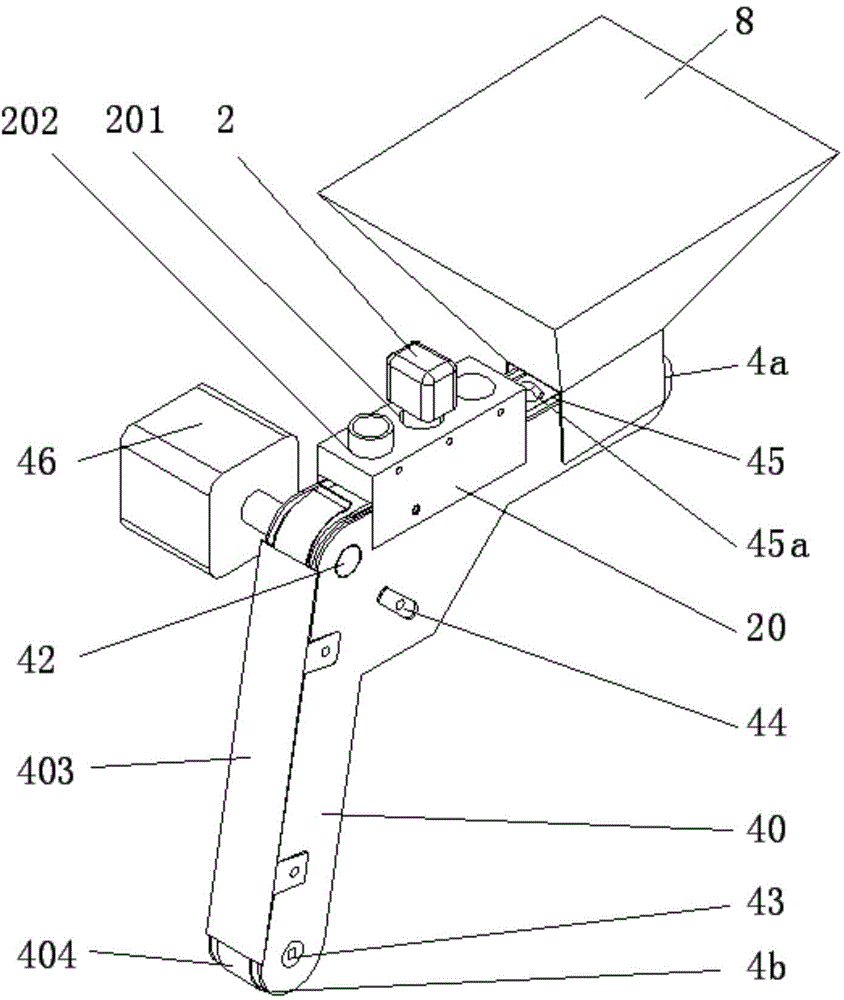

Directional corn seeding machine

InactiveCN105660003AQuick identificationAccurate removalSeed depositing seeder partsRegular seed deposition machinesEngineeringMechanical engineering

The invention discloses a directional corn seeding machine. The directional corn seeding machine comprises a seeding machine frame; a cache material hopper for containing the corn granules is installed on the seeding machine frame; a granule positioning mechanism is installed on the seeding machine frame; the granule positioning mechanism comprises a first material inlet end and a first material outlet end, wherein the first material inlet end is corresponding to the material outlet of the cache material hopper so as to receive the corn granules discharged from the cache material hopper; the corn granules are positioned in the predetermined direction by the first material inlet end and then conveyed to the first material outlet end; a seed arranging mechanism is installed on the seeding machine frame; the seed arranging mechanism comprises a second material inlet end and a second material outlet end, wherein the second material inlet end is corresponding to the first material outlet end so as to receive the corn granules discharged from the first material outlet end; the corn granules are arranged in the predetermined direction and intervals by the second material inlet end and then conveyed to the second material outlet end; and the corn granules are then discharged from the second material outlet end and placed on a seedbed. The corn granules are seeded in the predetermined direction and intervals by the directional corn seeding machine, so that the corn seedlings grow in the predetermined direction and predetermined intervals; thus, illumination conditions of the corns are improved, and yields of the corns are thereby increased.

