Numerical control machining angle automatic measurement method

A technology for automatic measurement and processing angles, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., to simplify programming, solve A-axis precision calibration, and ensure the safety of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

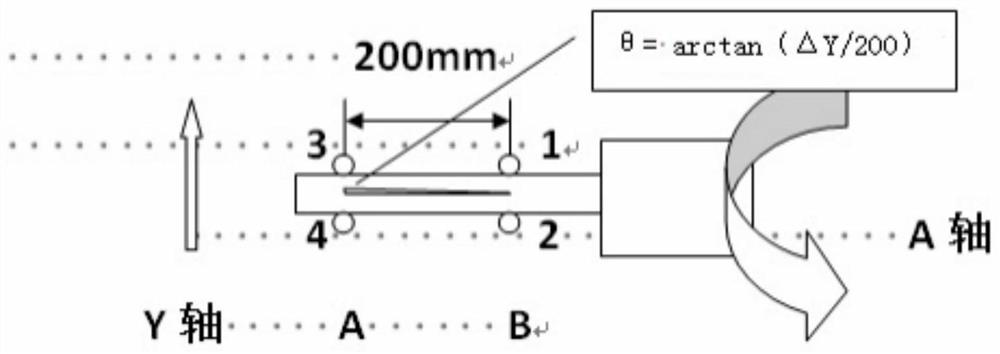

[0020] A method for automatically measuring a numerically controlled machining angle comprises the following steps:

[0021] Step (1) Analyze the structure of the CNC machine tool and the processing technology of the part, measure the characteristic elements for the angle of the part, analyze the measurement method, determine the moving axis and the data extraction axis, so as to establish the characteristic measurement plan:

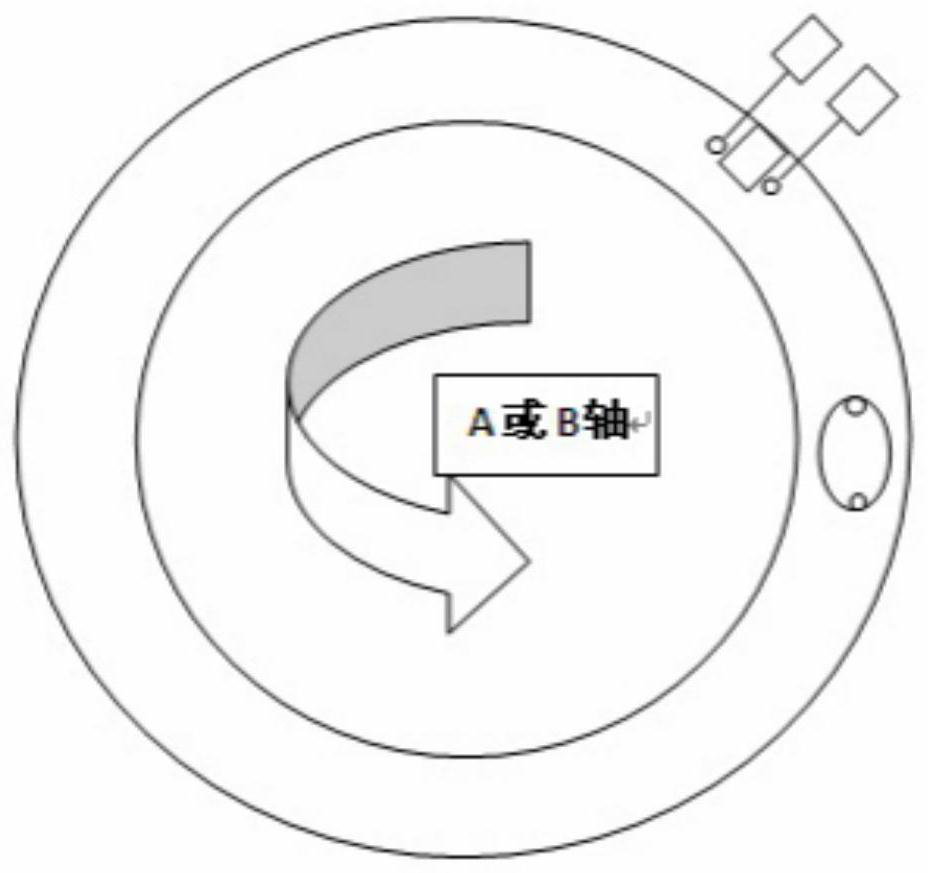

[0022] According to the structure of the machine tool, the existing five-coordinate machining center has two layout methods, one is one swing head and one swing table, and the other is double swing table. The A and B-axis precision calibration of the double pendulum table can use the infrared or Bluetooth probe of the CNC machining center to measure and correct the A-axis workbench plane and the B-axis alignment belt of the worktable; the five-coordinate machining center with one pendulum head and one pendulum table It is quite special. The measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com