Method for mounting seat pulp cushion plates of petrochemical static equipment and foundation structure

A petrochemical and installation method technology, which is applied in the direction of infrastructure engineering, construction, etc., can solve the problem that the seat grout plate is not suitable for the installation of large-scale petrochemical static equipment, shorten the construction period of equipment installation, improve the quality of equipment installation, and reduce the cost of materials. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

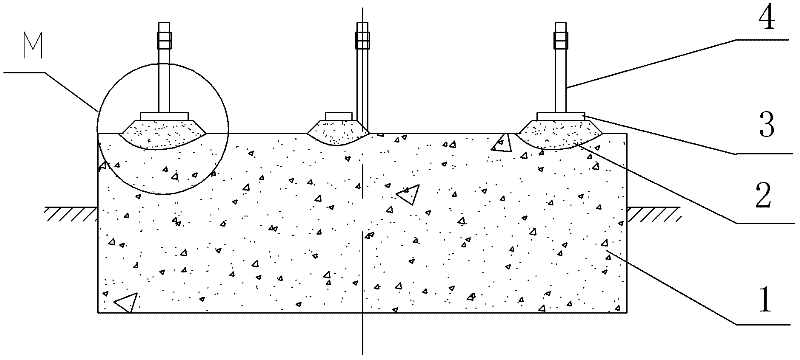

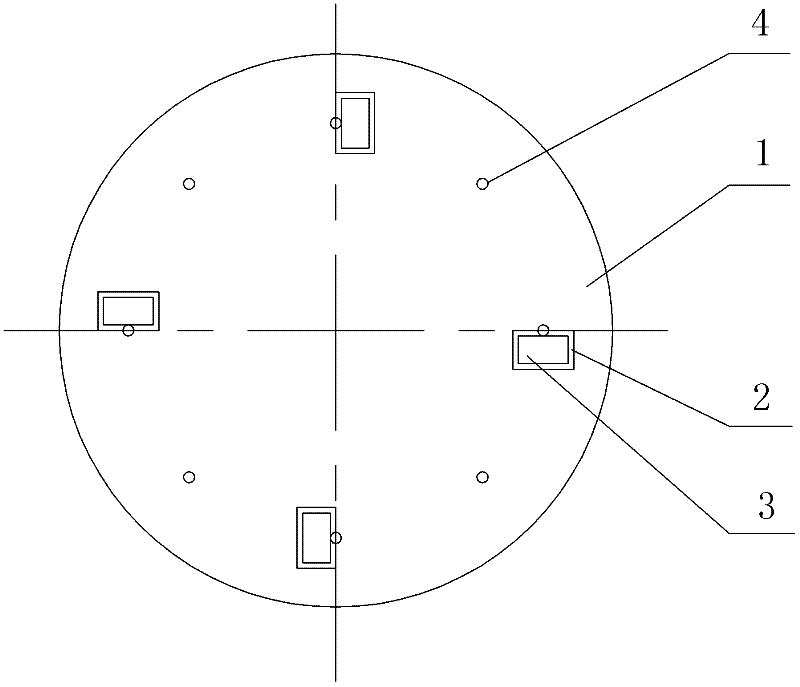

[0046] Example of installation method for base plate of static equipment in petrochemical industry

[0047] This embodiment is the installation method of the base plate of the vertical cylindrical chemical reactor equipment with a skirt. The equipment weighs 10 tons in 5 pieces and is equipped with 8 anchor bolts of M24.

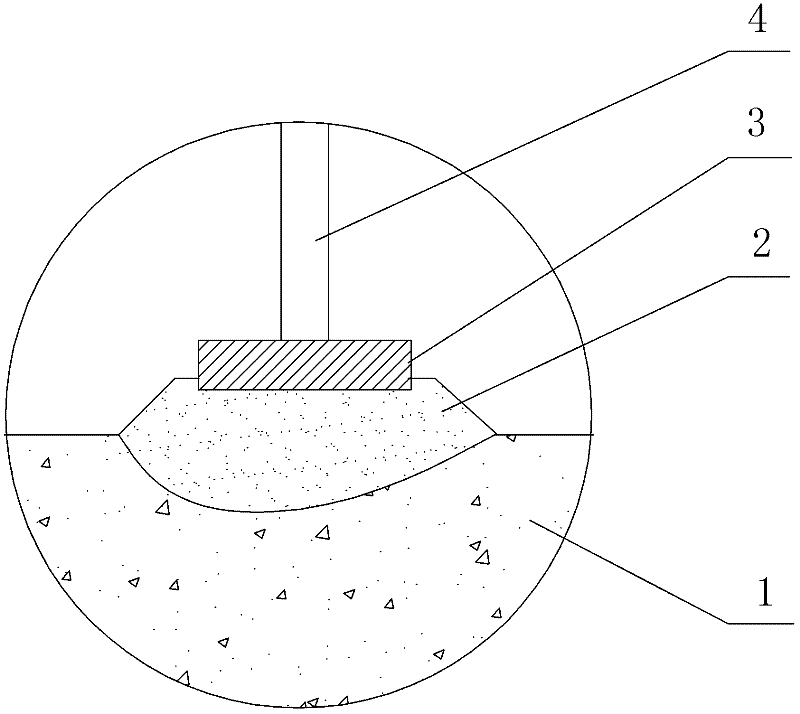

[0048] I. Making concrete base

[0049] According to the design and construction drawings, pour the cylindrical concrete base 1 according to the size of the base of the equipment 5, and install the vertical anchor bolts 4; the sides of the concrete base 1 are 50mm larger than the sides of the base of the equipment 5;

[0050] II. Making the backing plate

[0051] In this example, a concrete pier 2 is arranged every two anchor bolts 4 . A total of 4 concrete piers 2 are used to make 4 backing plates 3 .

[0052] Calculate the area A of the single backing plate 3 according to the following formula

[0053] A≥C×(Q1+Q2) / R

[0054] In the formula: A - the mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com