Owner:TIANJIN FUKANG AGRI DEV

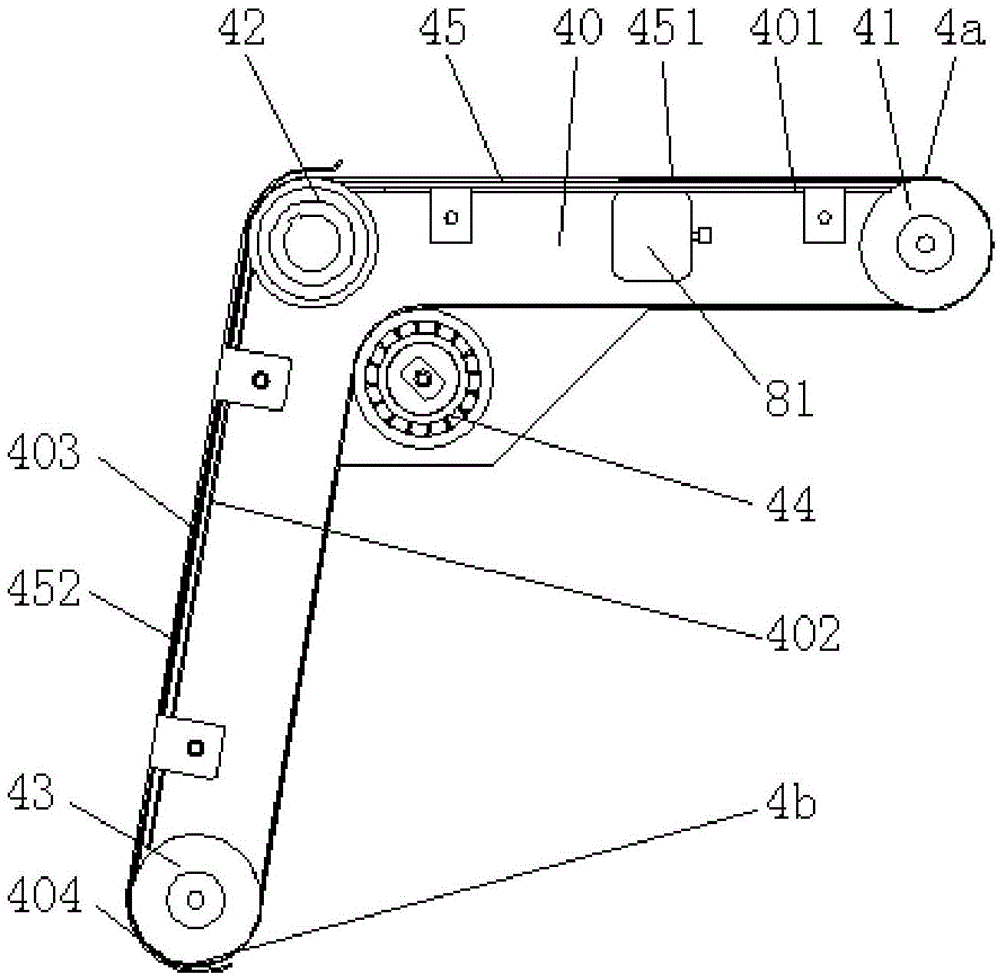

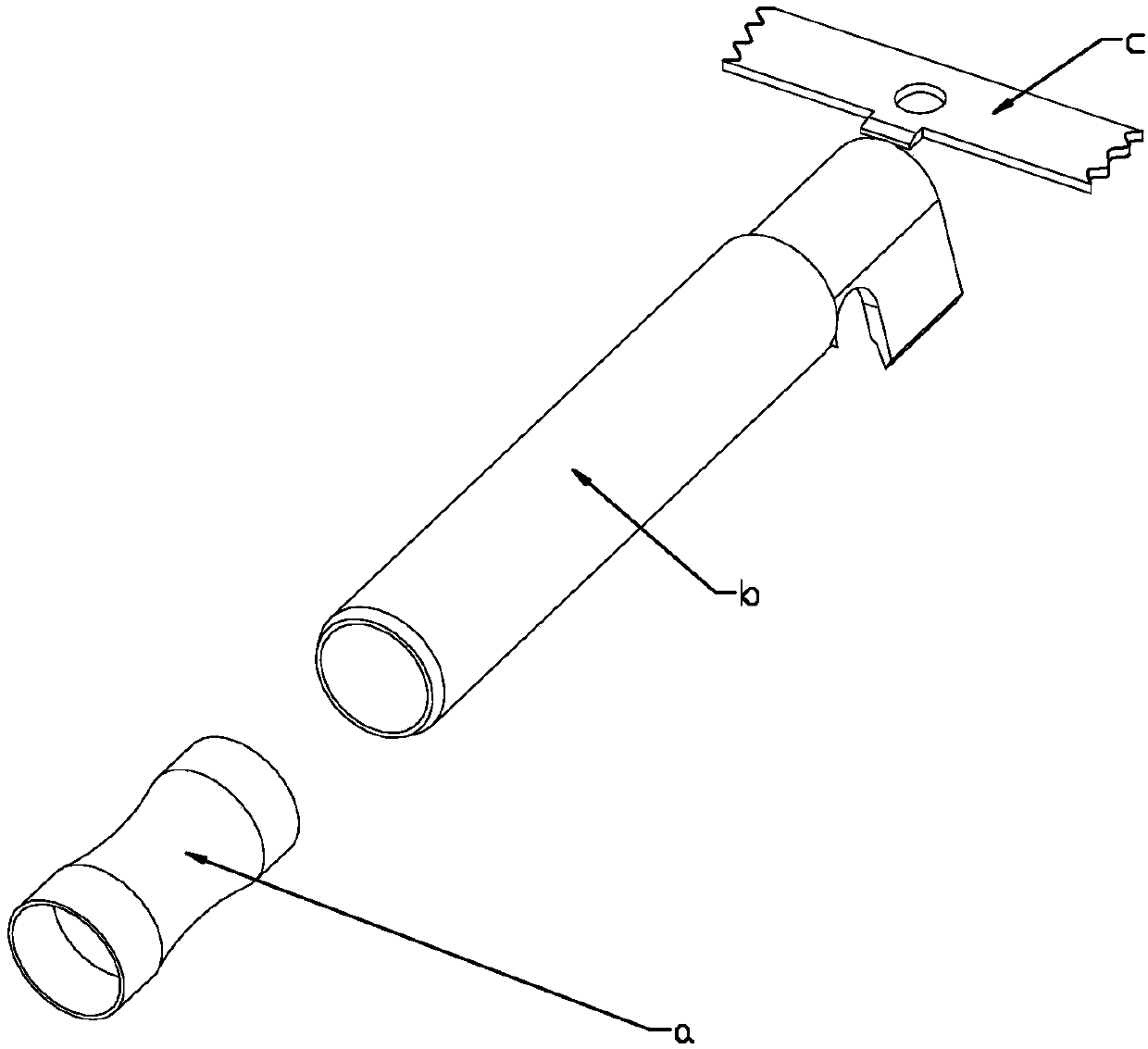

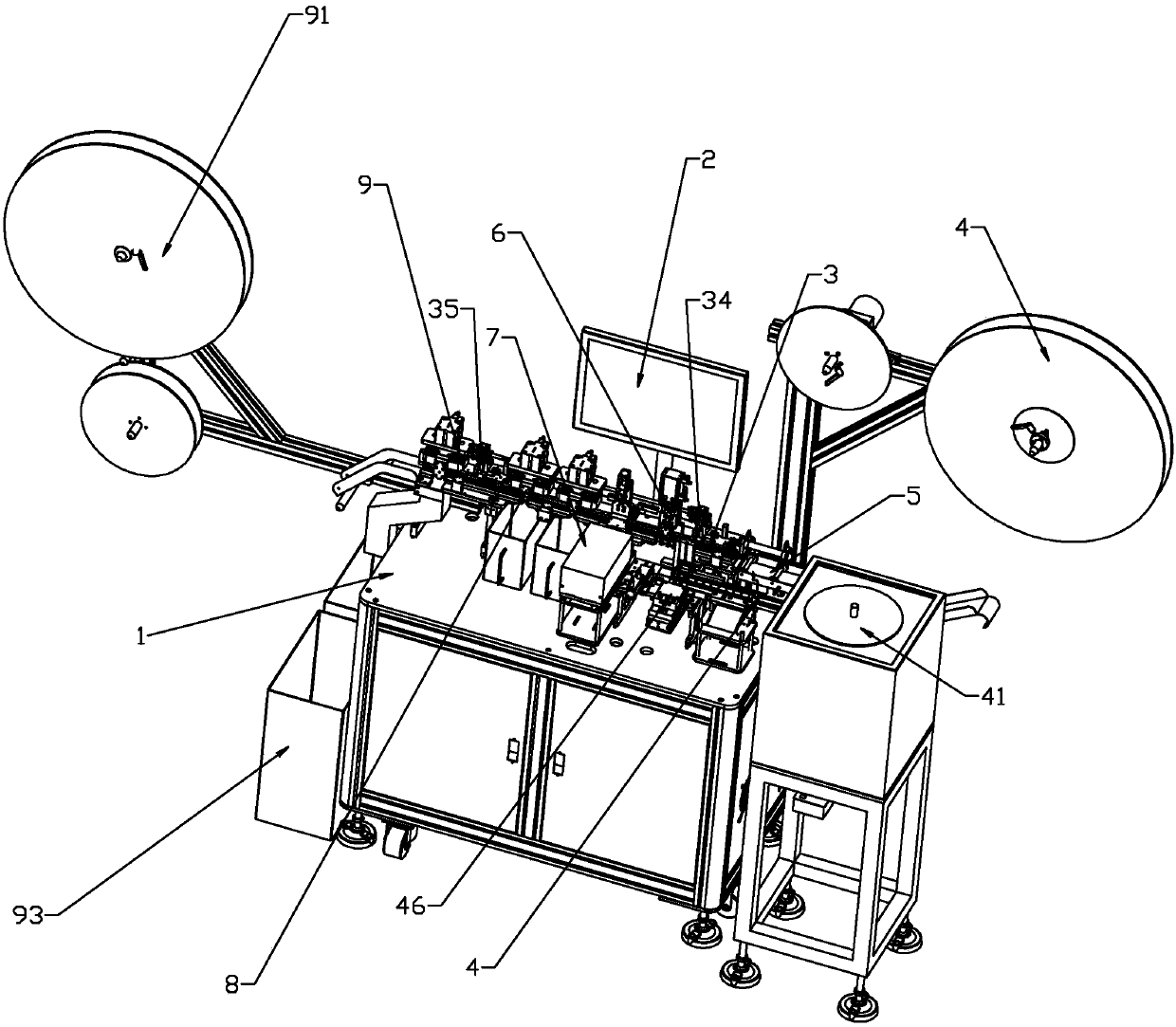

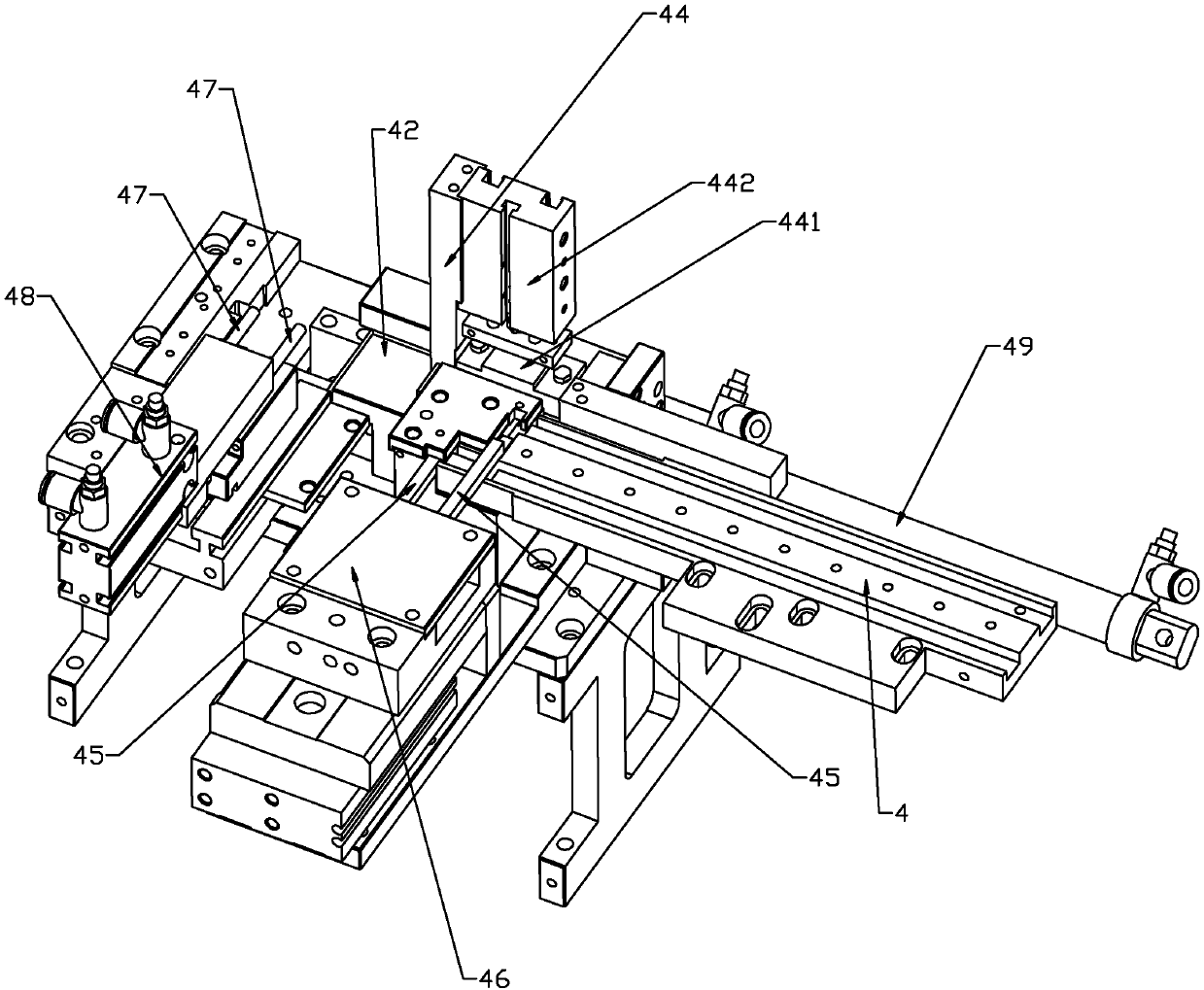

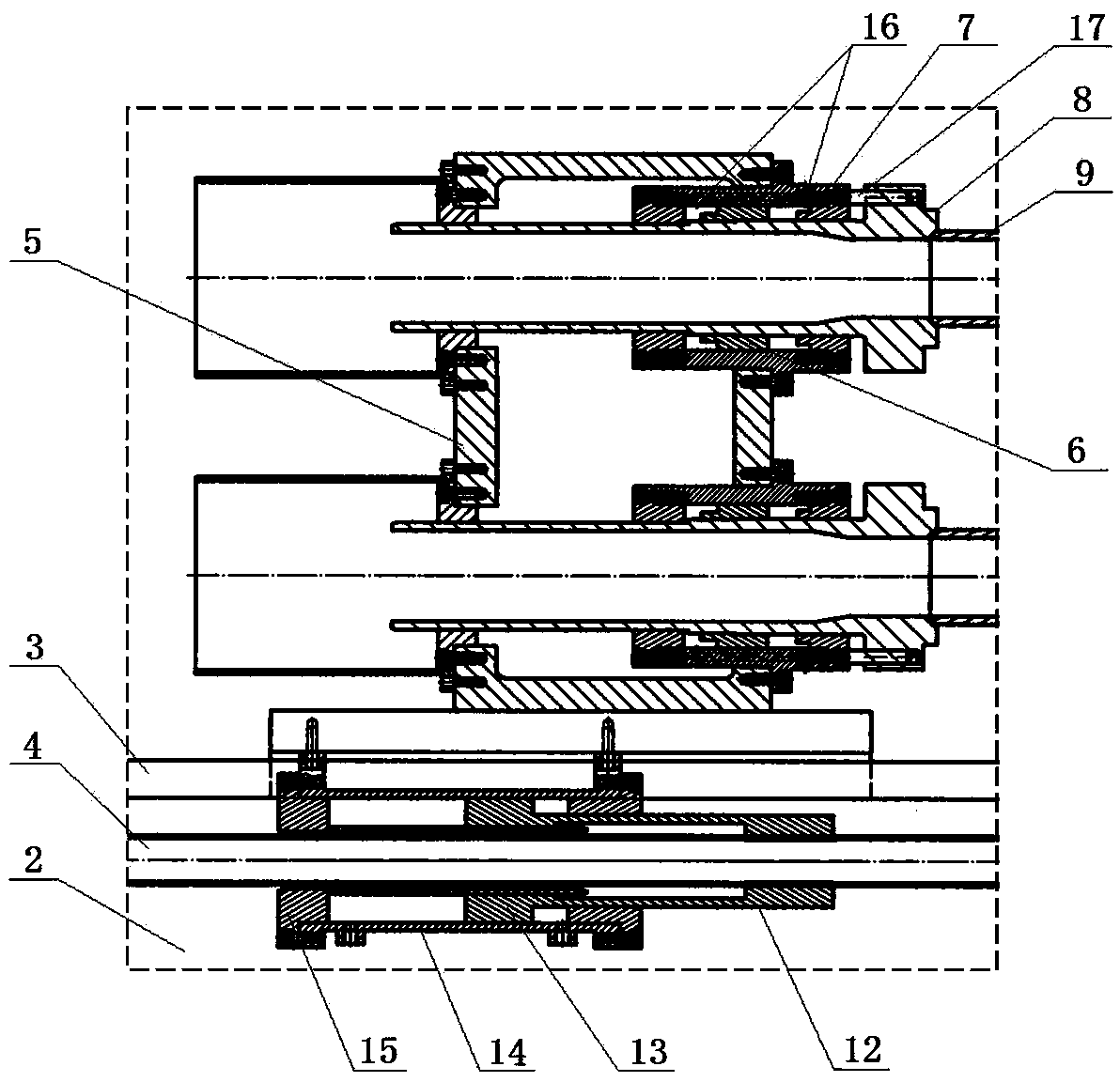

Drum spring and insertion sleeve automatic assembling machine with rejecting function

PendingCN107834340AEnhance the imageGuaranteed comparison efficiencyContact member manufacturingContact member assembly/disassemblyImage detectionEngineering

The invention relates to a drum spring and insertion sleeve automatic assembling machine with a rejecting function, which comprises a frame and a control processor. The frame is provided with a main transmission track and a drum spring distribution track in parallel, and the main transmission track is provided with an insertion sleeve transmission device. The main transmission track is provided with a coiled material unwinding device, a coiled material leveling device, a fixing device, an image detection device, a rejecting device and a finished product output device in order in the transmission direction. A drum spring vibration disk is disposed at one end of the drum spring distribution track, and the other end is provided with an assembly device. The main transmission track is providedwith an alignment device that performs alignment at multiple positions on the coiled material. With the above solution, the present invention provides the drum spring and insertion sleeve automatic assembling machine with the rejecting function, which has an on-line quality inspection function, eliminates the non-qualified products in a timely manner, and improves assembly efficiency and installation strength.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

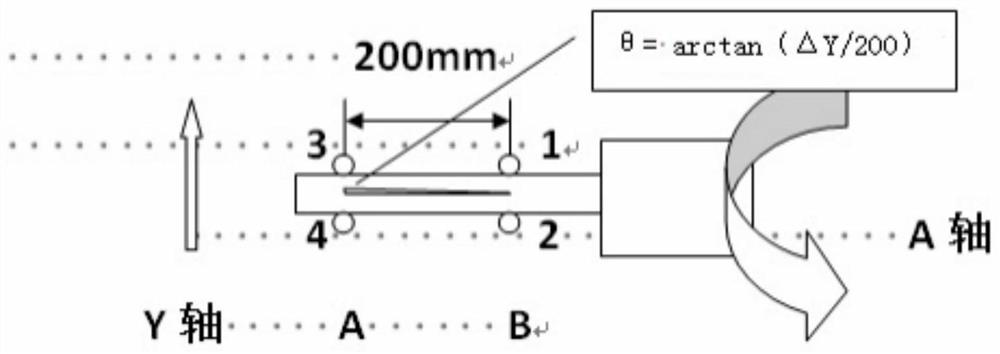

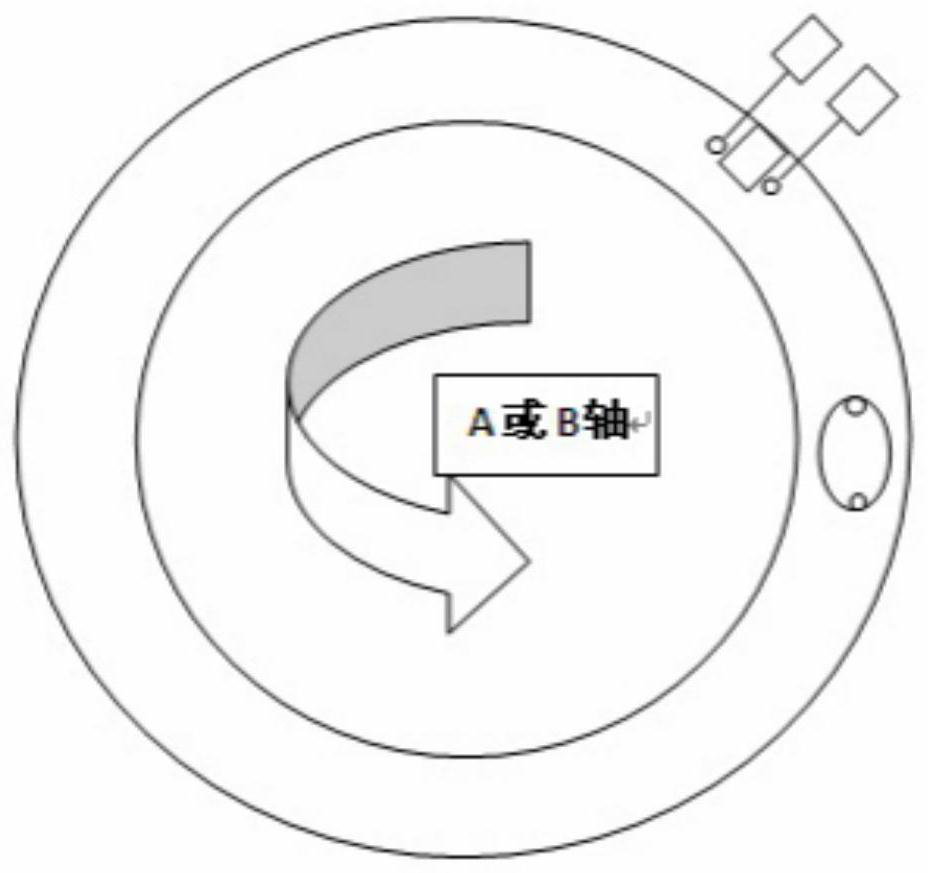

Numerical control machining angle automatic measurement method

ActiveCN112496863AEnsure safetyAccurate measurementMeasurement/indication equipmentsCharacter and pattern recognitionNumerical controlData ingestion

The invention relates to a numerical control machining technology, specifically to a numerical control machining angle automatic measurement method. The method comprises the following steps: (1) analyzing a numerical control machine tool structure and a part machining process, analyzing a measurement mode according to part angle measurement characteristic factors, and determining a moving shaft and a data extraction shaft so as to determine a characteristic measurement scheme; (2) establishing a characteristic measurement model according to the characteristic measurement scheme, classifying part characteristics, and compiling a modular characteristic measurement program for different part characteristics; and (3) establishing a whole-process mistake-proofing system of a data measurement and acquisition period according to the characteristic measurement program. The method improves the control precision of the rotation angle of a machine tool, guarantees the machining quality of parts,effectively improves the machining automation, standardization and intelligence level, improves the machining efficiency, reduces the cost, and reduces the machining risk.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

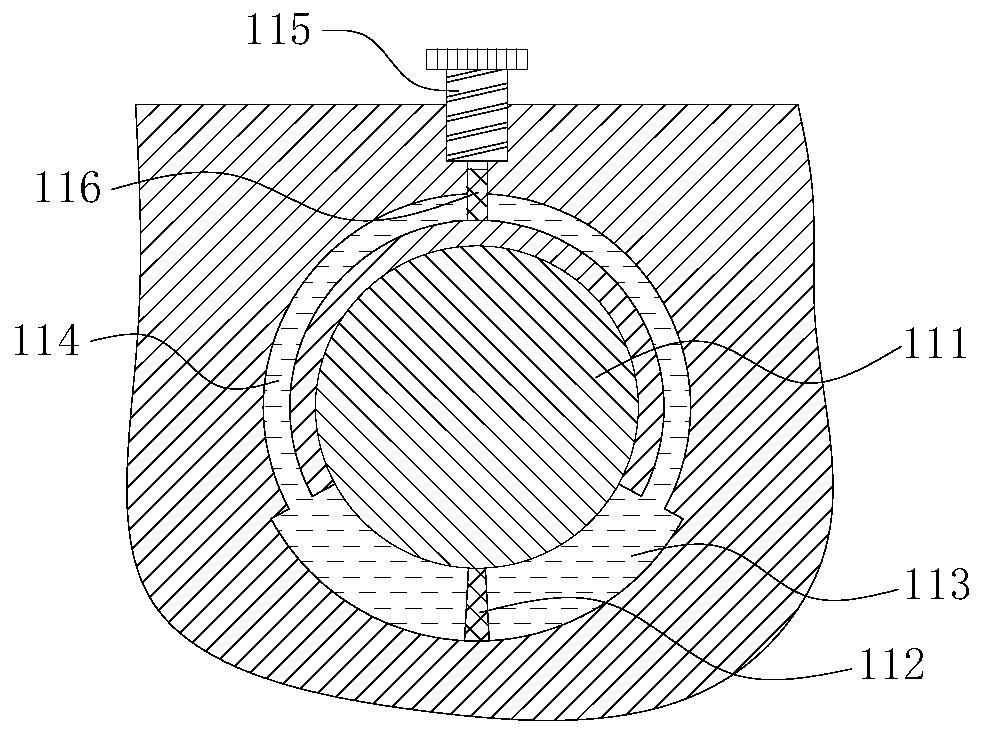

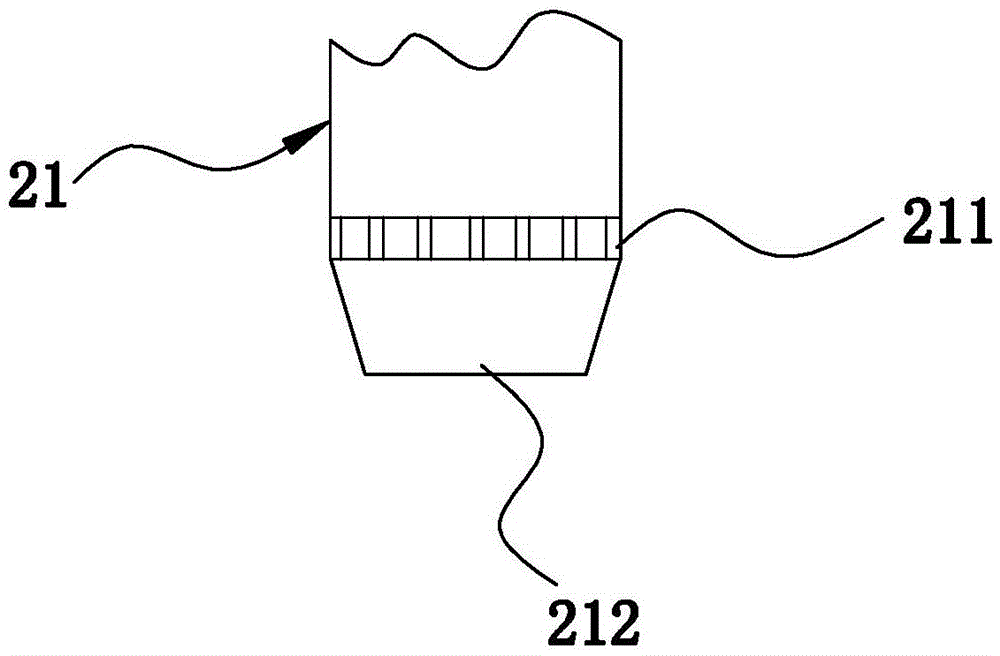

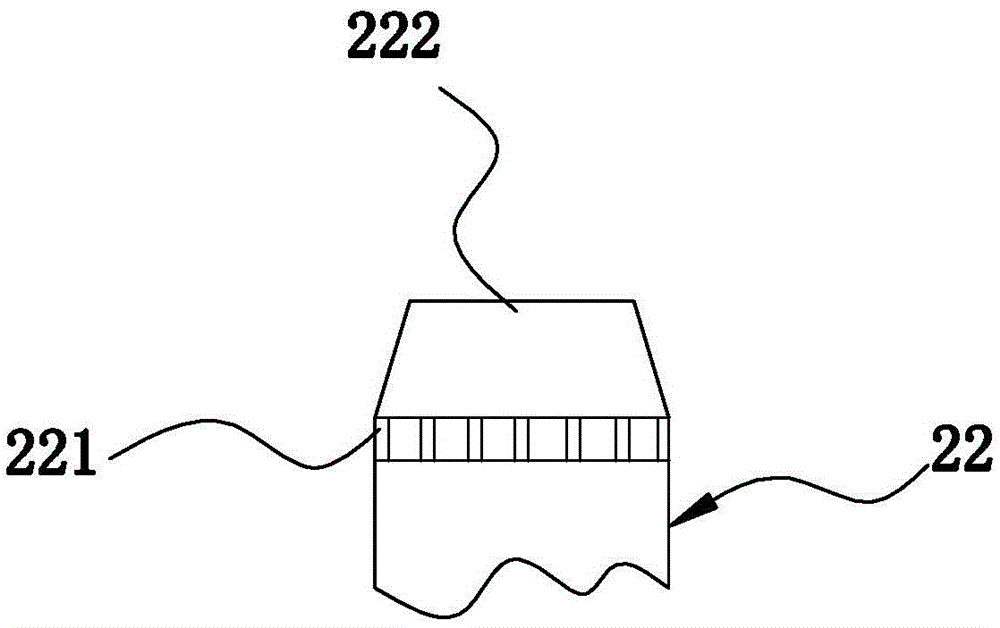

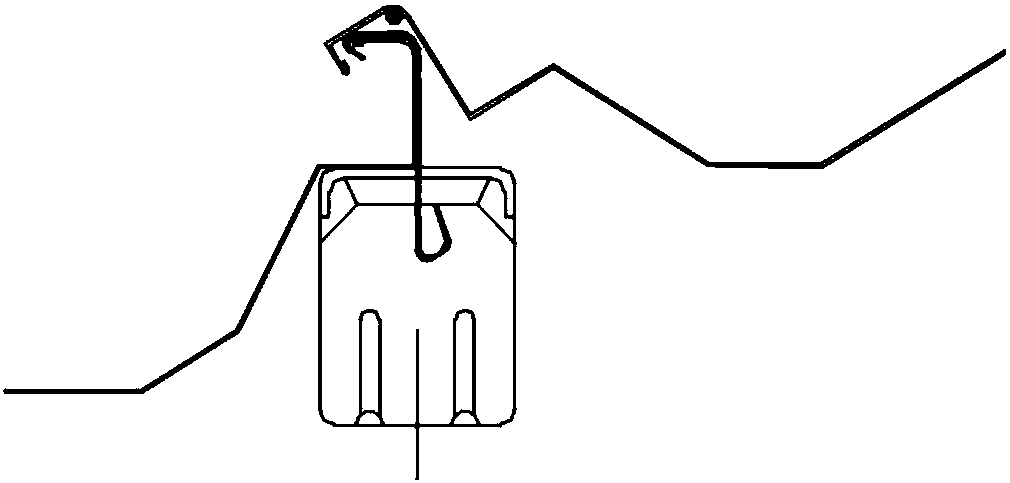

Implantable cardiac pacemaker connector sealing structure

PendingCN107596563ANo mobilityWon't fall offEngine sealsElectrotherapyCardiac pacemaker electrodeEngineering

Disclosed is an implantable cardiac pacemaker connector sealing structure. An inverted-T shaped cylinder sealing cavity is formed above a mounting hole of a connector of the implantable cardiac pacemaker connector sealing structure. Besides, the small end inner diameter of the sealing cavity is larger than the inner diameter of the mounting hole of the connector. An inverted-T shaped cylinder sealing plug is installed in the cylinder sealing cavity, and the small end outer diameter of the cylinder sealing plug is slightly larger than the small end inner diameter of the sealing cavity, so thatthe small end of the cylinder sealing plug seals the small end of the cylinder sealing cavity. The large end of the cylinder sealing plug is embedded into the large end of the cylinder sealing cavityto achieve positioning. According to the implantable cardiac pacemaker connector sealing structure, a cylinder cavity structure of which the upper end is small and the lower end is large is adopted, so that not only is the sealing performance ensured, but also it is ensured that the sealing plug is not likely to move or fall off because a torque spanner is inserted in or pulled out, and the sealing requirements of the implantable cardiac pacemaker are met.

Owner:SHAANXI QINMING MEDICAL CO LTD

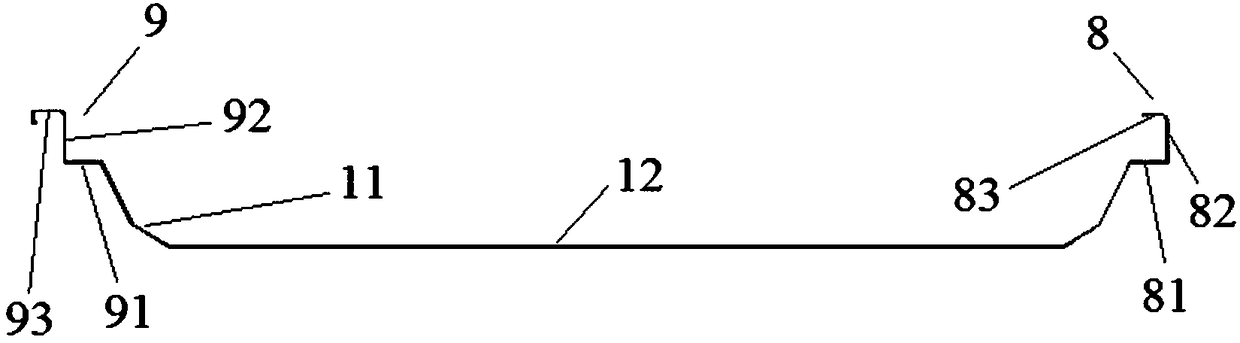

Lock stitch metal roof board system

PendingCN108691394AImprove compactnessImprove wind resistanceRoof covering using slabs/sheetsEngineering

The invention relates to a lock stitch metal roof board system comprising a roof board, a modulus ruler and a connecting support fixedly connecting the roof board on the modulus ruler; the roof boardcomprises a plane base plate, and a male rib plate and a female rib plate arranged on two ends of the plane base plate; a slide hook is arranged between two metal roof boards; the female rib plate wraps the slide hook and the top of the male rib plate of the adjacent metal roof board, and a 360-degree lock stitch is formed via an undercut machine through one-time bending; the modulus ruler comprises a horizontal bottom and lugs located on two sides of the horizontal bottom; the support bottom is connected in support mount holes of the modulus ruler; the slide hook is clamped on top of the support. The lock stitch metal roof board system is good in wind resistance and waterproof performances, high in mounting precision, and more suitable for existing light steel building roof systems.

Owner:SHANGHAI BESTSTEEL STEEL STRUCTURE BUILDING

Sheet metal part welding device

InactiveCN102371459ANo mobilityNo misalignmentWelding/cutting auxillary devicesAuxillary welding devicesCopperMechanical engineering

The invention relates to the field of welding dies, in particular to a sheet metal part welding device. The sheet metal part welding device comprises a welding copper plate and a support plate, wherein the copper plate is combined with the sheet metal part when welding, and the support plate is used for placing the welding copper plate. The sheet metal part welding device is characterized by also comprising fixed barrier strips and movable barrier strips for clamping two sides of the welding copper plate, wherein the movable barrier strips can move along a groove on the support plate. The sheet metal part welding device also comprises an upper platen for covering the sheet metal part. The sheet metal part welding device has the beneficial effect that an upper elastic flexible platen pin is arranged between the upper platen and the support plate; the sheet metal parts and the welding copper plates of different thicknesses can be embedded; the barrier strips, the upper platen and the support plate firmly fix the sheet metal part and the welding copper plate, and therefore the sheet metal part and the welding copper plate do not move and dislocate when being welded; the movable barrier strips ensure that the device is used for welding the sheet metal parts of different sizes; and the grid structure of the upper platen divides the welding area into a plurality of independent areas to make welding more stable.

Owner:KUSN BAOJIN LASER TAILOR WELDED

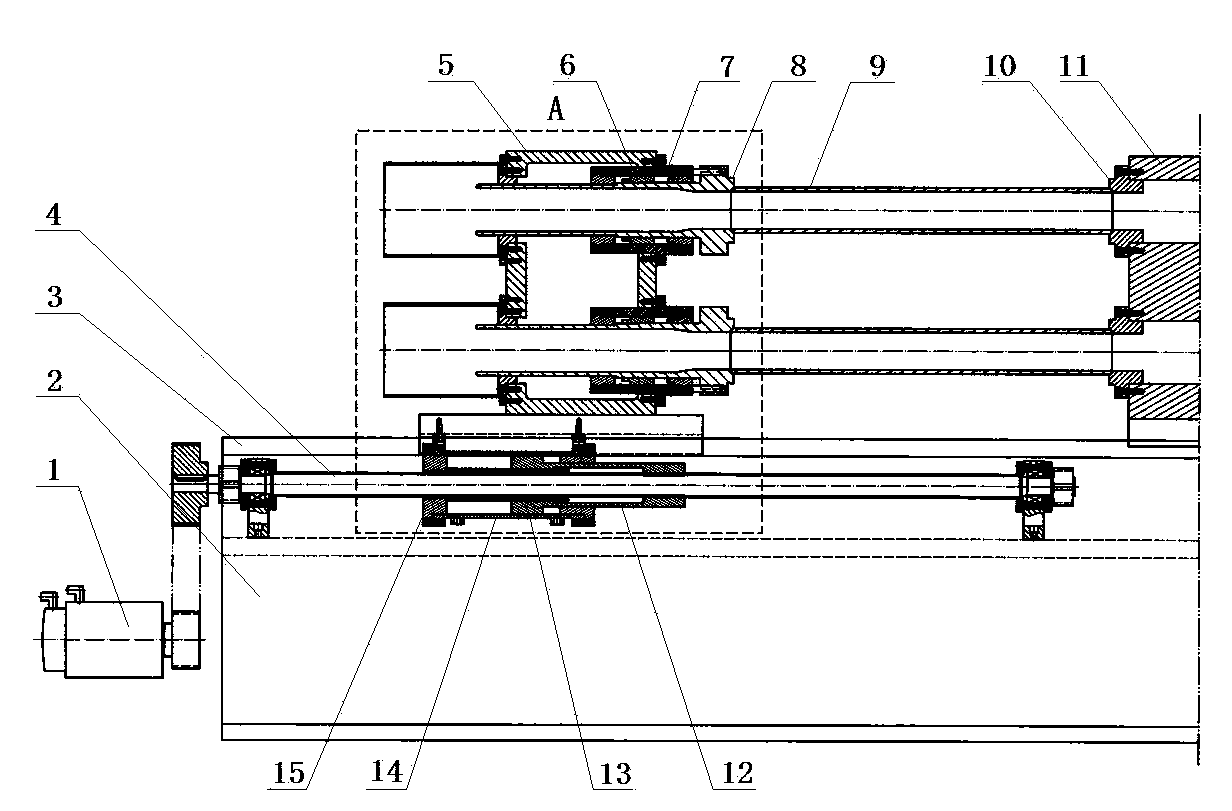

Clamping compensation device for use in machining of plurality of workpieces

InactiveCN104227461ANo slackNo mobilityWork clamping meansOther manufacturing equipments/toolsEngineeringMachining

The invention relates to a clamping compensation device for use in machining of a plurality of workpieces. The clamping compensation device comprises a frame, wherein a sliding seat and a fixing seat are arranged in sequence along the longitudinal direction on the frame; workpiece compression sleeves are arranged on the sliding seat; the fixing seat is provided with through holes; one end, which is adjacent to the sliding seat, of each through hole is provided with a workpiece positioning sleeve; the quantities of the through holes and the workpiece compression sleeves are the same, and are not less than two; the positions of the workpiece positioning sleeves on the through holes and the workpiece compression sleeves correspond one by one. The clamping compensation device is characterized in that compensating devices are arranged between the workpiece compression sleeves and the sliding seat; the compensating devices comprise first cylinder bodies which are arranged on the workpiece compression sleeves in a sleeving manner; piston sleeves are fixed on segments of the workpiece compression sleeves positioned in the first cylinder bodies; the peripheries of the piston sleeves are in hermetic movable fit with the inner walls of the first cylinder bodies. Corresponding first cylinder body side walls at the two ends of the piston sleeves are provided with oil holes. When the device is used for clamping the plurality of workpieces, each workpiece can be clamped completely, so that the subsequent machining accuracy of the workpieces can be ensured; meanwhile, automation of equipment can be realized, and the working efficiency is increased.

Owner:无锡振华机械有限公司

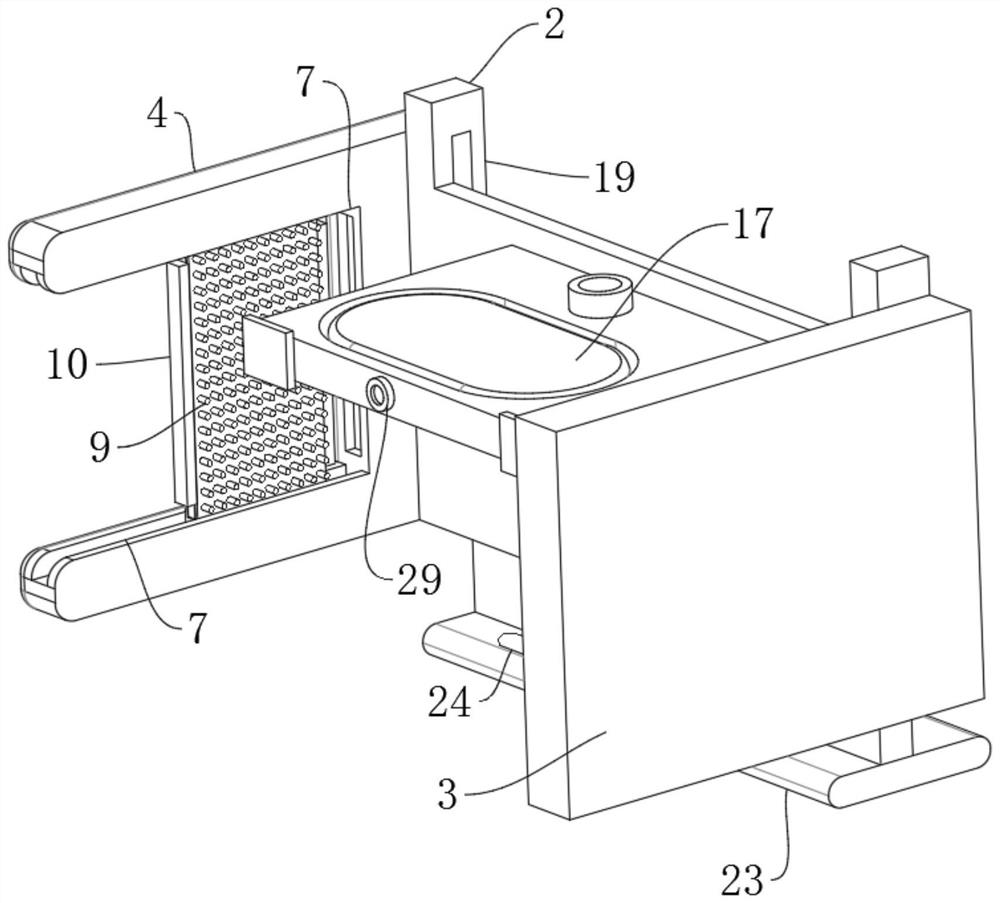

High-stability pneumoperitoneum machine for abdominal surgery

PendingCN114711856ASlow down the flowCause some damagesFouling preventionDiagnosticsReoperative surgeryMechanical engineering

The invention relates to the field of medical equipment, in particular to a high-stability pneumoperitoneum machine for abdominal surgery, which comprises a pneumoperitoneum machine body, protective plates are mounted at two ends of the pneumoperitoneum machine body, mounting grooves are formed in one sides, away from the pneumoperitoneum machine body, of the protective plates, and limiting mechanisms are mounted in the mounting grooves. A limiting plate and an installation plate are installed at the two ends of the side, close to the pneumoperitoneum machine body, of the protection plate correspondingly and installed on the two sides of the pneumoperitoneum machine body correspondingly, installation holes are formed in the end, away from the protection plate, of the side face of the installation plate, a protection mechanism is installed in one installation hole, and connecting holes are formed in the two ends of the pneumoperitoneum machine body correspondingly. And a fixing mechanism is mounted in the connecting hole. When the device is used, the surface of the pneumoperitoneum machine can be wiped and disinfected, bacteria on the surface of the pneumoperitoneum machine are prevented from making contact with a patient, and the patient can be well protected when the device is used.

Owner:STSIVITA MEDIKAL TECH KO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com